When you powder coat aluminum, you put dry powder on it. You use an electrostatic charge to make the powder stick. Then you heat the aluminum. This makes a strong, smooth layer on top. The coating keeps your parts safe from scratches and chips. It also protects them from bad weather. The finish does not fade easily and stays bright for a long time. Many people pick powder coating because it lasts a long time. It can save money and is better for the environment. There are many colors to choose from. You can find a color or style for almost any need.

Key Takeaways

- Powder coating aluminum means putting dry powder on it with an electric charge, then heating it to make a tough, protective layer.

- The process has key steps: cleaning, getting the surface ready, putting on the powder, heating it, and letting it cool. These steps help make the finish strong.

- Powder-coated aluminum does not scratch, chip, or fade as easily as liquid paint. This makes it last a long time.

- There are many colors and finishes to pick from. You can choose what fits your style or needs.

- Powder coating is good for the environment. It makes very little air pollution and uses no harmful chemicals, so it is safer for the earth.

- This coating saves money because it needs less care and lasts longer than other finishes.

- To get the best results, you must prepare the surface and heat it the right way. If you skip steps, the coating may not stick well and can fail early.

- Powder coating works well for many things, like cars, buildings, and products people use, because it is strong and looks nice.

Table of Contents

What is powder coating aluminum?

Powder coating basics

Powder coating aluminum means putting dry powder on the surface. You use an electrostatic spray gun to do this. The powder sticks because of the electric charge. Next, you heat the part in an oven. The powder melts and makes a smooth layer. This layer protects the aluminum. It also gives it a bright finish.

The steps for powder coating aluminum are important:

- Pre-treating the aluminum: You clean off dust and grease. You can use power washing or a solvent.

- Surface preparation: You might use phosphate treatment or blasting. This removes aluminum oxide and helps the powder stick.

- Applying the powder: You use an electrostatic spray gun to cover the aluminum.

- Curing: You heat the coated aluminum in an oven. The powder melts and bonds to the surface.

- Cooling: You let the part cool. The finish gets hard and strong.

Tip: Aluminum is more sensitive to heat than steel. You must watch the oven temperature during curing. This stops the part from warping or getting damaged.

Here is a table that compares powder coating aluminum and steel:

| Aspect | Aluminum | Steel |

|---|---|---|

| Surface Preparation | Needs less preparation | Needs more preparation |

| Cost | More expensive because of the process | Usually less expensive |

| Durability | Not as strong in tough conditions | More durable |

| Heat Sensitivity | More heat-sensitive | Less heat-sensitive |

Powder coating aluminum can cost more than coating steel. The process needs extra care and sometimes more steps. Aluminum also needs careful handling when curing. It can bend if it gets too hot.

Why choose powder coat aluminum?

Many manufacturers and engineers pick powder coat aluminum. They do this because it gives protection, looks good, and is a good value.

- Durability: Powder coating aluminum makes a thick, tough layer. It stops scratches, chips, and fading. Your parts look new longer, even with lots of use.

- Corrosion resistance: The coating keeps out moisture, chemicals, and UV rays. This matters most for outdoor or factory parts.

- Wide color selection: You can choose from many colors and finishes. You can get glossy, matte, or textured looks.

- Environmental benefits: The process uses no solvents and has very low VOCs. This makes powder coating aluminum better for the environment.

- Cost-effectiveness: The finish lasts a long time and needs little care. You save money because you do not need to repaint or fix it often.

Note: Powder coating aluminum does not chip or peel as much as liquid paint. The finish stays smooth and even, even on tricky shapes.

If you use machining to make aluminum parts, powder coating helps even more. The coating covers sharp edges and complex shapes. Your machined parts look even and nice. It also protects the special features you made. You get a part that looks good and works well in tough places.

Here is a table showing how powder coating helps machined aluminum parts:

| Benefit | Description |

|---|---|

| Wear Resistance | The thick layer stops wear and tear. Your parts last longer. |

| Corrosion Resistance | The coating protects against hits, chemicals, and weather. |

| Cost-Effective | The strong finish means less care and lower costs over time. |

| Aesthetic | Smooth, even color with many choices for gloss and texture. |

| Environmentally Friendly | No solvents and very little VOCs help you meet green standards. |

When you pick powder coat aluminum, you get quality, good looks, and long-lasting parts. This finish is smart for many industries, like building and cars.

Step-by-step guide to powder coating aluminum

If you want your aluminum parts to look perfect, you must follow each step. Every part of the powder coating process is important. You get the best results when you clean the surface well. You also need to put the powder on evenly. The right oven temperature is needed for curing. Here is how you can get a professional finish, even if your parts are made by machining.

Surface preparation

Getting the surface ready is the key to a strong powder coating. If you skip this step, the coating may not stick well. It can also fail early.

Cleaning and degreasing

First, take off all oil, dust, and dirt from the aluminum. Use an alkaline degreaser or a solvent wash. This makes sure nothing is left that could make the coating peel or chip.

If a chip comes off, it often means the aluminum was not cleaned right. Even a little oil or dirt can stop the coating from sticking.

After degreasing, rinse the part with clean water. Let it dry all the way. For better results, use media blasting with aluminum oxide. This makes the surface rough, so the powder sticks better.

Pre-treatment methods

When the part is clean, you do pre-treatment. Sanding or blasting makes the surface rougher for better sticking. Next, use a chemical pre-treatment like phosphate or chromate conversion coating. This helps the powder bond and keeps away rust.

- Start with media blasting using aluminum oxide.

- Then use alkaline degreasing to get rid of oils and dirt.

- You can use passivation to remove iron-based leftovers.

- Powder coat the part soon after passivation to keep it from getting worse.

Check the surface before you move on. Make sure there is no dust, grease, or marks. If you see a problem, clean it again.

If there is still dirt or oxide, the coating may not stick. A blasted surface and a good primer make a strong bond. This keeps water from getting under the coating.

Applying the powder coat

Electrostatic spray process

Now you are ready to spray the powder. Use an electrostatic spray gun for this step. The gun gives the powder an electric charge. This makes the powder stick to the grounded aluminum.

- Keep the spray gun 150–300 mm from the part. If you hold it too close, it can cause problems. If you hold it too far, the powder may not cover well.

- Set the voltage between 60–90 kV. This helps the powder stick well. More voltage does not always mean better results.

Move the gun in smooth, even lines. Cover every part, even the edges and corners. If your part has tricky shapes, take extra care to reach all spots.

Tip: Put on the powder at the right thickness. Too much powder can make bumps or rough spots. Too little powder can leave the metal bare.

Curing and finishing

Oven curing

After spraying, you cure the part. Put the coated aluminum in a hot oven. The heat melts the powder and makes it stick to the surface.

| Temperature (°F) | Time (minutes) |

|---|---|

| 400 | 10 |

| 350 | 20 |

Most parts cure at 400°F for 10 minutes. Bigger or thicker parts can cure at 350°F for 20 minutes. Always check the powder maker’s instructions for the best results.

- Curing is very important. If you do not cure long enough or at the right heat, the finish may look good at first but will chip or peel later.

Cooling and inspection

When curing is done, take the part out of the oven. Let it cool in a clean place with no dust. The coating gets hard as it cools. Do not touch the part until it is cool.

Check the finished part for any problems. Look for smooth color and even texture. You can do simple tests, like an ‘X’ cut test or a hot water test, to check how well the coating sticks. For important uses, a salt fog test can show if it resists rust.

Good cleaning and curing make your powder coating last. If you skip steps or hurry, the coating may not stick, chip, or wear out fast.

By following these steps, you get a strong and nice finish on your aluminum parts. Every step, from cleaning to curing, is important for a good and long-lasting powder coating.

Benefits of powder-coated aluminum

Durability and protection

Powder-coated aluminum is strong and lasts a long time. The coating makes a thick layer that protects your parts. It helps stop scratches, dents, and fading. This layer does more than look nice. It acts like a shield and helps stop rust. Your parts will last longer, even in rain, sun, or with chemicals.

- Powder-coated aluminum does not chip or peel easily. Your parts stay strong and look good.

- The coating keeps out water and bad stuff. This means less rust and fewer fixes.

- In lab tests, powder-coated aluminum did very well against rust. For example:

- Samples in salty water at 40°C for 200 hours kept their coating.

- Tests showed that thicker coatings with fewer holes worked best.

If you make tricky aluminum parts, powder coating covers every spot. Even small edges and corners get full protection.

Appearance and color options

Powder-coated aluminum is not just tough. You can pick from many colors and finishes. Choose classic colors like Satin White, Satin Black, or Aluminum Silver. If you want bright colors, pick Red, Blue, Orange, or Magenta. There are also fancy finishes like Oil-Rubbed Bronze, Copper, or Brass.

- You can get glossy, matte, or textured looks.

- Special finishes like anodized effects or antimicrobial coatings are also possible.

- You can match colors to make your own style.

With powder-coated aluminum, you do not have to pick boring colors. There is always a finish that fits your style, whether you want modern, classic, or industrial.

Environmental and cost advantages

Powder coating is good for the earth and saves money. The process does not use bad solvents or make dangerous fumes. This helps keep the air clean and your workspace safe.

- Powder coating makes almost no VOCs, unlike liquid paint.

- You can reuse extra powder, so there is less waste.

- The process uses less energy and means fewer do-overs.

You save money over time with powder-coated aluminum. It costs less to keep up than other finishes. You do not need to fix, repaint, or throw away as much.

- Fewer mistakes mean you save money on rejected parts.

- Lower energy and labor costs make powder coating smart for any project.

Picking powder-coated aluminum gives you a finish that is strong, looks great, and is better for the planet. You also keep your costs low.

Consistency and repeatability in powder coating

If you want every aluminum part to look the same, you need consistency. Powder coating helps you get this, whether you make a few or many parts. You can count on the process for a smooth finish and strong protection. Your parts will always look neat and professional.

Uniform coverage

Every part should have a smooth, even layer. Powder coating does this by using careful methods. Automated spray systems control how much powder goes on. The conveyor moves each part at the right speed and spot. This makes sure the coating is even everywhere. It stops thick or thin spots and missed corners.

- Automated systems keep the coating the same on all parts.

- You do not get mistakes that people might make by hand.

- The finish stays even, even on tricky shapes or edges.

Tip: When the coverage is even, your parts look better and last longer. You lower the chance of weak spots that could chip or rust.

Quality control

Quality control is very important for powder coating. You can use easy tests to check each batch. These checks help you find problems early and keep your work good.

- Visual Inspection: Look for rough spots, drips, or uneven areas. Trained workers can see these before the parts leave.

- Adhesion Testing: Make sure the coating sticks well to the aluminum. This matters for parts that face tough weather or lots of use.

- Thickness Measurement: Use special tools to check the coating’s thickness. This makes sure the finish is strong and looks even.

- Regular tests are fast and do not cost much.

- Checking often helps you feel sure about your results.

Scalability for production

Powder coating works for both small and big jobs. If you make a few parts, you can do each step by hand. For large orders, machines do the work. These systems keep every part moving at the right speed. You get the same good quality from start to finish.

| Production Scale | Method | Benefit |

|---|---|---|

| Small batch | Manual or semi-auto | Flexible, easy to adjust |

| Large batch | Fully automated lines | Fast, uniform, less waste |

Automated lines help you work faster and waste less. They save time and make sure every part is up to your standards. You can make more parts without losing quality.

When you use good equipment and follow the steps, you get the same results every time. Your customers will see the high quality and trust your work.

By doing these things, you make sure powder coating gives great results, no matter how many parts you make.

Powder coating aluminum vs. other finishes

When you pick a finish for aluminum, you want it to protect, look nice, and be worth the money. Let’s look at how powder coating is different from liquid paint and anodizing. This will help you choose the best finish for your project, especially if you use machined aluminum parts.

Powder coating vs. liquid paint

You might ask if powder coating or liquid paint is better for aluminum. Both have good points, but powder coating has some big advantages. Here is a quick look at how they compare:

| Feature | Powder-Coated Aluminum | Liquid-Painted Aluminum |

|---|---|---|

| Texture | Grainy but even | Varies |

| Thickness | 2 mm to 8 mm | 0.5 mm to 1.5 mm |

| Flexibility | Withstands expansion | Prone to cracking |

| Durability | More resistant to wear | Less resistant |

Powder coating makes a thicker and smoother layer. This helps your parts handle bumps, scratches, and bad weather. The finish stays strong and does not crack when the metal moves. Liquid paint can look nice at first, but it chips and fades faster. If you want your aluminum parts to last longer, powder coating is the better choice.

Powder coating vs. anodizing

Anodizing is another finish for aluminum. It makes a thin, hard layer by changing the metal’s surface. Both finishes protect aluminum, but they work in different ways. Here is how they compare:

| Characteristics | Anodizing | Powder Coating |

|---|---|---|

| Eco-friendliness | Good | Excellent |

- Powder coating makes very few VOCs.

- You can reuse extra powder, so there is less waste.

- Anodizing makes some harmful byproducts, so it is not as good for the earth.

Powder coating also gives you more choices for color and texture. Anodizing usually gives a shiny metal look with fewer color options. If you want bright colors or special textures, powder coating is the best choice.

When to choose powder coating

Pick powder coating if you want a finish that is strong, colorful, and good for the earth. It works well for many machined aluminum parts. Here are some common uses and what you get:

| Scenario | Benefit |

|---|---|

| Outdoor applications | Better protection from rust |

| Playground equipment | Stronger against hits and damage |

| Fencing | Looks nice with many color choices |

| Signage | Lasts long in tough weather |

Tip: Powder coating is great for parts that get used a lot, face bad weather, or need to look good for a long time.

If you want a finish that keeps your parts safe, looking new, and helps the planet, powder coating is the smart choice. You get a strong, even layer that stands up to daily use. You can also match any color or style you want.

By knowing these differences, you can pick the best finish for your aluminum project. Powder coating gives you better performance, looks, and is better for the environment.

Applications of powder-coated aluminum in machining

Architectural and industrial uses

Powder-coated aluminum is used a lot in buildings today. Builders like it because it is strong and light. It also looks nice and modern. The powder coating makes the aluminum last longer. It protects against rain, bumps, and daily use. This makes it good for both inside and outside jobs.

- Window and door frames use powder-coated aluminum. The finish keeps them looking new and stops rust.

- Curtain walls and building fronts use powder-coated panels for a modern look.

- Handrails, fences, and balustrades have a tough coating. This stops scratches and fading.

- Factories and warehouses use powder-coated aluminum for beams and supports.

- You also see powder-coated finishes on signs, lights, and elevator panels.

Powder coating can be used on aluminum, steel, MDF, or glass if prepared correctly. You can pick from many colors and textures to match any style. In the last twenty years, powder coating has become very popular for buildings. It lasts as long as PVDF paints and keeps buildings looking good.

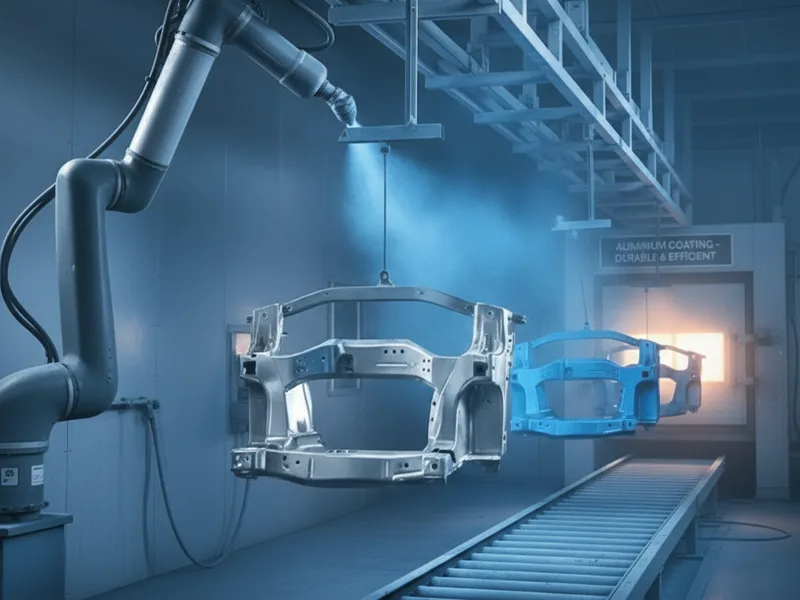

Automotive and transportation

Powder-coated aluminum is used in cars and trucks. The car industry likes it because it is tough and looks good. Powder coating keeps parts safe from scratches, rust, and bad weather. Some coatings last up to ten years, so they are a smart choice for vehicles.

| Application/Benefit | Description |

|---|---|

| Engine Components | Strong finish and nice look for intake manifolds. |

| Wheel Market | Stops rust and gives a smooth finish, so fewer wheels are thrown out. |

| Interior and Exterior Trim | Makes the trim look better and protects it from the sun. |

| Compliance with Regulations | Replaces VOC coatings to meet air rules with better finishes. |

| Durability and Aesthetics | Tough finish that keeps looking good on many car parts. |

You see powder-coated aluminum on wheels, engine covers, roof racks, and trim. The finish stands up to road salt, mud, and sun. Makers use different powders, like polyester for sun or epoxy for rust. Hybrid coatings mix the best parts for special needs. This keeps car parts strong and looking good for years.

Consumer products and appliances

You use powder-coated aluminum in many things at home. Many products and appliances use this finish to last longer and look nice.

- Outdoor furniture, like benches and tables, uses powder-coated aluminum to stop rust and fading.

- Big home systems, like outdoor heaters and air conditioners, use this finish to protect from the weather.

- Light posts, railings, and playground gear stay safe and bright with powder coating.

- Home appliances, like fridges, washers, and dryers, have powder-coated panels for a clean look.

- Tools and yard gear, like lawn mowers and wheelbarrows, use powder-coated aluminum to handle rough use.

Powder coating helps these things last longer and look better. The finish stops chips, scratches, and stains. This means you do not have to fix or clean them as much, so you get more value from what you use every day.

Outdoor and specialized equipment

Outdoor and special equipment must work well outside. Powder-coated aluminum helps your gear last in tough places. If you run a park or fix city things, you want strong products. You also want them to look nice and not need much care.

Powder coating makes a tough layer on aluminum. This layer keeps out rain, sun, snow, and salt spray. You do not need to worry about rust or fading. The coating blocks water and chemicals. Your gear stays strong and looks good for many years.

Here is how powder coating helps outdoor and special aluminum gear:

| Benefit | Description |

|---|---|

| Durability | Makes a tough layer that stops rust and scratches. |

| Lifespan Extension | Helps aluminum last longer, so you replace it less. |

| Aesthetic Appeal | Gives you many colors and finishes to make things look better. |

You can see these good things in real life:

- Playground slides and park benches use powder-coated aluminum. They do not get ruined by weather or lots of use.

- Outdoor lights and flagpoles keep their color and shine, even in strong sunlight.

- Sports gear like soccer goals and bleachers stays safe and does not rust for a long time.

- Marine and dock parts do not rust, even with saltwater.

- Special tools for rescue, like ladders and boxes, work well in hard places.

Powder coating gives you more value too:

- The process is good for the earth. It does not use bad chemicals and produces less waste.

- Powder coating saves money. You do not spend as much time fixing or replacing things.

Tip: Picking powder-coated aluminum for outdoor or special gear means your stuff lasts longer and costs less to take care of.

You can pick from many colors and finishes. This lets you match your gear to your brand, your area, or safety rules. You can choose shiny, flat, or rough looks. Some finishes even stop graffiti or germs, which is good for public places.

Powder coating covers every part, even small corners and edges. Your gear gets full protection, even on tricky shapes or moving parts. You do not have to worry about rust starting in hidden spots.

Maintenance and care for powder-coated aluminum

Keeping your powder-coated aluminum parts in top shape does not take much effort. With the right care, you can keep the finish looking new and extend the life of your machined parts. Here are some practical tips to help you maintain both the appearance and performance of your powder-coated aluminum.

Cleaning tips

You should clean powder-coated aluminum regularly to prevent dirt and grime from building up. Use a soft cloth or sponge with mild soap and warm water. Avoid harsh chemicals or abrasive pads. These can scratch or dull the finish.

- Rinse the surface with clean water before you start. This removes loose dust and grit.

- Mix a small amount of gentle dish soap in a bucket of warm water.

- Wipe the surface with a soft cloth or non-abrasive sponge. Work in small sections.

- Rinse again with clean water to remove any soap residue.

- Dry the surface with a soft towel or let it air dry.

Tip: For stubborn spots, use a solution of water and vinegar. Test it on a small area first to make sure it does not affect the color.

You should never use steel wool, scouring pads, or strong solvents. These can damage the powder coating and make it easier for rust or stains to form.

Longevity and touch-up advice

Powder-coated aluminum is tough, but accidents can happen. If you notice a scratch or chip, you can fix it with a few simple steps. Acting quickly helps prevent further damage and keeps your parts looking their best.

- Inspect the area. Look closely to see how deep the scratch or chip is.

- Clean the surface. Remove any dirt, grease, or debris from the damaged spot.

- Apply a repair product. Use a powder coating touch-up pen or spray that matches your color. These products work well for small chips and scratches.

- Blend and finish. Lightly sand the repaired area if needed. Apply a clear coat or matching topcoat to protect the spot and blend it with the rest of the surface.

- Prevent future damage. Handle your parts with care. Clean them regularly and consider using a protective wax or coating for extra defense.

Note: For larger repairs or if you see peeling, contact a professional. They can restore the finish and make sure the protection stays strong.

You can maximize the lifespan of your powder-coated aluminum by following these care steps. Regular cleaning, quick touch-ups, and gentle handling keep your machined parts looking sharp and performing well for years.

Powder coating makes your aluminum parts tough and nice-looking. The finish lasts a long time. You get many good things from it:

- It helps stop chips, scratches, and fading.

- You can pick from many colors and finishes.

- The process is safe for the earth with almost no VOCs.

- You save money because you do not need much upkeep.

You should think about powder coating for any aluminum project. This is extra helpful if you use machining. If you want to know more, look at expert guides or ask a professional finisher for help.

FAQ

You get powder-coated steel when you apply a dry powder to steel and then cure it with heat. This process creates a strong, even finish. Powder-coated steel resists scratches, chips, and fading. You can use it for outdoor furniture, fences, and machinery.

Powder-coated steel lasts longer than painted steel. The finish on powder-coated steel forms a thicker, more durable layer. You will notice fewer chips and less peeling. Powder-coated steel also resists rust and weather damage better than most paints.

Yes, you can use powder-coated steel outside. The finish acts as a protective barrier against rain, sun, and chemicals. Powder-coated steel keeps its color and strength in harsh weather. You will see it on playgrounds, railings, and outdoor equipment.

You should clean powder-coated steel with mild soap and water. Use a soft cloth or sponge. Avoid harsh chemicals or abrasive pads. Regular cleaning keeps powder-coated steel looking new and helps the protective barrier last longer.

Powder-coated steel resists rust much better than bare steel. The coating blocks water and air from reaching the metal. If the coating gets scratched, rust can form. You should repair any damage quickly to keep the protective barrier strong.

The aluminum pretreatment process includes cleaning, degreasing, and applying a chemical treatment. This step removes dirt and oils. It also prepares the surface for powder coating. The aluminum pretreatment process helps the powder stick better and last longer.

You should check with the manufacturer before using powder-coated steel for food contact. Some powders are food-safe, but not all. Always use powder-coated steel that meets safety standards for your application.

Yes, you can repair small chips or scratches on powder-coated steel. Clean the area first. Use a touch-up kit or matching paint. For large damage, you may need professional help. Keeping powder-coated steel in good shape protects the metal underneath.