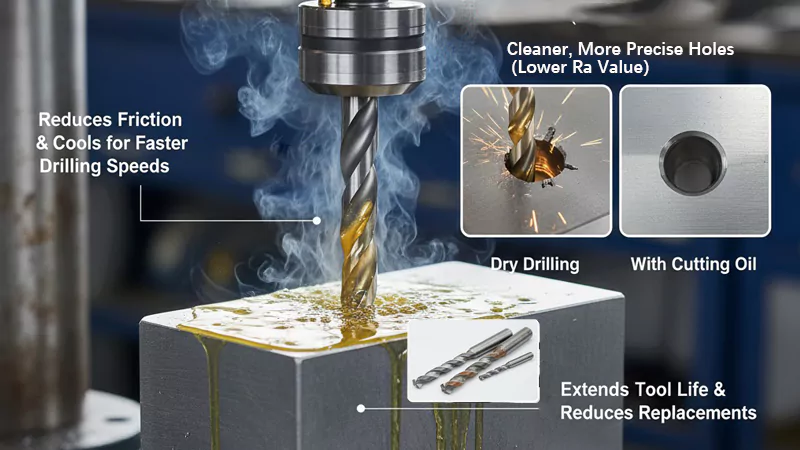

When drilling metal, use cutting oil to lubricate it and keep both your drill bit and metal workpiece safe. You’ll experience less friction and heat when drilling metal if you remember that when drilling metal, use cutting oil to lubricate it, making the process smoother. Special cutting oils form a thin layer, cool the drill, and help maintain the correct shape of the workpiece.

- When drilling metal, use cutting oil to lubricate it, as this reduces friction and heat.

- Cutting oil creates a protective shield on the cutting edges, so the drill remains strong and the workpiece stays steady.

- The cooling effect helps both the tool and the metal stay in good condition.

Key Takeaways

- Cutting oil lowers friction and heat when you drill metal. This helps the drilling go more easily and keeps your tools safe.

- Cutting oil makes a shield on the drill and workpiece. This helps the tool stay strong and steady while you drill.

- Cutting oil cools the drill bit. This keeps it sharp for longer and helps it work better.

- Cutting oil helps make cleaner holes with fewer rough edges. This gives a nicer finish and means less extra work.

- Cutting oil stops rust by making a barrier. It keeps out water and air, so your metal stays safe for a long time.

- The right cutting oil can help you drill faster. It also helps your tools last longer.

- Put cutting oil on before and during drilling. This keeps things smooth and cool, and stops overheating.

- Pick the best cutting oil for your metal. This gives you the best results and protects your tools.

Table of Contents

Friction reduction

Cutting oil helps lower friction when you drill metal. Less friction means drilling is easier. It also helps your drill bit last longer. Your workpiece will look better, too. Studies showthat cutting oil lowers resistance a lot. Drilling goes smoother with less force needed. Here are some research results:

| Study | Findings |

|---|---|

| Rech et al. | Lubricating oil cuts down friction during metal cutting. |

| Pin-on-ring tests | Metalworking fluid dropped the friction from 0.6 to 0.1. |

| Vegetable oil studies | Vegetable oils lower friction and help tools last longer. |

Lubrication effect

Cutting oil makes a thin, slippery layer on the metal. This layer stops the drill and metal from rubbing hard. You get less heat and less damage to your drill.

Less wear on the drill

You want your drill bits to last longer. Cutting oil helps by lowering friction and keeping drills cool. Cooling systems use cutting oil to stop overheating. If your drill stays cool, it stays sharp longer. It does not get dull fast. When drilling tough steel, cutting oil helps your drill last longer. It stops heat from building up.

Smoother drilling

Drilling feels smoother when you use cutting oil. The drill moves through metal with less pressure. You do not need as much strength. Drilling is easier and more exact. This helps when drilling fast or with lots of pressure. Use cutting oil when drilling metal. You will see the drill work much better.

Surface protection

Friction can hurt your drill and your workpiece. Cutting oil protects the metal surface. It lowers direct contact between the drill and metal.

Fewer scratches

You want your finished metal to look nice. Cutting oil helps by stopping scratches and marks. Here are ways cutting oil protects your workpiece:

- Lubrication lowers friction for better tool life and smoother finishes.

- Cooling keeps heat low, so part quality stays high.

- Cutting oil stops corrosion, so your metal stays good during and after drilling.

Using cutting oil protects your drill and your workpiece. You get longer tool life and a better final product.

Cooling and heat control

When you drill into metal, heat builds up fast. This heat can damage your drill bit and the workpiece. Cutting oil helps you control this heat, keeping your tools and materials safe.

Heat dissipation

Cutting oil acts as a coolant. It draws heat away from the drill bit and the metal. You get a safer and more stable drilling process.

Prevents overheating

If your drill bit gets too hot, it can lose its sharpness or even break. Cutting oil keeps temperatures lower. Here are some measured temperature differences:

- Maximum temperature during dry drilling at 1.3 mm depth: 110 °C

- Maximum temperature with external coolant: 60 °C

- Temperature increase with internal coolant: about 5 °C

You can see that using cutting oil or coolant makes a big difference. Lower temperatures mean your drill bit stays sharp and strong.

Maintains drill hardness

High heat can soften your drill bit. When the bit gets soft, it wears out faster and loses its cutting edge. Cutting oil helps you keep the drill bit hard by cooling it down. You get more drilling done before you need to replace your tool.

Stable performance

You want your drilling to stay steady from start to finish. Cutting oil helps you keep things under control.

Reduces risk of deformation

Heat can change the shape of your workpiece. If the metal gets too hot, it may bend or warp. Cutting oil keeps the temperature low, so your workpiece stays in the right shape. You get cleaner holes and better results.

Tip: When drilling metal use cutting oil to lubricate it. This simple step protects your drill, keeps your workpiece cool, and helps you avoid costly mistakes.

Recent studies show that using minimum quantity lubrication (MQL) gives you even better results than traditional flooded cooling. MQL improves tool life, helps chips move away from the drill, and gives you a smoother finish. You also use less cutting fluid, which saves money and helps the environment. Flooded cooling, on the other hand, leads to more tool wear and higher costs.

Cutting oil gives you control over heat and performance. You get longer tool life, better results, and a safer drilling process.

When drilling metal, use cutting oil to lubricate it

Cutting oil is not just any lubricant. You need a product made for metal drilling. Regular oils do not provide the same level of protection or cooling. When drilling metal, use cutting oil to lubricate it; you get better results and protect your tools.

Efficiency boost

Drilling metal can be tough on your equipment. Specialized cutting oils help you work faster and keep your tools in good shape.

Faster drilling

You want to finish your job quickly. Cutting oil reduces friction and cools the drill bit. This means you can drill at higher speeds without damaging your tool or the workpiece. The right oil helps you move through metal with less resistance.

Here is a comparison of drilling performance:

| Metric | Dry Drilling | Drilling with Cutting Oil |

|---|---|---|

| Surface Roughness (Ra) | Higher values | Ra 0.6 µm at lower feed rates |

| Cylindricity | Worse | 0.02 mm at optimal conditions |

| Cutting Forces | Higher | Lower due to the cooling effect |

You see lower cutting forces and smoother surfaces when you use cutting oil. This means you spend less time on each hole.

Fewer tool replacements

Drill bits wear out quickly if you do not use the right lubricant. When drilling metal use cutting oil to lubricate it, you extend the life of your drill bits. You save money because you do not need to replace tools as often. Even a small amount of oil can make a big difference. Users report that just a drop or two keeps the drill edge sharp.

Tip: Choose a cutting oil designed for metal. Sulfurized oils like DuraKut 2100 and 128N work well for steel and tough metals. These oils handle high pressure and keep your tools working longer.

Better results

You want clean, precise holes in your metal workpiece. Cutting oil helps you achieve this goal.

Cleaner holes

Cutting oil keeps the drill bit cool and lubricated. This leads to smoother holes with fewer burrs. You get better surface quality and less need for extra finishing. Users often describe the difference as “like night and day” compared to dry drilling.

- Minimum quantity lubrication (MQL) reduces flank wear and improves hole quality.

- Cutting oil lowers surface roughness, especially at lower feed rates.

- Even though metals like steel benefit from sulfurized cutting oils, which improve machinability and hole finish.

You get consistent results and cleaner holes every time you use the right cutting oil. When drilling metal, use cutting oil to lubricate it, you protect your tools and get the best possible outcome.

Chip removal

When you drill into metal, chips form quickly. These chips can cause problems if you do not remove them right away. Cutting oil helps you clear chips from the hole, keeping your drill and workpiece safe.

Chip clearing

Chips can build up fast during drilling. If you let them stay, they can clog the drill and scratch the metal. Cutting oil makes chip removal easier and more efficient.

Prevents clogging

You want your drill to keep moving without stopping. Cutting oil helps chips slide away from the drill bit. This keeps the hole open and prevents clogging. When you use cutting oil, you avoid jams that can damage your tool or ruin your workpiece.

- Cutting fluids help remove chips, so they do not get stuck between the drill and the metal.

- Chips that stay in the hole can cause scratches and poor surface finishes.

- Cutting oil reduces friction and heat, so the metal does not expand and trap chips.

Researchers have studied how different factors affect chip removal. The table below shows some key findings:

| Key Findings | Implications on Chip Removal Efficiency |

|---|---|

| Tool geometry, cutting parameters, and cutting fluid conditions influence chip morphology. | Understanding these factors is crucial for optimizing drilling processes. |

| Higher spindle speed and feed rate increase chip curl radius. | Optimizing these parameters can enhance chip evacuation efficiency. |

| Air flow rate depends on drill coolant hole diameter and input air pressure. | Larger coolant hole diameters improve chip removal efficiency. |

| Increasing spindle speed enhances chip evacuation for helical drills. | Higher spindle speeds lead to better chip removal. |

| Higher feed rates produce long-pitch chips, while very low rates generate thin chips. | Adjusting feed rates can optimize chip evacuation. |

| Increased coolant pressure enhances chip fragmentation. | Better chip fragmentation improves evacuation efficiency. |

Reduces surface marks

You want your finished metal to look smooth and clean. Cutting oil helps by keeping chips away from the cutting area. When chips do not rub against the metal, you get fewer scratches and marks.

- Cutting oil forms a barrier that protects the surface.

- Chips move out of the way, so the drill makes a cleaner cut.

- The workpiece keeps its shape and size because the oil controls heat and friction.

Clean workspace

A clean workspace helps you work faster and safer. Cutting oil makes cleanup easier after drilling.

Less post-drill cleanup

When you use cutting oil, chips do not stick to the drill or the workpiece. The oil helps carry chips away, so you spend less time cleaning up after the job. Studies show that oil-based drill cuttings can be broken down and removed more easily, leading to a cleaner workspace. You finish your work faster and keep your tools in better shape.

Tip: Always use cutting oil when drilling metal. You will see fewer chips left behind and enjoy a smoother, cleaner workspace every time.

Corrosion prevention

Cutting oil cools and lubricates metal. It also protects metal from rust. Metal can rust when it touches water or air. Rust makes metal weak and old. Cutting oil stops water and air from touching the metal. This keeps your metal safe.

Protective barrier

Cutting oil makes a thin film on metal. This film blocks water and air. Rust cannot start if water and air do not touch metal. The oil has special molecules. These molecules stick to metal and make a shield. Your metal gets extra protection.

| Mechanism | Description |

|---|---|

| Barrier Film | The oil creates a film on the metal that protects against moisture and oxygen. |

| Inhibitor Action | Inhibitor molecules adsorb on the surface, forming a protective film against corrosion. |

Blocks moisture

Water causes rust on metal. Cutting oil pushes water away from metal. Your workpiece stays dry and safe. RUSTGARD™ Rust & Corrosion Preventive Oil moves water off metal. It protects metal from wet air and rain. You do not need to worry about rust after drilling.

- RUSTGARD™ Rust & Corrosion Preventive Oil displaces moisture.

- The oil protects metal surfaces from humidity that could lead to rust and corrosion.

Prevents rust

Rust makes metal weak and ugly. Cutting oil stops rust by blocking water and air. Your workpiece stays strong and looks new. Studies show coolants and lubricants protect metal from rust (Brinksmeier et al., 2015). You get better results and metal lasts longer.

| Study/Source | Key Findings |

|---|---|

| Brinksmeier et al. | Coolants and lubricants block oxygen or moisture, preventing corrosion on metal surfaces. |

| Industry Reports | Cutting fluids regulate temperature, prevent corrosion, and improve machinery lifespan. |

Long-term tool care

You want your drill bits to last long. Cutting oil helps you do this. The oil covers your drill bit and tools. You get less damage each time you use cutting oil.

Extends drill life

Rust can hurt your drill bit and make it wear out. Cutting oil keeps your tools working well. You avoid rust and holes in your drill bit. You can drill more before you need new tools. Cutting fluids keep machines cool, stop rust, and help tools last longer. You save money, and your workshop works better.

Tip: Always use cutting oil when drilling metal. You protect your workpiece and tools from rust. You get better results and longer tool life every time.

Surface finish

When you drill metal, the final look of the hole matters. Cutting oil helps you get a smooth, clean finish every time. You want fewer rough edges and less extra work after drilling. Cutting oil makes this possible by reducing friction and cooling the drill bit.

Smoother holes

Cutting oil gives you smoother holes in your metal workpiece. The oil forms a thin layer between the drill and the metal. This layer reduces heat and stops the drill from grabbing or tearing the metal. You see a big difference in the quality of the hole.

Fewer burrs

Burrs are sharp edges or pieces left behind after drilling. You want to avoid them because they make your workpiece look messy and can cause problems later. Cutting oil helps you get fewer burrs. The oil keeps the drill bit cool and lubricated, so it cuts cleanly through the metal. You spend less time removing burrs and more time finishing your project.

- Cutting oil lowers cutting forces and heat.

- You get a cleaner cut with fewer rough spots.

- Your workpiece looks better and feels smoother.

Tip: Always use cutting oil when you want a professional finish. You will see fewer burrs and save time on cleanup.

Less rework

When you drill without cutting oil, you often need to fix rough holes or remove extra material. Cutting oil helps you avoid this extra work. The oil keeps the drill sharp and the metal cool, so you get a better result the first time. You finish your job faster and use less effort.

The use of cutting fluids, such as cutting oil, is crucial for enhancing the surface finish of metal parts during machining. Cutting fluids increase tool life and improve the quality of the machined surface. By preventing thermal expansion and changes in material properties, cutting fluids help you achieve a superior surface finish. You spend less time fixing mistakes and more time moving forward.

Precision

Precision means you get the same result every time you drill. Cutting oil helps you drill with accuracy and consistency. The oil keeps the drill bit sharp and the metal stable, so you get holes that match your measurements.

Consistent results

You want every hole to look the same and fit your needs. Cutting oil helps you get consistent results by reducing friction and keeping the drill bit cool. The oil also stops chips from sticking to the drill, so you get a clean cut each time.

Here is how cutting oil improves precision and consistency:

| Key Findings | Description |

|---|---|

| Importance of Lubrication | Lubrication cools and protects tool and workpiece surfaces during drilling. |

| Reduction of Friction | Lower friction increases tool life and improves surface quality. |

| Prevention of Chip Adhesion | Lubrication stops chips from sticking, keeping cuts precise. |

| Stable Cutting Forces | Vegetable oil keeps cutting forces steady during drilling. |

| Minimal Wear | Effective lubrication means less tool wear and fewer disruptions. |

| Tolerance Levels | Soybean oil-assisted MQL achieves tolerances under 60 μm in hard drilling. |

Cutting fluids are essential in machining operations. They reduce heat and provide lubrication, which improves surface finish and lowers cutting forces. You get holes that meet your standards every time. Cutting oil helps you work faster, get better results, and keep your tools in top shape.

Note: Using cutting oil is the key to getting smooth, precise holes in metal. You protect your tools and your workpiece, and you get results you can trust.

Choosing and applying cutting oil

Picking the right cutting oil helps your drill and metal. You should know how oils are different and how to use them well.

Oil types

Sulfurized vs. regular

You can pick regular cutting oil or sulfurized cutting oil. Each one works best for certain jobs and metals.

| Type of Cutting Oil | Properties | Applications |

|---|---|---|

| Regular Cutting Oil | Mineral-based, needs mixing | Light to heavy jobs, non-ferrous metals |

| Sulfurized Cutting Oil | Has sulfur additives | Tough jobs with ferrous metals, precise work |

- Neat cutting oils give great lubrication for hard jobs.

- Sulfurized oils are good for ferrous metals and fast drilling.

- Regular cutting oils work for many metals but may not work well for tough jobs.

Tip: Always match your oil to your metal. Using the wrong oil can hurt your tool and workpiece.

Light vs. heavy

You also need to pick light or heavy cutting oils. Each type has its own benefits.

| Type of Cutting Oil | Characteristics | Best Use Cases |

|---|---|---|

| Heavy Cutting Oils | Great lubrication, not mixed | Threading, turning, deep drilling, gear cutting |

| Light Cutting Oils | Better cooling, synthetic or semi-synthetic | Fast machining jobs |

- Heavy cutting oils, like straight oils, are good for deep drilling and gear cutting.

- Light cutting oils cool tools better when drilling fast.

Note: Straight oils like X-HONE® and X-CUT® work well for hard jobs.

Application tips

How much to use

You need to use the right amount of cutting oil for each job.

- When you use a new drill bit, put on a little oil.

- After using the drill a few times, add more oil to stop overheating and help your drill last longer.

- Drill slowly at first to keep the drill cool.

Tip: Too much oil can be messy. Too little oil can make your drill too hot. Find the right amount for your job.

When to apply

Putting cutting oil on at the right time helps a lot.

- Put some oil on before you start drilling. This keeps things cool and smooth.

- Use a good cutting oil, like WD-40 Specialist Multi-Purpose Cutting Oil. It works under high pressure and lowers friction.

- Keep the temperature low to protect your drill.

- Make sure the oil helps move chips away for a better finish.

⚠️ Common mistakes are using the wrong oil, letting dirt build up, and forgetting to clean. Always clean your metal before you use oil and check for dirt.

You should also think about how you put on the oil. Neat cutting oils give better lubrication. Water-soluble fluids cool your tools more. Pick the right one for your job, metal, and drill.

Managing cutting fluids well stops spills and keeps things clean. Good chip removal and waste handling help the environment and keep your workspace safe.

Cutting oil helps your drill and metal workpiece in many ways. It lowers friction and keeps things cool. It also makes your work faster and easier. Cutting oil helps move chips away and stops rust. It makes the surface look better. Experts say these are important benefits:

- Cutting oil cools and lubricates your tool.

- Your tools last longer and you get more work done.

- Chips come out easier and your workpiece looks nicer.

- Using oil the right way saves money and helps the environment.

| Cost Type | Percentage of Production Costs |

|---|---|

| Cutting Fluid Costs | Up to 16% |

| Tool Costs | 3% to 4% |

| U.S. Fluid Costs | 3 to 4 times higher than tool costs |

Pick the best cutting oil for your job. You will get better results and save money in the long run.

FAQ

You use cutting oil to reduce friction, cool the drill bit, and protect your workpiece. It helps you drill smoother holes and keeps your tools in good shape.

You should not use regular oil. Cutting oil has special additives for metal drilling. It gives better cooling and lubrication. Regular oil does not protect your drill or workpiece as well.

Apply cutting oil before you start drilling. Add more if you see smoke or if the drill bit gets hot. Keep the area wet with oil for best results.

Yes, cutting oil forms a barrier that blocks moisture and air. This barrier helps you prevent rust and keeps your metal workpiece strong.

Sulfurized cutting oils work best for steel. These oils handle high pressure and heat. You get longer tool life and smoother holes with sulfurized oils.

Most cutting oils work for many metals. Some oils, like sulfurized types, suit steel and tough metals. Always check the label to make sure the oil matches your metal.

Yes, cutting oil helps you get smoother holes with fewer burrs. It reduces friction and heat, so your finished workpiece looks cleaner and needs less extra work.