When you look at modern fabrication in 2025, you see ten types of welding leading the way. These are Shielded Metal Arc Welding, Gas Metal Arc Welding, Gas Tungsten Arc Welding, Flux-Cored Arc Welding, Submerged Arc Welding, Laser Beam Welding, Electron Beam Welding, Resistance Spot Welding, Friction Stir Welding, and Ultrasonic Welding. Picking the right type of welding is important. It helps you work faster and achieve better results. It also allows you to match the process to new materials.

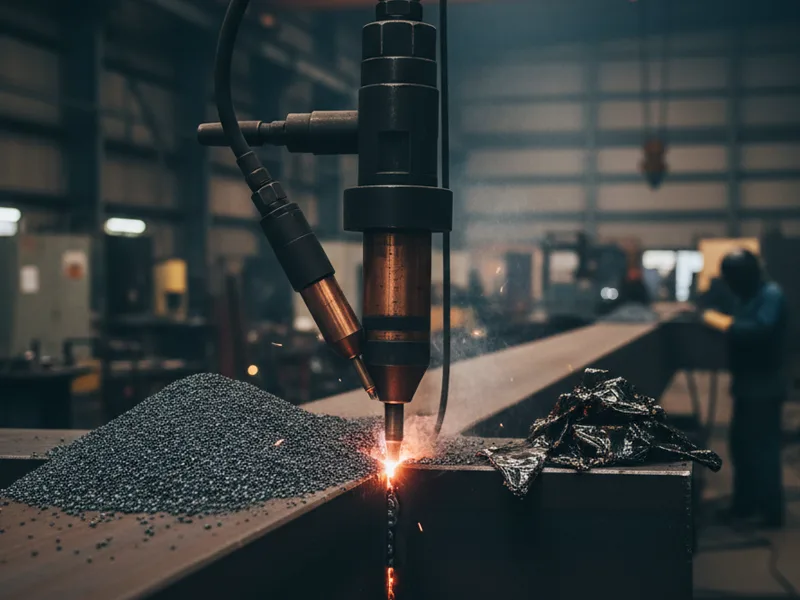

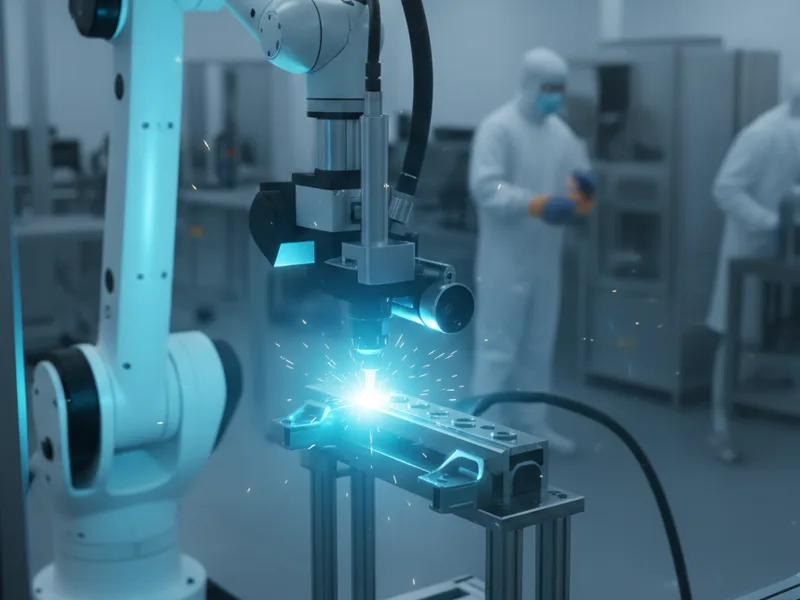

New technology is changing how things are done. Automation and robots now provide you with more control and less waste. You get consistent quality and improved safety. You also spend less money. Today’s automated systems operate longer and produce welds that look the same every time. They help you save on labor and increase production.

| Impact Area | Description |

|---|---|

| Productivity | Automation enables you to accomplish more without significant extra costs. |

| Quality | New technology offers better precision and cleaner welds. |

| Safety | Machines handle difficult tasks, ensuring you stay safer. |

You want to match the types of welding to your needs and the materials you use. As you strive to be greener, you also seek welding methods that consume less energy and benefit the environment.

Key Takeaways

- Learn about the ten main welding types: SMAW, GMAW, GTAW, FCAW, SAW, LBW, EBW, RSW, FSW, and ultrasonic welding. Each type is good for different jobs and has special uses.

- Pick the best welding method for your material, its thickness, and what your project needs. This helps you avoid errors and get good results.

- Using machines and robots can make welding faster and safer. It also helps use less material and makes less waste. Think about using machines to work better.

- Try to help the planet by picking welding methods and supplies that are better for the environment. This can lower harm to nature and save money over time.

- If you need very exact work, use TIG welding. It makes clean and strong welds. It is great for thin materials and important jobs.

- MIG welding is quicker and easier to learn. It is good for people just starting and for making many things at once.

- Friction stir welding works well with light materials and mixes. It makes strong joins without melting the main material.

- Always follow safety rules and wear the right safety gear. This keeps you safe while you weld.

Table of Contents

Welding Method Selection

Factors to Consider

Picking the right welding method is very important. It can help your project succeed or fail. You want good results and to save time. You also want to avoid expensive errors. There are many welding types to choose from. You should think about a few key things before you begin.

Here’s a simple table to show what matters most:

| Factor | Description |

|---|---|

| Material Type | Different materials like aluminum, steel, and titanium need special welding processes. |

| Material Thickness | Thin materials need careful heat control. Thick materials need deeper welds. |

| Welding Position | How much you know about welding matters? Automation helps if you are new. |

| Quality and Aesthetics | Some methods, like TIG, make cleaner and nicer-looking welds. |

| Speed and Efficiency | MIG welding is usually faster than TIG. It is good for quick jobs. |

| Welder Skill and Experience | How much do you know about welding matters? Automation helps if you are new. |

| Cost Considerations & ROI | You should think about both starting costs and long-term savings. |

You might use aluminum one day and steel the next day. Each metal reacts to heat in its own way. Thin sheets need a gentle process so they do not burn. Thick parts need a weld that goes deep. The way you weld—flat, up, or overhead—also changes what works best. TIG welding gives a nice finish. MIG welding helps you work fast. Your skill level is important, too. If you are just starting, robots or machines can help you do better work. Do not forget about cost. Spending more at first can save you money later.

Tip: Always pick your welding method based on your material and project. This helps you avoid mistakes and get the best outcome.

Trends in 2025

Welding is changing quickly. In 2025, new trends will make your work easier and better. Here are some popular things right now:

| Welding Method | Application Areas | Key Features |

|---|---|---|

| EBW | Aerospace, Nuclear | Deep welds, less bending |

| LBW | High-tech industries | Very exact and dependable |

| Robotic Welding | Many fields | More work done, fewer mistakes |

| Automation | Big factories | Same quality, very fast |

| Green Technologies | Eco-friendly work | Better for the planet |

| AR Training | Learning skills | New ways to practice |

More companies now use electron beam welding (EBW) and laser beam welding (LBW) for hard jobs. These methods give deep, clean welds with little bending from heat. Robotic welding is used a lot now. It helps you work faster and keeps welds looking the same. Automation is important if you make many parts. People also want green welding. They want to use less energy and make less waste. Augmented reality (AR) training is another cool thing. It lets you practice welding on a screen before you try it for real.

If you want to do well, watch these new trends. Try new tools and ways of working when you can. The right choice helps you work smarter and more easily.

Types of Welding for Modern Fabrication

When you look at modern fabrication, you see many types of welding. Each one has its own strengths. You want to pick the right one for your job, your materials, and your goals. Let’s break down the most important types of welding you’ll use in 2025.

Shielded Metal Arc Welding (SMAW)

Process Overview

Shielded Metal Arc Welding, or stick welding, is one of the oldest and most trusted types of welding. You use a metal rod (the electrode) coated in flux. When you strike an arc, the flux melts and creates a shield of gas and slag. This keeps the weld clean from air and dirt.

Applications in Machining

You’ll find SMAW everywhere heavy-duty work happens. It’s great for:

- Construction sites

- Shipbuilding

- Oil and gas pipelines

- Repairing big machines

- Building bridges and steel frames

You can use it outside, even when it’s windy or dirty. That’s why so many people trust it for tough jobs.

Materials Suitable for Welding

SMAW works well on:

- Carbon steel

- Stainless steel

- Cast iron

- Some types of nickel and copper alloys

You can weld thick or rusty metal. You don’t need a super clean surface, which makes it handy for repairs.

Pros and Cons

| Pros | Cons |

|---|---|

| Works outdoors | Slower than some methods |

| Handles dirty/rusty metal | More spatter and cleanup |

| Simple equipment | Needs skill for good results |

| Good for thick materials | Not ideal for thin metals |

Case

Imagine you’re fixing a steel beam on a bridge. The metal is thick and a bit rusty. You grab your stick welder and get to work. Even with wind and dust, you make a strong weld that holds up to heavy loads.

Cost

SMAW is budget-friendly. The machines are simple and don’t cost much. You only need rods and a power source. It’s a smart choice if you want to keep costs low and don’t mind a little extra cleanup.

Gas Metal Arc Welding (GMAW/MIG)

Process Overview

Gas Metal Arc Welding, also called MIG welding, uses a wire that feeds through a gun. A shielding gas (like argon or CO₂) protects the weld from the air. You pull the trigger, and the wire melts into the joint.

Uses in Machining and Fabrication

You’ll see MIG welding in:

- Car factories

- Sheet metal shops

- Robotic assembly lines

- Pipe fitting

- Track and railway work

It’s popular for making lots of parts fast. Robots love it because it’s easy to automate.

Materials Suitable for Welding

MIG welding works on:

- Mild steel

- Stainless steel

- Aluminum (with special wire and gas)

- Some nickel and copper alloys

You get the best results on clean, thin to medium-thick metals.

Pros and Cons

| Pros | Cons |

|---|---|

| Fast and easy to learn | Needs clean metal |

| Great for thin materials | Not good in windy places |

| Low spatter, less cleanup | Needs shielding gas supply |

| Easy to automate | More expensive than a stick |

Case

Picture a car factory. Robots zip around, welding car bodies together with MIG. The welds are neat and strong. The process is fast, and every car looks the same. You can also use MIG at home for small projects because it’s easy to pick up.

Cost

MIG welding costs a bit more than stick welding. You need a machine, wire, and gas. But you save time and get cleaner welds. If you do lots of welding, the speed and quality pay off.

Gas Tungsten Arc Welding (GTAW/TIG)

Process Overview

Gas Tungsten Arc Welding, or TIG welding, uses a tungsten electrode that doesn’t melt. You hold a torch in one hand and feed a filler rod with the other. Argon gas shields the weld. You control the heat and the filler, so you get a very clean weld.

Precision Machining Applications

TIG welding shines when you need perfect, pretty welds. You’ll use it for:

- Aerospace parts

- Electronics

- Bike frames

- Food and medical equipment

- Art and sculpture

You can weld thin metals and tricky alloys. The welds look smooth and shiny.

TIG welding gives you the most control. You can make tiny, neat welds that look great and hold strong. That’s why industries like aerospace and electronics rely on it for critical parts.

Materials Suitable for Welding

TIG works on:

- Stainless steel

- Aluminum

- Magnesium

- Copper

- Titanium

- Thin sheet metals

It’s the best choice for metals that need a gentle touch.

Pros and Cons

| Pros | Cons |

|---|---|

| Super clean, pretty welds | Slower than MIG or stick |

| Works on thin and exotic metals | Needs lots of skill |

| No spatter, little cleanup | Equipment costs more |

| Great for precision work | Not ideal for thick materials |

Case

Think about building a custom bike frame. You want every weld to look perfect and be strong. TIG welding lets you join thin tubes without burning through. The finished bike looks amazing and rides even better.

Cost

TIG welding gear costs more. You need a special machine, a torch, and pure argon gas. It takes longer to learn and to weld. But if you want the best-looking, highest-quality welds, it’s worth it.

Tip: Always match the types of welding to your material and project. Aluminum, steel, and stainless steel all need different approaches. If you want speed, try MIG. If you want beauty, go with TIG. For tough jobs outside, stick welding is your friend.

| Welding Type | Description | Applications |

|---|---|---|

| Stick Welding (SMAW) | Simple and rugged, it uses a consumable electrode coated in flux. | Outdoor work, structural jobs, thick materials. |

| MIG Welding (GMAW) | Feeds a wire electrode through a gun, using shielding gas. | Beginners, production welding. |

| TIG Welding (GTAW) | Offers high control and clean welds, uses a non-consumable tungsten electrode. | Precision work, high-quality welds. |

You have many types of welding to choose from. Each one fits a different job. Think about your material, your project, and what matters most—speed, looks, or strength.

Flux-Cored Arc Welding (FCAW)

Process Overview

Flux-Cored Arc Welding, or FCAW, is a flexible welding method that uses a special wire filled with flux. You feed this wire through a welding gun, and as it melts, the flux creates a shield to protect your weld from air. Sometimes, you add extra shielding gas, but many wires work fine without it. This makes FCAW great for working outside or in tough spots.

Heavy Fabrication and Machining Uses

You’ll see FCAW used a lot in heavy fabrication. It’s a favorite for:

- Building ships and bridges

- Making large steel structures

- Repairing heavy equipment

- Manufacturing construction machinery

If you work with thick steel or need to weld big parts fast, FCAW is a solid choice. The process gives you deep welds and high productivity, which is perfect for industrial jobs.

Materials Suitable for Welding

FCAW works best on:

- Carbon steel

- Low-alloy steel

- Stainless steel (with special wire)

- Some nickel alloys

You can weld thick plates and even some rusty or painted surfaces. That’s handy when you can’t always clean everything perfectly.

Pros and Cons

Here’s a quick look at what you get with FCAW:

| Advantages of FCAW | Disadvantages of FCAW |

|---|---|

| Faster than stick and MIG welding | Can get weld defects like slag or porosity |

| Deep welds, great for thick metal | Sensitive to wind and drafts |

| High productivity for big jobs | Makes a lot of smoke and spatter |

| Good for outdoor and indoor work | Wires and supplies can cost more |

Tip: Always use good ventilation and wear proper safety gear. FCAW can make a lot of smoke and fumes.

Case

Imagine you’re building a steel bridge. The beams are thick, and you need strong welds that go deep. You grab your FCAW machine and get to work. Even if the weather isn’t perfect, you can keep welding and finish the job quickly.

Cost

FCAW machines and wires cost more than stick welding, but you save time. You get more done in less time, which means lower labor costs. For big projects, FCAW is a smart investment.

Submerged Arc Welding (SAW)

Process Overview

Submerged Arc Welding, or SAW, uses a wire electrode and a special powder called flux. You lay the flux over the weld area, and as you weld, the arc stays hidden under the powder. This keeps the weld clean and stops sparks and fumes from flying everywhere.

Industrial Machining Integration

You’ll find SAW in factories and workshops where you need to weld long, thick pieces of metal. Here’s why it fits right in with modern machining:

- You can weld really thick plates with deep, strong welds.

- The process is highly automated, so you get the same quality every time.

- You don’t have to bend over the workpiece, which is easier on your back.

- There’s almost no spatter or smoke, making your workspace safer.

- You can weld fast—over 100 pounds of metal per hour with multiple wires.

SAW is perfect for making pipes, tanks, beams, and other big parts. It’s a favorite in shipyards, heavy machinery plants, and steel mills.

Materials Suitable for Welding

SAW works best on:

- Carbon steel

- Low-alloy steel

- Some stainless steels (with special wire and flux)

You usually use it on thick, flat pieces. It’s not great for thin metal or welding in tricky positions.

Pros and Cons

- High deposition rates mean you finish jobs quickly.

- Deep penetration gives you strong, reliable welds.

- An automated process means less skill is needed once you set it up.

- Low fume and no open arc make it safer for you.

But:

- Not good for thin or vertical welds.

- The equipment is big and not very portable.

- You need to clean up leftover flux after welding.

Case

Think about welding a giant steel tank. You set up the SAW machine, pour on the flux, and let the system run. The welds are deep and strong, and you don’t have to worry about sparks or smoke. You finish the job faster and with less effort.

Cost

SAW equipment costs more up front, but you save on labor and materials. The process is efficient, so you use less wire and get less waste. For big, repetitive jobs, SAW pays off quickly.

Laser Beam Welding

Process Overview

Laser Beam Welding uses a powerful, focused beam of light to melt and join metals. You aim the laser at the joint, and it creates a tiny, hot spot that fuses the metal. The process is super fast and very precise.

Advanced Machining and Automation

Laser welding is a top pick for advanced machining and automated production lines. Here’s what makes it stand out:

| Feature/Application | Description |

|---|---|

| Weld Speed | Four to five times faster than traditional welding. |

| Weld Quality | Thin, neat welds with small seams and little distortion. |

| Automation | Easy to automate with robots and continuous-feed systems. |

| Learning Curve | Modern systems are user-friendly with pre-set parameters. |

| Heat-Affected Zone | Very small, so your parts don’t warp or lose strength. |

| Energy Efficiency | Uses less power, great for high-volume manufacturing. |

| Applications | Medical, automotive, aerospace, electronics, tooling, and even jewelry. |

You’ll see laser welding in places where you need perfect, repeatable welds—like car factories, airplane plants, and electronics assembly lines. It’s also used for making medical tools and even art.

Note: Laser welding lets you design lighter, stronger parts. You can weld tiny components with amazing accuracy.

Materials Suitable for Welding

Laser welding works on:

- Stainless steel

- Carbon steel

- Aluminum

- Titanium

- Nickel alloys

- Precious metals (for jewelry and electronics)

You can weld thin sheets or small, delicate parts with ease.

Pros and Cons

- Super fast and precise.

- Makes strong, clean welds with little heat damage.

- Easy to automate for big production runs.

- Works on many metals and alloys.

But:

- Equipment costs a lot.

- Needs careful setup and safety measures.

- Not ideal for thick, heavy plates.

Case

Picture a car factory using robots to weld body panels. The laser moves quickly, making perfect seams with almost no distortion. Every car comes out looking the same, and the process runs day and night.

Cost

Laser welding machines are expensive, but you save money in the long run. You use less energy, make fewer mistakes, and finish jobs faster. For high-tech industries, the investment is worth it.

Electron Beam Welding

Process Overview

Electron Beam Welding (EBW) is like using a super-focused beam of electrons to melt and join metal parts. You do this in a vacuum chamber. The electron beam hits the metal, making it so hot that the pieces fuse. You get a very narrow, deep weld that is super clean and strong. Because you work in a vacuum, there’s no air to mess up your weld.

High-Precision Machining

If you need to make parts that must be perfect, EBW is your friend. You can weld thick pieces—over 150 mm—without worrying about weak spots. You can also join tricky materials like titanium or duplex steels. EBW lets you weld sensitive parts without damaging what’s inside. You can even tailor the weld shape for special jobs, which is great for electronics or semiconductors.

Here’s a quick look at what makes EBW stand out:

| Feature | Description |

|---|---|

| Precision | Lets you make high load-bearing parts and weld thick sections (over 150 mm). |

| Material Range | Works on standard metals and tough ones like titanium and duplex steel. |

| Integrity | Welds sensitive internal parts without hurting them. |

- You can join aluminum, copper, and stainless steel.

- You can shape the weld for each job, making it super precise.

- It’s perfect for electronics and semiconductor packaging.

The best part? EBW keeps the heat in a tiny area. That means less distortion and a cleaner weld. Your parts stay strong and keep their shape.

Materials Suitable for Welding

You can use EBW on:

- Steel (carbon, stainless, tool steels)

- Titanium and its alloys

- Nickel alloys

- Copper and copper alloys

- Aluminum alloys

- Special metals for aerospace and electronics

It’s great for both thick and thin materials, and for metals that are hard to weld with other methods.

Pros and Cons

| Pros | Cons |

|---|---|

| Super precise, deep welds | Needs a vacuum chamber |

| Minimal heat-affected zone | Equipment is expensive |

| Works on many metals and alloys | Not portable—done in a lab or shop |

| Clean, strong joints | Setup takes time |

Note: EBW is your go-to for high-value, high-precision parts. If you need perfect welds with little distortion, this is the way to go.

Case

Imagine you’re making a jet engine part. The metal is thick, and the weld must be flawless. You use EBW to join the pieces. The weld is deep, clean, and doesn’t mess up the rest of the part. The engine runs safely at high speeds because your weld holds strong.

Cost

EBW machines cost a lot. You need a vacuum chamber and special controls. But if you make expensive or safety-critical parts, the investment pays off. You save money by avoiding mistakes and rework. For aerospace, nuclear, and electronics, EBW is worth every penny.

Resistance Spot Welding

Process Overview

Resistance Spot Welding (RSW) is like using a giant set of tongs to squeeze two pieces of metal together and zap them with electricity. The metal heats up where the pieces touch, and they melt just enough to stick together. You don’t need any filler metal or extra stuff—just pressure and current.

Sheet Metal and Machining Applications

You’ll see RSW everywhere in sheet metal work. It’s the secret behind car bodies, appliances, and even some airplane parts. Here’s where you’ll find it:

| Industry | Application Description |

|---|---|

| Automotive Industry | Assembling car bodies with thousands of spot welds. |

| Electronics and Battery | Welding battery tabs and electrical components. |

| Aerospace Engineering | Joining lightweight metal parts for aircraft. |

| Sheet Metal Fabrication | Making enclosures, panels, and home appliances. |

- Car factories: Spot welding holds the frame together.

- Electronics: Used for battery tabs and connectors.

- Aerospace: Joins thin, light parts for planes.

- Sheet metal shops: Make panels and boxes.

You get fast, repeatable welds that are strong enough for most jobs.

Materials Suitable for Welding

RSW works best on:

- Low-carbon steel

- Stainless steel

- Aluminum (with special settings)

- Nickel alloys

You mostly use it for thin sheets—usually less than 3 mm thick.

Pros and Cons

| Pros | Cons |

|---|---|

| Super fast—great for mass production | Not good for thick materials |

| No filler metal needed | Welds can be hard to inspect |

| Easy to automate | Not ideal for all metals |

| Clean, no extra mess | Needs good fit-up and clean surfaces |

Tip: If you need to join lots of thin metal pieces quickly, RSW is your best bet. It’s the backbone of car and appliance manufacturing.

Case

Picture a car factory. Robots grab panels and zap them together with spot welds. Each car gets thousands of welds in just a few minutes. The process is fast, clean, and reliable. That’s why every car on the road today uses spot welding.

Cost

RSW equipment costs more than a basic welder, but you save big on labor and time. The process is so fast that you can make thousands of welds per hour. For high-volume production, RSW is a money-saver.

Friction Stir Welding

Process Overview

Friction Stir Welding (FSW) is a cool way to join metal without melting it. You use a spinning tool that rubs the edges of two pieces together. The friction heats the metal until it’s soft, then the tool stirs the edges together. When it cools, you get a solid, strong joint.

Machining of Lightweight and Composite Materials

FSW is a game-changer for lightweight and composite materials. You can join aluminum, magnesium, and even some plastics without making them brittle or weak. Here’s why FSW is so popular now:

| Advantage | Description |

|---|---|

| High-quality joints | No melting, so you avoid cracks and weak spots. |

| Controlled heating | Keeps the material strong—perfect for lightweight metals. |

| Low-cost equipment | Machines are simpler than traditional welders. |

| No consumables required | You don’t need extra filler or gas. |

| Lower processing time | The process is quick and efficient. |

| Suitable for thermoplastics | Great for joining plastics and composites. |

- FSW helps you use materials more efficiently and recycle more.

- It’s big in electric cars, renewable energy, and green tech.

- You can fine-tune the tool and process for better results and less waste.

Note: FSW is especially good for making battery trays, car panels, and wind turbine parts. You get strong, lightweight joints that last.

Materials Suitable for Welding

FSW works on:

- Aluminum and its alloys

- Magnesium alloys

- Copper

- Titanium

- Thermoplastics and composites

It’s perfect for joining materials that don’t like heat or that melt easily.

Pros and Cons

| Pros | Cons |

|---|---|

| No melting—so no cracks or porosity | Not good for very thick or hard metals |

| Strong, clean joints | Needs special tools for each job |

| Low energy use, eco-friendly | Not as fast as some fusion welding |

| Great for recycling and green tech | Limited to straight or simple joints |

Case

Imagine you’re building an electric car. You need to join aluminum panels for the battery tray. FSW lets you make strong, lightweight joints without melting the metal. The car is safer, lighter, and more efficient.

Cost

FSW machines cost less than many traditional welders. You don’t need to buy filler rods or shielding gas. The process is quick, so you save on labor. For companies focused on sustainability and lightweight design, FSW is a smart investment.

If you want to keep up with the latest types of welding, try out these advanced methods. They help you work smarter, save money, and build better products.

Ultrasonic Welding

Process Overview

Ultrasonic welding is a special way to join things. It uses sound waves that are too high for us to hear. You press the pieces together and send these sound waves through them. The sound makes the parts vibrate very fast. This vibration creates heat at the spot where they touch. The heat softens the material just enough to stick together. The bond cools down quickly and becomes strong. You do not need glue, bolts, or extra heat. This makes ultrasonic welding quick, clean, and safe for fragile parts.

Note: Ultrasonic welding works for plastics, thin metals, and some composites. It is best for small or delicate parts. Other welding methods might hurt these parts.

Non-Metallic and Composite Machining

Ultrasonic welding is used in many industries. It is very helpful for joining non-metal materials or composites. Here are some ways people use it:

- In medicine, you can weld things like filters, IV tubes, and clean clothing. This keeps everything safe and free from germs.

- In packaging, you seal boxes, tubes, and packs with ultrasonic welding. The seals are strong and keep air out.

- In aerospace, you join carbon fiber and other composites. This helps make light and strong parts for planes and spaceships.

You can also use ultrasonic welding for electronics, toys, clothes, and car parts. The process is gentle and does not harm sensitive pieces.

Materials Suitable for Welding

Ultrasonic welding works best on:

- Thermoplastics like ABS, PVC, polycarbonate, and nylon

- Thin non-ferrous metals such as aluminum, copper, and gold

- Composite materials like carbon fiber and glass fiber plastics

- Some fabrics and thin films

You get the best results when the materials are close in type and thickness. If you try to weld thick or hard metals, it may not work well.

Pros and Cons

Here is what is good and bad about ultrasonic welding:

| Pros | Cons |

|---|---|

| No glue, bolts, or solder needed | Not good for thick or hard metals |

| Fast and saves energy | Only works on small or medium parts |

| Clean, no smoke or mess | Needs the pieces lined up just right |

| Good for fragile or clean items | Machines can cost a lot |

| Works on plastics and composites | Not for every material combination |

Tip: If you need to join plastic or composite parts fast and clean, ultrasonic welding is a great choice.

Case

Imagine you are making IV tubes for hospitals. You need a strong seal that does not leak. You also want to keep everything clean. Ultrasonic welding joins the plastic parts in seconds. You do not use glue or heat. The finished tube is safe for patients and meets health rules.

Now think about working in aerospace. You need to join carbon fiber panels for a drone. Ultrasonic welding bonds the panels without adding weight or hurting the fibers. The part is strong and works well in the air.

Cost

Ultrasonic welding machines cost more than simple welders. But you save money in other ways. The process is fast, so you spend less on work. You do not need to buy glue or solder. There is little waste, and you get the same results every time. For making lots of parts, ultrasonic welding saves money quickly.

If you want a clean and fast way to join plastics or composites, ultrasonic welding is a good choice. It is one of the most advanced welding types for modern fabrication.

Choosing the Right Welding Type

Material Compatibility

When you pick a welding method, you want to make sure it matches your materials. Not every welding process works for every metal. Some metals need special care, while others are more forgiving. If you use the wrong method, your weld might not hold up or could even crack.

Here’s a handy table to help you check what matters most:

| Criteria | Description |

|---|---|

| Matching Base Material Properties | Choose a filler metal that matches your base metal’s strength and toughness. |

| Environmental Considerations | Think about where your part will live. Wet or salty places need stainless or nickel-based metals. |

| Welding Position Requirements | Some welds need to be done overhead or vertical. Pick a method that works for those positions. |

| Quality Standards and Codes | Always follow the rules set by AWS, ASME, or API for your project. |

Tip: Always double-check your material and filler metal before you start. If you’re not sure, ask an expert or look up the welding codes for your job.

Project Scale and Budget

The size of your project and your budget play a big role in choosing the right welding type. If you’re fixing a small part, you don’t need a fancy machine. For big jobs, you might need something faster or more powerful.

- For small repairs, stick welding or MIG might be enough. These are affordable and easy to set up.

- If you’re building a fence or a gate, you might want a method that works quickly and keeps costs down.

- Large projects, like making a bridge or a big machine, often need automated welding. This saves time and money in the long run.

Here’s a quick look at how costs can change:

| Project Size | Average Cost Range | Description |

|---|---|---|

| Small repair | $100–$250 | Minor fixes or patch jobs |

| Medium job | $250–$700 | Gates, railings, or car repairs |

| Large build | $700–$2,500 | Full fences or big steel structures |

You also need to think about labor and equipment. Skilled welders cost more, and high-tech machines can be expensive. But if you pick the right method, you can save money by working faster and making fewer mistakes.

Note: Always balance your budget with your needs. Spending a little more on the right equipment can save you a lot in the end.

Machining Integration

If your project involves both welding and machining, you want everything to work together smoothly. Good planning helps you avoid problems and get better results.

Here’s a table of best practices for combining welding with machining:

| Best Practice | Description |

|---|---|

| Material Compatibility | Pick materials that are easy to weld and machine. |

| Process Optimization | Plan your steps so you don’t waste time moving parts around. |

| Quality Control | Test and inspect your welds to catch problems early. |

| Technological Advancements | Use the latest tools and machines for better accuracy and speed. |

| Training and Skill Development | Make sure your team knows how to use both welding and machining equipment. |

| Safety Considerations | Always follow safety rules and wear the right gear. |

Tip: If you want the best results, plan your welding and machining steps together. This helps you finish faster and get a cleaner, stronger product.

Choosing the right welding type is all about matching your materials, your project size, and your machining needs. When you take the time to plan, you avoid common mistakes and get the most out of all types of welding.

Sustainability and Safety

When you pick a welding type, you want to think about more than just speed or cost. You also want to keep your work safe and make choices that help the planet. Today, many shops and factories care about sustainability and safety as much as they care about quality.

You might wonder, “How can I make my welding safer and greener?” Here are some simple ways you can do that:

- Use fume extraction systems. These systems pull harmful fumes and smoke away from your workspace. They help keep the air clean for you and everyone nearby. When you use a good fume extractor, you breathe easier and stay healthier. Make sure you check and clean these systems often so they work their best.

- Try eco-friendly consumables. Some welding rods and fluxes are made to be safer for you and the environment. For example, water-based fluxes make less smoke and create less waste. When you switch to these products, you help protect your lungs and reduce pollution.

- Choose automation when possible. Automated welding machines do more than just speed up your work. They use less energy and make fewer mistakes. That means you waste less material and don’t have to redo bad welds. Automation also keeps you away from the hottest and most dangerous parts of the job.

Tip: If you want to make your shop safer and greener, start with small changes. Swap out your old rods for eco-friendly ones. Add a fume extractor if you don’t have one. Even one step can make a big difference.

Safety is not just about equipment. You should always wear the right gear—like gloves, a helmet, and a welding jacket. Keep your workspace clean and free of clutter. If you work with others, remind them to follow safety rules, too.

Sustainability also means thinking about the future. When you use less energy and create less waste, you help the planet. You also save money over time. Many companies now look for welders who know how to work safely and care about the environment.

So, when you choose a welding type, ask yourself: “Is this the safest and most sustainable option for my project?” If you keep safety and the environment in mind, you’ll build better products and set yourself up for long-term success.

Future of Welding and Machining

Automation and Robotics

Robots and smart machines are changing how you weld and make parts. Today’s welding robots use sensors to check their work as they go. These robots can find problems and fix them fast. This means your welds are better and you finish jobs quicker. Sometimes, you see cobots working with people.

Cobots help with hard welds or lifting heavy things. This makes your job safer and easier. Machine learning and AI help robots get smarter every day. Robots learn from each weld and improve over time. You do not need to be a robot expert to use them. Modern robots are easy to set up and use.

Eco-Friendly Welding

You want to help the planet, and so does welding. Many shops now use green welding to cut down on waste and pollution. Here are some ways to make welding better for the earth:

Prepare your materials well to stop bad fumes. Recycle scrap metal and throw away waste the right way. Try new welding methods like laser welding or friction stir welding. These make less pollution. Use TIG welding to make fewer fumes. Use robots to save energy and make fewer mistakes. Put in fume extractors to keep the air clean. Pick PVC-free fabrics and recycled stuff. Choose rods and wires that make less smoke. Check your machines often to save energy. Plan your work to use less material and make less scrap. Use tools that need less power. Look for new welding supplies that are safe for you and the earth.

Tip: Even small changes, like using greener rods or better fans, can help your health and the planet.

Smart Manufacturing

Welding and machining now work together in new ways. You do not have to use old assembly lines anymore. Now, you can use systems that change when your design or material changes. Multi-axis robots and smart tools help you do custom jobs fast. CNC machines, 3D printers, and robots work together to make your shop better. Welding is now flexible and can change in real time. Smart robots and controls mean you do not need as many manual skills. You can make custom products faster and with less waste. CNC machines, 3D printers, and robots work as a team. Digital tools let you track every step and check your quality.

Industry 4.0 is here and makes your work easier and faster. When you use welding and machining in a smart factory, you get speed, quality, and can handle any job.

You get the best results when you match your welding type to your project and machining goals. Each method—like TIG for precision or MIG for speed—has its own strengths. Always consider your material, weld strength, and equipment.

Want to stay ahead?

- Check out resources like FMA, The Fabricator, and FABTECH for the latest tips.

- Ask experts for help with tricky jobs or when you need perfect results.

| Quick Tips for Success |

|---|

| Use tabs and slots to make assembly easier. |

| Keep material thicknesses similar. |

| Choose the right tolerances for quality. |

Stay curious and keep learning—your next weld could be your best yet!

FAQ

You should try TIG or MIG welding for aluminum. TIG gives you clean, strong welds. MIG works faster for bigger jobs. Always clean the metal first for best results.

Yes, you can. Some welding types, like TIG and friction stir welding, work well for joining different metals. You may need special filler rods or settings. Always check material compatibility.

Welding is safe if you follow the rules. Wear gloves, a helmet, and a jacket. Use a fume extractor. Never look at the arc without protection. Ask for help if you feel unsure.

MIG and TIG welding both work great for thin metal. TIG gives you more control and a neater finish. MIG is easier to learn and faster for long seams.

Try these tips:

- Use clamps to hold your parts.

- Weld in short sections.

- Let the metal cool between welds.

- Use the lowest heat that still gets good penetration.

Yes! Many shops use robotic MIG or laser welding for fast, repeatable results. Automation helps you save time, reduce mistakes, and improve safety. Start small with simple machines, then add more as you grow.

Friction stir welding and laser welding use less energy and make less waste. TIG welding also produces fewer fumes. Choose green consumables and recycle scrap to help the planet.