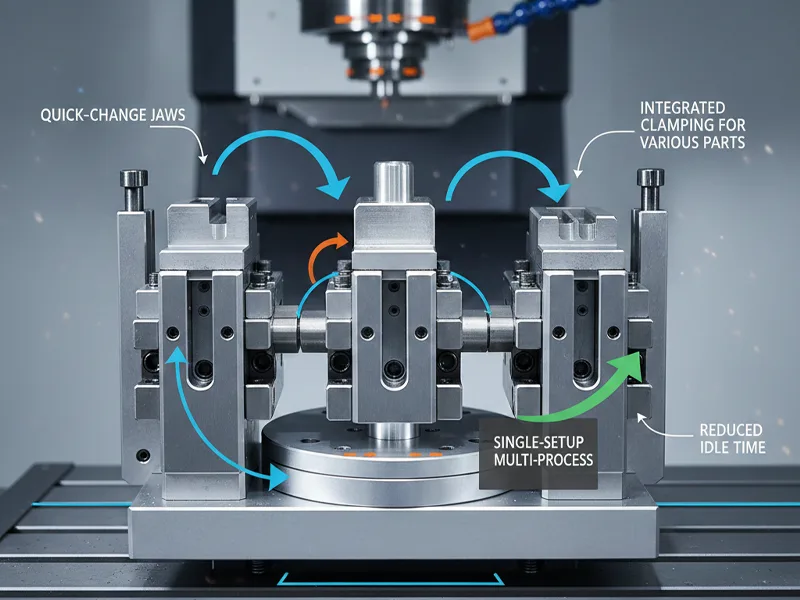

You usually think about the shape of your parts. But you might forget how often you move and clamp them. This mistake makes machining take longer and cost more. In CNC machining, extra setups mean more time spent on turning and moving. These actions go beyond the main axes.

If you plan your part design well, you need fewer setups, effectively reducing secondary fixturing. This helps you work faster. When using multi-axis milling or 3-axis machining, consider fixture and design issues. A well-designed machining process helps reduce secondary fixturing.

Key Takeaways

- Make parts so you only need to clamp them once. This saves time and makes parts more exact.

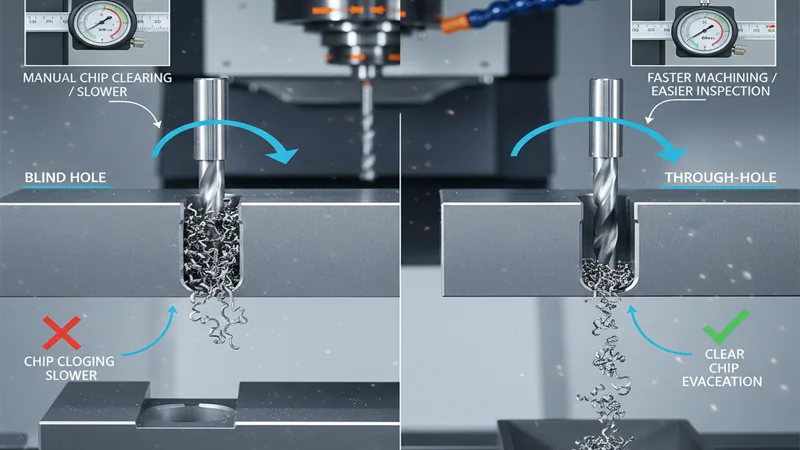

- Use through-holes, not blind holes, to make work faster. Through-holes help chips fall out and save setup time.

- Buy materials with machining in mind. Plan early and talk to suppliers to save money and get parts faster.

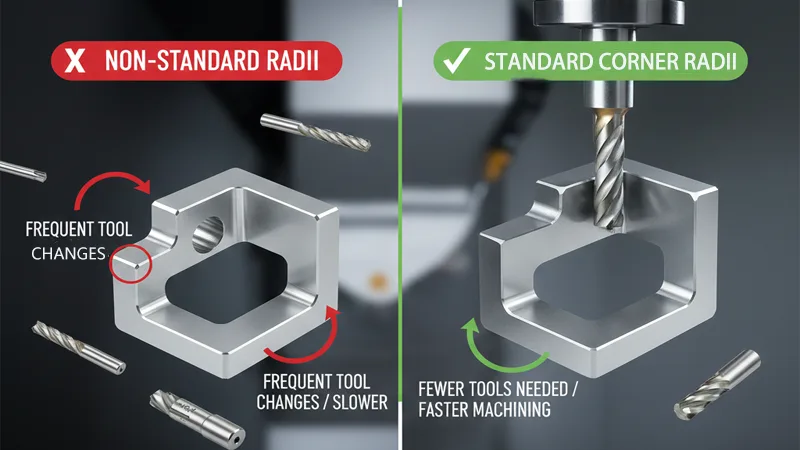

- Use the same features and tools when you can. This means you change tools less and work does not stop as much.

- Do not use designs with deep holes or undercuts. Simple shapes are quicker to make and have fewer errors.

Table of Contents

The trade-off between efficiency and precision: How does the number of clamping operations affect the final product?

Loss of accuracy

You want your parts to be very exact. Every time you unclamp and move a part, small mistakes can happen. These mistakes add up over time. With 3-axis machining, each new setup can move the part by about ±0.0002 inches. After a few setups, these small moves can make your part not fit the rules.

More clamping and moving means you might lose the right size and shape. Changing the machining base each time makes it less precise. If you design with fewer setups, your parts stay more accurate. Five-axis machines can make hard shapes in one setup. This way, you get fewer mistakes and better precision. By cutting down on secondary fixturing, your parts stay within the limits and you avoid wasting money on bad parts.

Labor costs

You use more time and money when you do more setups. Each time you clamp, someone must stop the machine, move the part, and check if it is lined up. This takes longer and costs more for workers. If your design needs many setups, your team does more manual jobs. You pay for extra work, more waiting, and more chances for errors. Fewer setups make the work go faster. Workers spend less time on things that do not cut and more time making parts. You save money and get more done.

Procurement perspective

If you design parts for single-setup machining, buying gets easier. You need fewer special fixtures and less stock. You do not wait as long and make fewer mistakes. AFI Industrial Co., Ltd’s machines work with many materials and hard shapes, so you can match your buying plan to your design.

Tip: Smart design choices help you machine faster and better. If you try to use less secondary fixturing, you save time, spend less, and make better products.

Design Optimization Techniques: 5 Strategies for Achieving “reducing secondary fixturing”

If you want to make machining faster and cheaper, you should use smart design ideas. These ideas help you do single-setup machining. They also help you use CNC machining better.

Strategy A: Feature Centralization

Skill

Try to put important features close together on one side or in one area. This lets you machine more surfaces at once. When features are close, the cutting tool can reach them without moving the part. You do not need to flip or turn the part as much. This works well with multi-axis machining, where the tool can move in many ways.

Tip: Putting features together saves time and makes parts more exact. You also make fewer mistakes because you do not move the part as much.

Case Study

A company had to make a bracket with holes, slots, and pockets. They changed the design so all features were on one side. The team finished the part in one setup with advanced machines. This made setup time shorter by 60% and made the parts more alike.

Strategy B: Use through-holes instead of blind holes

Skill

Pick through-holes instead of blind holes when you can. Through-holes let chips fall out and are easier to check. Machining through-holes is quicker because you do not stop to clear chips. You also do not have to check for stuck debris. This means you do not flip the part, which helps with single-setup machining.

- Through-holes make the job easier and help tools last longer.

- You do not have to worry about chip removal or coolant problems with blind holes.

- It is easier to check and measure the finished part.

Strategy C: Reserve “process datum plane” and clamping positions.

Skill

Set a main datum plane using three support points. This keeps the part from moving and makes it stable. The 3-2-1 kinematic rule helps you hold the part in place. Save clear spots for clamping so you can hold the part tight. This keeps your measurements right. This way, the part does not bend, and you can machine it in one setup.

Note: Always design with special datum planes and clamping spots. This is very important for high-precision machining.

Case Study

A team made a gearbox housing with flat spots for clamping and a clear datum plane. The part stayed steady and accurate during machining. They finished all important features in one setup. This made the job faster and the part better.

Strategy D: Standardize corner radii and tool specifications.

Skill

Match fillet radii to common tool sizes. Using standard corner radii means you do not need special tools. This lowers how often you change tools. When you use regular tool sizes, you machine faster and avoid waiting. If edge details are not clear, it can slow things down and wear out tools.

- Standard radii make machining faster.

- You need fewer tools, and programming is easier.

- You do not have to change tools as much, so work keeps going.

Strategy E: Avoid deep holes and complex undercuts

Skill

Do not design parts with deep holes or tricky undercuts. Deep holes, which are deeper than six times their width, can trap chips and bend tools. Undercuts, like inside T-slots or grooves, are hard to reach with normal tools. These need special tools or more setups, which slows things down.

| Challenge | Problem Description | Solution/Consideration |

|---|---|---|

| Undercuts | Inside grooves are hard to reach because tools get blocked. | Use special tools or change the design |

| Deep Holes | Chips get stuck, tools may bend, coolant may not reach. | Make sure chips come out and avoid deep holes |

| Overhangs | Parts with no support can shake or break while machining. | Give support and plan for stress relief |

- Not using hidden features like blind holes and undercuts means you do not flip the part or use special tools.

- This makes machining easier and helps you do it in one setup.

- You make parts more reliable and lower the chance of breaking.

Tip: If you design for easy access and simple shapes, you use your machining skills better and make the process smoother.

By using these five ideas, you can design for single-setup machining. You need less secondary fixturing, make parts faster, and get better quality. AFI Industrial Co., Ltd’s machines can do these jobs, so you can work with tough features and materials easily.

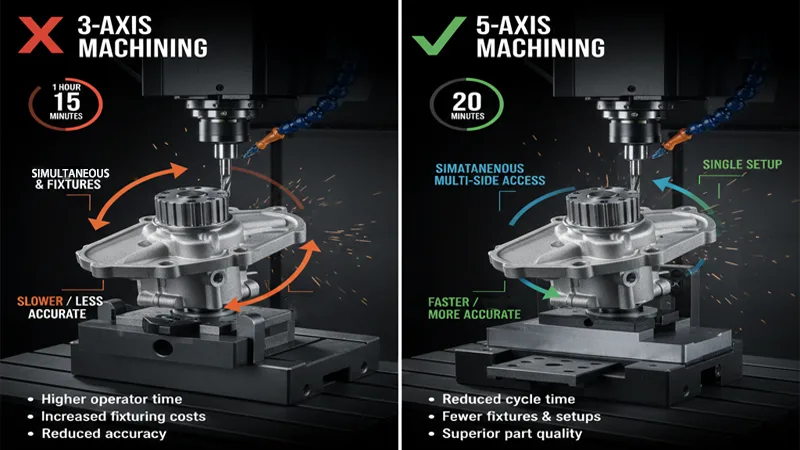

Advanced solution: The economics of 3-axis vs. 5-axis machining

Advantages of 5-axis machining

You get great efficiency with 5-axis machining. This method lets you work on every side in one setup. You do not need to turn or move the part. This lowers mistakes and makes parts more accurate. For example, making a car water pump housing with a 3-axis needed five fixtures and four moves. It took more than an hour. With a 5-axis, the job finished in only 20 minutes. You save time and make more parts. Doing everything at once means fewer setups and less manual work. You also get better part quality.

- 5-axis machining works with hard shapes in one go.

- You spend less time getting ready and work faster.

- You get exact sizes and smooth surfaces.

Cost analysis

You need to think about both running and purchase costs when picking between 3-axis and 5-axis machining. The table below shows the main differences:

| Factor | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Operating Cost | Lower | Higher (maintenance, training, energy) |

| Typical Capex Range | Lower initial investment; suitable for small to mid-size shops | Higher initial investment; justified for frequent complex work |

| Lifecycle Cost Drivers | More fixtures, more setups, higher operator time on complex parts | Higher programming complexity but fewer fixtures and setups per part |

| Machine Type | $50,000-150,000; moderate programming; entry to intermediate skill | $200,000-500,000+; high programming; intermediate to advanced skill |

Pick 5-axis machining if you need to work on many sides, want to finish jobs faster, and need very exact parts. The cost is higher at first, but you work faster and save time on hard jobs.

AFI parts’ Advantages

AFI Industrial Co., Ltd provides professional CNC machining service to help you use fewer setups and work faster. Fewer setups mean less stopping and fewer mistakes. Sub-spindle machines let you work on both sides in one go. Using many tools at once can cut cycle time by 30% to 50%. Multi-tasking lets you do many jobs in one step, so you set up less and work more quickly. Automatic tool changers and standard holders help you change tools fast. Multi-tasking can make your project finish much sooner, so you get your parts faster.

Tip: You can make your work better by designing for single-setup machining and using advanced CNC.

Common design mistakes that increase fixturing needs:

- Not holding the part tight enough. This can make it move or shake and cause mistakes.

- Starting with designs that are too hard. Extra details make jobs take longer and cost more.

- Adding features that do not need machining. Simple designs can work just as well and save time.

Do not add features that need extra machining. Make designs that help single-setup machining. This lowers fixturing needs and helps you work faster.

International Procurement Pitfall Avoidance Guide: How to Reduce Costs Through Design Communication

Inquiry Techniques

You want to save money when buying machined parts from other countries. It is important to talk clearly with your suppliers. You need to tell them exactly what you want. Most importers say clear instructions help keep quality high and stop mistakes. Suppliers try to meet your needs, so you must explain everything. Make a checklist for quality control. Write down what you need for the product and packaging. Add tests and checks to make sure everything is right. This helps you find problems early and keeps your machining work going well.

- List all important sizes and limits for CNC work.

- Tell your supplier what you want for fixturing and setup.

- Check how you work with suppliers often to save money and avoid waiting.

- Talk openly to find ways to improve and stop problems.

Tip: Importers with experience know suppliers want long-term customers. Talking clearly helps build trust and makes sure your machining needs are met.

The importance of DFM reports

Design for manufacturability (DFM) reports help you skip extra fixturing steps. These reports match your design to what the supplier can do. You can change your part to fit their machines. This saves money and stops delays. DFM rules say to use rounded corners, not sharp ones. Rounded corners spread out stress and make it easier for tools reach. If you think about how parts are held, you cut machining time and make parts more reliable.

- DFM reports help you use normal tools by matching your design to common ways of making things.

- They make it easier for tools to reach, so you do not need extra fixturing.

- You get advice to change your part so it is easier to machine.

| DFM Benefit | Impact on Machining |

|---|---|

| Rounded corners | Tools reach easier |

| Standard features | Setup is faster |

| Planned clamping surfaces | Parts are more reliable |

You should always ask for a DFM report before you finish your design. This makes sure your part is ready for fast machining and helps you save money when buying parts.

Conclusion: Efficient design is a prerequisite for low-cost manufacturing.

summary

If you want to make things for less money and work faster, you need a smart design. Good design is the basis for saving money and getting more done in machining. When you use single-setup CNC milling, you do not need as many extra fixtures. This makes your work go smoother, and your parts turn out better.

Here are some main reasons why good design helps in machining:

- CNC machines help you work faster and more accurately. You can do all the steps in one place, so you do not need lots of machines. This makes things simpler.

- CNC machining helps you spend less money. You can make more parts without wasting stuff. You use less power and do not need as many people, so you pay less for workers.

- You can make parts that are very exact. You do not need to pay for a lot of handwork. You can make special parts with fewer mistakes.

- You use your materials better. You throw away less, do not need as many steps, and finish faster. This is good for the planet and helps you work better.

When you plan for single-setup milling, you do not have to clamp or move your part as much. This saves you time and money. Your work also becomes steadier. Using advanced CNC lets you finish hard parts in fewer steps. You get the same good results each time, and the surfaces look nicer.

Tip: Always think about machining when you design. Use ways that help you do single-setup milling. This will help you make better products for less money.

| Benefit | Impact on Manufacturing |

|---|---|

| Faster milling | Shorter cycle times |

| Fewer setups | Less manual labor |

| Efficient material use | Lower waste and cost |

| High accuracy | Reliable, repeatable results |

Good design is not just about how your part looks. It is also about how you plan for milling, holding the part, and how the work moves along. If you use these ideas, you will do well in today’s factories.

You can make your part design better by using simple steps. These steps help you need less secondary fixturing and make machining faster. Try to use symmetrical features and common drill sizes. Pick good ratios that work well. Give clear drawings and set easy-to-follow tolerances. If you design for single-setup machining, you finish parts faster. You also spend less on labor and get better quality. Advanced machines, like 5-axis systems, can reach hard spots in one setup. This means you need less secondary fixturing and can cut machining time by up to 84%. Use these ideas in your next projects to get results that are reliable and save money.

| Key Step | Benefit |

|---|---|

| Symmetrical design | Improved accuracy |

| Standard drill sizes | Faster machining |

| Clear specifications | Fewer errors |

Tip: Always think about machining when you design to get the best speed and quality.

FAQ

Minimizing secondary fixturing significantly reduces custom metal parts manufacturing costs by eliminating the labor-intensive process of designing, building, and maintaining specialized jigs. When a part is designed to be “self-fixturing” or requires fewer setups, you reduce the direct labor hours and machine downtime. This allows for more competitive pricing on high-volume metal fabrication and small-batch CNC machining services.

Design for Manufacturing (DFM) is critical for efficiency. Key strategies include:

- Integrating features: Designing parts with built-in alignment tabs or slots.

- Simplifying geometry: Avoiding complex undercuts that require specialized workholding.

- Standardizing datums: Ensuring that the same reference points can be used throughout the CNC machining process to avoid repositioning. These methods streamline custom metal part production and reduce the risk of human error during manual setups.

Every time a part is moved to a new fixture (a “secondary setup”), there is a risk of losing dimensional accuracy due to stacking tolerances. By reducing the number of setups through multi-axis CNC machining or clever part design, we maintain tighter tolerances and higher consistency. This is essential for industries requiring high-precision metal components, such as aerospace or medical device manufacturing.

Yes, absolutely. Secondary fixturing often acts as a bottleneck in custom metal fabrication. Designing parts that require minimal specialized workholding allows us to move projects directly to the machine floor without waiting for custom tool builds. This lean approach speeds up the transition from prototype to production, ensuring faster delivery of your custom-machined metal parts.

Beyond the initial cost of the fixture itself, secondary fixturing involves hidden expenses like storage, maintenance, and the extended setup time required for each production run. For long-term custom metal manufacturing contracts, these costs add up. By engineering the need for fixtures out of the part design, we provide a more scalable and cost-effective solution for our clients.

5-axis CNC machining is one of the most effective ways to reduce secondary fixturing. Because the machine can access almost every angle of a part in a single setup, it eliminates the need for multiple custom jigs that would be required on standard 3-axis machines. This technology is a cornerstone of modern precision metal manufacturing, offering both complexity and cost-efficiency.