A step-by-step guide to the galvanizing process for metal parts

October 17, 2025

You use the galvanizing of metal parts process to cover them with zinc. First, you clean the metal. Then you pickle and flux…

Read More

October 17, 2025

You use the galvanizing of metal parts process to cover them with zinc. First, you clean the metal. Then you pickle and flux…

Read More

October 17, 2025

You want to see your brass shine like a mirror, right? You can do it, even if you’ve never tried brass polishing before.…

Read More

October 17, 2025

When drilling metal, use cutting oil to lubricate it and keep both your drill bit and metal workpiece safe. You’ll experience less friction…

Read More

October 17, 2025

You might ask, can AI replace CNC machinists? The answer is no. Human skills are still very important in CNC machining. Experts say…

Read More

October 16, 2025

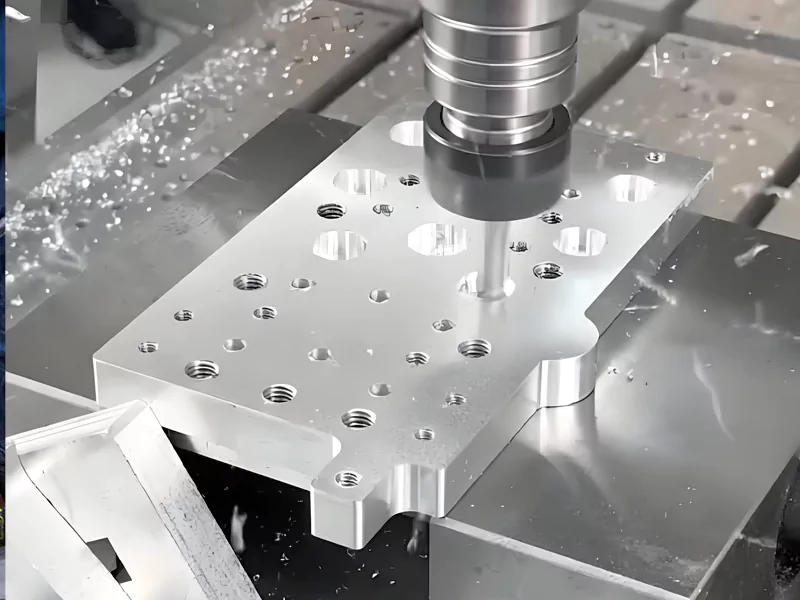

Precision is important when you learn how to machine aluminum parts. This is true for aerospace, cars, and electronics. You will face some…

Read More

October 16, 2025

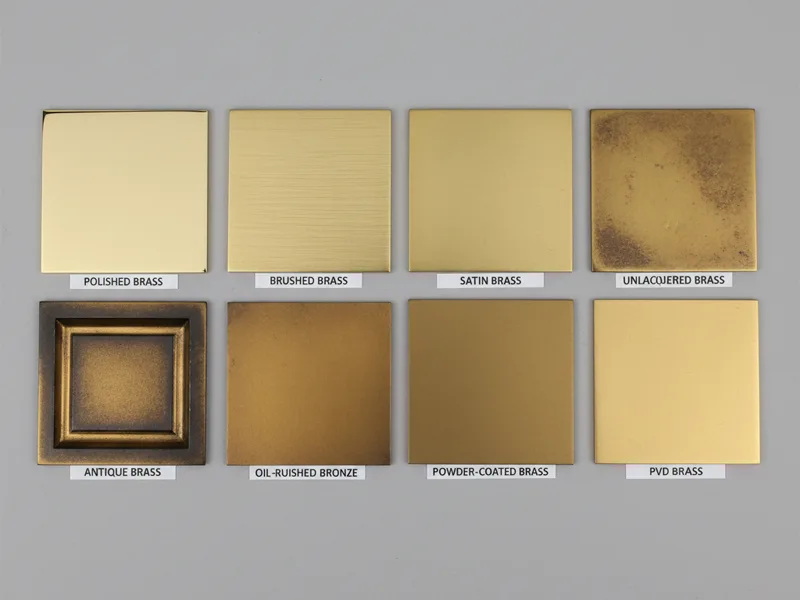

You will learn how brass finishing changes plain things into cool items. Brass finishing uses special steps to make things look better and…

Read More

October 15, 2025

When you ask, “Is steel easy to manufacture?” most people refer to mild steel. Experts and the AFI Industrial Co., Ltd team agree…

Read More

October 15, 2025

When deciding how to manufacture metal parts, focus on your specific needs. You might want durable metal parts for strength, or you may…

Read More

October 15, 2025

You can cut metal safely if you use the right tools for metal cutting. Always think about safety before you start your metal…

Read More

October 15, 2025

If you want metal that does not rust, pick 316 stainless steel. If you want metal that is easy to shape and costs…

Read More7075 vs. 6061 Aluminum Alloy: The Ultimate Choice for Aerospace and Structural Components

Cryogenic Machining Technology: Principles, Applications, and Engineering Implementation Guide

Achieving Optical-Grade Surfaces through Diamond Turning and Precision Polishing

The Threading Cost for Custom Metal Parts Manufacturers is Determined by the Machining Depth

Biocompatible Machining: Handling PEEK and Titanium Composites for Medical Implants

Professional answers for you