Aerospace companies face significant challenges when it comes to titanium machining. Tools can break or overheat, leading to ruined parts and halted machinery. The table below outlines the primary cost risks associated with this issue:

| Cost Risk | Description |

|---|---|

| Tool Breakage Cost | Broken tools can ruin parts and damage machines. |

| Production Yield Impact | Losing even one part reduces the overall production output. |

| Profitability and Customer Impact | Repairing parts incurs costs and can frustrate customers. |

| Production Capacity Bottlenecks | Malfunctioning machines result in decreased production rates. |

Aerospace parts require meticulous manufacturing. If titanium machining processes fail, it leads to delays and financial losses for companies.

Key Takeaways

- Titanium machining is hard because heat builds up fast. High temperatures can lead to tool wear and part damage. Good heat control is very important to stop cracks. It can also ensure the safety of aerospace parts. High-pressure coolant systems help tools last longer. And it makes the processed surface smoother. Choosing the optimal cutting speed and cutting depth is crucial. It helps lower heat and tool wear. Special coatings on tools make them stronger. These coatings also help tools last longer when cutting titanium. Adaptive control systems can change settings while the machine works. This optimizes the machining process and prevents unexpected machine tool failures. Adopting green manufacturing methods, such as reducing the use of lubricants, can save costs and benefit environmental protection. Learning about new technology and methods is very important. It helps make titanium machining better.

Table of Contents

Why Heat Management Matters in Titanium Machining

Impact on Aerospace Quality and Safety

Managing heat is very important in titanium machining. If the heat is not controlled properly, stress will be generated inside the parts. This stress can make cracks form before the part wears out. Parts with cracks are not suitable for aerospace applications.

Note: In aerospace, every part must follow strict safety rules.

The table below explains how heat changes the structure and strength of aerospace parts:

| Issue | Description |

|---|---|

| Heat Concentration | Titanium does not move heat away well, so heat builds up at the tool tip. |

| Microstructural Changes | Localized heating can alter the internal structure of a material, thereby affecting its properties. |

| Residual Stress | Too much heat can leave stress inside, which can cause cracks to form early. |

| Surface Damage | High heat can hurt the surface, making the part work less well. |

Bad machining can also hurt the surface of the parts. This damage will reduce the service life of the parts. Over time, the probability of failure increases. In the aerospace field, even a single failure can lead to extremely serious consequences.

Cost and Productivity Effects

Improper temperature control during titanium processing increases costs and reduces processing speed. When the cutting zone temperature of a tool becomes excessively high, the tool may soften or bend. This will cause the cutting tools to wear out faster, requiring more frequent replacement. Each tool change causes the machine tool to stop, thereby reducing part output.

- Too much heat at the cutting spot makes tools soft and bends parts.

- Short tool life means more money spent and more stops.

- Bad surface finish needs extra work, which takes more time and money.

- To prevent machine overheating and wear, workers may slow down the machine speed, which will reduce the number of parts produced.

The table below shows how different things affect tool wear and machine stops:

| Variable | Impact on Tool Wear and Downtime |

|---|---|

| Cutting Forces | Higher forces wear out tools faster and cause more stops. |

| Temperatures | Too much heat wears out tools and causes problems. |

| Tool Changes | Changing tools often means more stops and higher costs. |

High loads and heat make tools wear out faster. This results in unexpected downtime and increased costs; In the aerospace sector, these issues can lead to delivery delays and reduced profits.

Titanium Alloy Machining Challenges

Material Properties and Heat Buildup

Titanium alloys are hard to machine for aerospace parts. The properties of titanium cause significant heat generation during the cutting process. The table below shows how these properties change machining:

| Property | Effect on Machining |

|---|---|

| Low Thermal Conductivity | Heat stays at the cutting edge, causing rapid tool wear. |

| High Chemical Reactivity | Titanium sticks to cutting tools; it adheres to cutting tools, affecting the surface finish of machined parts. |

| High Strength and Toughness | Cutting forces increase, requiring strong machines. |

| Elasticity (Springback) | Titanium bends and returns, making accuracy difficult. |

| Work Hardening | The surface becomes harder after each pass, increasing tool load. |

Low Thermal Conductivity

Titanium has very poor heat dissipation properties. Heat stays in the cutting area. The cutting edge gets hot fast. The table below compares thermal conductivity for common aerospace materials:

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Titanium | 6.7 – 22 |

| Stainless Steel | 16.2 |

| Carbon Steel | 49.8 |

Machining titanium needs careful heat control. Heat stays at the cutting spot. This can hurt the tool and the part.

High Strength and Work Hardening

Titanium is difficult to bend or form, and it also requires high cutting forces. Machines must be strong to cut titanium. Titanium gets harder at the surface after each cut. Every pass makes the surface tougher. This puts more stress on the tool. To solve these problems, workers must control heat and force.

Tool Wear Mechanisms in Titanium Machining

When machining titanium alloys, tool wear occurs rapidly. The main reasons are adhesion, diffusion, and notching.

- Adhesion: Titanium sticks to the tool when it gets hot. This changes the cutting edge.

- Diffusion: Parts of the tool move into the titanium, making the tool weaker.

- Notching: The tool edge wears down at the contact point and forms a notch.

Titanium’s low thermal conductivity and high chemical reactivity alter the wear patterns of cutting tools. These problems are not the same as with steel or aluminum. Workers must adjust cutting parameters to reduce tool wear.

Note: Tool wear in titanium machining can stop production and raise costs.

Comparison with Other Aerospace Materials

Machining titanium alloy is harder than machining other aerospace materials. Aluminum and steel offer superior heat dissipation properties, which means cutting tools used to process these materials have a longer service life. Machining titanium needs special ways to handle heat and tool wear. In aerospace, picking the right cutting settings helps solve machining problems.

Advanced Heat Management Solutions for Machining Titanium Alloy

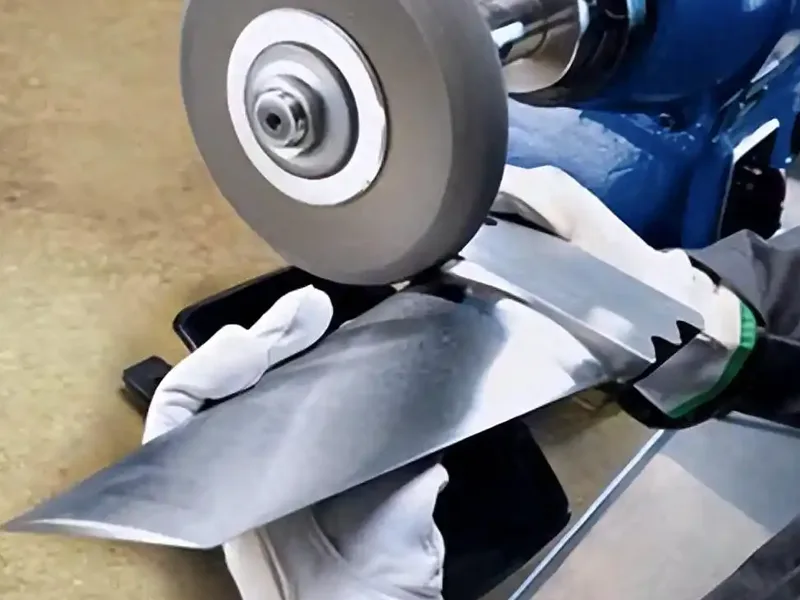

Tool Materials and Coatings for Titanium Machining

Carbide, Cermet, Ceramic Tools

Carbide tools are used to cut titanium alloy. These tools can withstand high heat at the tip. Cermet tools mix ceramic and metal. They do not wear out fast and can cut titanium quickly. Ceramic cutting tools are particularly suitable for high-speed machining. They stay hard even when hot. When cutting titanium, tools wear out from notches, grooves, and sticky spots. Picking the right tool helps control heat and makes tools last longer.

AlTiN, TiAlN, DLC Coatings

Tool coatings help tools last longer and handle heat. AlTiN coatings work well in high heat and do not break down. TiAlN coatings also protect tools but are not as strong as AlTiN. DLC coatings, with TiAlN, make tools resist wear better. These coatings help tools stay sharp and last longer. AlCrN and AlTiSiN coatings are also good for nickel alloys. They stop tools from wearing out due to heat and chemical changes.

Tip: Use coated tools to make tools last longer in aerospace work.

Optimizing Cutting Parameters

Speeds, Feeds, Depth of Cut

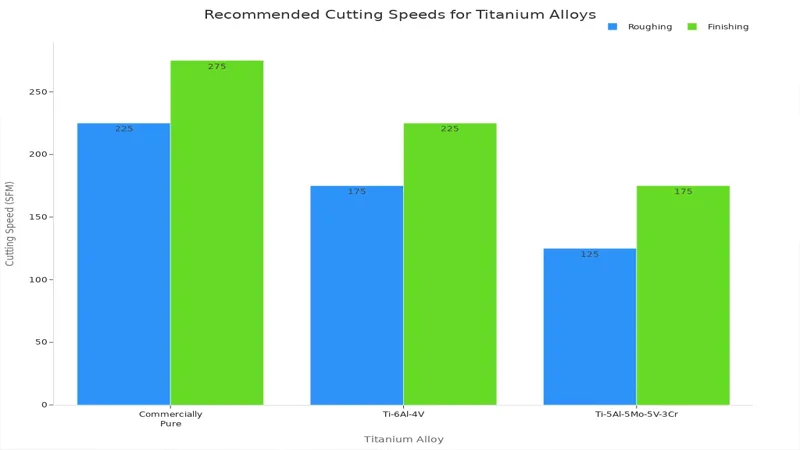

Cutting settings change how long tools last and how smooth the part is. The right settings help keep the heat low and tools from wearing out. The table below shows the best speeds and coolant types for different titanium alloys and jobs:

| Titanium Alloy | Operation Type | Recommended Cutting Speed (SFM) | Coolant Requirement |

|---|---|---|---|

| Commercially Pure | Roughing | 200-250 | Flood |

| Commercially Pure | Finishing | 250-300 | Flood |

| Ti-6Al-4V | Roughing | 150-200 | High-pressure |

| Ti-6Al-4V | Finishing | 200-250 | High-pressure |

| Ti-5Al-5Mo-5V-3Cr | Roughing | 100-150 | High-pressure |

| Ti-5Al-5Mo-5V-3Cr | Finishing | 150-200 | High-pressure |

A good depth of cut is one to two times the tool’s width. The width of the cut should be about one third of the tool’s width. This way, the force goes along the tool and not sideways. It also spreads heat and uses the whole tool edge. This method can reduce the number of cuts required.

The chart below shows the best speeds for each titanium alloy and job type:

Cutting speed and depth of cut each matter a lot for tool life and finish. Feed rate matters too, but not as much. The table below shows how each setting changes tool life and finish:

| Cutting Parameter | Effect on Tool Life | Effect on Surface Finish |

|---|---|---|

| Depth of Cut | 46.6% | 46.7% |

| Cutting Speed | 46.7% | 46.6% |

| Feed Rate | 20.2% | 31.9% |

- Cutting speed: Use medium speeds to keep heat and wear low.

- Feed rate: Set for smooth cutting and less tool stress.

- Depth of cut: Shallow cuts are easier on tools, but deep cuts add stress.

Coolant and Lubrication Strategies

High-Pressure Coolant

Coolant is important for keeping heat down when cutting titanium. High-pressure coolant takes heat away from the cutting spot. This helps tools last longer and makes the part smoother. High-pressure coolant is needed for Ti-6Al-4V and Ti-5Al-5Mo-5V-3Cr alloys.

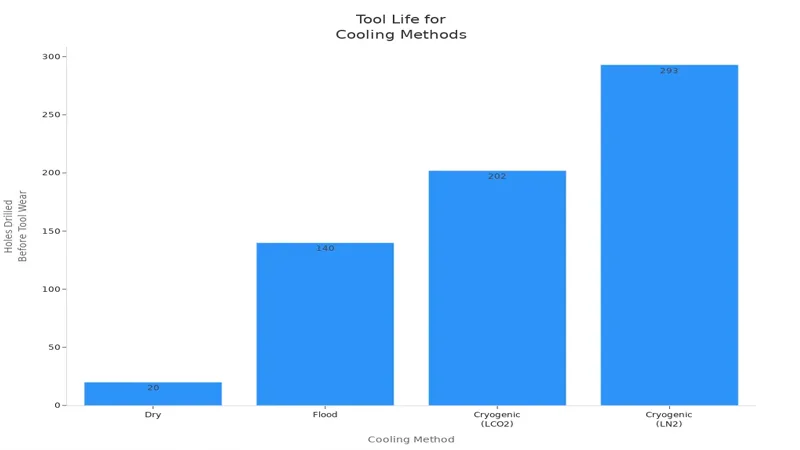

Cryogenic and Supercritical CO2 Cooling

Cryogenic cooling uses very cold liquids like liquid nitrogen or carbon dioxide. These coolants make the cutting edge much colder. Cryogenic cooling stops the metal from getting soft and keeps chips from sticking. The table below compares cooling methods:

| Cooling Method | Number of Holes Drilled Before Tool Wear | Surface Finish Improvement | Power Consumption Reduction |

|---|---|---|---|

| Dry | 20 | N/A | N/A |

| Flood | 140 | N/A | N/A |

| Cryogenic (LCO2) | 202 | Better | Reduced |

| Cryogenic (LN2) | 293 | Better | Reduced |

Cryogenic cooling can make tools last up to 30 times longer than dry cutting. The surface is also 30-40% smoother than with no coolant. The chart below shows how many holes can be drilled before the tool wears out with each cooling method:

Minimum Quantity Lubrication (MQL)

Minimum quantity lubrication uses just a little fluid. MQL is better for the environment and saves fluid. It gives good results with less fluid. MQL works best at slow speeds. At high speeds, it may not cool enough, so tools can wear out faster and make more burrs. For fast cutting of tough metals, MQL may not cool enough.

Note: Pick the best coolant plan for your job and machine speed.

Using new cutting methods, tool coatings, and coolant plans helps control heat and tool wear in aerospace work. These ways help make titanium parts well and keep machines running smoothly.

Advanced Machining Techniques

High-Speed and Interrupted Cutting

High-speed machining helps make more parts faster in aerospace. Interrupted cutting stops the tool from touching titanium all the time. This lets the tool cool down between cuts. The tool does not touch hot metal for long. This lowers tool wear and keeps heat under control.

In titanium alloy milling, tools can fail because titanium sticks to them. Heat makes this problem worse. When tools get too hot, they do not last as long. The part’s surface can also look bad. If a tiny pattern is put on the tool’s rake face, it can lower heat. This happens because friction goes down.

Titanium is hard to machine because of its special properties. It gets very hot when cut. The cutting edge must handle high heat. Titanium does not move heat away well. More heat stays in the cutting area. This makes tool wear happen faster.

Trochoidal Milling, Adaptive Control

Trochoidal milling uses a round path for the tool. This spreads heat out over the cutting area. The tool goes in and out of the metal. Chips leave the cutting zone more easily. The tool does not stay in one spot, so heat does not build up. Adaptive control changes how the machine cuts while working. The machine checks tool load and changes speed or feed. This stops the tool from getting too hot.

- Trochoidal milling spreads heat more evenly.

- It helps chips move away from the cutting area.

- This method lowers cutting pressure and heat.

- Fewer tool changes save money.

- Cutting forces can drop by 70% with this method.

- The tool cools off during the cutting breaks.

- Tool life and surface finish get better with good heat control.

Machining Technology from AFI Industrial Co., Ltd

Precision, Automation, and Customization Advantages

AFI Industrial Co., Ltd uses new machining methods for aerospace parts. Machines work with high accuracy. Automation helps set cutting and coolant settings. Customized services ensure optimal machining results for every part. The table below shows how these features help customers:

| Benefit | How You Gain Value |

|---|---|

| Increased Throughput | Machines run longer with less downtime |

| Improved Quality | Automated checks catch errors before they reach you |

| Predictive Maintenance | Machines alert you before breakdowns occur |

Application to Aerospace Titanium Machining

Machining titanium alloy for aerospace applications requires smart machining and coolant strategies. AFI Industrial Co., Ltd uses automation to pick the best settings for each product. Machines check for mistakes and change settings if needed. Predictive maintenance helps stop breakdowns. Customized machining ensures that each titanium alloy part receives the appropriate processing technique. These steps help control heat and tool wear. The process stays steady for aerospace titanium machining.

Case Studies in Aerospace Titanium Machining

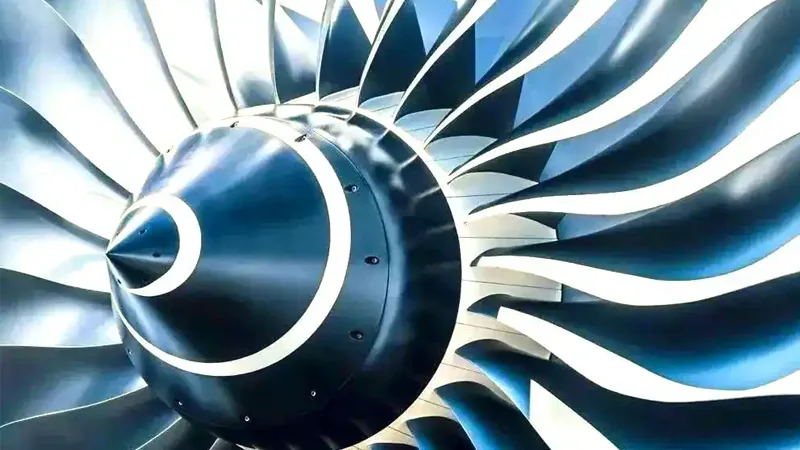

High-Pressure Coolant in Jet Engine Blade Production

Jet engine blades are made from titanium alloys. High-pressure coolant systems help with this job. These systems move heat away from where the tool cuts. This keeps tools from breaking and stops parts from changing shape. Chips do not stick to the tool or the blade. The surface stays smooth for a long time. The table below lists the main benefits of high-pressure coolant systems in making jet engine blades:

| Advantage | Description |

|---|---|

| Heat Reduction | Stops tools from breaking and parts from warping. |

| Chip Control | Stops chips from sticking to the tool or blade. |

| Surface Consistency | Keeps the surface smooth for many parts. |

AFI Industrial Co., Ltd uses these coolant systems in its machines. These systems help machines work longer and keep parts the right size. Using coolants helps tools last longer and makes the surface better.

Tool Life Extension with Advanced Coatings

Tool coatings change how tools wear out when cutting titanium. Coated tools last longer and work better. The time before tools wear out is longer. This means tools work well for a long time. The table below shows how coatings help tools:

| Coating Type | Effect on Steady-State Wear Region | Tool Life Extension | Source |

|---|---|---|---|

| Various Coatings | Makes the good-wear time longer | Tools last longer and work better | tool coating |

- Cutting tool solutions show better results in aerospace work.

- RPHX1204 milling inserts work better for titanium alloy parts.

AFI Industrial Co., Ltd picks coatings for each titanium machining. This helps tools last longer, and machines stop less often.

Adaptive Control for Landing Gear Components

Landing gear parts are made from titanium alloys. Adaptive control systems help keep tool pressure steady. These systems change the feed rate while cutting. Sensors watch for vibration, power, and heat. This helps find out when tools are wearing out. Predictive maintenance uses AI to guess tool life. It helps stop surprise tool breaks. The table below shows what adaptive control systems do:

| Evidence Type | Outcome Description | Improvement Metrics |

|---|---|---|

| Adaptive Toolpaths | Keeps tool pressure steady by changing feed rates. | Makes jobs faster by 15–25%. |

| Sensor-Based Monitoring | Watches vibration, power, and heat to spot tool wear. | First Pass Yield goes up from 93% to 98%. |

| Predictive Maintenance | AI checks tool wear and stops surprise tool breaks. | Lowers surprise stops by 20–25%. |

AFI Industrial Co., Ltd uses adaptive control and sensors in its machines. These systems help make more good parts and stop machines from breaking down.

Future Trends in Titanium Machining and Heat Management

Emerging Tool Materials and Coatings

New tool materials and coatings are making titanium machining better. These new technologies help control heat and extend tool life. Some important trends are:

- Carbide tools with coatings like Titanium Aluminum Nitride (TiAlN) or Titanium Carbonitride (TiCN) can work in high heat and do not wear out fast.

- Aluminum titanium nitride (AlTiN) coatings help tools last longer and move heat away from where the tool cuts.

- Cryogenic cooling uses very cold liquids, like liquid nitrogen or carbon dioxide, to cool the cutting area. This lowers tool wear and results in less friction.

- High-pressure coolant systems spray coolant right at the cutting spot. This keeps the temperature down and helps control chip size.

Tool makers are also trying materials like cubic boron nitride (CBN) and polycrystalline diamond (PCD). These materials can handle heat and do not wear out quickly when cutting titanium.

Digitalization and Smart Machining

Digital tools are changing how people machine titanium. Smart machining uses sensors and data to watch the process as it happens. For example, some tool holders have sensors that check temperature, shaking, and speed. Workers can use this information to change cutting speeds and plan when to fix machines.

High-pressure coolant systems, with at least 1,000 psi, spray coolant at the cutting area. This stops heat from building up. Machines can use robots and automation to make more parts and be more exact. Watching the process in real time helps find problems before tools break or parts get ruined.

Note: Digital tools help workers make good choices and keep machines working.

Sustainable and Green Machining Approaches

Titanium machining now uses ways that are better for the planet and safer for people. These ways help cut down on waste, save energy, and keep workers safe. Some main ways are:

- Minimum quantity of lubricant

- Cryogenic lubrication

- Minimum quantity of cooling lubrication

- High-pressure coolant

These ways use less fluid and less energy. They also help control heat and tool wear. Companies get benefits like:

- Using less energy

- Making less waste

- Safer places to work

- Healthier workers

- Lower costs for machining

Tip: Using less lubricant and better cooling helps protect the environment.

Looking Ahead

The next ten years will bring more changes to titanium machining. Tool materials like carbide, CBN, and PCD will help tools last longer and handle heat better. Cooling methods, like cryogenic cooling, will help control heat. Robots and automation will help make more parts and be more exact.

Learning about new technology and always trying to get better will matter a lot. Companies that follow these trends will do better in titanium machining.

- High-pressure coolant at 12–14% helps control heat in titanium machining. – Iscar’s FTP milling cutter makes chips thinner, so heat moves away better, and tools last longer. – Walter’s coating puts heat into the chip, not the insert, so the tool does not chip or flake.

Better heat control means parts break less often. This makes things safer and more reliable. Using less energy saves money. Aerospace companies can check and improve how they machine parts by using new technology from AFI Industrial Co., Ltd. Keeping up with new ideas and making processes better leads to improved results.

FAQ

Titanium is known for its exceptional strength-to-weight ratio, but it presents unique challenges during CNC machining. Its low thermal conductivity means heat doesn’t dissipate through the chip; instead, it concentrates at the cutting edge, leading to rapid tool wear. As a specialized custom metal parts manufacturer, we utilize high-pressure cooling systems and specialized carbide tooling to manage these temperatures and ensure the integrity of your titanium components.

The choice depends on your application’s requirements:

- Grade 2 (Commercially Pure): Offers excellent corrosion resistance and ductility, ideal for chemical processing and marine environments.

- Grade 5 (Ti-6Al-4V): The most common “aerospace grade.” It provides much higher strength and heat resistance, making it the go-to choice for aerospace titanium machining and high-performance automotive parts.

Titanium’s tendency to “spring back” requires expert calibration. At AFI Parts, our precision titanium machining services typically achieve tolerances as tight as ±0.0005 inches (0.0127 mm). We use multi-axis CNC centers to maintain high dimensional stability for complex geometries in medical-grade titanium parts and critical engine components.

Titanium is a premium material, but costs can be managed through Design for Manufacturing (DFM):

- Minimize Deep Cavities: Reducing the depth-to-diameter ratio of holes prevents tool breakage.

- Avoid Ultra-Thin Walls: Extremely thin sections can vibrate and warp during the machining process.

- Standardize Radii: Using standard internal corner radii allows for faster material removal with common tools.

Due to its biocompatibility and extreme durability, custom titanium machining is essential for:

- Medical & Dental: Bone screws, implants, and surgical instruments.

- Aerospace: Fasteners, airframes, and turbine blades.

- Defense: Lightweight armor and structural components for naval vessels.

- Energy: Subsea components for oil and gas that must resist saltwater corrosion.

Yes. Beyond the raw CNC milling and turning, we offer various finishing services to enhance performance, including anodizing (for color coding and wear resistance), passivation (for improved corrosion resistance), and bead blasting (for a uniform matte finish).