When you learn about types of titanium alloy, you find three main groups. These are alpha, beta, and alpha-beta. Each group has special features that make it different.

Alpha alloys have good weldability and resist rust well. They are used in jobs that need medium strength. Beta alloys are very strong and tough. They are also easy to shape. This makes them good for planes and other strong machines. The alpha-beta group mixes both phases. You can change their features with heat treatment. For example, Ti–6Al–4V is an alpha-beta alloy. It is over half of the titanium market. This is because it has a good mix of strength and stretchiness.

Titanium alloys are sorted by their crystal structure and grade. This helps you pick the right one for each job. The table below shows how the types compare in features and uses:

| Alloy Type | Characteristics | Applications |

|---|---|---|

| Alpha Alloys | Good weldability, high-temperature strength, corrosion resistance, and moderate strength | Moderate strength applications |

| Beta Alloys | Excellent strength, formability, toughness, and responsive to heat treatment | Aerospace, high strength industries |

| Alpha-Beta Alloys | The balance of strength and ductility, properties can be tailored through heat treatment | Aerospace, automotive, medical |

Each titanium alloy type has special features. These features make them useful for different engineering problems.

Key Takeaways

- Titanium alloys are sorted into three main types. These are alpha, beta, and alpha-beta. Each type has its own special features.

- Alpha alloys are easy for welding and do not rust easily. This makes them good for jobs that need medium strength. Beta alloys are very strong and can be shaped well. They work well in places with a lot of stress, like aeroplanes. Alpha-beta alloys have both strength and flexibility. You can change their features by using heat.

- Titanium alloys are light but also very strong. This is why they are used in planes, medicine, and cars.

- Titanium alloys do not rust, even in tough places. This is a big benefit.

- When cutting titanium alloys, you need special tools and ways to keep them cool and accurate.

- Pick the right titanium alloy based on what you need. Think about strength, rust resistance, and what you will use it for.

Table of Contents

Titanium Alloy Types Overview

What Are Titanium Alloys

Titanium alloys are special metals. They are made by mixing titanium with other elements. Scientists group them by their structure and what they can do. There are three main types in materials science. Each type has a different crystal structure and its own properties. The table below shows how they are different:

| Alloy Type | Structure Type | Key Properties |

|---|---|---|

| α | HCP | Low-temperature stability, high strength |

| α + β | Mixed | Versatile properties for various applications |

| β | BCC | High-temperature stability, good creep resistance |

Alpha alloys have a hexagonal close-packed structure. They stay strong when it is cold. Beta alloys have a body-centered cubic structure. They work well when it is hot and do not change shape easily. Alpha-beta alloys have both structures mixed. This gives them a good balance for many uses. When you pick a titanium alloy, you look at its structure and what you need it to do.

Why Titanium Alloys Are Important

Titanium alloys are used in many high-tech industries. They are strong and also light. This makes them great for aeroplanes and cars. Every pound saved is important. Here are some reasons why people use them a lot:

- High strength-to-weight ratio: These metals are light but also strong. This helps make things tough but not heavy.

- Corrosion resistance: These alloys do not rust easily. You can use them near water, chemicals, or salty air. Parts last longer and need less fixing.

- High-temperature stability: Many titanium alloys stay strong when they get hot. You see them in jet engines and exhaust pipes.

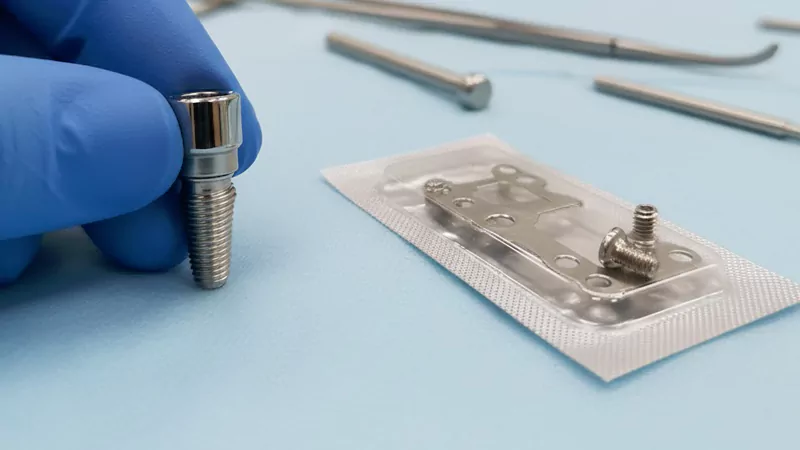

- Biocompatibility: Doctors use them for implants. The body accepts them, and they do not cause harm.

You can see why titanium alloy types are important. They help solve problems in aerospace, medicine, and more. Picking the right alloy gives you the best mix of strength, weight, and durability.

Classification of Titanium Alloys

There are two main ways to sort titanium alloys. One way is by their crystal structure. The other way is by grade. Grade depends on what they are made of and how they act. Both ways help you pick the best alloy for your job.

By Crystal Structure

Titanium alloys fit into three groups by their crystal structure. Each group has its own features and uses.

Alpha Alloys

Alpha alloys have a hexagonal close-packed structure. This structure shows up below 882°C. These alloys stay stable when it is cold. They do not rust and are easy to weld. People use them when they need medium strength and good performance in hard places. Alpha alloys do not change much with heat. They are used in chemical plants and at sea.

Beta Alloys

Beta alloys have a body-centered cubic structure. This structure forms when it is hotter than 882°C. Beta alloys have elements like vanadium or molybdenum. These elements help the beta phase stay even when it is cool. Beta alloys are strong and easy to shape. You can heat treat them to make them stronger. They are used in planes and places that need high strength.

Alpha-Beta Alloys

Alpha-beta alloys have both alpha and beta phases. This gives them a mix of strength and flexibility. You can change their features with heat treatment. Ti-6Al-4V is a well-known example. It is the most used titanium alloy in the world. You see it in planes, cars, and medical tools. Alpha-beta alloys let you change the material for many jobs.

Tip: The crystal structure changes how the alloy acts. Alpha alloys are stable and do not wear out fast, but they are not the strongest. Beta alloys are very strong, but they may not like heat as much. Alpha-beta alloys let you pick the right balance for your needs.

Here is a table to help you compare the types of titanium alloys by structure:

| Alloy Type | Crystal Structure | Key Features | Common Uses |

|---|---|---|---|

| Alpha Alloys | HCP | Good weldability, corrosion resistance, and moderate strength | Chemical, marine, moderate strength |

| Beta Alloys | BCC | High strength, formability, heat treatable | Aerospace, high-strength parts |

| Alpha-Beta Alloys | Mixed | Balanced strength and ductility, heat treatable | Aerospace, automotive, medical |

By Grade

Titanium alloys can also be sorted by grade. Grade depends on what is in the alloy and how it works. Grades help you pick the right alloy for your job.

Commercially Pure Grades

Commercially pure titanium grades go from Grade 1 to Grade 4. These grades have almost no extra elements. As the grade number goes up, the strength goes up, but the material bends less. These grades are used in medical implants, chemical plants, and sea parts. They do not rust easily.

Alloyed Grades

Alloyed grades have elements like aluminium, vanadium, or molybdenum. These elements make the alloy stronger or tougher. Grade 5 (Ti-6Al-4V) is the most common. It has a good mix of strength, weight, and rust resistance. Grade 9 (Ti-3Al-2.5V) is easier to shape and is used in tubes and planes. Grade 23 (Ti-6Al-4V ELI) has fewer extra bits, so it is good for medical implants and very cold places.

Here is a table showing how grades relate to properties and uses:

| Grade | Composition | Key Properties | Typical Applications |

|---|---|---|---|

| 1–4 | Pure Titanium | Increasing strength from 1 to 4 | Medical, chemical, marine |

| 5 | 6% Al, 4% V | Excellent all-round, most used | Aerospace, implants, industry |

| 9 | 3% Al, 2.5% V | Lower strength, better formability | Tubing, aerospace structures |

| 23 | 6% Al, 4% V (ELI) | Extra low interstitials, high purity | Medical implants, cryogenics |

Note: International rules set what goes in each grade and how it acts. Following these rules is important for selling around the world. You see these rules in planes, medicine, and cars.

When you know how titanium alloys are sorted, you can pick the right type and grade for your job. This helps you get the best safety, value, and performance.

Key Properties of Titanium Alloy Types

When you pick titanium alloys, you should know how their features help your project. Each type—alpha, beta, and alpha-beta—has its own good points. These types are different in strength, corrosion resistance, weldability, and machinability.

Strength and Toughness

Titanium alloys are strong but not heavy. They can hold big weights without being heavy. That is why they are used in planes, race cars, and medical parts. The strength and toughness change with the alloy type:

| Property | Alpha Titanium | Beta Titanium | Alpha-Beta Titanium |

|---|---|---|---|

| Heat treatable | Yes | No | Yes |

| Weldable | Limited | Yes | Yes |

| Corrosion-resistant | High | Moderate | High |

| High temperature creep strength | High | Moderate | Better than pure |

| Cold forming abilities | Limited | Good | Limited |

| Hot forming abilities | Moderate | Good | Desirable |

| Superplastic forming | No | Yes | Yes |

Alpha alloys stay strong at high temperatures and do not rust easily. Beta alloys are tough and can be shaped when hot. Alpha-beta alloys give a mix of strength and stretchiness. You can heat treat them to get what you need. When you look at titanium alloys next to stainless steel or aluminium, titanium alloys have better fatigue strength. This means they last longer when used over and over, especially if weight is important.

Tip: If you need a part that must not break or bend, pick an alloy with high toughness and the right heat treatment.

Corrosion Resistance

Corrosion resistance is one of the best things about titanium alloys. You can use them in hard places like the ocean, chemical plants, or inside the body. They do not rust or break down fast. A natural oxide layer keeps titanium safe from many chemicals and salty water.

Some grades are even better at fighting rust because of special elements. For example:

- Grade 7: This alloy is best at stopping rust. It is used in pipes, fittings, and heat exchangers.

- Grade 11: This grade gives extra help against crevice corrosion. It is good for sea and chemical jobs.

- Grade 12: Nickel and molybdenum make this grade strong and good with acids. You see it in planes and hot jobs.

| Titanium Alloy Grade | Corrosion Resistance Characteristics | Applications |

|---|---|---|

| Grade 7 | Most corrosion-resistant, includes 0.2% palladium | Piping, fittings, valves, condensers, heat exchangers |

| Grade 11 | Enhanced crevice corrosion resistance, including 0.25% palladium | Chemical processing, desalination, and marine applications |

| Grade 12 | Excellent high-temperature strength, crevice corrosion resistance, includes 0.6-0.9% nickel and 0.2-0.4% molybdenum | Heat exchangers, chemical manufacturing, marine, aerospace |

Grade 7 is the best if you need top corrosion resistance. Grade 12 is strong and fights acids, so it is used in tough places. These alloys last a long time, even with chemicals or saltwater.

Note: The right titanium alloy can save you money on repairs and replacements because of its outstanding corrosion resistance.

Weldability and Machinability

You may need to join or shape titanium alloys for your project. Weldability and machinability show how easy it is to work with these metals.

| Alloy Type | Weldability Characteristics | Machinability Characteristics |

|---|---|---|

| Alpha | Very weldable, always welded in the annealed condition. | It can be strengthened by cold working, but does not respond to heat treatment. |

| Beta | Generally weldable, but strength is low when welded; requires cold working post-welding. | Fully heat treatable, possesses good hardenability, and is high strength. |

| Alpha-Beta | Generally weldable, but weldability decreases with higher Beta content; can be heat treated. | It can undergo machining while still ductile and then heat treated for further strengthening. |

Alpha alloys are easy to weld, especially when annealed. Beta alloys can be welded, but you may need more steps to keep them strong. Alpha-beta alloys are usually weldable, but you must watch the beta amount. You can machine these alloys when soft, then heat treat them to make them stronger.

Machining Titanium Alloys

Machining titanium alloys can be hard. You may see tool wear, heat, and sharp chips. These metals are strong and do not conduct heat well, so the cutting area gets hot fast. Chips are sharp and hot, which can hurt tools and surfaces. You also need to handle big cutting forces and shaking.

To fix these problems, you should:

- Use special tools, like carbide-coated or ceramic tools.

- Use high-pressure coolant to cool and move chips away.

- Set slow cutting speeds and fast feed rates to help tools last.

- Pick the right tool, like PVD-coated carbide for most jobs, ceramic for fast finishing, or PCD for pure titanium.

Tip: Always watch the heat and shaking when machining. Keeping things steady helps you get a better finish and longer tool life.

Machining is important in jobs like planes, medical devices, and car parts. Companies like AFI Industrial Co., Ltd use advanced machining to make complex titanium alloy parts with tight fits and smooth surfaces. These methods help you make parts that fit well and last long, even in hard places.

Note: When you machine titanium alloys, you get parts that are strong, light, and do not rust. This is why industries that need high performance use these metals.

Common Types of Titanium Alloys by Grade

Grade 1-4 (Commercially Pure)

Grades 1 to 4 are the purest titanium grades. They have almost no extra elements. Each grade has special features for different jobs. Grade 1 bends easily and does not rust, but it is soft. People use it in chemical plants and the sea, where rust is a problem. Grade 2 is stronger than Grade 1 and still fights rust. It works well in planes, boats, and medical tools. Grade 3 is even stronger and also resists rust. It is good for pipes and tanks. Grade 4 is the strongest pure titanium. It is used for medical implants and aeroplane parts where you need both strength and rust resistance.

Here is a table to help you compare these grades:

| Grade | Chemical Composition | Mechanical Properties | Common Applications |

|---|---|---|---|

| 1 | Pure Titanium | High ductility, excellent corrosion resistance, and low strength | Chemical processing, marine, aerospace |

| 2 | Pure Titanium | Moderate strength, good corrosion resistance | Aerospace, marine, and medical devices |

| 3 | Pure Titanium | High strength, good corrosion resistance | Pressure vessels, piping, aerospace |

| 4 | Pure Titanium | Highest strength, excellent corrosion resistance | Surgical implants, aircraft, and marine applications |

Note: Commercially pure titanium alloys cost less than alloyed types. You can use them when you need corrosion resistance more than high strength.

Grade 5 (Ti-6Al-4V)

Grade 5 titanium alloy is called Ti-6Al-4V. It is the most used titanium alloy. Many industries pick it because it is strong, light, and does not rust. This alloy has 6% aluminium and 4% vanadium. It is much lighter than steel but still very strong. Grade 5 titanium is easy to shape and weld. This helps make the tricky parts.

Key features of grade 5 titanium include:

- High strength-to-weight ratio

- Lightweight

- Excellent corrosion resistance

- Biocompatibility

You see grade 5 titanium in:

- Jet engines and aeroplane frames

- Medical implants like bone screws and joints

- Car parts for fast cars

- Marine hardware that needs to fight saltwater

If you need a strong and light material, grade 5 titanium alloy is a smart pick. It costs more than pure grades, but it saves money over time because it lasts longer.

Grade 9 (Ti-3Al-2.5V)

Grade 9 titanium is called Ti-3Al-2.5V. It gives a good mix of strength and easy shaping. It has 3% aluminum and 2.5% vanadium. Grade 9 is not as strong as grade 5, but you can bend and shape it more easily. It is great for making tubes or parts with curves. Grade 9 is much stronger than grade 2 titanium. It works well for high-pressure tubes and aeroplane parts.

Here is a quick comparison:

| Grade | Strength (MPa) | Formability Comparison |

|---|---|---|

| Grade 9 | 620 | Superior to Grade 5, ideal for complex shapes |

| Grade 2 | N/A | Much stronger than Grade 2, better formability |

| Grade 5 | N/A | Lower strength than Grade 5, easier to work with |

You often see grade 9 titanium in:

- Aeroplane hydraulic tubes

- Sports gear like bike frames

- Marine tubes

- Pipes for chemical plants

Grade 9 is strong and easy to shape. If you need to make tubes or curved parts, this alloy is a great choice among titanium grades.

Grade 23 (Ti-6Al-4V ELI)

If you need a titanium alloy for medical implants, you will often see grade 23. This alloy is also called Ti-6Al-4V ELI. ELI means “Extra Low Interstitials.” Many medical devices use this alloy because it helps keep people safe and healthy.

Grade 23 titanium alloy is popular in medicine. Doctors and engineers use it for bone screws, joint replacements, dental implants, and pacemaker cases. You can trust this alloy. It is strong, safe, and lasts a long time inside the body.

Here are some reasons to pick this alloy for medical use:

- It has high strength and durability. The part will not break or wear out fast, even under stress.

- It has enhanced fracture toughness. The alloy can handle bending and movement. This is important for implants that move with your body.

- It has excellent biocompatibility. The body accepts this alloy. It does not cause harm or toxic reactions. Surgeons use it for implants that stay in the body for many years.

- It has outstanding corrosion resistance. The alloy does not rust or break down in body fluids. It also stands up to cleaning and sterilisation.

You can see these features in the table below:

| Property | Description |

|---|---|

| High Strength and Durability | Great mechanical properties, good for high-stress places. |

| Enhanced Fracture Toughness | Good for implants that face repeated loads. |

| Biocompatibility | Safe for the human body, used in things like pacemaker cases. |

| Corrosion Resistance | Stays strong in body fluids and during cleaning. |

Tip: If you need a material for a medical device or implant, grade 23 titanium alloy is a smart choice. It keeps patients safe and helps devices last longer.

This alloy is also used in other industries. For example, it works well in aerospace and cryogenic equipment. It stays strong in very cold places. The extra low interstitials make it purer than grade 5. This means it is less likely to have tiny flaws that could cause problems.

When you pick grade 23 titanium alloy, you get a material that meets strict safety and performance rules. This is why hospitals, doctors, and engineers around the world trust it for life-saving devices.

Applications of Titanium Alloy Types

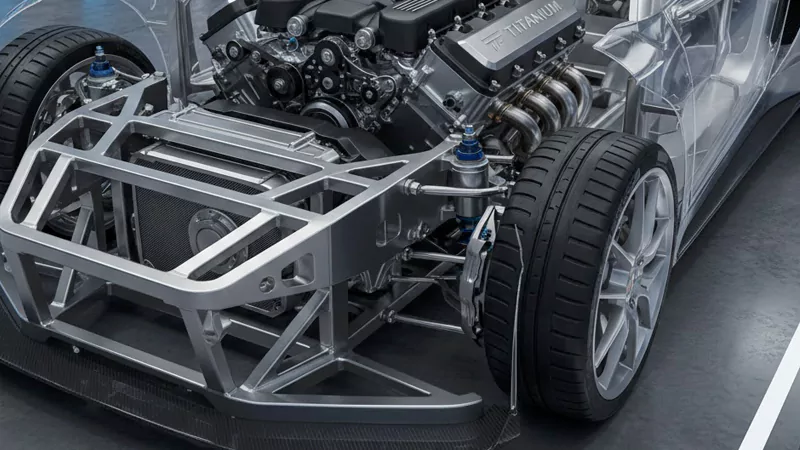

Aerospace

Titanium alloys are used a lot in aerospace. They help make aeroplanes, rockets, and spacecraft. These metals are strong but also light. This means parts can be tough but not heavy. That is important for flying. About 40% of all titanium alloys are used in aerospace. You find them in jet engines, airframes, landing gear, and fasteners. These alloys do not rust and can handle heat. They last a long time in hard places. Machining is important for making these parts. You need to shape titanium alloys into complex pieces. Advanced machining helps make parts that fit just right. This keeps planes safe and helps them use less fuel.

Tip: Using titanium alloys in aerospace saves weight and fuel. This makes flying safer and cheaper.

Medical Devices

Titanium alloys are very useful in medicine. You see them in many implants and tools. Doctors use them for hip joints, bone screws, dental implants, and pacemaker cases. These alloys work well inside the body. They do not cause harm and can join with bone and tissue. This helps implants stay in place.

Here are some reasons why titanium alloys are used in medical devices: Titanium bonds with bone and tissue. It is strong and does not rust. Titanium alloys are as strong as steel but lighter. They have a special film that stops rust. You see them in pacemaker cases and replacement joints. They are good for implants like hip joints.

Titanium alloys last a long time and are safe for people. They have a lower Young’s modulus, which is better for bones. Titanium is the most inert metal used in medicine. You can heat-treat it to make it stronger. Ti-6Al-4V titanium alloys have a tensile strength of 120,000 psi. Yield strength can reach 150,000 psi after ageing.

Machining is important for medical devices. You need to make small, detailed parts that fit well in the body. High-precision machining helps make smooth and exact parts. This makes implants safer and more comfortable for patients.

Chemical Processing

Titanium alloys help chemical plants work safely and well. These metals do not rust, even with strong acids or harsh chemicals. That is why they are used for pipes, tanks, valves, and reaction vessels. You can use titanium alloys with tough chemicals like nitric acid and chlorine dioxide. Here is why they are good for chemical processing: Titanium’s corrosion resistance keeps equipment safe. It works well with strong chemicals, making things safer and better. These alloys last a long time, so you do not need to replace parts often. They help stop leaks and failures, which is important for safety. You find them in vessels, heat exchangers, tanks, and piping systems.

Machining titanium alloys for chemical plants lets you make parts with tricky shapes and tight fits. This helps keep chemicals inside and the plant running well. When you use these alloys, your equipment lasts longer and works better in hard places.

Note: The uses of titanium alloys show how helpful these metals are in many industries. You can count on them for strength, safety, and long life.

Marine and Automotive

Titanium alloys are important in ships, submarines, and cars. These metals help things work better and last longer. Why do engineers pick titanium instead of steel or copper? Titanium alloys have special features that make them a good choice.

Let’s look at why titanium alloys are helpful:

| Advantage | Description |

|---|---|

| High Strength-to-Weight Ratio | Titanium is strong like steel but weighs less. This is good for many uses. |

| Corrosion Resistance | It does not rust in tough places, like seawater or acids. |

| Durability | It does not crack or wear out fast, so it lasts longer. |

People call titanium “ocean metal” because it works well in the sea. Steel and copper can get small holes or rust, but titanium does not. Tiny sea creatures do not hurt it either. That is why it is used for ship hulls, propellers, and pipes underwater. Titanium stays strong in salty or sour water for a long time.

In cars, titanium alloys help make vehicles lighter. Lighter cars use less fuel to move. This means you save gas and produce less pollution. Titanium is strong, so cars stay safe and work well even when they are lighter. Car makers use titanium for exhausts, valves, springs, and some body parts.

Here are some reasons to use titanium alloys in ships and cars:

- Titanium is almost half as light as steel but just as strong.

- It does not get ruined by saltwater or strong chemicals.

- It does not crack or break easily, so it lasts longer.

- Using titanium helps cars use less fuel.

Note: Titanium is light and does not rust, so it is great for ships and cars. You get strong parts that last a long time and need less fixing.

Machining is important for making titanium alloy parts. Special machines can shape titanium into tricky forms and tight fits. CNC machines help make smooth and exact parts. This is needed for things like ship propellers or car engine parts.

Machining helps because:

- You can make parts with hard shapes.

- Every part is made the same, even if you make a lot.

- The finished parts fit well and look good.

Titanium alloys help ships go farther, and cars use less fuel. With good machining, you get parts that are strong, light, and last a long time.

Comparison Table: Types of Titanium Alloys

Structure, Properties, and Uses

When you pick a titanium alloy, you want to know how they are different. There are three main types: alpha, beta, and alpha-beta. Each type has its own structure, features, and uses. The table below shows how they compare:

| Feature | Alpha Alloys | Alpha-Beta Alloys | Beta Alloys |

|---|---|---|---|

| Crystal Structure | HCP (hexagonal) | Mixed (HCP + BCC) | BCC (body-centered) |

| Heat-Treatable | No | Yes | Yes |

| Weldability | Very good | Most are weldable | Generally weldable |

| Strength | Low to medium | Medium to high | Highest |

| Corrosion Resistance | Excellent | High | Good |

| Formability | Good | Moderate | Good |

| High-Temperature Creep Resistance | Optimum | Not as good as alpha | Limited |

| Common Uses | Chemical, marine, biomedical | Aerospace, automotive, medical | Aerospace, automotive, sports |

Tip: If you need the best corrosion resistance and easy welding, alpha alloys are a smart pick. For the highest strength, beta alloys work well. If you want a balance, alpha-beta alloys give you both strength and flexibility.

Key Points for Each Alloy Type

- Alpha Alloys

- These alloys are easy to weld and shape.

- They do not rust and can handle chemicals.

- You see them in chemical plants, ships, and medical tools.

- They do not get stronger with heat, but they stay stable when hot.

- Alpha-Beta Alloys

- You can use heat treatment to change their strength.

- They mix strength and stretchiness, so they work in planes, cars, and medical devices.

- Most can be welded, but you should check the beta amount.

- Beta Alloys

- These alloys are the strongest and lightest for their size.

- You can shape them easily, even into tricky parts.

- They are used in planes, cars, and sports gear like bike frames.

Note: Pick the titanium alloy that fits your needs. If you want something that lasts in tough places, choose alpha alloys. For strong and light parts, beta alloys are best. Alpha-beta alloys are good if you want a mix of features.

This comparison helps you choose the right titanium alloy for your project. Each type has special features. Think about what you need most—strength, rust resistance, or flexibility. With this info, you can make a smart choice for your next engineering job.

You now know there are three main titanium alloy types: alpha, beta, and alpha-beta. Each type has its own special features and uses. When you pick a titanium grade, think about how strong it is, if it resists rust, and if it fits your project. The table below shows what to look for:

| Factor | Description |

|---|---|

| Mechanical Properties | How strong, bendy, and tough the alloy is. |

| Corrosion Resistance | How well it avoids rust and chemical damage. |

| Application Needs | If it works in heat, is easy to machine, or fits special jobs. |

Knowing these things helps you pick the best titanium grade for your work. Always match the alloy’s features to what you need. Think about how you will shape the part with machines. Picking the right titanium grade gives you better results, longer-lasting parts, and more value from your materials.

FAQ

You get titanium alloys by mixing titanium with other elements. This makes them stronger, lighter, or more resistant to rust than pure titanium. You can choose the right alloy for your job based on what you need.

You can weld most titanium alloys, especially alpha and alpha-beta types. Always keep the area clean and use the right tools. This helps you avoid weak spots and keeps the weld strong.

You can weld most titanium alloys, especially alpha and alpha-beta types. Always keep the area clean and use the right tools. This helps you avoid weak spots and keeps the weld strong.

Yes! Doctors use titanium alloys for implants because your body accepts them. They do not cause harm or react with body fluids. They last a long time inside you.

You need special tools and coolants to machine titanium alloys. These metals are tough and get hot fast. Use slow speeds and steady feeds to protect your tools and get a smooth finish.

Ti-6Al-4V, also called Grade 5, is the most common. You find it in planes, cars, and medical devices. It gives you a great mix of strength, weight, and rust resistance.

Titanium alloys resist rust very well, even in seawater. You can use them for ship parts, pipes, and marine equipment. They last much longer than steel in salty water.