How to Cut Aluminum Extrusion Safely and Accurately

October 10, 2025

To cut aluminum extrusion accurately, use a carbide saw blade. You can use a table saw or a cutoff saw. Always make sure…

Read More

October 10, 2025

To cut aluminum extrusion accurately, use a carbide saw blade. You can use a table saw or a cutoff saw. Always make sure…

Read More

October 9, 2025

Metal fusion plating uses heat and pressure to stick a metal layer onto another material. This makes a strong and protective surface. You…

Read More

October 9, 2025

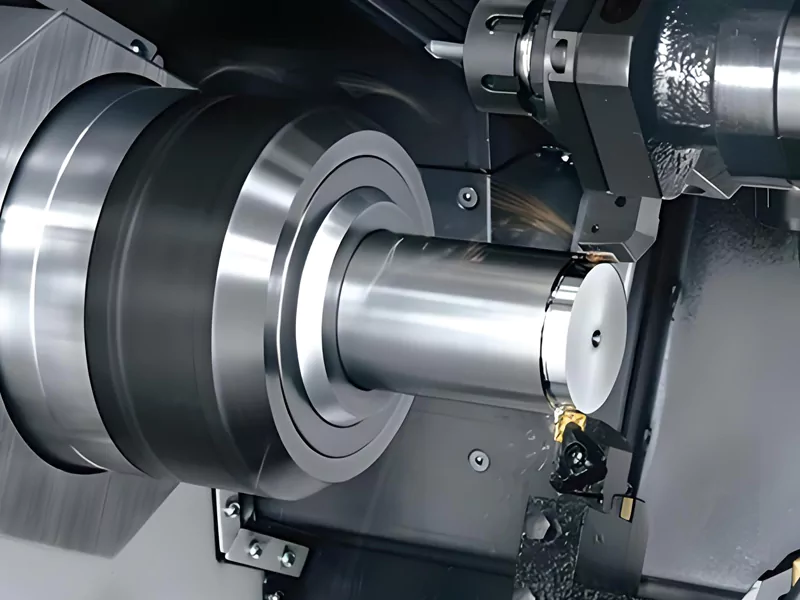

Precision in straight turning affects how good each part is. If you pay attention to accuracy, you make parts the same every time.…

Read More

October 9, 2025

When you think about metal injection molding for your project, you notice its good points and bad points. Look at the table below…

Read More

October 8, 2025

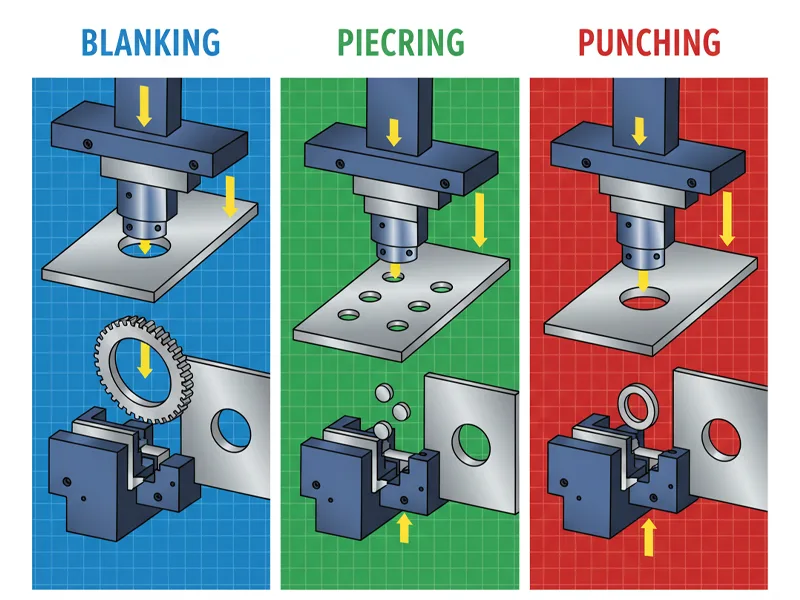

You need to know the main differences between the blanking process, piercing, and punching. This helps you pick the best way to make…

Read More

October 8, 2025

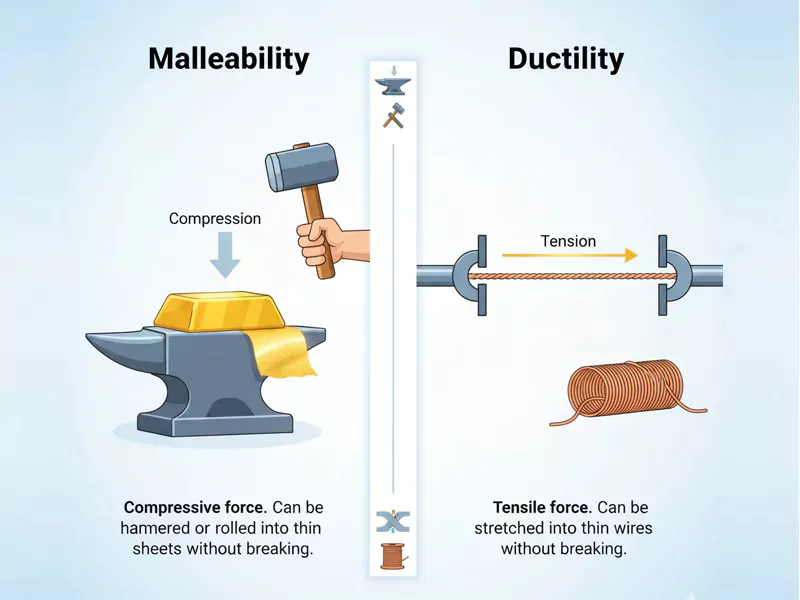

You might ask about the difference between malleability and ductility. Malleability indicates whether you can press or hammer a material into thin sheets…

Read More

October 8, 2025

When you pick steel for your project, plating is important. Nickel, chromium, and zinc each have special uses. Nickel stops rust and makes…

Read More

October 7, 2025

You may ask, “Is aluminum magnetic?” The answer is no; aluminum is not magnetic, so magnets do not stick to it. Instead, magnets…

Read More

October 7, 2025

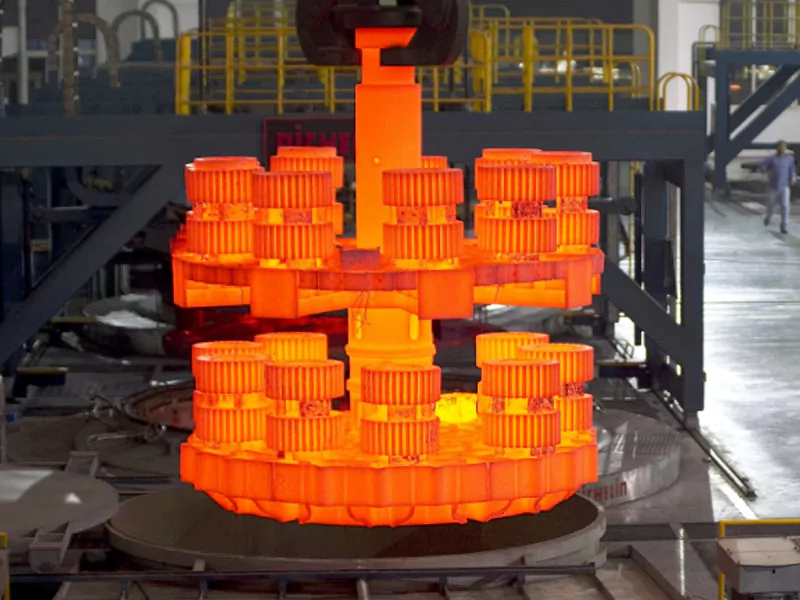

When you use metal in tools, machines, or buildings, you want it to be strong and reliable. Heat treatment of metals means you…

Read More

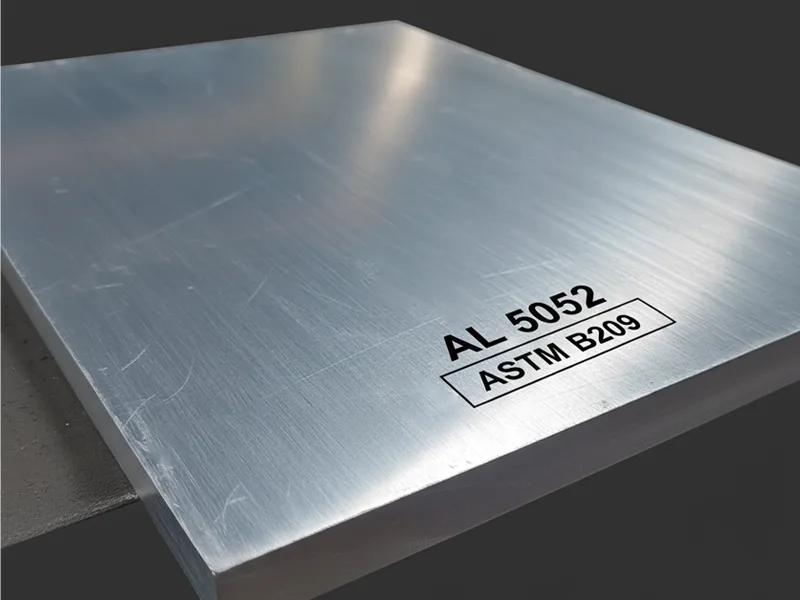

October 6, 2025

Alloy 5052 is a type of aluminum known for its impressive alloy 5052 properties. You see it in many items around you. It…

Read MoreProfessional answers for you