How to Achieve Precision When Machining Aluminum Parts

October 16, 2025

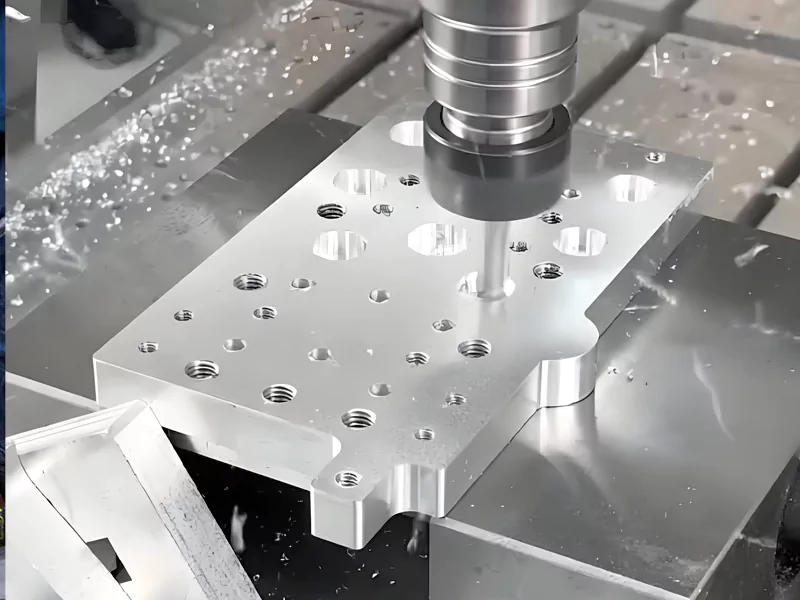

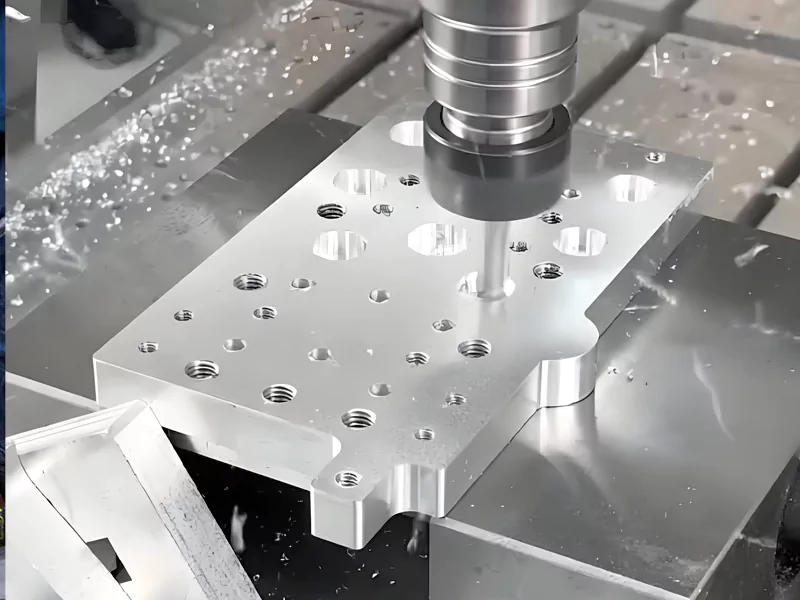

Precision is important when you learn how to machine aluminum parts. This is true for aerospace, cars, and electronics. You will face some…

Read More

October 16, 2025

Precision is important when you learn how to machine aluminum parts. This is true for aerospace, cars, and electronics. You will face some…

Read More

October 16, 2025

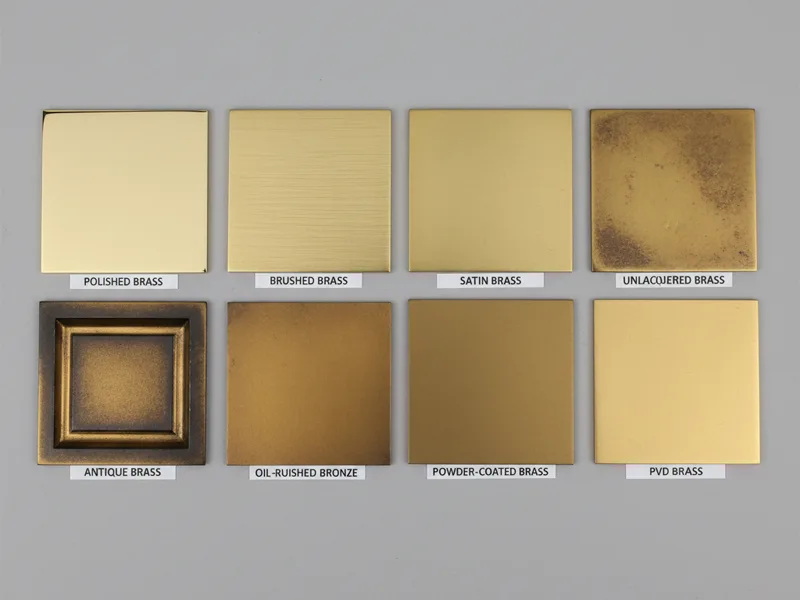

You will learn how brass finishing changes plain things into cool items. Brass finishing uses special steps to make things look better and…

Read More

October 15, 2025

When you ask, “Is steel easy to manufacture?” most people refer to mild steel. Experts and the AFI Industrial Co., Ltd team agree…

Read More

October 15, 2025

When deciding how to manufacture metal parts, focus on your specific needs. You might want durable metal parts for strength, or you may…

Read More

October 15, 2025

You can cut metal safely if you use the right tools for metal cutting. Always think about safety before you start your metal…

Read More

October 15, 2025

If you want metal that does not rust, pick 316 stainless steel. If you want metal that is easy to shape and costs…

Read More

October 14, 2025

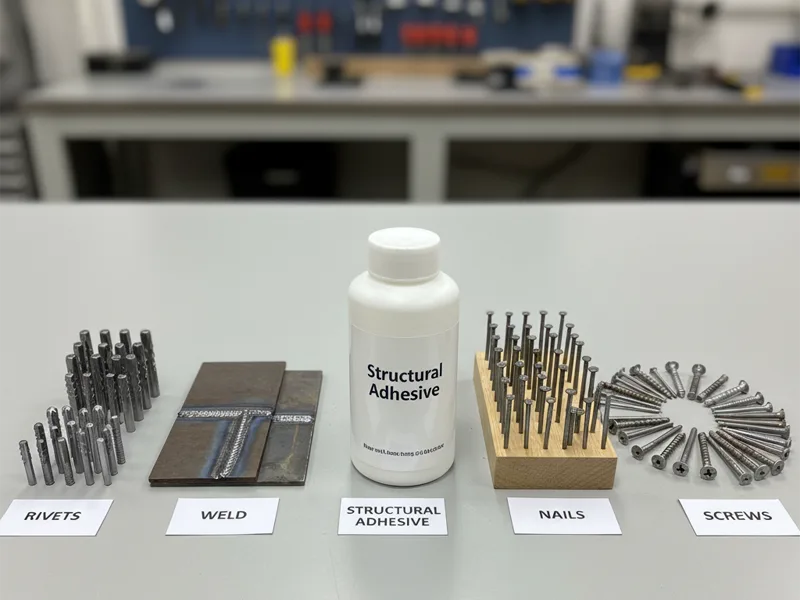

If you want your project to last, you need strong choices. Here are five permanent fasteners that always hold tight: rivets, welds, structural…

Read More

October 14, 2025

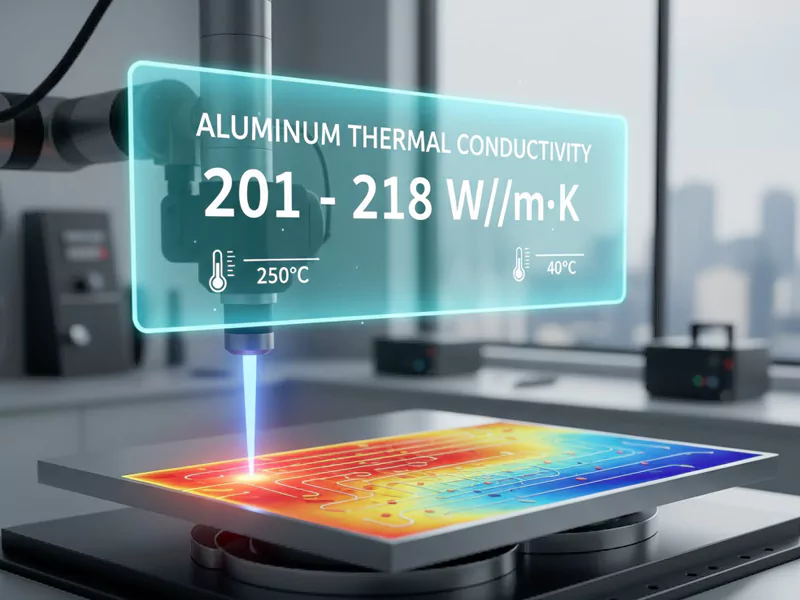

Aluminum 6063 thermal conductivity ranges from 201 to 218 W/(m·K), indicating its excellent ability to transfer heat. You can refer to the table…

Read More

October 14, 2025

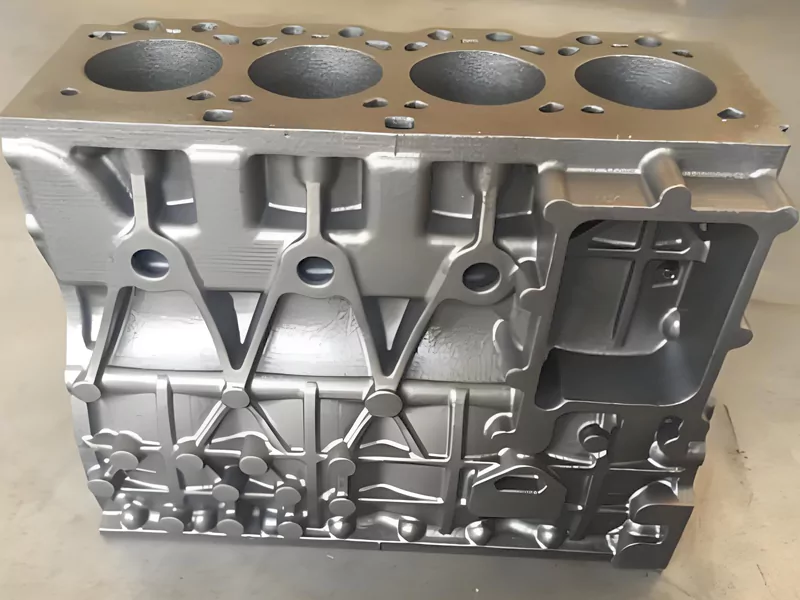

When you look at which metals work best for casting engine blocks, you find two main choices: cast iron and aluminum. These metals…

Read More

October 13, 2025

Imagine you finish a part and see sharp edges. These edges can hurt quality and safety. You must pick advanced deburring tools. The…

Read MoreProfessional answers for you