Precision machining for robotic joints is very important. It helps robots work accurately and reliably in factories. Advanced CNC machining makes parts with very exact sizes. This helps robots move the same way every time. Multi-axis CNC systems make fewer mistakes when putting parts together. They also help joints work the same each time. Smooth surface finishes lower friction and stop parts from wearing out fast. This helps robots last longer. AFI Industrial Co., Ltd gives machining solutions that follow these tough rules. They also fix common problems in robotic joints.

- Tight tolerances help robots move accurately and repeat steps.

- Multi-axis machining makes fewer mistakes when building parts.

- Smooth surface finish helps joints work better.

Key Takeaways

- Precision machining helps robotic joints move the right way. This is very important for factories. Tight tolerances in parts stop mistakes from happening. This lets robots do jobs the same way every time. It also keeps them safe. Multi-axis CNC machining makes fewer mistakes when making parts. This gives better robotic joints. Smooth surface finishes result in less friction. This helps joints work better and last longer. Picking the right materials, like titanium alloys, is important. It makes parts strong for heavy jobs. Heat treatment makes materials stronger. This helps robotic joints handle stress better. Quality control checks every step in making parts. This makes sure each joint is safe and works well. Feedback loops help companies get better over time. They improve how they make robotic joints.

Table of Contents

Precision Machining for Robotic Joints: Core Principles

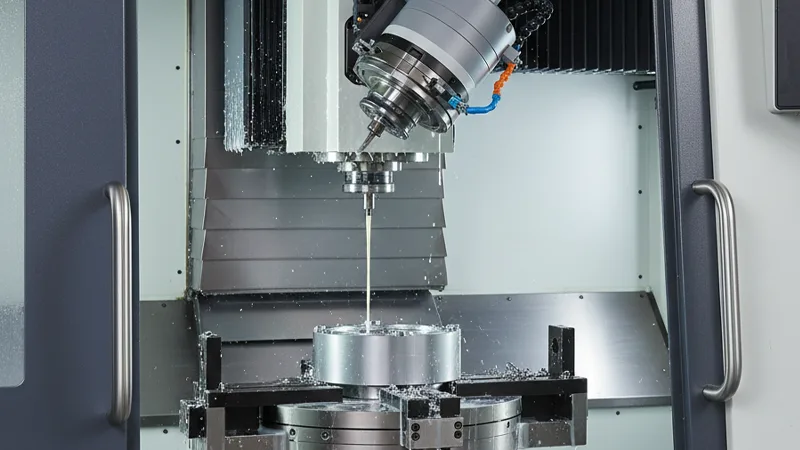

For modern industrial robots, particularly those utilized in automotive assembly or aerospace component positioning, “precision” is no longer defined by simple linear dimensions but by the synchronization of multi-axis CNC systems to mitigate cumulative error. At AFI Industrial Co., Ltd, we implement advanced CNC machining strategies to produce components that maintain structural integrity under dynamic load cycles.

The Engineering Necessity of Tight Tolerances

In high-torque applications, the deviation of a single micron can lead to catastrophic failure. Advanced CNC technology allows us to maintain tolerances as tight as ±0.0025mm (±0.0001 inches) on critical features like servo motor housings and precision shafts. This level of control is essential to prevent “drift” during high-speed operations and to ensure that the robot maintains its 5-micron repeatability standards.

Why Precision Matters in High-Torque Gearboxes

High-torque gearboxes serve as the mechanical muscle of a robot, requiring a delicate balance between torque density and motion smoothness. Precision machining ensures that gear teeth profiles (Involute or Cycloidal) mesh with zero-interference, which is critical for the following features

Key Challenges in Robotic Joint Production

The production of high-performance robotic joints is fraught with variables that can compromise the final assembly. From a manufacturing standpoint, the primary challenges involve managing the relationship between Preload, Backlash, and Load Capacity.

Quantitative Analysis of Backlash and Preload

One of the most common failures we observe in the field is the premature degradation of joint accuracy due to improper Preload. If the preload is insufficient, the joint exhibits excessive backlash. Conversely, excessive preload leads to:

- Parasitic Torque: Increasing motor energy consumption.

- Thermal Expansion: Where heat generation causes dimensional changes, further increasing friction in a “runaway” loop.

The relationship between preload force (Fp) and bearing stiffness can be modeled as Stiffness α Fp1/3 for ball-based systems. At AFI Industrial, we utilize custom jigs and sensor-integrated assembly to ensure Fp is within ±5% of design specifications to balance stiffness and service life.

Tight Tolerances and Motion Accuracy

Tolerance Control in Robotic Joints

Tight tolerances are the prerequisite for functional fits—specifically interference fits used in bearing seats, and transition fits used in shafts. In a robotic joint, if the tolerance stack-up is not managed, the “lost motion” (the sum of mechanical backlash and elastic deformation) increases exponentially.

We focus on three critical components:

- Servo Motor Housings: Requiring high concentricity to avoid eccentric loading on the motor shaft.

- Linear Rail Blocks: Where parallelism is vital to prevent binding.

- Precision Shafts: Often requiring $h6$ or $g6$ fits to ensure seamless torque transmission.

Impact on Torque Transmission and Repeatability

Repeatability is the robot’s ability to return to the same coordinate. By utilizing 5-axis CNC mills, we can machine complex shapes in a single setup, which eliminates the “clamping error” associated with multiple fixtures. This ensures that the geometric centers of all joint components are perfectly aligned, facilitating smooth torque transfer and reducing vibrational resonance.

Advanced Precision Manufacturing Methods

Multi-Axis CNC Machining for Complex Geometries

The evolution of robotic joints toward “Humanoid” or “Collaborative” (Cobot) designs requires lightweight, complex geometries that cannot be produced via traditional 3-axis milling. Multi-axis CNC machining allows for the creation of internal cooling channels and weight-reduction pockets without compromising the part’s rigidity.

Minimizing Assembly Errors

Assembly errors are often the result of “out-of-roundness” or poor cylindricity in machined parts. By maintaining strict process control and utilizing In-Process Probing (IPP), our machines can detect and compensate for tool wear in real-time. This ensures that every part in a 1,000-unit production run is identical to the prototype.

Customization and Scalability with Machining

Engineering is an iterative process. AFI Industrial supports the full lifecycle of robotic development—from Rapid Prototyping (using 6061-T6 aluminum for weight-sensitive tests) to Scaled Production (using 17-4 PH stainless steel for industrial durability). Our DFM (Design for Manufacturing) feedback loops help clients reduce part count by integrating multiple features into a single CNC-machined component.

Surface Finish and Joint Performance

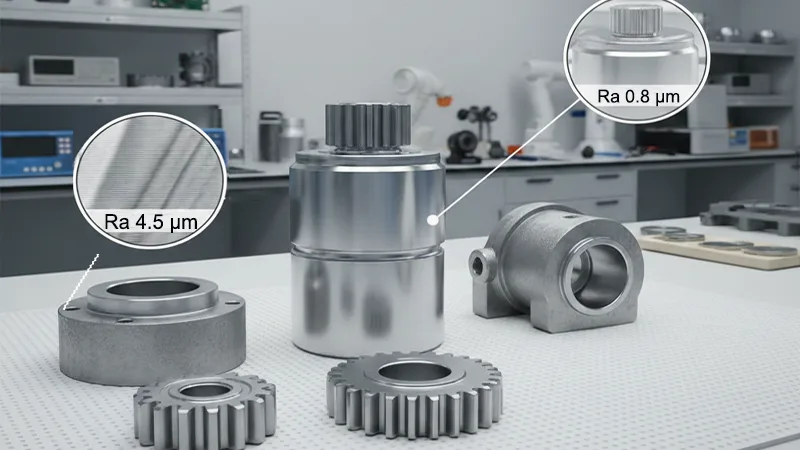

Surface finish is not merely aesthetic; it is a critical engineering parameter defined by the Ra (Arithmetic Mean Deviation).

Surface Roughness and Friction Reduction

The interaction between two sliding surfaces in a joint is governed by the Stribeck Curve. If the surface is too rough (Ra >1.6㎛), the “asperities” (microscopic peaks) collide, causing high initial friction and “stick-slip” motion.

AFI Specification: We target Ra 0.4 to 0.8㎛ for sliding surfaces to ensure a stable lubricant film.

Result: A 20% reduction in starting torque compared to standard finishes, directly translating to smoother robot movement.

Wear Resistance and Service Life

A superior surface finish inhibits the initiation of micro-cracks. By reducing the surface roughness, we increase the effective contact area, which lowers the local “Hertzian contact stress”. This extends the L10 life of the joint by preventing surface fatigue and pitting.

Lubrication and Surface Compatibility

In high-precision robotics, the lubricant is a structural component. We analyze the surface energy of our machined parts to ensure compatibility with synthetic esters or perfluorinated polyethers (PFPE). Proper lubrication management reduces the “Thermal Signature” of the joint, allowing for continuous operation in 24/7 manufacturing environments.

Material Selection and Heat Treatment for Durability

Choosing Materials for High-Load Applications

The selection of materials is based on the Strength-to-Weight Ratio and Fatigue Limit.

Heat Treatment and Microstructure Control

To achieve the necessary hardness for gear teeth (HRC 58-62), we employ Vacuum Heat Treatment and Cryogenic Tempering. This process stabilizes the retained austenite in the metal’s microstructure, preventing dimensional “growth” over time, which would otherwise destroy the tight tolerances of the gearbox.

Managing Consistency and Traceability

Quality Control in Precision Machining

At AFI Industrial, quality is quantified through data. We employ a multi-layered inspection protocol:

- CMM Inspection: 3D coordinate measuring machines verify geometric tolerances to sub-micron levels.

- Surface Profilometry: Measuring Ra and Rz values to confirm tribological performance.

- Material Traceability: Every part is linked to a Mill Test Report (MTR), ensuring no “counterfeit” or sub-standard alloys enter the supply chain.

Maintaining Standards Across Production Runs

Transitioning from prototype to mass production requires a robust PPAP (Production Part Approval Process). We utilize Statistical Process Control (SPC) to monitor the “Process Capability Index” (Cpk). A Cpk > 1.33 indicates that our machining process is highly centered and consistently produces parts within tolerance.

Integrating Precision Machining for Reliable Robotic Joints

The synergy of materials science, heat treatment, CNC precision, and surface engineering yields a robotic joint that is more than the sum of its parts. For the end-user, this means:

- Reduced Total Cost of Ownership (TCO): Through longer service intervals.

- Enhanced Safety: Critical for collaborative robots (Cobots) working alongside humans.

- Operational Efficiency: Faster cycle times due to high-acceleration capabilities.

Case Studies and Industry Applications

In a recent application for a medical surgical robot, AFI Industrial produced a custom joint assembly requiring ±0.005 mm tolerances and a mirror finish (Ra < 0.2㎛). By utilizing specialized diamond-tipped tooling and high-pressure coolant systems, we eliminated thermal deformation during the machining of thin-walled titanium housings. This allowed the surgical arm to perform high-torque maneuvers with zero perceptible vibration, a requirement for microsurgery.

FAQ

Precision machining makes parts with very exact sizes. This helps robotic joints move the right way and last longer. CNC machines help make these parts.

Tight tolerances help parts fit together just right. This lowers shaking and stops parts from wearing out fast. Robots can do the same moves over and over.

A smooth surface finish lowers friction between parts. This helps joints move quietly and stops them from wearing out quickly. Robots work better and use less energy.

Engineers pick titanium, steel, or strong polymers for these jobs. These materials are tough, last a long time, and do not wear out easily.

Heat treatment changes how metals act inside. It makes them stronger and harder to break. This helps parts hold heavy loads.

AFI uses advanced CNC machines and checks every part carefully. They have strict rules to keep parts safe and accurate.

Yes. CNC machining lets engineers change designs quickly. It works for making a few test parts or many parts for big jobs.

Many industries use these joints, like car making, electronics, airplanes, and hospitals. Robots in these places need strong and reliable joints.