In the hyper-competitive landscape of global industrial manufacturing, the ability to transition from a digital CAD model to a high-precision physical component in record time is no longer a luxury—it is a strategic necessity. For mechanical engineers and procurement specialists, the bottleneck has traditionally been the complexity of multi-stage production. However, the emergence of multi-tasking turning and milling (often integrated into Mill-Turn centers) has fundamentally shifted the paradigm of metal parts manufacturing.

Multi-tasking machining accelerates the production of complex metal components by integrating disparate operations into a single, seamless process. By addressing the core demands for shorter lead times, enhanced production speed, and superior efficiency, this technology serves as the backbone of modern advanced machining services. At AFI Industrial, we provide integrated CNC Turning and Milling services engineered for the demanding requirements of the medical, aerospace, and automotive industries. Our facility operates under ISO 9001:2015 standards, ensuring that every component—from simple fasteners to complex manifold blocks—meets rigorous dimensional stability and surface integrity requirements. This article explores how adopting a “Done-in-One” philosophy through multi-tasking can transform the manufacturing outcomes.

Table of Contents

Challenges in Traditional Metal Parts Manufacturing

Multiple Setups and Transfers

It is hard when you must move parts between machines. Each setup can make the part less accurate. Every time you transfer a part, it takes longer. Mistakes are more likely with each move. Here is a table that shows setup time and error risk:

| Process Step | Traditional 3-Axis | 5-Axis CNC Machining |

|---|---|---|

| Initial Setup | 45 minutes | 60 minutes |

| Subsequent Setups | 4 x 30 minutes | 0 minutes |

| Total Setup Time | 165 minutes | 60 minutes |

| Risk of Error | High | Low |

Old ways often need three or more setups. More setups can cause errors in where things are placed. Extra setups also mean you wait longer to finish a part. If you use only one setup, all features stay lined up. This lowers the chance of mistakes or wasted parts. Metal parts manufacturers can finish metal parts jobs faster this way.

Longer Cycle Times and Labor

Old methods make you move parts from one machine to another. It takes a lot of time to set up and move each part. This makes the whole process take longer. You need more people to do each step. More workers cost more money and can make more mistakes. Rotary transfer machining can make hundreds or thousands of parts every hour. Using one fixture helps stop human mistakes and keeps things running well. It can save time and money.

Precision and Quality Risks

You want every part to be made just right. Old ways depend on how good the worker is. Tired workers or small mistakes can cause problems. Even tiny errors can make a part not fit or work. Bad tolerance design means more parts get rejected and costs go up. Wrong bend calculations can make parts break when put together. If you forget surface treatment, you can have problems with how the part looks or works. Precision matters a lot in fields like aerospace and medical devices. Small mistakes can cause big trouble or safety issues. CNC machining follows exact steps, so parts are more alike and better.

What is Multi-Tasking Turning and Milling?

Defining the Technology

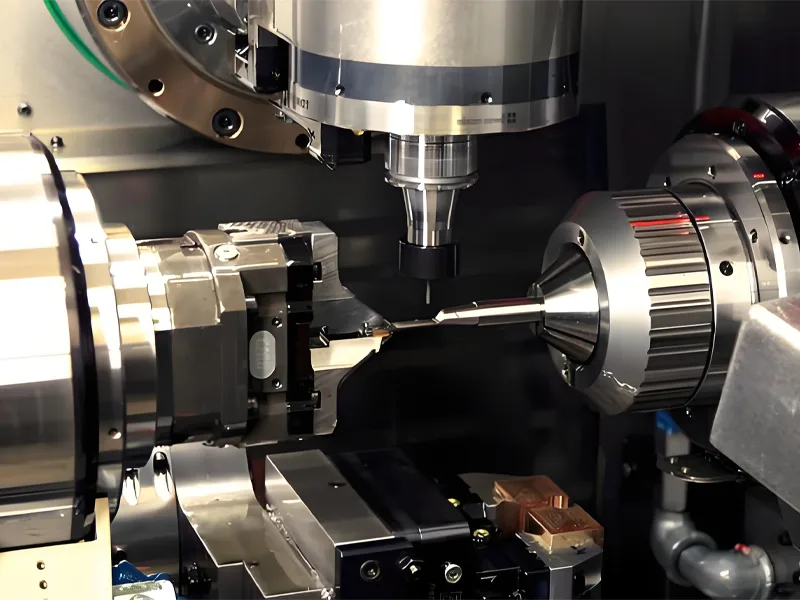

At its core, multi-tasking turning and milling refers to the integration of CNC lathe capabilities (turning) and CNC mill capabilities (milling) within a single machine tool. While traditional lathes may feature limited “live tooling,” a true multi-tasking center—often a 5-axis Mill-Turn machine—possesses the structural rigidity and spindle power to perform heavy milling, drilling, and tapping alongside high-speed turning.

Integration of Turning and Milling

Turning and milling together make work faster. You do not waste time with extra setups. You also keep parts accurate by not moving them. One CNC machine does both jobs in less time. Here is a table that shows how this helps:

| Benefit | Description |

|---|---|

| High Integration, Reduced Processes | Many jobs done in one setup, fewer mistakes, and time saved. |

| Improved Machining Accuracy | No moving parts means better accuracy and parts match up. |

| High Efficiency, Shorter Lead Time | Doing jobs at the same time cuts tool-change wait, so you finish faster. |

| Superior Complex Part Machining | Multi-axis lets you make hard shapes and curves. |

Role of Machining in Modern Production

Machining is very important today. You must make parts that are good and on time. Multi-tasking helps you do this. With CNC machining, you get high precision and can repeat jobs well. You can use many materials and make different parts. Companies like AFI Industrial Co., Ltd use advanced machines to help you. Their multi-tasking machines let you make big or small batches fast. You stay ahead because you can change quickly for customers. Multi-tasking machining is now the main way to make parts.

Note: If metal parts suppliers buy multi-tasking and cnc machines, their business will do better for a long time. They waste less, make better parts, and finish jobs faster than others.

How Multi-Tasking Machining Boosts Productivity

The most significant driver of speed in metal parts manufacturing is the reduction of setups. Every time a part is moved from one machine to another, the production clock stops, and the risk of error increases.

One-Setup Operations

Turning and Milling Integration

Advanced multi-tasking machines utilize a sub-spindle architecture. While the main spindle handles the primary turning and milling of the first side, the sub-spindle can pick up the part mid-cycle to process the “back side”. This integration means that a part that once required four separate setups can now be completed in a single automated cycle. The core advantage of AFI’s integrated approach is the elimination of Tolerance Stack-up. In traditional separate processes, transferring a part between a lathe and a mill introduces setup variances. By utilizing Turn-Mill centers, we maintain the geometric relationship between features (like the perpendicularity of a hole to a turned face) within a single coordinate system.

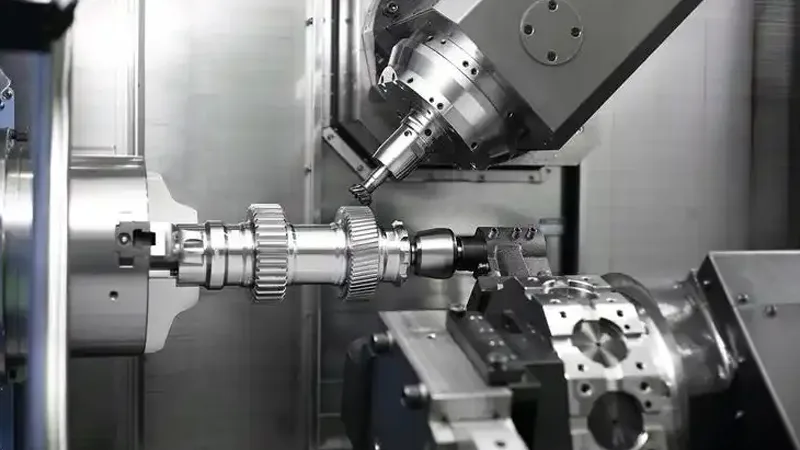

Simultaneous Machining

High-end Mill-Turn centers allow for simultaneous operations, where multiple tools engage the workpiece at once. For example, a machine might be milling a complex pocket with a B-axis head while a lower turret performs a finishing turn on a different diameter. This parallelism directly translates to a 30% to 50% reduction in total cycle time.

Streamlined Workflow

Multi-tasking machining combines turning, milling, drilling, and tapping into a single step. Manufacturers do not have to wait for other machines or workers. They finish more jobs in less time. With fewer setups, you spend less time getting ready and more time making parts.

By consolidating operations, manufacturers achieve a “faster flow” of work-in-progress (WIP).

- Elimination of Wait Times: Parts do not sit in bins waiting for a milling machine to become available.

- Reduced Fixturing Costs: There is no need for multiple expensive custom jigs for each intermediate step.

- Streamlined Logistics: The internal movement of parts is minimized, reducing the logistical burden on the factory floor.

Drastic Lead Time Reduction with Multi-Tasking Machining

For international procurement managers, the total lead time—from order placement to delivery—is the most critical metric. Multi-tasking technology is the most effective tool for compressing this timeline.

Changeover and Downtime Savings

Traditional machining often involves “stacking” setups, where the time spent calibrating machines and changing fixtures can exceed the actual cutting time. Multi-tasking machines utilize automated tool changers (ATC) and standardized work-holding to minimize changeover. A single machine can hold 40 to 120+ tools, allowing it to switch between diverse operations in seconds.

Streamlined Workflow

In a multi-tasking environment, the workflow is linear rather than fragmented. This predictability allows for more accurate scheduling and eliminates the “bottleneck effect” where one slow milling operation stalls the entire production line.

Shorter Production Cycles

By combining turning and milling, the total time a part spends on the shop floor is slashed. Projects that typically take six weeks in a traditional shop can often be delivered in two weeks or less using on-demand multi-tasking solutions.

On-Demand CNC Machining for Custom Parts

Modern product design cycles are shorter than ever, requiring a manufacturing partner that can provide both flexibility and rapid response.

Flexibility and Rapid Response

Multi-tasking machines are inherently adaptable. Because they possess a full suite of cutting capabilities, they can pivot between different part designs without requiring significant hardware retooling. This makes them ideal for on-demand CNC machining, where engineers may need to iterate on a design rapidly.

Small Batch and High-Mix Production

The high cost of traditional setups often makes small-batch manufacturing (1-50 units) prohibitively expensive. Multi-tasking lowers this barrier. Since the setup is consolidated, the “cost per setup” is spread across fewer operations, making high-mix, low-volume (HMLV) production economically viable for custom metal parts.

Precision and Quality Advantages

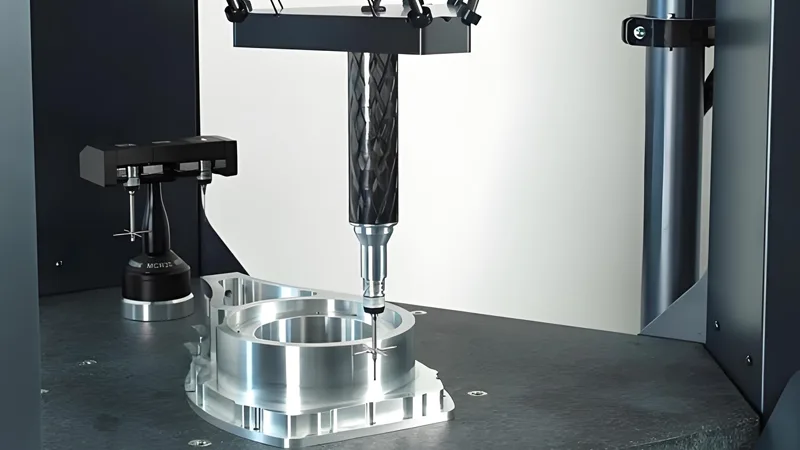

Improved Dimensional Accuracy

In traditional machining, every time a part is re-fixtured, “tolerance stack-up” occurs. Small alignment errors in each setup accumulate, potentially pushing the part out of specification. Metal parts manufacturers can avoid this situation by using combined turning and milling processes.

- It can stop mistakes from recurring, so parts match the plan.

- because they use the same reference point, so accuracy gets better.

- It keeps shapes like circles and straight lines correct.

- It can reduce bending and stress, so parts stay strong.

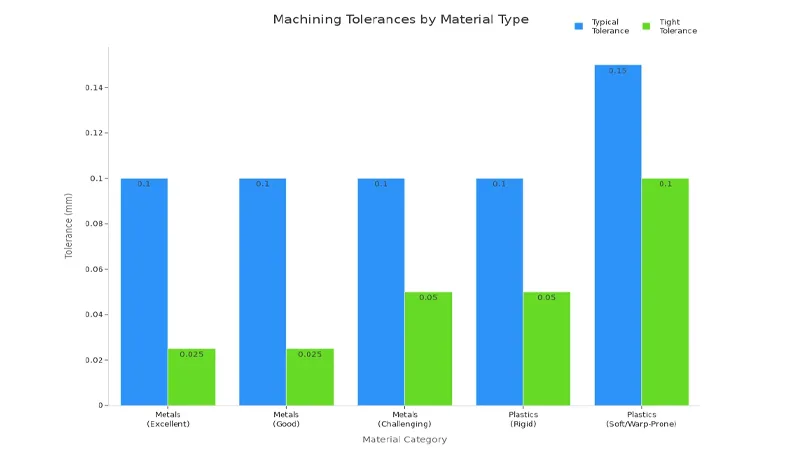

With advanced machining, metal parts suppliers can make parts with tight tolerances and smooth finishes. The table below shows common tolerances for different materials:

| Material Category | Examples | Typical Tolerance (Linear Dimensions) | Tight Tolerance (Achievable with Process Control) |

|---|---|---|---|

| Metals (Excellent) | Aluminum Alloys (6061, 7075) | ±0.1 mm (±.004″) | ±0.025 mm (±.001″) or better |

| Metals (Good) | Steel, Stainless Steel (304, 316) | ±0.1 mm (±.004″) | ±0.025 mm (±.001″) |

| Metals (Challenging) | Titanium, Inconel | ±0.1 mm (±.004″) | ±0.05 mm (±.002″) |

| Plastics (Rigid) | ABS, PC, Acrylic, Nylon | ±0.1 mm (±.004″) | ±0.05 mm (±.002″) |

| Plastics (Soft/Warp-Prone) | PP, POM, PE | ±0.15 mm (±.006″) | ±0.1 mm (±.004″) |

Consistency in Complex Parts

We want every part to be the same, even if the shape is hard. Multi-tasking machining helps metal parts machining vendors do this. Five-axis CNC machines move in five ways at once. Production personnel can make tough shapes and many surfaces in one clamp. This makes work faster and keeps parts accurate. Do not need to move the part, so they avoid mistakes.

- They make hard shapes in one step.

- They shape many sides without moving the part.

- They get the same results every time, even for tricky jobs.

Teams use five-axis machining for turbocharger parts. They finish the whole part in one go. This stops problems with accuracy and surface finish. You see better performance and trust that the parts work well. They know every part meets your standards the first time.

Reduced Error Risk

We want fewer mistakes when making parts. Multi-tasking machining uses smart systems to watch the process. Cameras look at what workers do. If someone makes a mistake, the system warns them right away. Workers can fix problems fast. This stops mistakes from getting worse and saves money.

- Detect errors early and prevent problems before they occur.

- Fewer errors will be found when inspecting finished parts.

- To make the parts more precise and better.

With these systems, we lower the chance of bad parts, save time, and money. Customers trust us because we always deliver good parts.

Tip: Using multi-tasking machining helps metal parts producers get better accuracy, higher first-pass quality, and more reliable results for every job.

Cost and Lead Time Reduction

Cost and Resource Efficiency

While the initial investment in multi-tasking equipment is higher, the long-term savings for the customer are substantial:

Resource Optimization: Efficient use of floor space and energy results in a more sustainable and cost-effective manufacturing process.

Lower Labor Costs: Fewer setups require fewer operators and less manual handling.

Reduced Scrap Rates: High process stability leads to fewer rejected parts, saving material and time.

You also have less waiting time. Machines with automation can work longer without stopping. You do not wait for someone to set up the next step. This makes metal parts manufacturing faster and more steady.

Material and Process Efficiency

Multitasking machining allows for optimal utilization of resources and avoids waste. Turning, milling, drilling, and tapping can be completed in a single setup. This reduces the number of machines and fixtures used by machinists. This not only improves production accuracy but also shortens setup time. Machining cycles can be reduced by 30% to 50%, and setup time can be reduced by up to 75%. Five-axis machining means that parts do not need to be re-clamped, allowing more work to be completed in a single operation.

- Using less material because it does not move parts as much.

- Finishing jobs faster, and can do more work.

- Making machines run better, so they get more done.

Using less material and finishing jobs quicker lowers your costs. You also help the planet by making less scrap and using less energy.

Faster Time-to-Market

Metal parts manufacturers should deliver products to customers quickly. Multitasking machining can increase speed. It allows for quick job switching, easily handling both large and small production runs. These machines enable production personnel to easily manufacture customized parts, thus quickly meeting diverse customer needs without long waiting times.

| Benefit | Impact on Your Business |

|---|---|

| Rapid Changeovers | Less waiting between jobs |

| Customization | Make special parts for customers |

| Scalable Production | Do small or big orders |

| Shorter Lead Times | Get products to customers faster |

Adapting to Complex Metal Parts Manufacturing

Flexibility for Complex Geometries

Machining complex-shaped parts can be difficult. Multi-functional machining can help machining suppliers complete these tasks. They can perform milling, turning, and drilling with just one machine tool. They can also add new machining processes to the same machine. There’s no need to move the part to another machine. This ensures that all components are aligned, improving accuracy. Complex parts can be machined in a single setup. They can machine parts with sharp bends and deep holes. Machining of special structures also becomes easier. It saves time and reduces the probability of errors. Therefore, they can take on more challenging projects.

Application in Precision Industries

Some industries need very exact and fast parts. Multi-tasking machining is best for these jobs. These fields want parts that fit and work every time. Here is a table that shows where this technology helps most:

| Industry | Benefits |

|---|---|

| Aerospace | Very exact parts, odd shapes, faster jobs, better quality. |

| Automotive | Lots of parts, strict rules, quick work, saves money. |

| Medical | Custom parts, fast samples, follows rules, same results each time. |

| Tooling | Makes tricky molds, fewer mistakes, and more work done. |

| Custom Production | Quick changes, less waiting, good for fast changes in electronics. |

An OEM manufacturer as AFI Industrial can help aerospace, automotive, and medical companies. They give them parts that meet tough rules. They also help customers who need quick changes and custom work. Multi-tasking machining helps them do well when details matter most.

Industry Applications

- Aerospace: Complex turbine components and landing gear parts that require exotic alloys and extreme precision.

- Medical: Orthopedic implants and surgical instruments that demand complex geometries and superior surface finishes in a single setup.

- Automotive: Performance engine components and transmission housings where weight reduction and high-strength tolerances are paramount.

Conclusion: The Future of On-Demand CNC Machining

Multi-tasking, turning, and milling represent the pinnacle of modern production efficiency. By integrating advanced machining solutions, manufacturers can drastically reduce lead times, enhance precision, and offer the adaptability required for today’s fast-paced markets.

For mechanical engineers and procurement professionals, partnering with a manufacturer that utilizes multi-tasking technology is the most effective way to gain a competitive advantage. As the industry moves toward more integrated, on-demand CNC machining, these capabilities will continue to define the leaders in high-quality metal parts manufacturing.

If you are looking for a partner to accelerate your next project with advanced multi-tasking machining, contact our engineering team today for a technical consultation and DFM (Design for Manufacturing) review.

FAQ

Multi-tasking machining uses one machine for many jobs. It does turning, milling, drilling, and tapping. You finish parts with just one setup. This saves time and helps parts stay accurate. You also make fewer mistakes.

You do all steps in one setup. You do not move parts between machines. This makes production go faster. You can deliver parts more quickly.

Yes. You can make hard shapes and features in one process. Advanced machines help you create tricky parts. You get high precision and can repeat the job well.

You save money on labor and setup, even for small batches. Quick changes and fewer setups make it work well. It is good for custom jobs and small orders.

Aerospace, automotive, medical, and tooling industries use it a lot. You get very precise parts and fast work. It is great for jobs that need high quality.

Automation does boring and repeated jobs for you. You do not have to handle parts as much. This lowers the chance of getting hurt. Your team works in a safer place.

You get modern machines and skilled workers. Their team uses proven ways to make parts. AFI Industrial Co., Ltd gives you good results and helps your business grow.