You might ask, “Is passivation of steel the same as heat treat?” The answer is no. Passivation only changes the metal’s surface, helping it resist rust better. In contrast, heat treatment alters the inside of the metal, making it stronger or harder. This difference is crucial for producing strong parts. In machining, you must choose the right process. AFI Industrial Co., Ltd. explains when to use passivation and also demonstrates when heat treatment is best for performance.

Key Takeaways

- Passivation forms a shield on the metal’s surface. This shield helps stop rust.

- Heat treatment changes the whole metal inside. It makes the metal stronger or harder.

- Picking the correct passivation process is very important. Passivation of the surface alone cannot fix deep rust problems.

- Passivation works best for parts near water or chemicals. Heat treatment is better for making things strong and tough.

- You can use both processes together. First, use heat treatment for strength. Then, use passivation to stop rust.

- Knowing about these processes helps you choose better. It can save money and make products better.

- AFI Industrial Co., Ltd. gives expert help. They help you pick the best way to treat your metal parts.

- Is Passivation the Same as Heat Treat

Table of Contents

Key Differences Explained

When you ask, “is passivation the same as heat treat,” you are asking something many people wonder about in metalworking. The answer is no. Passivation and heat treatment are not the same. Each process has its own job and effect on metal parts.

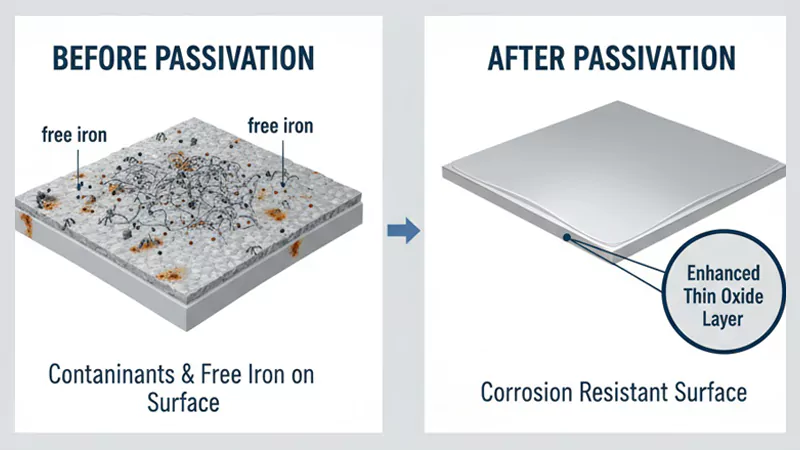

Passivation is a metal-finishing process that works on the metal’s surface. It makes a thin, protective oxide layer. This layer helps the metal fight rust and corrosion. To do this, you put the part in a mild acid bath. The acid cleans off dirt and free iron from the surface. After passivation, the metal, like stainless steel, resists corrosion much better. Passivation does not change the inside of the metal. It only helps the outside.

Heat treatment changes the whole metal, not just the surface. You heat the metal to a certain temperature. Then you keep it there for a while. Next, you cool it down slowly or quickly. This can make the metal harder, softer, stronger, or more bendable. The way you heat and cool the metal changes how it acts. For example, you might want a cutting tool to be harder. Or you might want a machine part to be tougher. Heat treatment changes the inside and outside of the metal.

Do not mix up the two processes. Is passivation the same as heat treat? No. Passivation makes the outside better at fighting rust. Heat treatment changes how the whole metal behaves.

Tip: Many people think passivation fixes every problem with stainless steel. But it cannot fix old rust or deep metal issues. Passivation is not a cure for all alloys. You must pick the right process for your material and use.

Why the Distinction Matters in Machining

Knowing the difference between passivation and heat treatment is very important in precision machining. If you choose the wrong process, you could hurt the part or make it wear out faster.

Here are some reasons why this matters:

- Passivation makes a shield that stops rust, especially in stainless steel and metals that resist corrosion. This is important for parts that touch water or chemicals.

- Heat treatment changes the inside of the metal. You can make a part harder, stronger, or easier to bend, depending on what you need.

- If you skip passivation, your parts might rust sooner and break early.

- If you use the wrong heat treatment, the metal could get too brittle or bend out of shape.

Many people think passivation is the same as heat treatment, but this is not true. Some believe passivation is quick and works for every metal. Others think it can clean off all heat marks or fix every surface issue. Really, you need to know what each process can and cannot do.

Note: In jobs like aerospace, medical devices, and car making, picking passivation or heat treatment affects how good and long-lasting the parts are. AFI Industrial Co., Ltd. helps you choose the best process so your parts meet tough rules for quality and strength.

When you know the answer to “Is passivation the same as heat treat?” you can make smarter choices for your machining work. You save money, make better products, and help your parts last longer.

Passivation Process Overview

What Is Passivation

Passivation helps make a shield on metal surfaces after machining. The metal goes into an acid bath to clean off dirt and help a strong oxide layer form. This layer keeps the metal from rusting and helps it look good for a long time. The science behind passivation is about re-establishing the oxide layer. This layer blocks more rust from forming.

Here is a simple look at the chemical parts:

| Aspect | Description |

|---|---|

| Protective Layer | Metals get a thin oxide or nitride layer that stops more rust. |

| Thickness of Oxide Layer | The thickness depends on the metal. Aluminum gets a 5 nm layer after years. |

| Mechanisms of Passivation | Oxygen moves in, oxide grows, and grain edges affect how rust forms. |

| Passivation Conditions | You need to clean, use acid, and check that the surface is passive. |

| Common Acids | Nitric acid is common, but citric acid is safer and better for the environment. |

Nitric acid is often used for passivation, but it can be dangerous and bad for the environment. Citric acid is safer and works faster, so it is a better choice.

Passivation of Steel and Stainless Steel

Passivation of Steel

When you passivate steel, you remove iron and dirt left from machining. This is important because these things can cause rust if not cleaned off. You put the steel in a mild acid, like citric or nitric acid, to clean it. After rinsing and drying, the steel gets a thin, even layer that protects it from water and air.

Stainless Steel Passivation

Passivating stainless steel is almost the same, but you focus more on bringing back the chromium-rich oxide layer. Here is the usual order of steps:

- Clean and remove grease with sodium hydroxide at a high temperature.

- Rinse well with water.

- Put the part in a nitric or citric acid bath to clean and help the oxide layer grow.

- Rinse again.

- Use a mild alkaline solution to neutralize.

- Rinse and dry.

Doing these steps right makes sure stainless steel gets a strong passivation layer. This is needed to stop rust for a long time.

Benefits for Machining and Surface Quality

Passivation gives you many good things in precision machining:

- Passivation makes a shield that keeps parts from rusting and helps them last longer.

- It gives a smooth, shiny finish that looks good and works well.

- By cleaning off dirt from machining, you lower the chance of parts breaking early and keep quality high.

- Tests like salt spray show that passivation really helps stop rust.

| Improvement Type | Description |

|---|---|

| Corrosion Resistance | Passivation helps parts fight rust, so they last longer and need less fixing. |

| Uniform Appearance | The process gives a smooth, shiny look that is nice to see. |

| Cleanliness | Passivation makes sure surfaces are clean, which helps them work better and last longer. |

| Measurable Testing | Tests like salt spray give proof that passivation works well. |

When you work with AFI Industrial Co., Ltd., every part gets the right surface treatment. This careful work helps your parts meet tough rules for strength and quality.

Heat Treatment Basics

What Is Heat Treatment

Heat treatment changes how metals act. You heat the metal to a set temperature. Then you cool it down. This can make the metal harder or stronger. Sometimes it makes the metal easier to shape. You use heat treatment during different steps in making parts. It helps you get the right qualities for each part. For example, you can make a part last longer. You can also help it fight wear and rust. Heat treatment makes metal work better and stops problems like bending or breaking too soon.

Types of Heat Treatment in Machining

There are several main types of heat treatment in machining. Each type gives the metal special qualities. Here is a table that lists the most common types and what they do:

| Process | Purpose | Benefits |

|---|---|---|

| Annealing | Softens metal, relieves stress, refines grain | Easier machining, better ductility, less cracking |

| Quenching | Hardens and strengthens metal by rapid cooling | Higher wear resistance, stable dimensions |

| Tempering | Reduces brittleness, improves toughness | More stable parts, better machinability |

| Normalizing | Refines grain, improves ductility | Stress relief, prepares for hardening |

| Case Hardening | Hardens only the surface, keeps the core soft | Tough core, hard surface, longer fatigue life |

| Precipitation Hardening | Increases yield strength with small particles | Stronger parts, less distortion, selective hardening |

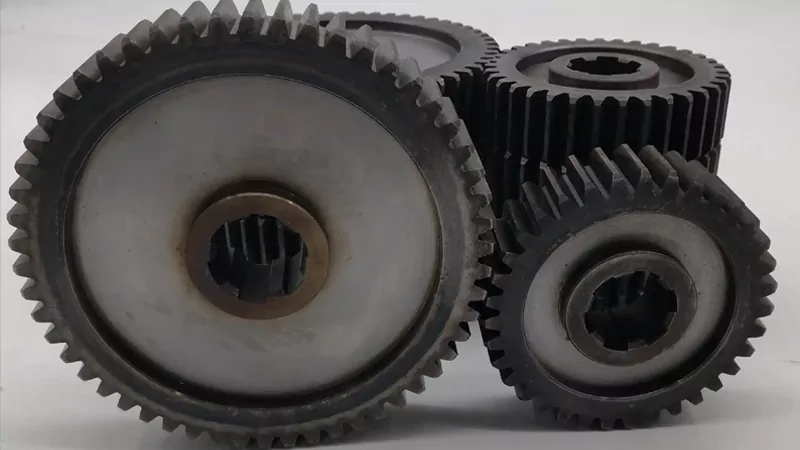

You pick the right type based on what the part needs to do. For example, if you want a gear to last longer, you might use case hardening. This makes the outside tough but keeps the inside strong and bendy.

Effects on Material Properties

Heat treatment changes the inside of the metal. When you heat steel, it forms a new structure called austenite. As you cool it, the structure changes again. Fast cooling makes the grains small and the metal hard. Slow cooling makes the grains bigger and the metal softer. By controlling these steps, you can change how hard, strong, or bendy the metal is.

After heat treatment, machined parts work much better. Here are some of the main changes:

- Hardness goes up, so parts wear out more slowly.

- Strength increases, so parts do not break as easily.

- Ductility gets better, so parts can bend without snapping.

- Toughness rises, so parts can take hits without breaking.

You also get better rust resistance and longer life. Parts last longer in tough places and keep their shape. Here is a table that shows what you gain:

| Improvement Type | Observed Benefits |

|---|---|

| Hardness | Parts become harder and resist wear |

| Wear Resistance | Service life increases by 3-5 times |

| Fatigue Life | Parts avoid early cracking under repeated use |

| Dimensional Stability | Parts keep their shape in precision assemblies |

| Stress Relief | Less chance of cracks from machining stresses |

At AFI Industrial Co., Ltd., experts use heat treatment for your parts. This makes sure your parts are strong, resist rust, and last a long time.

Passivation vs. Heat Treatment in Machining

Method and Process Comparison

When you work with metals, you must pick the right process. Passivation and heat treatment are both important, but they do different things. Passivation is a finishing step for metal surfaces. You put the metal part in an acid bath. This bath takes away dirt and helps make a thin shield called an oxide layer. The shield keeps the metal safe from rust and helps it stay clean.

Heat treatment is not just about the surface. It changes the whole metal inside. You heat the metal to a set temperature. Then you keep it hot for a while. After that, you cool it down. This can make the metal harder, stronger, or easier to bend. Heat treatment is used when you want to change how the whole part acts, not just the outside.

Here is a table that shows the main differences:

| Aspect | Passivation | Heat Treatment |

|---|---|---|

| Primary Focus | Creates a corrosion-resistant surface layer | Alters internal structure to enhance properties |

| Process | Acid bath to remove impurities and form an oxide layer | Heating and cooling cycles to change the structure |

| Surface Change | Yes, forms a protective oxide layer | No, primarily structural changes |

| Structural Change | No | Yes, changes the mechanical properties |

Passivation gives a shield on the outside to stop rust. Heat treatment changes how the metal acts from the inside.

Surface vs. Structural Changes

Passivation works on the outside of the metal. It makes a thin layer that blocks water, air, and chemicals. This is good for parts that need to stay clean or face tough places. After machining, there might be iron bits on the surface. Passivation helps get rid of these, which stops rust from starting fast.

Heat treatment goes deep into the metal. It changes the way the grains inside the metal are set up. When you heat and cool the metal, you can make it harder. This is needed if a part must hold a heavy weight or last a long time. Heat treatment does not add a new layer. It changes the whole part from the inside.

Passivation helps stick to dirt and lets you wash it away. This is important to keep products clean during machining.

Remember, passivation protects the outside. Heat treatment makes the whole part stronger or tougher.

When to Use Each Process

You should pick passivation or heat treatment based on what your part needs. Here are some tips to help you choose:

- Use passivation if you want to:

- Get rid of iron bits after machining.

- Make a shield that stops rust.

- Keep parts clean and stop dirt from sticking.

- Make stainless steel or other metals look better.

- Use heat treatment if you need to:

- Make the metal harder or stronger.

- Help the metal work better in tough jobs.

Heat treatments can make metal parts much stronger and better.

Think about the type of metal and where it will be used:

- Stainless steel often needs passivation to fight rust and last longer.

- Steel parts that must be tough or not wear out fast may need heat treatment.

- Aluminum parts are usually better with anodizing or powder coating.

- If parts will be in places with lots of water or chemicals, use passivation, plating, or anodizing.

- For parts that rub a lot, use case hardening or other heat methods.

When you work with AFI Industrial Co., Ltd., you get help picking the best process. Their team helps you choose so your parts are strong, meet rules, and last longer.

Practical Applications and Industry Use Cases

Passivation of Stainless Steel in Precision Machining

Passivation is needed when parts must not rust. This is important for medical tools, food machines, and boat parts. These parts need to stay clean and not get rusty. Passivation takes away the free iron left after machining. It helps a strong oxide layer form on the surface. This layer protects the part from water, chemicals, and air. Passivated parts last longer and look nicer. Many industries use passivation to keep products safe and working well.

Passivation helps parts pass tough salt spray tests. It also helps meet rules for cleanliness and strength.

Heat Treatment for Enhanced Performance

Heat treatment is used when parts must be strong and tough. Think about gears in cars or shafts in machines. Jet engine parts also need heat treatment. These parts work under heavy loads and big temperature changes. Heat treatment helps parts keep their shape and strength. They do not bend or break easily. They last longer, so you fix them less often. Your machines work better and save money.

You can pick hardening, tempering, annealing, or normalizing. Each method gives the right mix of hardness and toughness for the job.

AFI Industrial Co., Ltd. Solutions

AFI Industrial Co., Ltd. helps you get good results with both passivation and heat treatment. Their team picks the best process for your needs. Here is what they do:

- They do all the main heat treatment steps, like hardening and tempering, to match what you need.

- They make stainless steel better at fighting rust by removing free iron and making a strong passive layer.

- They use many high-quality metals, so you get the right one for your project.

- Their quality checks cover every step, from raw materials to finished parts, so you get only the best.

| Quality Control Stage | Description |

|---|---|

| Incoming Quality Control | Check raw materials to make sure they are right for you. |

| Input Process Quality Control | Inspect while making to keep quality high at every step. |

| Final Quality Control | Check finished parts to make sure they meet your needs. |

| Outgoing Quality Control | Only perfect parts leave the factory, so you get good products every time. |

You get stainless steel that passes hard salt spray tests. You also get titanium parts that work well in tough jobs. AFI Industrial Co., Ltd. gives you passivated and heat-treated parts that last in real life.

Common Questions About Passivation and Heat Treatment

Is Passivation the Same as Heat Treat?

Some people think passivation and heat treatment are the same. They are not.

You use heat treatment to change how metal acts inside and outside.

Here are questions people ask a lot:

- Will passivation make my part stronger?

No, it just helps stop rust. - Can passivation fix deep rust or damage?

No, it only works on the surface. - Does passivation change the size of my part?

Sometimes, the part gets a tiny bit smaller. This happens because strong acids clean off the iron from the surface. - Is electro polishing the same as passivation?

Electro polishing is a different process. It removes more material and makes the surface smoother.

If you do not know which process you need, ask AFI Industrial Co., Ltd. Their experts help you pick the right one for your parts.

How Does Passivation of Steel Work?

Passivation of steel uses chemicals to clean the surface. It takes away the iron and dirt left from making the part. After cleaning, a thin layer forms. This layer keeps steel from rusting and helps it last longer.

Let’s see how passivation compares to other ways to stop rust:

| Aspect | Passivation | Coating |

|---|---|---|

| Method | Chemical treatment to boost natural resistance | A physical barrier is put on the surface |

| Process | Makes a passive oxide layer | Uses paints, polymers, or metal coatings |

| Environmental Impact | Usually better for the environment | Depends on what is used |

| Maintenance | Needs little care, helps metal stay strong | May need new coats over time |

| Applications | Used for medical, aerospace, and food parts | Used in many different industries |

Passivation is good for parts that must stay clean and not rust, like food machines or medical tools.

When Should I Choose Passivation or Heat Treatment?

Pick passivation when you want to:

- Stop rust and corrosion on the surface.

- Keep the part shiny and clean.

- Use the part where it touches water, chemicals, or food.

Pick heat treatment when you need to:

- Make metal harder or stronger.

- Change how metal bends or wears out.

- Get parts ready for heavy jobs or high heat.

Picking the right process matters. If you choose wrong, your part may not last or work well. AFI Industrial Co., Ltd. can help you decide. Their team knows when to use passivation or heat treatment for the best results.

If you have more questions, contact AFI Industrial Co., Ltd. Their experts help you get strong, high-quality parts.

You can see that passivation and heat treatment do different jobs in machining. The table below shows how they are not the same:

| Process | Purpose | Key Characteristics |

|---|---|---|

| Passivation | Makes metal better at fighting rust by cleaning the surface | Mostly for stainless steel; it helps keep the outside clean and protected. |

| Heat Treatment | Changes how strong or bendy the metal is | Uses heat to make metal stronger and less likely to break. |

Picking the right process helps your parts meet tough rules and last longer. If you need help or want good machining, talk to AFI Industrial Co., Ltd. You can also visit their website to learn more about how these processes help your parts work better.

FAQ

You use passivation to create a protective layer on metal surfaces. This layer helps your parts resist rust and corrosion, especially after machining or cleaning.

No. You can use heat treatment to make metal harder, softer, or tougher. The result depends on the process you choose and the needs of your part.

You usually passivate stainless steel and some other alloys. Not all metals benefit from passivation. Always check if your material responds well before starting the process.

You decide based on your part’s function. If you need corrosion resistance, choose passivation. If you want to change strength or hardness, select heat treatment.

Passivation removes a very thin surface layer. You might see a tiny size reduction, but it is usually too small to affect your part’s fit or function.

Yes. Passivation is common for food and medical parts. It helps keep surfaces clean and free from rust, meeting strict industry standards.

Yes. You can use both processes on the same part. You often heat treat first, then passivate to get both strength and corrosion resistance.

AFI Industrial Co., Ltd. can guide you. Their experts help you pick the best process for your project, ensuring your parts meet all quality and performance needs.