A Complete Guide to Surface Roughness Measurement Techniques

August 23, 2025

Surface roughness measurement helps you see if a surface is smooth or rough. This is important because it changes how products work and…

Read More

August 23, 2025

Surface roughness measurement helps you see if a surface is smooth or rough. This is important because it changes how products work and…

Read More

August 22, 2025

Manufacturers use casting to make parts with hard shapes. Casting helps them work fast and save money. There are many casting processes. Each…

Read More

August 22, 2025

Machining tolerances are important for quality and cost. Tight tolerances can make parts better, but they cost more. Loose tolerances can save money,…

Read More

August 21, 2025

Stainless steel can develop rust if exposed to harsh environments or cleaned with the wrong products. Knowing how to remove rust from stainless…

Read More

August 21, 2025

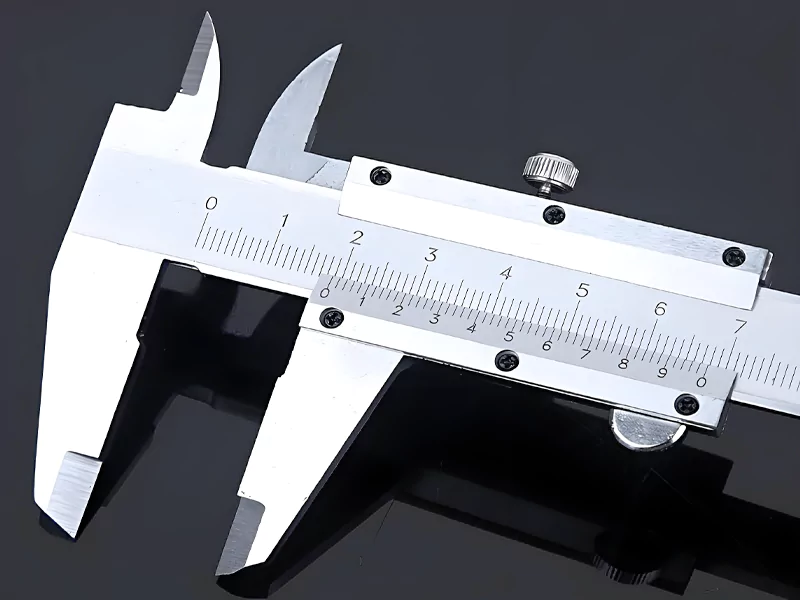

You can learn how to read a vernier caliper by following simple steps. First, make sure to set the vernier caliper to zero…

Read More

August 21, 2025

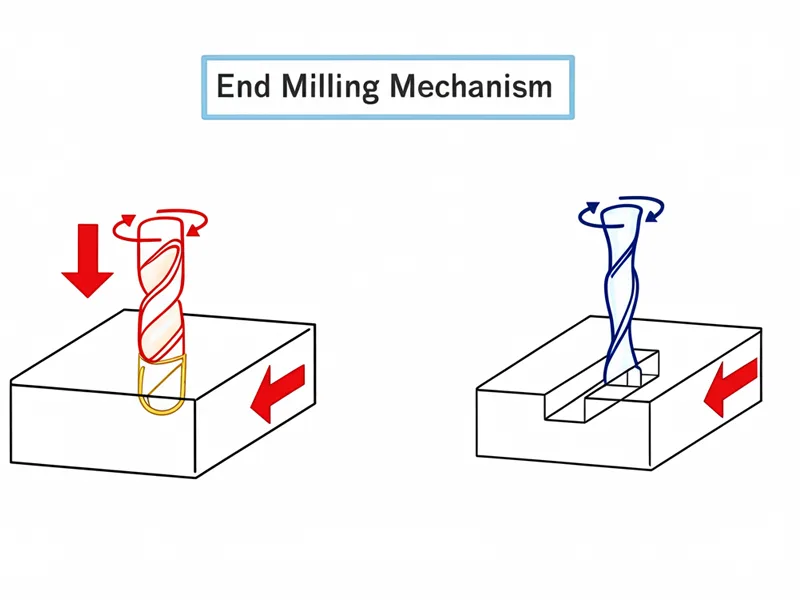

End milling lets you cut or shape materials with great control in the machining process. You use a spinning end mill to take…

Read More

August 20, 2025

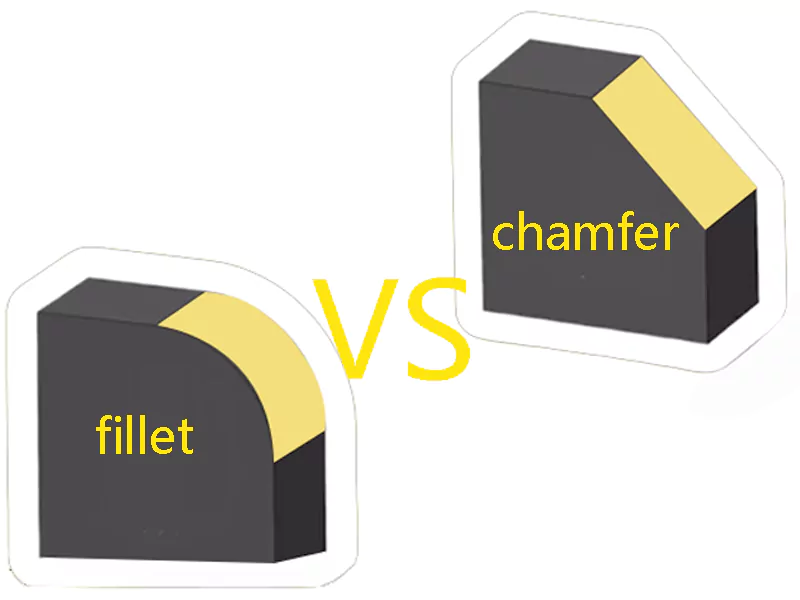

When deciding between a fillet vs a chamfer, you should pick a fillet if you want more strength. Fillets help lower stress in…

Read More

August 19, 2025

Mild steel fabrication involves transforming mild steel into useful products through cutting, joining, and finishing processes. People use mild steel because it is…

Read More

August 19, 2025

You want to learn how to clean brass fast and well. Get lemon juice, vinegar, baking soda, or ketchup from your kitchen. These…

Read More

August 18, 2025

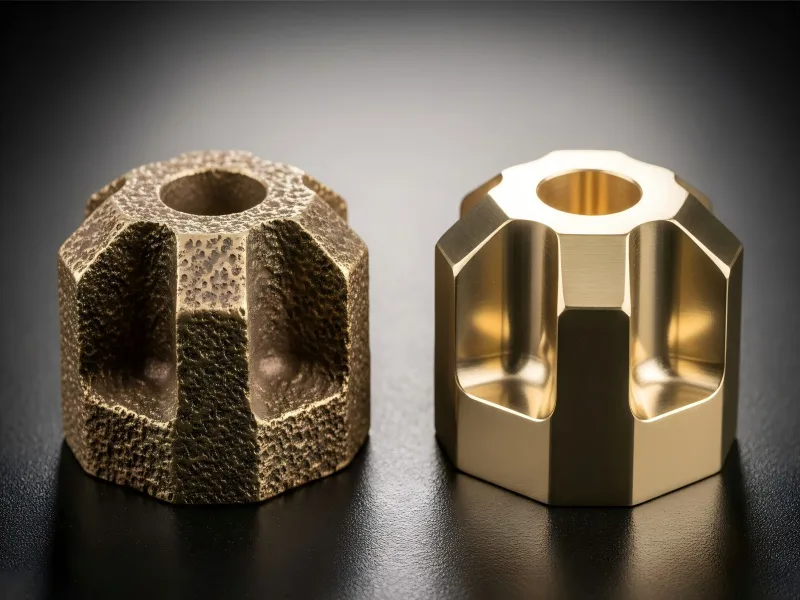

Brass casting and machining are strong tools for making things with care. You begin by casting, which shapes brass to fit your design.…

Read MoreProfessional answers for you