You need the right Metal parts measuring tools to get good results. These tools help you work faster and more accurately. Accurate measurement makes sure your parts fit well and work right. Professional machinists use these important tools:

- Micrometers let you measure small sizes very accurately.

- Calipers help you check inside, outside, depth, and steps.

- Dial indicators help you check if surfaces are flat and lined up.

Using the right tool helps you do better work and finish faster. Each tool helps you make better parts and avoid mistakes.

Key Takeaways

- Using the right measuring tools helps you work better and faster in metalworking. Micrometers and calipers are important for measuring both small and big sizes correctly. Checking your measuring tools often stops expensive mistakes and keeps your work exact. Having all the measuring tools you need is important for good machining and checking quality. Surface plates give a flat and steady place for taking correct measurements and setting up tools. Digital measuring tools show results fast and help you make fewer mistakes. Taking care of your tools and cleaning them often makes them last longer and keeps your measurements right. Knowing what each tool does helps you pick the best one for your job.

Table of Contents

Importance of Precision in Metalworking

Being exact is very important in metalworking. Every measurement counts when you work with metal. A small mistake can make a part not fit or break. Each piece must match the design closely. This is extra important in machining. Machining shapes metal parts to very tight limits.

The Role of Measuring Tools in Machining

Measuring tools help you get the accuracy you need. You use them at every step, from the first cut to the last check. Metal parts measuring tools help you find mistakes early. This stops problems before they get expensive.

Tip: Measure two times before you cut. This habit saves time and materials.

Good measurement helps you control quality. It also helps you meet industry rules. Some industries, like aerospace and medical devices, have strict rules. If your measurements are wrong, the part may not work or be safe. People have needed precision since the first machines. Today, it matters even more. Parts must fit together and work every time.

Here is a table that shows how being exact affects quality and safety:

| Evidence Description | Impact on Quality and Safety |

|---|---|

| Accurate measurements ensure parts conform to design specifications. | Essential for functionality and safety in critical applications like aerospace and medical devices. |

| Inaccuracies can lead to part failures. | Poses significant safety risks, especially in high-stakes industries. |

| Maintaining high standards of precision enhances product quality. | Reduces defects and fosters customer satisfaction. |

| Precision and accuracy contribute to overall quality of machined parts. | Ensures functionality and longevity of components. |

You use many Metal parts measuring tools to keep tight limits. Micrometers, calipers, and gauge blocks help you check sizes very closely. Micrometers are good for small features. Calipers check inside, outside, and depth sizes. Coordinate measuring machines and laser scanners compare parts to the design. This makes sure you follow industry rules.

Note: High precision measuring tools are needed for tight limits. Use micrometers and digital calipers to check sizes at important steps.

Quality control needs regular checks. Measuring tools let you check parts during production. This helps you find problems early and fix them. Regular checks also show if your tools are wearing out. Worn tools can make bad parts.

You can see why measuring tools matter in this table:

| Tool Type | Function |

|---|---|

| Dial Calipers | Measure outer, inner, depth, and step sizes very closely. |

| Custom Measurement Gauges | Make quality checks faster and measure special shapes. |

| Air Gauge | Checks many sizes and finds leaks; used by hand or on lines. |

| Bore Gauge | Checks inside sizes, tapers, and grooves. |

| Defect Stickers | Mark bad parts so they can be removed fast. |

CNC technology has changed machining. CNC machines control tool paths and cut very exactly. This lets you make parts that meet strict size and shape rules. You can trust each part will match the design if you use the right measuring tools.

Essential Metal Parts Measuring Tools

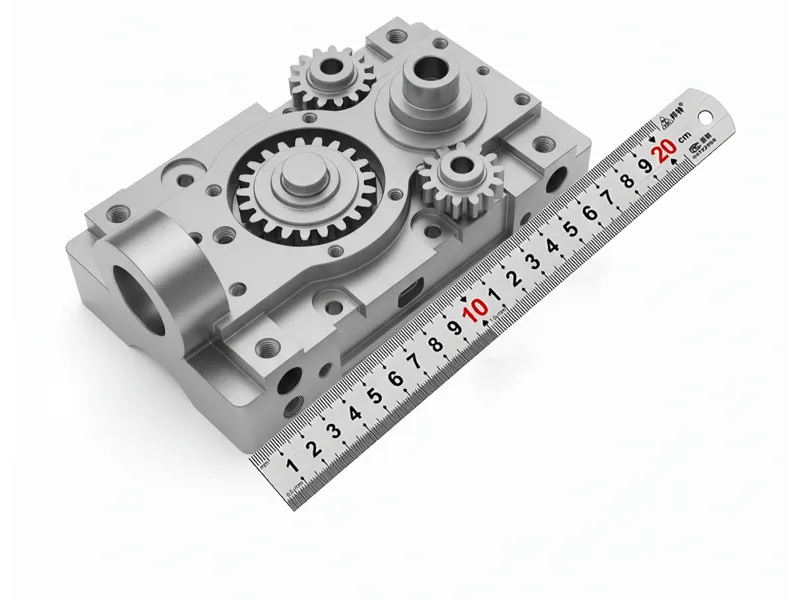

Steel Rule

The steel rule is a basic Metal parts measuring tool. It looks simple, but it works well for many jobs. You use it to check lengths and mark lines. It helps you see if part sizes are correct during machining. The steel rule is made from strong steel. This keeps it straight and stops it from wearing out.

A steel rule is very useful for:

- Making sure parts match in small batches.

- Cutting soft things like foam or rubber.

- Making new shapes that need to be exact.

- Jobs where you want good results without spending too much.

Steel rules have different marks for measuring. Here is a chart to help you:

| Measurement Type | Increment |

|---|---|

| Fractional Inches | 1/64, 1/32, 1/16, 1/8 |

| Decimal Inches | 0.100 (1/10), 0.010 (1/100), 0.050 (1/20), 0.020 (1/50) |

You will use a steel rule for quick checks. It is important you use more exact Metal parts measuring tools. Every machinist should have one.

Tip: Keep your steel rule clean and smooth. Even a small dent can change your measurements.

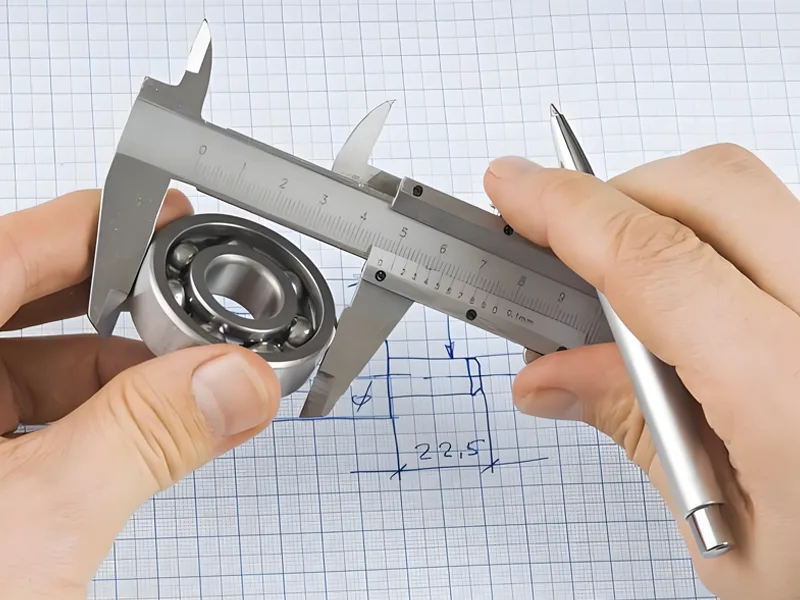

Calipers (Vernier, Dial, Digital)

Calipers are flexible Metal parts measuring tools for machining. You can pick vernier, dial, or digital calipers. Each kind helps you measure inside, outside, steps, and depth easily.

- Vernier calipers are accurate and work well for long parts.

- Dial calipers move smoothly and last a long time.

- Digital calipers are fast and easy to read. They work best for daily jobs.

You use calipers to:

- Measure how thick metal sheets are.

- Check the size of rods or holes.

- Set up machines for exact cuts.

Calipers help you work faster and better. When you use calipers with other Metal parts measuring tools, you make fewer mistakes. You get good results every time.

Note: Digital calipers are great for daily use. Heavy-duty verniers are better for big parts.

Micrometer

Micrometers are very exact Metal parts measuring tools. You use them for small features or tight limits in machining. A micrometer has an anvil and a spindle. You put the part between them and turn the thimble to read the size.

There are different micrometers for different jobs:

| Type of Micrometer | Application |

|---|---|

| Standard or Vernier | Measures the outside sizes of metal parts |

| Digital | Shows exact numbers for accuracy |

| Ball Micrometers | Measures round parts |

| Thread Micrometer | Checks thread sizes |

| Internal or Bore | Measures the inside sizes of round parts |

| Depth Micrometer | Measures how deep holes or grooves are |

Most mechanical micrometers measure to 0.001 inches. Digital micrometers can measure even smaller, down to 0.00005 inches. You need this for important machining jobs. It helps you check shaft sizes, thread sizes, or groove depths.

Pro Tip: Clean the measuring faces before you use it. Even a tiny chip or oil can change your reading.

Using a micrometer helps you waste less and save money. You find mistakes early and avoid fixing parts later. When you use micrometers with calipers and other Metal parts measuring tools, you make sure every part is the best it can be.

CMM

A coordinate measuring machine (CMM) is a very advanced Metal parts measuring tool. You use a CMM to check the size, shape, and position of hard parts. The machine has a probe that touches the part. It records the spot in three dimensions. This lets you see if the part matches the design with high accuracy.

CMMs help you find mistakes early. You get quick feedback, so you can fix problems fast. The machine can fix offsets by itself. This means you make fewer bad parts and use your materials better. You also save time because you do not check every part by hand.

Here are some ways a CMM helps you:

- Find mistakes early in production

- Give you fast feedback on part quality

- Make inspection faster

- Lower the number of parts you throw away

- Make machining more accurate for cast, forged, or molded parts

A CMM can measure parts from 5 mm up to 700 mm. It can be as exact as a few microns. This is important for aerospace, automotive, and medical device jobs. When you use a CMM, your parts meet strict rules and fit right every time.

Tip: Use a CMM to check your most important parts. This helps you avoid costly mistakes and keeps your quality high.

Height Gauge

A height gauge is a key tool for measuring up and down in machining. You use it to check part height, mark lines, and check tolerances. The tool has a base that sits flat and a pointer that moves up and down. You read the size from a scale, dial, or digital screen.

You need a height gauge to make sure your parts are the right size. Even a small mistake in height can mean a part gets rejected or needs fixing. The height gauge helps you mark lines for cutting or drilling. This keeps your work correct from the start.

In machining, you use a height gauge to:

- Measure the height of steps, slots, or holes

- Mark the exact lines for more machining

- Check if a part meets the needed tolerance

Pick the right height gauge for your job. For very exact work, use a digital or dial height gauge. For simple jobs, a vernier height gauge may be enough.

Note: Always use your height gauge on a clean, flat plate for best results.

Surface Plate

A surface plate is the base for good measurement in any metal shop. You use it as a flat plane to check if parts are flat and straight. Most surface plates are made from granite or cast iron. Granite is popular because it stays flat, does not rust, and handles heat well.

Here are the main surface plate materials and their benefits:

- Granite: Very hard, stable, and does not rust. It keeps its shape even when it gets hot or cold.

- Cast Iron: Strong and good at stopping shakes. It costs less but is best for jobs that do not need top precision.

A surface plate helps you set other Metal parts measuring tools. You put your part or tool on the plate to check if it is flat or to set up for more checks. This step is important before and after machining to make sure your parts meet the needed rules.

Main reasons to use a surface plate:

- Gives a steady base for all measurements

- Makes sure your measuring tools stay correct

- Helps you find mistakes before they hurt your final product

Pro Tip: Keep your surface plate clean and free from dust. Even a tiny bit of dirt can change your measurements.

Protractor

You need a protractor to measure and mark angles in metalworking. This tool helps you set up precise angles for cutting, welding, or machining. Most protractors for metalwork are made from stainless steel or aluminum alloy. These materials make the tool strong and keep it accurate over time. The typical measuring range for a protractor is from 0 to 180 degrees.

- The round head design makes it easy to read angles.

- Clear markings help you avoid mistakes.

- Some protractors have a locking mechanism to hold the angle steady.

- You can use a protractor to check or set angles on parts, jigs, or fixtures.

A protractor is essential when you need to cut or weld at a specific angle. It ensures your parts fit together as planned. In machining, you use a protractor to check the angle of milled surfaces or to set up machines for angled cuts. This tool helps you avoid errors that could ruin a part or slow down your work.

Tip: Always check that your protractor is clean and free from burrs. Dirt or damage can affect your angle readings.

Feeler Gauge

A feeler gauge is a set of thin metal blades, each with a precise thickness. You use it to measure small gaps or clearances between two surfaces. This tool is very important for machine setups, adjustments, and quality checks in metalworking.

You can use a feeler gauge for:

- Machine setups

- Leveling adjustments

- Checking parallelism and alignment

- Measuring small clearances

- Checking valve lash

- Tool offsets

- Part separation

The thinnest blade in a feeler gauge can measure extremely small gaps. Here is a table showing some of the smallest measurements you can check:

| Measurement (mm) | Description |

|---|---|

| 0.001 | Very thin gap |

| 0.0015 | Very thin gap |

| 0.002 | Very thin gap |

| 0.003 | Very thin gap |

| 0.004 | Very thin gap |

| 0.005 | Very thin gap |

| 0.006 | Very thin gap |

| 0.007 | Very thin gap |

| 0.008 | Very thin gap |

| 0.009 | Very thin gap |

| 0.01 | Very thin gap |

| 0.012 | Very thin gap |

| 0.014 | Very thin gap |

| 0.015 | Very thin gap |

| 0.016 | Very thin gap |

| 0.018 | Very thin gap |

| 0.02 | Very thin gap |

| 0.022 | Very thin gap |

| 0.024 | Very thin gap |

| 0.025 | Very thin gap |

You need a feeler gauge to check if parts are too close or too far apart. This is important in machining, where even a small gap can affect how a machine runs or how parts fit together. Using a feeler gauge helps you keep your Metal parts measuring tools and machines working at their best.

Note: Always clean the blades before and after use. Oil or dirt can change the thickness and give you a wrong reading.

Tape Measure

A tape measure is a flexible ruler used to measure long distances or large parts. In metalworking, you use a tape measure to check the length, width, or height of big pieces. Steel tape measures are best because they last longer and stay accurate.

Tape measures come in different lengths for different jobs:

| Length Range | Application |

|---|---|

| 3 meters (10 feet) | Smaller, retractable versions |

| 50 meters (164 feet) | Long-range applications like surveying |

| 100 meters (328 feet) | Large-scale construction projects |

Some high-end tape measures can measure to 1/1000 of a foot. Look for a tape measure with clear markings in both imperial and metric units. A standout length is helpful if you work alone.

When you compare a tape measure to other Metal parts measuring tools, you see that it is less precise for short distances. Here is a table to show the difference:

| Measuring Tool | Accuracy up to 12 ft | Accuracy beyond 12 ft | Notes on Error Sources |

|---|---|---|---|

| Tape Measure | ±1/32 in. | ±1/16 in. | Hook assembly can affect measurement accuracy. |

You use a tape measure for rough measurements or when you need to check something quickly. For more exact work, use calipers or micrometers. Always check that the tape is not bent or damaged, as this can change your results.

Tip: Retract the tape slowly to avoid bending or breaking the blade. Store it in a dry place to prevent rust.

Gauge Blocks

Gauge blocks are also called slip gauges. They are the best for precision in metalworking. You use them to check and set other Metal parts measuring tools. Each block has a set length. The length is made very exact. When you stack gauge blocks, you get a very accurate reference length.

You use gauge blocks to check your tools in machining. They help you make sure micrometers, calipers, and height gauges are correct. Gauge blocks let you trust your measurements, even with tight tolerances.

Gauge blocks have different grades. Each grade has its own tolerance. The table below shows the standard tolerances for gauge blocks in metalworking:

| Grade | Tolerance (μm) |

|---|---|

| AAA | ±0.05 |

| AA | +0.10 to −0.05 |

| A | +0.15 to −0.05 |

| B | +0.25 to −0.15 |

You pick the grade based on how exact your work must be. For the hardest jobs, use AAA or AA grade blocks. For normal shop work, A or B grade blocks are fine.

Gauge blocks are important for keeping the measuring tools correct. Here is how you use them in your shop:

- Gauge blocks are a very exact standard for measuring tools.

- They help fix errors from temperature changes or handling.

- You check your tool readings against the gauge blocks to find mistakes.

- Regular checks, sometimes up to 1000 times a year, keep your tools correct. Temperature changes can affect both tools and parts.

When you use gauge blocks, you can trust your machining results. You know your tools are right, and your parts will meet the needed specs. Gauge blocks are key for quality control, calibration, and keeping high standards in metalworking.

Tip: Always touch gauge blocks with clean, dry hands. Even a fingerprint can change their accuracy. Keep them in a case to protect them from dust and scratches.

Building Your Measuring Toolkit

A complete measuring toolkit is very important for good machining. The right tools help you work faster and make fewer mistakes. They also keep your work moving smoothly. Every machinist needs a toolkit that fits today’s metalworking jobs. Here is how you can build and take care of your measuring toolkit.

Selecting Quality Tools

Picking the right measuring tools is the first thing to do. You need tools that match your job and help you get accurate results. Before buying, think about what you measure most and how exact you need to be.

- Know what you need to measure. Is it length, diameter, surface roughness, or temperature?

- Decide how exact your measurements must be. Some jobs need tools that measure very small amounts.

- Choose tools that are simple to use. Easy tools help you make fewer mistakes.

- Learn about the different tools you can buy. Compare brands and models to find what works best for your shop.

- Make sure the tool meets industry rules or standards.

- Think about how much you use your tools and how strong they need to be.

Tip: Write a checklist before shopping. This helps you remember what is most important for your machining work.

calibration

Calibration keeps your measuring tools correct. If you skip calibration, your tools can give wrong numbers and you may not notice until there is a problem. Checking your tools often is very important for every machinist.

- Use advanced measurement tools to check your parts at each step.

- Calibrate your tools often so your results stay the same.

- Use gauge blocks to make sure your tools are reading right.

- Write down calibration dates and results in a log.

| Calibration Practice | Why It Matters |

|---|---|

| Regular calibration | Lowers the chance of mistakes and expensive fixes. |

| Using gauge blocks for checks | Makes sure your tools are still correct. |

| Keeping a calibration schedule | Helps you never miss a check and keeps your process strong. |

| Checking after tool drops or shocks | Finds hidden damage that can change accuracy. |

Note: Even a small calibration mistake can cause big problems in machining. Make calibration a habit to avoid trouble.

Maintenance and Storage Tips

Taking care of your tools helps them last longer and keeps your results right. Dirty or broken tools can give wrong numbers and waste time and materials.

- Clean your tools before and after using them. Dust and oil can change your results.

- Store tools in soft cases to keep them safe from bumps and drops.

- Keep tools dry so they do not rust or corrode.

- Do not stack tools or leave them loose in drawers.

- Check your tools often for damage or wear.

- Change worn parts or send tools for repair if needed.

🛠️ Pro Tip: Treat your measuring tools with care. Good care means better machining, fewer mistakes, and higher quality parts.

A good measuring toolkit that is well cared for is your best friend in machining. It helps you meet tight limits, avoid expensive mistakes, and make parts that fit and work well. Buy good tools, check them often, and store them safely. You will see better results in your work.

You need all 10 essential measuring tools for the best results in metalworking. These tools help you work more accurately and faster. When you use the right tools, you make fewer mistakes. Your projects turn out better, especially when machining.

- Check which measuring tools you already have.

- Get new or missing tools to do a better job.

Tip: Buy a full measuring toolkit. You will make fewer errors and your work will be higher quality.

FAQ

Start with a steel rule or a digital caliper. These tools measure basic sizes easily. They are simple to use and give quick results.

Calibrate your tools every six months. Do it after any drop or shock. Regular calibration keeps measurements correct and stops expensive mistakes.

No, you cannot use just one tool. Each tool does a special job. Use a micrometer for small parts. Use a tape measure for big pieces. Pick the right tool for each task.

A surface plate gives you a flat base for checking parts. It helps you set up other tools. It keeps your measurements correct.

Clean your tools after you use them. Store them in a dry, padded case. Check for damage often. Replace worn parts fast to avoid mistakes.

A caliper measures inside, outside, and depth sizes. A micrometer measures very small features with more accuracy. Use a caliper for general jobs. Use a micrometer for tight limits.

Digital tools help you read measurements faster. They lower mistakes. You can use analog tools too. Digital tools work better in busy shops.