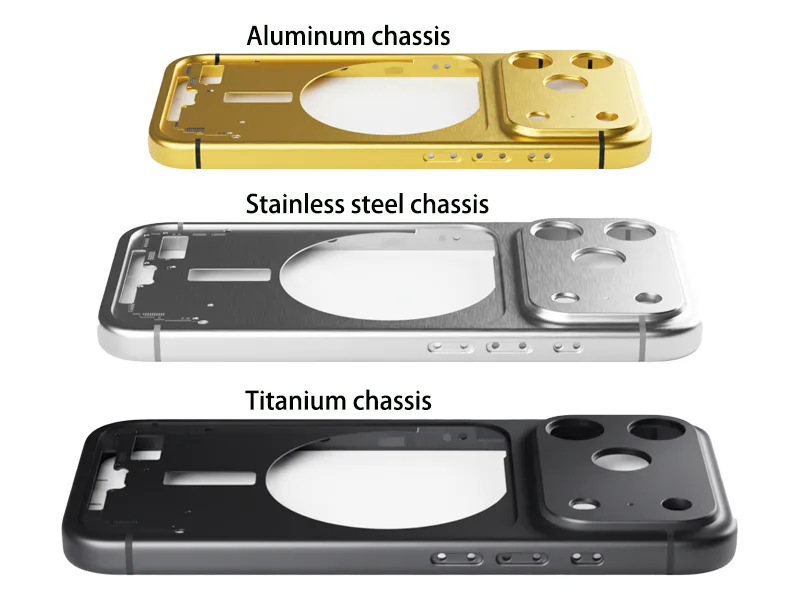

iPhone 17 Aluminum Chassis Versus Titanium and Other Materials Compared

September 16, 2025

If you want a phone that is strong, light, and not too expensive, the rumored iphone 17 aluminum chassis is probably the best…

Read More

September 16, 2025

If you want a phone that is strong, light, and not too expensive, the rumored iphone 17 aluminum chassis is probably the best…

Read More

September 15, 2025

You can spot brushed metal by its thin, straight lines and dull shine. This finish does not show fingerprints easily and hides scratches…

Read More

September 13, 2025

You may wonder, what is lost wax casting? This method is also called investment casting. It helps you make metal parts that are…

Read More

September 13, 2025

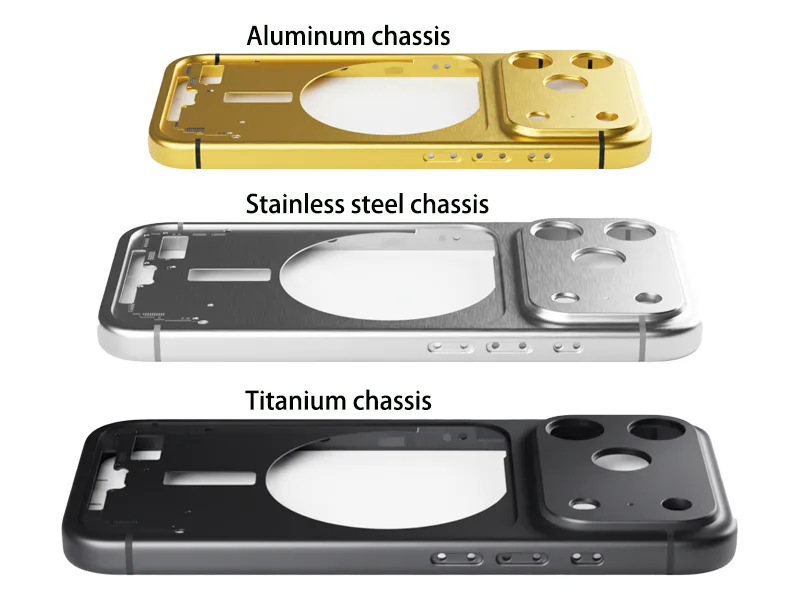

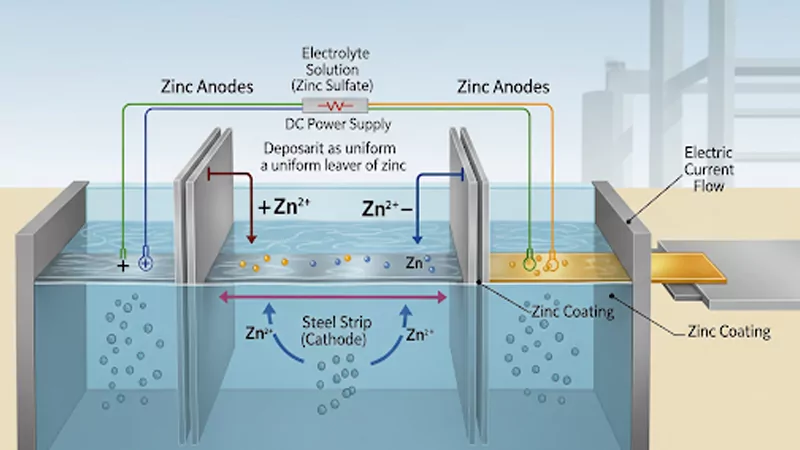

Embossing and debossing are two strong ways to make designs better in printing and packaging. Embossing makes a raised pattern on the top…

Read More

September 13, 2025

You discover the key difference between MIG and MAG welding by looking at the shielding gas. MIG welding uses inert welding gas, while…

Read More

September 12, 2025

You may ask what makes anodized aluminum different from aluminum hard anodized. The biggest difference is how strong it is. Aluminum hard anodized…

Read More

August 29, 2025

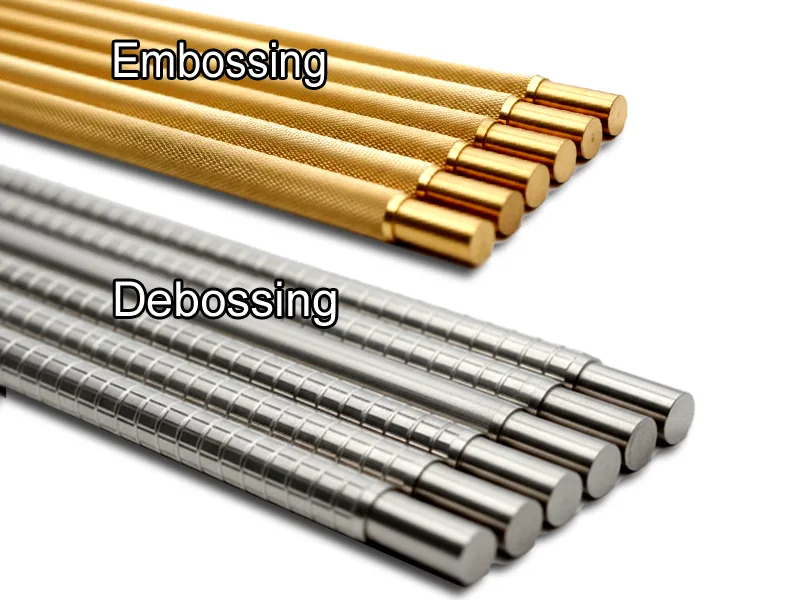

Zinc electroplating puts a thin zinc layer on metal with electricity. This gives strong rust protection because zinc works like a shield. If…

Read More

August 28, 2025

You can find pvd coating material in many industries today. This new technology makes thin and pure coatings. It does this by adding…

Read More

August 28, 2025

Differences Between Forging and Casting What is forging? Forging is a process that changes solid metal by applying force. In contrast, casting shapes…

Read More

August 28, 2025

You make machining bronze faster when you pick the right bronze alloy and tools. You get better results by using correct CNC programs…

Read MoreProfessional answers for you