When considering what the manufacturing processes for custom metal machined parts are, it’s important to select the most suitable method for machining manufacturers. The primary manufacturing processes for custom metal machined parts include CNC machining, additive manufacturing, and sheet metal fabrication. The table below outlines the manufacturing processes for custom metal machined parts and how each one operates:

| Manufacturing Process | Description |

|---|---|

| CNC Machining | Includes CNC milling and turning for precision parts. |

| Additive Manufacturing | Involves 3D printing techniques like FDM and SLA. |

| Sheet Metal Fabrication | Utilizes cutting technologies like laser and waterjet. |

By understanding what the manufacturing processes for custom metal machined parts are, we can better align the right process with your specific project requirements.

Key Takeaways

- CNC machining offers high precision and is ideal for creating complex parts with tight tolerances.

- Additive manufacturing, like 3D printing, allows for rapid prototyping and intricate designs, making it suitable for low-volume production.

- Sheet metal fabrication is efficient for producing simple shapes in large quantities, often at a lower cost.

- Material selection is crucial; different processes work better with specific metals, affecting cost and production speed.

- Custom machining is best for unique parts that require flexibility and quick adjustments without high tooling costs.

- Casting processes are effective for creating complex shapes but may not provide the same precision as machining.

- Understanding the differences in production speed and cost between machining and fabrication helps in choosing the right method.

- Consulting with manufacturers early in the process can guide you to the best manufacturing method for your specific needs.

Table of Contents

What Are the Manufacturing Processes for Custom Metal Machined Parts?

Overview of Main Methods

When you ask what the manufacturing processes for custom metal machined parts are, you find a range of options. There are various manufacturing processes, including CNC machining, casting, forging, metal injection molding, 3D printing, sheet metal fabrication, turning, milling, drilling, grinding, EDM, and welding. Each process shapes metal parts differently.

For example, CNC machining uses computer-controlled tools to cut and shape metal parts with high precision. We might use CNC machining to create a custom bracket for an automotive application.

Casting involves pouring molten metal into a mold. We could use casting to produce a custom gear for heavy machinery.

Forging uses force to shape metal parts, such as a custom crankshaft for an engine.

Metal injection molding combines metal powder and binder, then injects the mixture into a mold. We might select this process for small, complex custom parts.

3D printing builds metal parts layer by layer. We can use 3D printing for prototyping a custom heat sink.

Sheet metal fabrication includes cutting, bending, and assembling metal sheets. We might use this process to create custom enclosures for electronics.

You can see the differences between traditional and modern manufacturing processes in the table below:

| Feature | Custom Machining | Standard Machining |

|---|---|---|

| Production Volume | Small batches or single units | Large volumes of identical parts |

| Flexibility | High, tailored solutions | Limited, predefined specifications |

| Cost | Higher due to unique setups | Lower due to mass production efficiencies |

| Precision | High, capable of complex geometries | Moderate, suitable for simpler shapes |

You can also compare CNC metal machining and traditional processing:

| Feature | CNC Metal Machining | Traditional Processing |

|---|---|---|

| Precision | Up to ±0.005 mm | Typically ±0.1 mm or more |

| Repeatability | High (automated control) | Variable (manual-dependent) |

| Complexity of Parts | High (3D surfaces, multi-axis cutting) | Limited to simpler shapes |

Key Considerations for Process Selection

When selecting a manufacturing process for custom metalworking parts, several key factors should be considered. The type of material is one of the factors to consider. For example, you might choose CNC machining for aluminum because it offers predictable machining behavior and high precision. Stainless steel also works well with CNC machining, but you need to consider tool wear. Titanium requires CNC machining, but its hardness increases tool wear and cost. Plastics can be used in various processes, often with less finishing required.

| Material Type | Suitable Manufacturing Process | Key Considerations |

|---|---|---|

| Aluminum | CNC Machining | Predictable machining behavior, high precision |

| Stainless Steel | CNC Machining | Achieves tight tolerances, tool wear considerations |

| Titanium | CNC Machining | High hardness affects tool wear and costs |

| Plastics | Various Processes | Less tool wear, often requires less finishing |

As your machined parts supplier, we also need to consider the complexity of the parts, production volume, and cost. If you need a custom prototype, we might use 3D printing or CNC machining. For large quantities of simple metal parts, we might choose stamping or casting. If you want high quality and tight tolerances, CNC machining or the additive manufacturing process works well. We can use metal fabrication methods like laser cutting for complex shapes, welding for joining parts, and finishing processes like grinding for smooth surfaces.

Tip: We will select the appropriate manufacturing processes based on your project goals and the specific requirements of the metal parts. For example, if you need a custom enclosure for electronics, sheet metal fabrication offers flexibility. If you need a custom gear with complex geometry, CNC machining provides precision.

We can also use custom machining processes to achieve high quality and flexibility for unique metal parts. We choose additive manufacturing for rapid prototyping or CNC machining for tight tolerances. We can use metal fabrication for assembling multiple parts. We choose the right process by considering material, complexity, volume, and cost.

Equivalent manufacturing process

Sand Casting

How Sand Casting Works

Sand casting is a process of manufacturing metal parts by filling sand around a mold. We remove the pattern and pour molten metal into the cavity. The sand mold shapes the metal as it cools. We broke the mold to release the finished part. We can use sand casting for custom metal parts like pump housings or brackets. We often select sand casting for stainless steel and cast iron components. We see sand casting in the production of large steel valves and stainless steel flanges.

Applications

Sand casting is widely used in various industries. For example, it is used in the manufacture of automotive engine blocks, stainless steel pipe fittings, and steel gear blanks. In addition, it is applied in fields such as agricultural machinery, construction equipment, and marine hardware. Sand casting can produce customized metal parts in various quantities. For steel and stainless steel parts requiring flexible design, sand casting is often a good choice.

Sand casting remains one of the most widely used methods for custom metal parts. You see cast iron at 48% market share, aluminum at 27%, steel at 13%, zinc at 6%, magnesium at 4%, and others at 2%. You rely on sand casting for a wide range of metal types.

Pros & Cons

You compare sand casting to other manufacturing processes. You see versatility and low cost. You use simple tooling and scale up production easily. We adapt sand casting for different part sizes and materials. We achieve fast turnaround and few design limitations. We use sand casting for custom metal parts with a lower ecological footprint.

| Casting Method | Advantages | Disadvantages |

|---|---|---|

| Sand Casting | 1. Versatility 2. Low cost 3. Simple tooling 4. Adaptability 5. Easy scale-up 6. Fast turnaround 7. Few design limitations 8. Wide range of materials 9. Wide spectrum of part sizes 10. Lower ecological footprint | 1. Poor surface finish 2. Variable dimensional accuracy 3. Contaminated sand waste 4. Pattern degradation 5. Uncontrolled cooling rates 6. Handling complex cores 7. Requires skilled labor 8. Moderate to high automation costs 9. Low sand reusability |

Metal parts produced by sand casting have inconsistent surface quality, and there are variations in dimensional accuracy between parts. This process also involves dealing with contaminated sand waste and mold damage. Skilled workers are required to achieve high-quality finished products. Furthermore, you’ll find that automation costs are high, and the sand molds have a low rate of reusability.

Investment Casting / Lost-wax

How Investment Casting / Lost-wax Works

Investment casting is used to manufacture metal parts. First, a wax pattern is created, and then a ceramic material is coated onto the wax pattern. Next, the wax pattern is melted, and molten metal is poured into the ceramic mold. Finally, the mold is broken open to retrieve the finished part. Investment casting is commonly used for custom stainless steel turbine blades and steel medical instruments. It is an ideal choice for parts with complex shapes and tight tolerance requirements.

Applications

Precision casting is widely used in the aerospace, medical, and automotive industries. It is used to manufacture stainless steel surgical instruments, steel impellers, and custom metal jewelry. Precision casting is also used to produce stainless steel valves and steel brackets. It is ideal for parts requiring high dimensional accuracy and a high-quality surface finish.

Investment casting is suitable for ferrous metals such as stainless steel and steel. This process is ideal for custom metal parts that require reduced machining and precise details.

Pros & Cons

You can compare investment casting with sand casting. Investment casting offers higher dimensional accuracy and superior surface finish, reduces machining costs, and is suitable for ferrous metals. Investment casting can be used to manufacture custom metal parts with complex geometries.

| Casting Method | Advantages | Disadvantages |

|---|---|---|

| Investment Casting | 1. Superior dimensional accuracy 2. Excellent surface finish 3. Reduced machining costs 4. Ability to work with ferrous metals | 1. Higher cost 2. Longer production time 3. Complex mold manufacturing 4. Not suitable for large parts |

Permanent Mold / Gravity Die

How Permanent Mold / Gravity Die Works

Permanent mold casting is a process of manufacturing metal parts by pouring molten metal into reusable steel or cast iron molds. Under gravity, the metal fills the mold without the need for external pressure. The mold is then opened, and the finished part is removed. Permanent mold casting is commonly used for custom aluminum alloy wheels and stainless steel fittings. It is an ideal choice for parts requiring consistent quality and repeatable shapes.

Applications

Permanent mold casting is widely used in the automotive, marine, and electrical industries. It can be used to manufacture aluminum pistons, stainless steel connectors, and steel housings. Permanent mold casting is also used in the production of custom metal parts such as lighting fixtures and pump bodies. It is also an ideal choice for medium-volume production of stainless steel and steel components.

Permanent mold casting works well for aluminum, steel, and stainless steel. You use this process for custom metal parts that need improved mechanical properties.

Pros & Cons

Compared to sand casting, permanent mold casting yields better surface quality and dimensional consistency. The molds are reusable for multiple production cycles. For medium-volume production, it offers faster production speeds and lower unit costs. Permanent mold casting can be used to manufacture custom metal parts with uniform wall thickness.

- Pros:

- Improved surface quality

- Consistent dimensions

- Reusable molds

- Faster production rates

- Lower cost for medium volumes

- Cons:

- Limited to simpler shapes

- Higher initial tooling cost

- Not suitable for very large parts

- Restricted to metals with low melting points

For complex, custom metal parts, permanent mold casting should be avoided. Molds for high-melting-point metals (such as stainless steel) are more expensive and have numerous limitations.

Low-pressure Die Casting

How Low-pressure Die Casting Works

Low-pressure die casting is a metal parts manufacturing process in which molten metal is injected into a permanent mold from below. The mold is placed above a sealed furnace, and low-pressure air is applied to force the molten steel or aluminum upward through a pipe into the mold cavity. The pressure is maintained until the metal solidifies. After cooling, the finished part is removed. This process is suitable for custom parts requiring uniform wall thickness and excellent mechanical properties. Low-pressure die casting is commonly used to manufacture aluminum wheels, stainless steel pump bodies, and steel housings.

Applications

Low-pressure die casting technology is widely used in the automotive industry, for example, in the manufacturing of aluminum alloy wheels, steel suspension components, and stainless steel brake parts. In addition, this process is also used in the aerospace industry for custom metal parts, such as stainless steel brackets and steel structural components. It can also produce stainless steel impellers for pumps and steel casings for industrial equipment. If you require high-quality, repeatable production of custom metal parts, low-pressure die casting is an ideal choice.

Pros & Cons

Low-pressure die casting offers numerous advantages. It allows for better control of the filling process, thus reducing porosity in the finished metal parts. It also results in superior mechanical properties compared to gravity die casting. The molds can be reused multiple times, reducing costs for medium-volume production. Furthermore, it enables the production of high-quality stainless steel and steel parts with consistent quality.

However, this process also has some limitations. Compared to sand casting, the initial mold costs are higher. Furthermore, it is not suitable for very large metal parts. The complexity of the part geometry also needs to be limited. Additionally, low-pressure die casting is more suitable for metals with lower melting points, such as aluminum, steel, and stainless steel.

High-pressure Die Casting

How High-pressure Die Casting Works

High-pressure die casting is a process in which molten metal is injected into a steel mold at high speed and high pressure. The mold is tightly closed, allowing the metal to completely fill every corner of the cavity. The pressure is maintained until the metal solidifies. The mold is then opened, and the finished part is removed. This process is suitable for custom metal parts requiring precise dimensions and smooth surfaces. High-pressure die casting is commonly used for the mass production of steel, stainless steel, and aluminum parts.

Applications

High-pressure die casting technology is used in many industries. In the automotive industry, it is used to manufacture engine blocks, transmission housings, and oil pans. In the aerospace sector, it is used to manufacture lightweight structural components and aircraft engine valves. In the electronics industry, it is used to manufacture mobile phone parts, miniature toys, and heat sinks. In the medical device field, high-pressure die casting technology is also used to manufacture surgical instruments and imaging equipment housings. In the industrial sector, it is used to manufacture marine propellers, gas valves, and gearbox housings. In the consumer goods sector, it is used to manufacture lighting fixtures and household appliances.

| Industry | Common Applications |

|---|---|

| Automotive | Engine blocks, Transmission casings, Oil sumps |

| Aerospace | Aircraft engine valves, Lightweight structural components |

| Electronics | Cell-phone parts, Miniature toys, Heat sinks |

| Medical | Surgical tools, Imaging equipment casings |

| Industrial | Marine propellers, Gas valves, Transmission housings |

| Consumer Goods | Lighting fixtures, Household appliances |

Pros & Cons

When you need large quantities of custom metal parts, high-pressure die casting is the ideal choice. It allows for tight tolerance control and smooth surfaces, reducing the need for secondary processing, and can produce complex-shaped parts from various materials such as steel, stainless steel, and aluminum.

You also face some challenges. For example, initial mold costs are high. Due to machine capacity limitations, you need to limit part sizes. High-pressure die casting is best suited for non-ferrous metals, but it can also be used for steel and stainless steel with specialized equipment.

Counter-pressure Casting

How Counter-pressure Casting Works

Counter-pressure casting involves applying gas pressure above the metal bath and a vacuum below the mold to inject molten metal into the mold cavity. By controlling the pressure difference, molten steel or stainless steel can be injected into the mold. The pressure is maintained until the metal solidifies. After cooling, the finished part is removed. This process is suitable for custom metal parts requiring high density and low porosity.

Applications

In the automotive industry, counter-pressure casting is used to manufacture steel wheel hubs and stainless steel suspension arms. In the aerospace sector, it is used to produce stainless steel brackets and steel structural components. Additionally, it is used to produce custom metal parts for pumps, valves, and industrial machinery. Counter-pressure casting is the ideal choice when you require high-quality, high-density steel or stainless steel parts with minimal defects.

Pros & Cons

The counter-pressure casting process offers several advantages. It results in finished metal parts with high density and low porosity, improves the mechanical properties of steel and stainless steel components, reduces the risk of gas inclusions and shrinkage defects, and allows for the production of complex, customized parts.

Of course, this method also has some drawbacks. Equipment and tooling costs are high, precise control of the process is required, and the production cycle may be longer compared to other casting methods. Counter-pressure casting is best suited for medium-sized steel and stainless steel parts.

Squeeze Casting + Vacuum

How Squeeze Casting + Vacuum Works

Vacuum die casting is a process used to produce metal parts by pouring molten steel or aluminum into a preheated mold. First, a vacuum is applied to remove air from the mold cavity. Then, the mold is closed and high pressure is applied to force the metal into every detail of the mold. The vacuum ensures the removal of gases and reduces porosity. The pressure is maintained until the metal solidifies. Finally, the mold is opened and the finished part is removed. This method is commonly used to manufacture custom parts requiring high density and minimal defects. For example, vacuum die casting can be used to manufacture steel suspension arms or aluminum alloy wheels for automobiles.

Applications

Vacuum die casting is widely used in the automotive industry, for example, in the manufacturing of steel brake calipers, aluminum engine mounts, and custom transmission housings. This process is also used in the production of metal parts for industrial pumps and compressors, such as steel hydraulic components or custom brackets. Vacuum die casting is particularly important when high-strength, low-porosity parts are required. For example, steel gears for heavy machinery or custom metal housings for electrical equipment may utilize the vacuum die casting process.

Pros & Cons

Squeeze casting combined with vacuum technology offers numerous advantages. It enables high density and low porosity in steel and aluminum parts, improves the mechanical properties of custom metal components, reduces the risk of gas inclusions and shrinkage, and results in a better surface finish compared to traditional casting methods. However, this process also presents challenges such as higher equipment costs, more complex setup requirements, the need for precise process control, and potentially longer production cycles compared to other manufacturing methods.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Squeeze Casting + Vacuum | High density, low porosity, improved mechanical properties, better surface finish | Higher equipment cost, complex setup, longer cycle times |

You should consider squeeze casting with vacuum when you need custom steel parts with high quality and minimal defects.

Squeeze Casting / Liquid Forging

How Squeeze Casting / Liquid Forging Works

Squeeze casting (also known as liquid forging) involves pouring molten steel or aluminum into a mold, then closing the mold and applying high pressure to rapidly fill the mold cavity and solidify the metal. The part is then removed after cooling. This process is suitable for manufacturing custom parts requiring high strength and precise dimensions. For example, squeeze casting can be used to manufacture steel connecting rods or custom metal brackets.

Applications

In the automotive industry, extrusion casting is widely used. It is employed in the manufacturing of steel steering knuckles, aluminum alloy wheels, and custom suspension components. Furthermore, it is also used to produce metal parts for agricultural machinery and industrial equipment. For example, extrusion casting can be used to manufacture steel pump housings or custom metal levers. Extrusion casting is an ideal choice when high-strength and consistently high-quality parts are required. For instance, steel gears in construction machinery or custom metal frames for heavy-duty tools can be manufactured using the extrusion casting process.

Pros & Cons

The advantages of squeeze casting lie in its ability to produce high-strength, dimensionally accurate steel and aluminum parts. It reduces porosity, improves the mechanical properties of custom metal components, and achieves a better surface finish than sand casting. However, squeeze casting also has some drawbacks, such as higher mold costs, more complex mold structures, limitations on part size and complexity, and potentially longer setup times compared to other manufacturing processes.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Squeeze Casting / Liquid Forging | High strength, good dimensional accuracy, reduced porosity, improved mechanical properties | Higher tooling cost, complex dies, limited part size and complexity |

You should use squeeze casting or liquid forging when you need custom steel parts with high strength and reliable performance.

Semi-solid Casting

How Semi-solid Casting Works

Semi-solid casting is a process for producing metal parts by partially melting steel or aluminum. First, the metal is stirred to form a slurry consisting of a mixture of solid and liquid phases. Then, the slurry is injected into a mold under pressure. The semi-solid nature allows the metal to flow easily and fill the mold cavity. The pressure is maintained until the part solidifies. Finally, the finished part is removed from the mold. This process is suitable for custom parts requiring complex shapes and high mechanical properties. For example, semi-solid casting can be used to manufacture automotive steel control arms or custom metal housings.

Applications

Semi-solid casting is widely used in the automotive and aerospace industries. It is used to manufacture steel suspension components, aluminum brackets, and custom gearboxes. In addition, this process is also used in the production of metal parts for medical devices and industrial machinery. For example, semi-solid casting can be used to manufacture steel pump impellers or custom metal connectors. Semi-solid casting is ideal when manufacturing parts with thin walls and complex geometries. For instance, it can be used to manufacture steel gearbox housings or custom metal casings for electronic devices.

Pros & Cons

Semi-solid casting offers numerous advantages. It allows for excellent mechanical properties and dimensional accuracy in steel and aluminum parts, reduces porosity, and improves the surface finish of custom metal components. It also enables the production of thin-walled and complex-shaped parts. However, semi-solid casting also involves higher equipment costs and more complex process control, and requires limitations on part size. Compared to other manufacturing methods, its development cycle may also be longer.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Semi-solid Casting | High mechanical properties, good dimensional accuracy, reduced porosity, thin walls, complex shapes | Higher equipment cost, complex process control, limited part size, longer development time |

You should consider semi-solid casting when you need custom steel parts with complex geometry and high mechanical performance. You can also use this process for rapid prototyping with 3d printing to test new designs.

Centrifugal Casting

How Centrifugal Casting Works

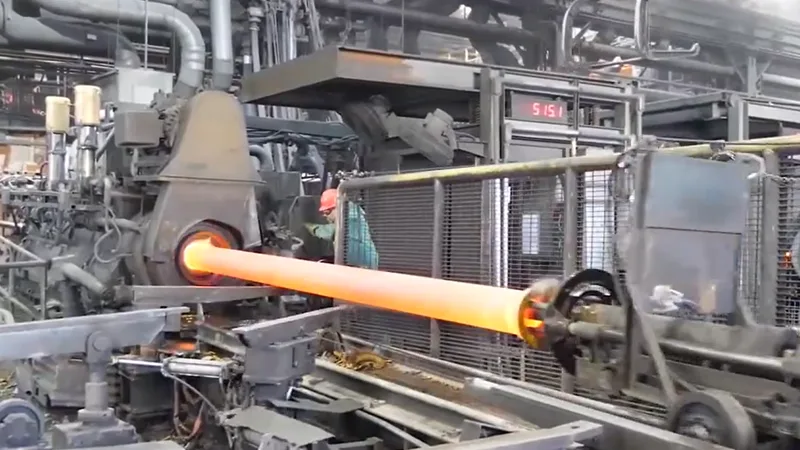

Centrifugal casting is a process for producing metal parts by pouring molten steel into a rotating mold. The mold rotates at high speed, and the centrifugal force pushes the metal outward against the mold walls. As the mold continues to rotate, the metal gradually solidifies. After cooling, the finished part can be removed. This process is commonly used to produce cylindrical steel parts, such as steel pipes or bushings with uniform density.

Applications

Centrifugal casting is widely used in industries that require circular metal parts. For example, it is used to manufacture steel pipes for water supply systems and steel rings for heavy machinery. In the automotive industry, it is used to manufacture steel cylinder liners for engines. In addition, centrifugal casting is used to produce custom bushings for mining equipment. The centrifugal casting process is ideal when parts with uniform wall thickness and high strength are required.

Centrifugal casting helps you achieve uniform quality in steel parts. You rely on this method for components that must withstand pressure and wear.

Pros & Cons

| Pros | Cons |

|---|---|

| High density and strength | Limited to round shapes |

| Few impurities in finished metal | High equipment cost |

| Good for large steel parts | Not suitable for complex geometries |

| Uniform wall thickness | Requires precise control of rotation speed |

Centrifugal casting is ideal when you need high-density, low-impurity steel parts. However, it does have some limitations if you require complex shapes or non-cylindrical parts.

Continuous Casting

How Continuous Casting Works

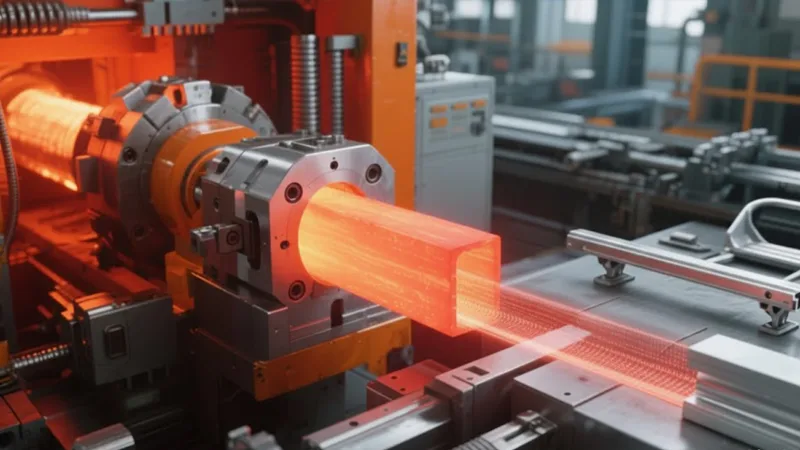

Continuous casting involves pouring molten steel into a water-cooled mold to produce metal parts. The molten steel gradually solidifies as it flows through the mold. The solidified steel is then cut into the desired lengths. This process is suitable for the large-scale production of steel billets, slabs, and bars. By adjusting the mold design, it is also possible to manufacture parts of various customized shapes.

Applications

Continuous casting is widely used in steel mills and metal processing plants. It is used to produce steel billets for subsequent processing. Additionally, it is used to produce steel slabs for rolling into steel plates. In the construction industry, continuous casting is used to produce reinforcing bars to strengthen concrete. In the shipbuilding industry, continuous casting is also used to produce custom-made steel bars. Continuous casting is ideal when large-scale production and consistent product quality are required.

Continuous casting allows you to produce steel parts efficiently. You use this method to supply raw material for other manufacturing processes.

Pros & Cons

| Pros | Cons |

|---|---|

| High production rate | Limited to simple shapes |

| Consistent quality | High initial setup cost |

| Reduced waste | Not ideal for small custom batches |

| Good for large steel parts | Requires continuous operation |

Continuous casting technology offers significant advantages in the production of large quantities of steel parts.

Vacuum Casting

How Vacuum Casting Works

Vacuum casting involves pouring molten steel into a sealed mold to produce metal parts. Vacuum is applied to remove air and gases from the mold cavity, allowing the metal to fully fill every detail of the mold. After cooling, the finished part can be removed. This process is suitable for custom steel parts requiring high surface quality and low porosity.

Applications

Vacuum casting is widely used in industries requiring precision metal parts. For example, it is used to manufacture steel turbine blades for power generation, and to produce complex-shaped steel medical implants. In the aerospace industry, vacuum casting is used to manufacture custom steel brackets for aircraft. Additionally, it is used in the production of stainless steel jewelry. The vacuum casting process is ideal when fine detail and high integrity parts are required.

Vacuum casting helps you achieve high quality in steel parts. You rely on this method for components that must meet strict standards.

Pros & Cons

| Pros | Cons |

|---|---|

| Low porosity and high integrity | Higher cost than other casting methods |

| Good for complex steel parts | Limited to small and medium sizes |

| Excellent surface finish | Requires specialized equipment |

| Suitable for custom production | Longer cycle times |

When your product requires low porosity and fine details, we recommend using the vacuum casting process. However, this will also result in higher costs and longer production cycles.

Ceramic Mold Casting

How Ceramic Mold Casting Works

Ceramic mold casting is achieved by creating a ceramic mold. First, a wax or plastic pattern is used. The pattern is dipped into a ceramic slurry, and then coated with a layer of fine ceramic sand. This process is repeated, gradually building up layers. The pattern is then heated to remove it, leaving a hollow ceramic mold. Molten metal is poured into the mold. The ceramic mold maintains its shape as the metal cools and solidifies. Finally, the mold is broken to remove the finished product. For example, stainless steel turbine blades can be produced using the ceramic mold casting process.

Applications

Ceramic mold casting is widely used in industries requiring complex shapes and fine details. For example, it is used in the aerospace industry to manufacture stainless steel turbine blades; in the medical device manufacturing industry to produce surgical instruments; in the automotive industry to create small gears and brackets; and also in jewelry production, such as for custom rings and pendants.

You select ceramic mold casting when you need parts with intricate features and smooth surfaces.

Pros & Cons

| Pros | Cons |

|---|---|

| High dimensional accuracy can be achieved | Facing higher production costs |

| The manufactured parts have very fine details | Longer delivery times are required |

| A wide variety of metals are involved | The mold must be broken after each use |

| A smooth surface finish can be achieved | Due to limitations in mold strength, the size of the parts is restricted |

Ceramic mold casting is suitable for producing precise and complex metal parts. However, its disadvantages include higher costs and longer production cycles, as a new mold needs to be made for each part, which increases production costs.

Graphite Mold Casting

How Graphite Mold Casting Works

Graphite mold casting is a method that utilizes graphite blocks to create molds. First, the graphite block is machined into the desired shape of the part. Then, molten metal is poured into the graphite mold. This mold is resistant to high temperatures and does not react with most metals. After the metal cools and solidifies, the mold can be opened. Graphite molds are reusable and can be used for multiple castings. For example, graphite mold casting can be used to produce copper electrical contacts.

Applications

In the electronics industry, graphite mold casting is used to manufacture copper and silver contacts. In jewelry making, it is used to create gold and silver rings. In the aerospace sector, this process is also used to manufacture small aluminum components. Furthermore, graphite mold casting is used to manufacture laboratory equipment, such as platinum crucibles.

You choose graphite mold casting when you need high purity and smooth surfaces in your metal parts.

Pros & Cons

| Pros | Cons |

|---|---|

| The mold can be reused multiple times | Wear and tear will limit the lifespan of the mold. |

| High purity can be achieved through metal casting | The dimensions of the parts must be limited based on the strength of the mold |

| A smooth surface finish can be achieved | Facing higher mold processing costs |

| Engaged in work related to reactive metals | Graphite dust must be dealt with. |

You benefit from graphite mold casting when you need clean, smooth metal parts. However, mold wear and dust problems mean that the molds must be replaced after only a few uses, which increases mold costs, and frequent mold changes also increase product manufacturing time.

Shell Mold Casting

How Shell Mold Casting Works

The principle of shell molding involves first creating a thin shell using sand and resin. A metal pattern is heated, and then a mixture of sand and thermosetting resin is applied to it. The heat hardens the resin, forming a shell around the pattern. This shell is then removed and assembled with other shell pieces to form a complete mold. Molten metal is poured into the shell mold. The shell maintains its shape as the metal cools and solidifies. Finally, the shell is broken away to reveal the finished product. For example, shell molding can be used to produce steel valve bodies.

Applications

In the automotive industry, shell molding is used to manufacture steel camshafts and brackets. In pump manufacturing, this process is also used to produce impellers. Furthermore, shell molding is used to produce small gears and levers for machinery. It is also used in the manufacture of hardware items such as door handles and lock components.

You select shell mold casting when you need parts with good dimensional accuracy and smooth surfaces.

Pros & Cons

| Pros | Cons |

|---|---|

| Better surface finish can be achieved | You face higher material costs |

| Dimensional accuracy has been improved | The mold must be broken after each use |

| Suitable for producing a thin-walled part | The dimensions of the parts must be limited to within the strength limits of the housing |

| Process automation can be easily implemented | Precise temperature control is required |

When you need precise, smooth metal parts, you can consider using the shell molding casting process.

Lost-foam / Full-mold

How Lost-foam / Full-mold Works

Using the lost-foam casting method, metal parts can be manufactured by shaping a foam model. First, the foam is coated with a layer of ceramic slurry or sand. Then, molten metal is poured directly onto the foam. As the foam vaporizes, the metal fills the cavity. Finally, the mold is broken to remove the finished part. For example, aluminum engine blocks can be produced using the lost-foam casting method. Steel pump casings can also be manufactured using this method.

Applications

In the automotive industry, lost foam casting is widely used. It is employed in the manufacturing of engine blocks, cylinder heads, and transmission housings. This process is also used in the production of pumps and valves. Furthermore, lost foam casting can be used to create custom metal sculptures or prototypes. This process is particularly suitable when complex shapes are required, and subsequent machining needs to be minimized.

You can produce intricate steel or aluminum parts with lost-foam casting. You often select this method for parts with internal channels or thin walls.

Pros & Cons

| Pros | Cons |

|---|---|

| Complex shapes have been achieved | Facing model vulnerabilities |

| Reduce processing requirements | There will be different surface finishes |

| Reduce mold costs | Foam and steam emissions must be dealt with. |

| Engaged in various metal-related work | Mold strength will limit part size |

You can get more benefits from lost-foam casting when you need detailed metal parts.

Vacuum HPDC

How Vacuum HPDC Works

Vacuum high-pressure die casting (HPDC) is a process in which molten metal is injected into a sealed mold. First, a vacuum is applied to remove air and gases from the mold cavity. Then, the metal is injected into the mold at high speed and high pressure. The vacuum reduces porosity and improves part quality. Finally, the mold is opened, and the finished part is removed. For example, the vacuum high-pressure die casting process can be used to produce aluminum automotive wheels. In addition, this process can also be used to manufacture magnesium alloy electronic housings.

Applications

Vacuum high-pressure die casting (HPDC) technology is widely used in the automotive and electronics industries, for example, in the production of wheels, gearbox housings, and engine covers. It is also used to produce lightweight magnesium alloy components for laptops and cameras. Furthermore, vacuum high-pressure die casting can be used for custom-made medical device housings. Vacuum high-pressure die casting is ideal when high strength and a smooth surface finish are required.

You select vacuum HPDC for parts that require minimal defects and tight tolerances. You often use this method for high-volume production.

Pros & Cons

| Pros | Cons |

|---|---|

| Low porosity has been achieved | They will face higher equipment costs |

| Improve mechanical properties | Precise process control is required |

| To create a smooth surface. | The size of the parts is limited by the machine’s production capacity |

| Production speed has been increased | Skilled operators are required |

You benefit from vacuum HPDC when you need strong, defect-free metal parts.

Spray Forming / Osprey

How Spray Forming / Osprey Works

Spray forming technology utilizes gas atomization of molten metal to manufacture metal parts. Molten metal droplets are sprayed onto a rotating target or substrate, and the droplets solidify to form a dense preform close to the final shape. The part is then machined to its final dimensions. For example, spray forming technology can be used to produce tool steel preforms and also to manufacture aluminum alloy blanks required for aerospace components.

Applications

Spray forming technology is widely used in the tool manufacturing field, for example, in the production of high-speed steel billets and high-temperature alloy preforms. In the aerospace industry, this process is also used to manufacture turbine disc blanks. Furthermore, spray forming technology can be used to customize aluminum alloy wheel hubs or copper electrical contacts. Spray forming is particularly suitable when fine microstructures and superior performance are required.

You select spray forming for parts that require high strength and uniform composition. You often use this method for specialty alloys.

Pros & Cons

| Pros | Cons |

|---|---|

| Obtain a fine microstructure | Facing high equipment costs |

| Reduced the need for isolation | Post-processing is required |

| Generate near-net shape | The spray coating setup limits the size of the parts |

| Using various alloys | Technical expertise is required |

You benefit from spray forming when you need advanced metal billets. Of course, the finished parts with machined after forming.

Open-die Forging

How Open-die Forging Works

Open die forging involves forging metal parts between flat or curved dies. The heated metal billet is placed on the lower die, and then the upper die is struck with a hammer or press to shape the billet. During the forging process, you can control the movement and position of the metal. By rotating or moving the billet, you can adjust the shape of the part. Open die forging is commonly used to manufacture large steel shafts, custom rings, or discs. For example, you can use this method to produce steel shafts for wind turbines.

Applications

Open die forging is commonly found in industries that require large or custom-shaped metal parts. For example, it is used to manufacture steel flanges for pipes, rings for bearings, and discs for heavy machinery. In the shipbuilding industry, open die forging is also used to manufacture propeller shafts. Furthermore, in the power generation industry, it is used to manufacture turbine rotors. Open die forging is the ideal choice when you need flexibility in size and shape.

Pros & Cons

Using open-die forging offers numerous advantages. We can control the grain flow, thereby improving strength and toughness. We can produce parts with excellent fatigue resistance. It also avoids expensive tooling costs. Furthermore, it allows for the manufacturing of large parts with customized dimensions.

We also face some limitations. The dimensional accuracy of the manufactured parts is generally average. Furthermore, skilled operators are required to control the machining process. If the parts have strict tolerance requirements, we may need to perform post-processing.

| Aspect | Open Die Forging |

|---|---|

| Dimensional Accuracy | Moderate precision |

| Typical Products | Shafts, rings, flanges, discs |

| Material Flow | Controlled by operator or automation |

You should choose open-die forging when you need large steel shafts or custom rings for heavy equipment.

Closed-die Forging

How Closed-die Forging Works

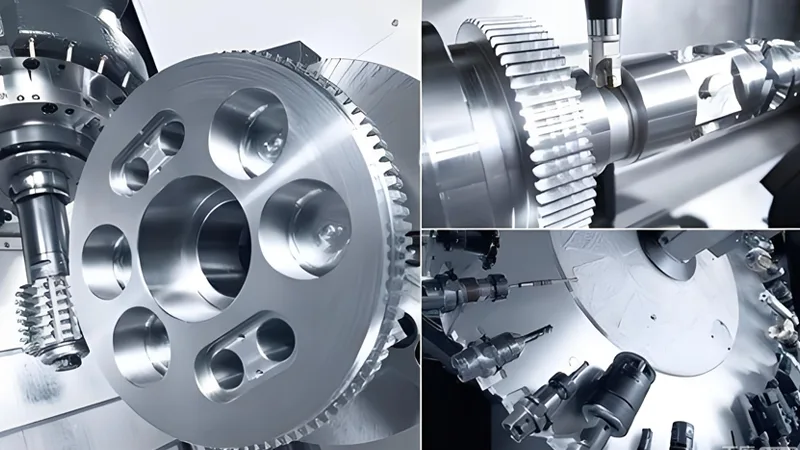

Closed-die forging is a process of forging metal parts within a die cavity. A heated steel billet is placed in the lower die, the upper die is closed, and pressure is applied. The metal fills the die cavity and takes its shape. After forging is complete, the finished part is removed. Closed-die forging is commonly used to manufacture steel gears, shafts, and valve bodies. For example, this method can be used to produce steel gears for automotive transmissions.

Applications

Closed-die forging is widely used in industries that require mass production of precision metal parts. For example, it is used to manufacture steel gears for vehicles, connecting rods for machinery, and flange nuts for pipelines. In the aerospace industry, closed-die forging is also used to manufacture landing gear components. Furthermore, in the oil and gas industry, it is used to manufacture valve bodies. Closed-die forging is ideal when strict tolerances and repeatable shapes are required.

Pros & Cons

The closed-die forging process offers several advantages. It enables high dimensional accuracy and repeatability, produces complex shapes with extremely tight tolerances, minimizes post-processing, and improves efficiency in high-volume production.

| Aspect | Closed Die Forging |

|---|---|

| Dimensional Accuracy | High precision and repeatability |

| Typical Products | Gears, rods, valve bodies, flange nuts |

| Material Flow | Confined within the die cavity |

You should select closed-die forging when you need steel gears or valve bodies with precise dimensions.

Precision Forging

How Precision Forging Works

Precision forging is a method for manufacturing metal parts with extremely tight tolerance requirements. First, the workpiece is heated and then placed into a specially designed mold. Controlled pressure is then applied to forge the metal. The entire process requires monitoring to ensure accuracy. Precision forging is commonly used in the manufacture of aerospace components, medical implants, or automotive parts. For example, you can use precision forging to produce titanium alloy hip joint implants.

Applications

Precision forging is widely used in industries that require extremely high dimensional accuracy and have low production volumes. For example, it is used in the manufacture of turbine blades for jet engines, orthopedic implants, and connecting rods for high-performance engines. In the electronics industry, precision forging is also commonly used to manufacture miniature connectors. When you need to manufacture parts with complex shapes and tight tolerances, precision forging is undoubtedly the ideal choice.

Pros & Cons

Precision forging offers numerous benefits. It allows for near-net-shape parts, thus reducing subsequent machining. It also produces parts with high surface quality. Furthermore, it enables the maintenance of tight tolerances and consistent performance.

- By producing near-net-shape parts, subsequent machining can be minimized.

- High surface quality and tight tolerances can be achieved.

- It maintained stable mechanical properties.

| Feature | Precision Forging |

|---|---|

| Tolerances | Very tight |

| Surface Quality | High |

| Machining Required | Minimal |

| Typical Products | Turbine blades, implants, connectors |

You should use precision forging when you need titanium implants or turbine blades with exact dimensions.

Hot-die & High-speed Forging

How Hot-die & High-speed Forging Works

When rapid forming of metal parts is required, hot die forging can be used. First, the mold and metal blank are heated to a high temperature. Then, the blank is placed between the molds, and rapid, high pressure is applied. The heated molds prevent the metal from cooling too quickly. This allows for rapid deformation while maintaining the metal’s ductility. High-speed forging presses are typically used to improve production efficiency. For example, this method can be used to produce steel connecting rods for engines or aluminum suspension arms for vehicles.

Applications

Hot die forging and high-speed forging are widely used in the automotive manufacturing industry, for example, in the production of steel crankshafts and aluminum wheel hubs. In the aerospace industry, this process is also used to manufacture titanium alloy landing gear components. Furthermore, it is used in the production of industrial tools such as steel wrenches and hammers. Hot die forging is ideal when parts with a uniform grain structure and high strength are required.

High-speed forging can increase output and shorten production cycles. This method is typically chosen for parts that require stable mechanical properties.

Pros & Cons

| Pros | Cons |

|---|---|

| High productivity has been achieved | Facing high equipment costs |

| It retained the ductility of the metal | Precise temperature control is required |

| The manufactured parts have a uniform grain structure | The size of the parts is limited by the capacity of the stamping press |

| Shorten the cycle time | Require skilled operators |

When you need a large quantity of high-strength metal parts, hot die forging and high-speed forging processes will offer you numerous benefits.

Isothermal Forging

How Isothermal Forging Works

Isothermal forging is a process of forging metal parts under constant temperature conditions. During the forging process, both the mold and the metal workpiece are heated to the same temperature, and this temperature is maintained throughout the process. Pressure is applied slowly to allow the metal to flow uniformly. This method is often used for forging difficult-to-forge metals, such as titanium alloys. For example, isothermal forging can be used to produce titanium alloy compressor blades for jet engines, and also nickel alloy rings for turbines.

Applications

Isothermal forging technology is widely used in the aerospace manufacturing industry, for example, in the production of titanium alloy aircraft fuselage components and nickel alloy turbine discs. This process is also used in the production of titanium alloy bone plates for medical devices. Furthermore, the energy industry utilizes isothermal forging technology to manufacture nickel alloy components in gas turbines. Isothermal forging is an ideal choice when manufacturing parts with complex shapes and tight tolerance requirements.

You can forge metals with low ductility using isothermal forging. You often choose this method for parts that require high accuracy and minimal defects.

Pros & Cons

| Pros | Cons |

|---|---|

| Precise tolerances have been achieved | Facing the problem of low productivity |

| Forging refractory metals | Requires high energy input |

| Reduce defects and cracks | Expensive equipment is required |

| To create complex shapes | The size of the parts is limited by the capacity of the mold |

When you need precise, defect-free metal parts, isothermal forging is the ideal choice.

Superplastic Forming

How Superplastic Forming Works

Superplastic forming is a manufacturing technique that creates metal parts by stretching metal sheets at high temperatures. First, the metal is heated to a superplastic state, allowing it to be stretched without fracturing. The sheet is then placed on a mold and gas pressure is applied. The metal flows into the mold and takes its shape. This method is often used to manufacture thin-walled, complex parts. For example, superplastic forming can be used to produce titanium alloy aircraft panels and aluminum car body panels.

Applications

In the aerospace industry, superplastic forming technology is used to manufacture titanium alloy wing panels and engine cowlings. In the automotive industry, it is used to manufacture aluminum body panels and heat shields. In medical device manufacturing, it is used to produce titanium alloy implant casings. In the electronics industry, it is also used to manufacture ultra-thin metal casings. When you need to manufacture lightweight and complex-shaped parts, superplastic forming technology is the ideal choice.

Using superplastic forming technology, parts with fine details and thin walls can be manufactured.

Pros & Cons

| Pros | Cons |

|---|---|

| Capable of producing thin-walled, complex parts | The formation process is slow |

| Achieve high formability | Precise temperature control is required |

| Reduce material waste | Special alloys are required |

| Creating lightweight components | Production was limited |

Superplastic forming technology can produce lightweight, high-precision metal parts. However, it also faces challenges such as slow forming speed and the need for specialized materials.

Roll Forging

How Roll Forging Works

Roll forging is a forming process that involves feeding a metal billet between two rotating rollers. Each roller has a specific groove pattern that gradually reduces the thickness of the metal and changes its cross-section. First, a heated billet is fed into the rollers. The rollers compress and stretch the billet as it passes through. This process is repeated until the desired shape is achieved. For example, roll forging can be used to manufacture truck axles.

Applications

In the automotive industry, roll forging is widely used. It can be used to produce axles, leaf springs, and hand tools. In the agricultural sector, roll forging is also used to manufacture plowshares and cultivator blades. In the construction industry, roll forging is used to manufacture structural steel bars and rods. For example, steel rods used in cranes can be manufactured through roll forging.

Pros & Cons

| Pros | Cons |

|---|---|

| High production efficiency | Limited to simple shapes |

| Good material utilization | Requires precise setup |

| Consistent product quality | Not suitable for small batches |

Roll forging is a highly efficient process when producing large quantities of parts (such as axles or rods). However, it can be challenging when producing complex shapes or small quantities of parts.

Ring Rolling

How Ring Rolling Works

Ring rolling is a process that enlarges a metal ring by reducing its wall thickness and increasing its diameter. First, you need a pre-formed ring, typically made by stamping a metal blank. The pre-formed ring is placed between two rollers: one roller drives the ring’s rotation, and the other applies pressure to thin the wall thickness. The ring continuously expands during rotation. By controlling the rolling process, you can obtain the desired diameter and wall thickness. For example, ring rolling can be used to manufacture bearing rings for wind turbines.

Applications

The roll forming process is used in industries that require large, high-strength ring-shaped components. For example, it is used to manufacture bearing rings for wind turbines, flanges for pipes, and gear blanks for heavy machinery. In the aerospace industry, roll forming is used to produce piston rings for jet engines. For instance, you might need to roll form steel rings for large industrial gearboxes.

Pros & Cons

| Pros | Cons |

|---|---|

| Produces seamless rings | Requires specialized equipment |

| Good mechanical properties | Limited to ring-shaped parts |

| Efficient material use | High initial investment |

You select ring rolling when you need strong, seamless rings for heavy-duty applications. You must invest in special machines and limit production to ring shapes.

Cross-wedge Rolling

How Cross-wedge Rolling Works

Cross-wedge rolling is a process in which a heated steel billet is rolled between two wedge-shaped dies to form shafts and similar parts. The dies move in opposite directions, with the wedge-shaped sections gradually reducing the billet’s diameter and increasing its length. This method can create features such as steps, tapers, and shoulders in a single operation. For example, cross-wedge rolling can be used to manufacture automotive drive shafts.

Applications

The cross-wedge rolling process is commonly used in automotive manufacturing, for example, in the production of drive shafts, axles, and camshafts. In the railway sector, it is used to manufacture train axles. The cross-wedge rolling process is also applied in tool production, such as in the manufacturing of chisels and punches. For example, this process can be used to manufacture steel axles for freight trains.

Pros & Cons

| Pros | Cons |

|---|---|

| High material yield | Complex die design |

| Short production cycle | Requires precise temperature control |

| Suitable for mass production | Not ideal for small quantities |

You benefit from cross-wedge rolling when you need to produce many shafts or axles quickly. You must design the dies carefully and control the temperature to avoid defects.

Rotary Forging

How Rotary Forging Works

Rotary forging is a process that uses the rotation of a workpiece and applied pressure to shape metal parts. The process uses a set of dies that move along a circular path. A heated billet is placed between the dies. The dies apply pressure to the billet as it rotates, causing the material to flow and form the desired shape. Rotary forging can produce parts with tapered or complex profiles. For example, you can use rotary forging to produce aluminum wheel rims for automobiles. This process allows for precise diameters and thicknesses to be achieved without removing excessive material.

Applications

Rotary forging is widely used in industries that require symmetrical circular parts. For example, it can be used to manufacture automotive wheel hubs, aerospace components, and gear blanks. In the aerospace industry, rotary forging can be used to produce titanium alloy compressor discs for jet engines. In the automotive industry, rotary forging can be used to manufacture lightweight aluminum alloy wheel hubs. Furthermore, rotary forging is also used to produce steel bearing races for heavy machinery.

Pros & Cons

| Pros | Cons |

|---|---|

| Reduce material waste | Limit shapes to round profiles |

| Achieve high strength | Need specialized equipment |

| Improve dimensional accuracy | Require skilled operators |

| Increase production speed | Higher initial investment |

Rotary forging helps you create strong, round parts with less waste. You should consider this process when you need high-strength wheels or disks.

Cold Forging / Cold Forming

How Cold Forging / Cold Forming Works

Cold forging is a process of shaping metal at room temperature. The process involves placing a metal blank into a die and then applying high pressure using a punch or press. The metal flows into the die and takes shape without the need for heating. This method can be used to manufacture items such as bolts, screws, and shafts. For example, cold forging can be used to produce the steel bolts needed for bridges. This process increases the strength of the metal through work hardening.

Applications

Cold forging is widely used in the production of fasteners, such as bolts, nuts, and rivets. In the automotive industry, it is used to manufacture drive shafts and axles. The electronics industry also uses cold forging to produce the small steel pins required for connectors. In the construction industry, cold forging is used to manufacture anchor bolts for concrete structures.

Pros & Cons

| Pros | Cons |

|---|---|

| Increase metal strength | Limit the complexity of shapes |

| Reduce energy consumption | Require high press forces |

| Achieve a good surface finish | Need secondary machining |

| Lower production costs | Restrict the size of parts |

Cold forging works well for high-volume production of simple, strong parts. You should use this process when you need bolts or shafts with consistent quality.

Cold Extrusion

How Cold Extrusion Works

Cold extrusion is a process of forcing metal through a die at room temperature. A metal billet is placed in an extrusion chamber, and a punch pushes the billet through the die, shaping the metal into the form of the die opening. This process can produce long, uniform cross-section parts. For example, you can use cold extrusion to manufacture the aluminum tubing for a bicycle frame. Since this process does not require heating, it saves energy.

Applications

Cold extrusion technology is widely used in the production of tubes, rods, and containers. In the automotive industry, it is used to produce aluminum drive shafts and steel steering columns. In the consumer goods industry, it is used to manufacture toothpaste tubes or battery casings. Furthermore, cold extrusion technology is also used to produce copper pipes for plumbing applications.

Pros & Cons

| Pros | Cons |

|---|---|

| Save energy by avoiding heating | Limit material types |

| Achieve smooth surface finishes | Require high-pressure equipment |

| Produce long, uniform parts | Restrict part complexity |

| Increase production efficiency | Need lubrication |

Cold extrusion offers you a way to make long, consistent parts quickly. You should consider this process for tubes, rods, or cases that need smooth surfaces.

Micro-extrusion

How Micro-extrusion Works

Micro-extrusion technology is used to manufacture precisely shaped miniature metal parts. First, a metal blank or rod is used. Then, the metal is extruded through a die with a tiny opening. The die shapes the metal as it passes through. The entire process is controlled by specialized machinery capable of handling these miniature dimensions. For example, this method can be used to produce miniature tubes for medical devices. Micro-extrusion technology is typically used to manufacture parts with a diameter of less than one millimeter.

Applications

Microextrusion technology is widely used in industries that require miniature components. In the medical field, it is used to manufacture stents and surgical catheters. In the electronics industry, it is used to manufacture miniature connectors and pins on circuit boards. Furthermore, microextrusion technology is also applied to automotive sensors and fuel injector components. For example, microextrusion technology can be used to manufacture tubing for catheters or miniature pins for smartphone connectors.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve high precision | Require specialized equipment |

| Produce very small parts | Higher production costs |

| Use a wide range of metals | need strict process control |

| Create complex profiles | Limit output to small volumes |

Micro-extrusion helps you manufacture parts that standard extrusion cannot produce. You can choose this process when you need miniature metal components with tight tolerances.

Powder Forging

How Powder Forging Works

Powder forging is a technique used to manufacture metal parts from metal powder. First, the metal powder is placed into a mold. Then, the powder is compressed under high pressure to form a dense powder compact. Next, the powder compact is heated in a furnace to allow the powder particles to bond together. Finally, the heated powder compact is placed in a closed mold and forged to obtain the final shape and density. For example, powder forging can be used to manufacture steel connecting rods for engines.

Applications

In the automotive industry, powder forging technology is widely used. It is employed in the production of gears, connecting rods, and camshafts. In the tool industry, it is used to manufacture wrenches and pliers. Furthermore, in the agricultural machinery sector, powder forging is also used to produce sprockets and levers. For example, you can use powder forging technology to produce gears for tractor transmissions.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve near-net-shape parts | Expensive dies |

| Reduce material waste | Require precise powder handling |

| Improve mechanical properties | Limits on part size |

| Combine different alloys | Need secondary machining |

Powder forging lets you combine different metals in one part. You should use this process when you want to reduce waste and improve part strength.

Fine-blanking

How Fine-blanking Works

Fine blanking is a process for cutting metal sheets into precise shapes. The metal sheet is placed between a punch and a die, and high pressure is applied to cleanly shear the metal. This process uses a triple-action press that firmly clamps the material, preventing deformation. This allows you to produce parts with smooth edges and extremely tight tolerances. For example, fine blanking can be used to manufacture steel gears for transmissions.

Applications

Precision blanking technology is widely used in the automotive industry to produce gears, clutch plates, and seat belt components. In the electronics industry, it is used to manufacture connectors and brackets. Furthermore, precision blanking technology is also applied in the manufacturing of hand tools, such as plier jaws and scissor blades. For example, automotive automatic transmissions may require steel plates produced using precision blanking.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve smooth, precise edges | Need a high initial investment |

| Produce complex shapes | Limit material thickness |

| Reduce the need for finishing | Require specialized presses |

| Maintain tight tolerances | Higher tooling costs |

Fine-blanking gives you high-quality parts with minimal finishing. You should consider this process when you need flat metal components with exact dimensions.

Bending

How Bending Works

Bending is a forming process that involves applying force along a straight axis to metal sheets or rods. The metal is placed on a die and then pressed with a punch. The metal bends at the point of contact. By adjusting the pressure and tool position, the bending angle and radius can be controlled. For example, you can bend steel plates to create brackets for machinery. You can also use a bending machine to form aluminum sheets for enclosures.

Applications

Bending processes are used in many industries. For example, they are used in the manufacture of steel structural supports for buildings, the production of aluminum window frames, and the creation of stainless steel appliance handles. In automotive manufacturing, bent metal is used to make exhaust pipes and chassis components, as well as metal shelving for storage systems.

You can use bending to create custom shapes for prototypes or small batches. You often select this process for parts that need simple curves or angles.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve quick results | Limit the complexity of shapes |

| Use simple equipment | Risk of cracking on sharp bends |

| Produce consistent angles | Springback in some metals |

| Work with many metals | Need precise control for tight tolerances |

You benefit from bending when you need fast production and simple shapes. You face challenges with cracking and springback, especially in harder metals. We must monitor the process to maintain accuracy.

Deep Drawing

How Deep Drawing Works

Deep drawing is a method of forming sheet metal into a hollow shape. A metal blank is placed on a die, and then a punch is used to press it. The metal stretches and flows into the die cavity. This allows for the creation of parts with a depth much greater than their diameter. For example, you can deep draw a stainless steel blank to create a kitchen sink. This process can also be used to produce aluminum beverage cans.

Applications

In the packaging and home appliance manufacturing industries, deep drawing is a common process. It is used to manufacture steel pots for cooking, aluminum cans for food and beverages, and stainless steel containers for laboratory use. In automotive manufacturing, deep-drawn metal is used to make fuel tanks and oil pans, as well as battery casings for electronic products.

You select deep drawing when you need hollow parts with smooth walls and uniform thickness.

Pros & Cons

| Pros | Cons |

|---|---|

| Create deep, hollow shapes | Need high-quality metal blanks |

| Achieve smooth surfaces | Risk of tearing on thin materials |

| Reduce material waste | Require strong dies and punches |

| Produce large quantities | Limit design to round or simple shapes |

You gain efficiency with deep drawing for high-volume production. You face risks of tearing and wrinkling if the metal is too thin. You must use strong tools and control the process for best results.

Transfer Drawing

How Transfer Drawing Works

Using the transfer drawing process, complex hollow metal parts can be formed through multiple drawing stages. The metal blank is transferred from one die to another, with each die having a different shape or depth. The metal is gradually stretched and formed without fracturing. For example, the transfer drawing process can be used to form steel blanks into multi-stage automotive oil filter housings. This process can also be used to produce deep-drawn aluminum containers for industrial applications.

Applications

In the automotive and electronics manufacturing industries, transfer molding is widely used. It is employed in the manufacture of steel casings for filters and pumps, aluminum casings for capacitors, and stainless steel casings for medical devices. In electrical appliance production, transfer molding is used to manufacture multi-layer trays and coils. Furthermore, it is also used to manufacture battery casings with stepped profiles.

You choose transfer drawing when you need parts with multiple depths or complex contours.

Pros & Cons

| Pros | Cons |

|---|---|

| Form complex shapes | Require multiple dies and stages |

| Maintain material strength | Increase setup time |

| Reduce the risk of tearing | Need precise alignment |

| Produce consistent results | Higher tooling costs |

When you need to manufacture complex hollow parts, using the transfer drawing method can be very helpful. However, you will also face longer setup times and higher mold costs.

Bulging

How Bulging Works

The bulging process involves expanding a section of a metal tube or sheet by applying internal pressure. The metal workpiece is placed in a mold, which controls the final shape. Hydraulic fluid or air is injected into the tube. The pressure forces the metal outward against the mold walls. This allows you to create bulges, domes, or other expanded shapes. For example, you can use the bulging process to manufacture the ends of steel exhaust pipes for trucks. You can also create bulges on aluminum beverage cans.

Applications

In the automotive industry, you will frequently use the bulging process. It is used to create expansion sections in exhaust systems and fuel lines. In pipe engineering, you will use the bulging process to form flared joints in copper water pipes. In the aerospace industry, you will also use the bulging process to manufacture reinforced sections in aluminum air ducts. You might even choose the bulging process to manufacture metal containers with rounded ends.

You can use bulging to add strength to metal tubes or create custom shapes for connectors.

Pros & Cons

| Pros | Cons |

|---|---|

| Create expanded shapes quickly | Limit the process to ductile metals |

| Improve joint strength | Need precise pressure control |

| Reduce welding needs | Restrict the complexity of shapes |

| Use simple dies | Thinning in bulged areas |

You benefit from bulging when you need strong, expanded sections in tubes. You face challenges with material selection and shape complexity. We must control pressure to avoid defects.

Hole Flanging

How Hole Flanging Works

The flanging process involves forming a raised edge or flange around a hole in a metal sheet. First, a hole is punched in the metal sheet. Then, the metal sheet is placed on a matching die. A punch is used to press the metal around the hole upwards or downwards, thus forming the flange. You can create flanges for mounting or connecting parts. For example, you can use the flanging process to create reinforced openings in a steel plate for mounting car door handles.

Applications

In automotive body panels, you will find flanged holes. These are used to reinforce bolt and fastener holes. Flanged holes are also used in electrical manufacturing, such as in washing machine drums. They are also used in HVAC systems to connect ductwork. Electrical enclosures may also utilize flanged holes to provide secure mounting points.

You can use hole flanging to prevent cracking around holes and improve load distribution.

Pros & Cons

| Pros | Cons |

|---|---|

| Reinforce holes in metal sheets | Limit flange height by material thickness |

| Improve mounting strength | Need accurate hole placement |

| Reduce the risk of cracking | Distortion near the flange |

| Use standard punching equipment | Restrict process to flat sheets |

You benefit from hole flanging when you need strong, reinforced openings. You face challenges with material thickness and distortion.

Necking & Expanding

How Necking & Expanding Works

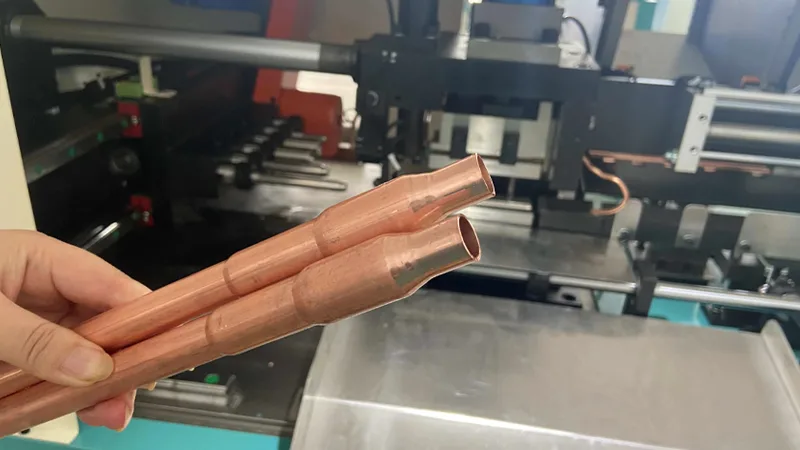

Neck reduction and neck expansion are methods used to change the diameter of metal tubes or shells. Neck reduction is achieved by using a die and punch to decrease the diameter of one end of the tube. Neck expansion, on the other hand, is achieved by increasing the diameter of the tube through internal pressure or a mandrel. These two processes can be combined to create stepped or tapered profiles. For example, neck reduction can be used to form the ends of aluminum beverage cans. Neck expansion can be used to fit steel pipes onto connectors in hydraulic systems.

Applications

In the packaging industry, you will frequently encounter necking and flaring processes. For example, necking is used to produce aluminum cans with narrower openings. In automotive manufacturing, flaring is used to attach steel pipes to exhaust pipe connectors. These processes are also used in piping systems to connect copper pipes. In the aerospace industry, necking and flaring processes may be chosen due to the need for pipes of different diameters.

You can use necking and expanding to create custom tube profiles for connectors and fittings.

Pros & Cons

| Pros | Cons |

|---|---|

| Create variable tube diameters | Limit process to cylindrical shapes |

| Improve fit for connectors | Need precise tooling |

| Reduce welding and joining steps | Thinning in necked areas |

| Use standard forming equipment | Restrict the process to ductile metals |

You benefit from necking and expanding when you need tubes with custom diameters. You face challenges with shape limitations and material thinning.

Metal Spinning

How Metal Spinning Works

Metal spinning is a process that forms a flat metal disc into a hollow, circular part. First, the disc is mounted onto a rotating mandrel. Then, while the disc is rotating, pressure is applied to it using a roller or tool. The tool shapes the metal as it spins. You can manufacture parts such as cones, cylinders, and hemispheres. For example, you can use metal spinning to create aluminum lamp reflectors or stainless steel cooking pots.

Applications

Metal spinning technology is widely used in lighting, cookware, and aerospace industries. It can be used to manufacture satellite antennas, ventilation cones, and musical instrument bells. In the automotive industry, it is used to produce wheel covers and intake components. Furthermore, metal spinning technology is also used in the production of decorative items such as vases and trophies.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve smooth surfaces | Limit shapes to round forms |

| Use simple tooling | Require skilled operators |

| Produce prototypes quickly | Thinning in the walls |

| Work with many metals | Restrict part complexity |

You benefit from metal spinning when you need round, symmetrical parts. You face challenges if you want complex or non-circular shapes.

Flow Forming

How Flow Forming Works

Spin forming is a common method for manufacturing long, thin-walled cylindrical parts. First, a preform or blank is used, typically shaped like a short cylinder. The blank is mounted on a rotating mandrel. As the mandrel rotates, rollers press against the blank and stretch it along the mandrel. The rollers reduce the wall thickness and increase the length. For example, spin forming can be used to manufacture steel gas cylinders or aluminum car wheels.

Applications

Spin forming is widely used in industries requiring high-strength, lightweight tubing. For example, it is used in the production of rocket engine casings, drive shafts, and pressure vessels. In the defense sector, spin forming is used to manufacture artillery shells. In the automotive industry, spin forming is used to produce lightweight wheels and transmission components. Furthermore, spin forming is also applied in the production of fire extinguisher casings.

Pros & Cons

| Pros | Cons |

|---|---|

| Achieve high strength | Need precise process control |

| Reduce material waste | Limit shapes to cylindrical forms |

| Produce thin-walled parts | Require specialized equipment |

| Improve dimensional accuracy | High initial costs |

You benefit from flow forming when you need strong, thin-walled cylinders. You face limitations if you want complex or non-cylindrical shapes.

MIM

How MIM Works

Metal injection molding (MIM) is used to produce small, complex metal parts. First, fine metal powder is mixed with a binder to create a feedstock. This feedstock is then injected into a mold, similar to plastic injection molding. Next, the binder is removed through a debinding process. Finally, the part is sintered at high temperature, causing the metal particles to fuse together. For example, MIM can be used to manufacture stainless steel surgical instruments or small gears for watches.

Applications

MIM technology is widely used in the medical, automotive, and electronics industries. It is used to produce orthodontic brackets, mobile phone components, and firearm triggers. In the automotive sector, it is used to manufacture turbocharger blades and sensor housings. Furthermore, MIM technology is also applied in the production of aerospace fasteners and connectors.

Pros & Cons

- It can produce complex shapes with tight tolerances.

- We can achieve high production rates for small parts.

- We can use a wide range of metals, including stainless steel and titanium.

However, you face several limitations with MIM:

- It needs specialized equipment, which leads to high start-up costs.

- There a long tooling lead times that can delay your production schedule.

- If design changes are required, new molds will need to be made, which will incur additional costs.

- MIM best for small to medium-sized parts, usually under 2 inches (50mm). Larger parts often show uneven density.