You use interference fit tolerances to make strong, tight assemblies in mechanical design. The fit you pick—interference, clearance, or transition—affects how parts move, carry weight, and handle tough conditions. For example:

- Clearance fits let parts move easily.

- Transition fits help parts line up exactly.

- Interference fits make strong, tight joints for heavy loads.

Precision machining from AFI Industrial Co., Ltd helps you get the right tolerances your project needs. Engineers and technical workers choose the right fit to make things work well and last long.

Key Takeaways

- Interference fit makes a very strong joint. The shaft is bigger than the hole. This fit is best for heavy loads.

- Clearance fit lets parts move easily. It works well for things like bearings and sliding parts.

- Transition fit mixes clearance and interference fit. It helps parts line up but can still come apart.

- Picking the right fit is very important. It helps machines work well and last longer. Think about how parts will move together.

- Material properties change fit tolerances. Hard materials like steel need tighter fits. Softer materials like aluminum can use looser fits.

- Use standard tolerance tables to pick the right fit. This helps you avoid mistakes when making parts.

- Surface finish changes how strong the joint is. Try to make surfaces smooth for a strong and steady fit.

- AFI Industrial Co., Ltd does careful machining. They meet strict fit tolerances for strong and lasting assemblies.

Table of Contents

Types of Fit

When you build machines, you must pick the right fit. There are three main types of fit. These are interference fit, clearance fit, and transition fit. Each type has its own job in engineering. Picking the right fit helps your machine work well. Some fits let parts move. Others help parts line up. Some fits make parts stay together tightly.

Tip: ISO and ANSI standards explain each type of fit. These rules help you choose the right tolerances for your project.

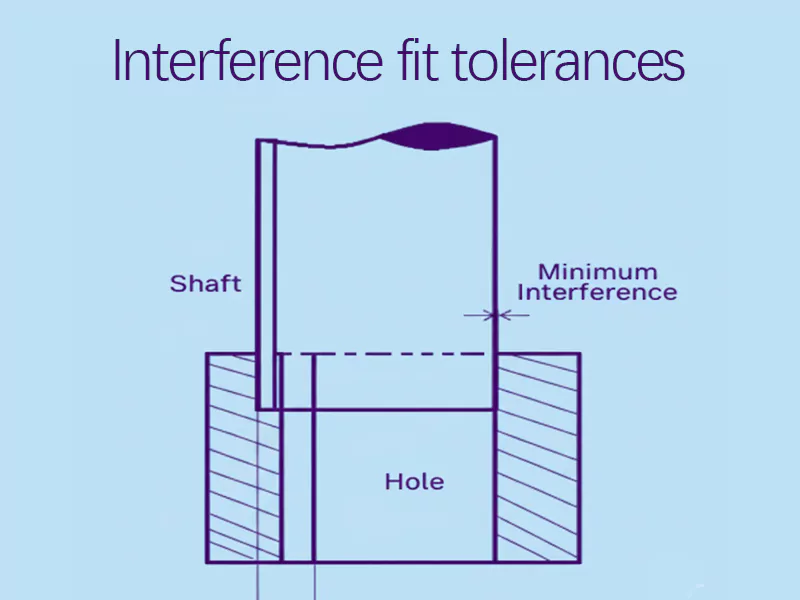

Interference Fit

An interference fit makes a strong, lasting joint. Here, the shaft is always slightly larger than the hole. You need to use force or special techniques, such as heating or cooling, to assemble the parts together. Once joined, the parts do not move. They can handle heavy loads and shaking.

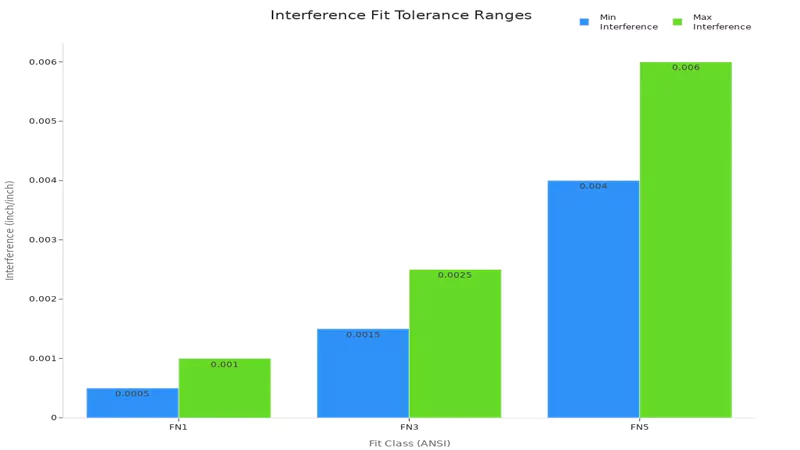

Tolerance Ranges

You can see common tolerance ranges for interference fit in this table. These numbers follow ISO and ANSI standards. They help you pick the right fit for your job.

| Fit Type | Hole Range (mm) | Shaft Range (mm) | Interference Range (mm) |

|---|---|---|---|

| H7/p6 | 50.000–50.025 | 50.026–50.042 | 0.001–0.042 |

| H7/s6 | 50.000–50.025 | 50.035–50.050 | 0.010–0.050 |

| Fit Class (ANSI) | Interference (inch/inch) | Application |

|---|---|---|

| FN1 | 0.0005–0.0010 | Light press, thin walls |

| FN3 | 0.0015–0.0025 | Standard interference |

| FN5 | 0.004–0.006 | Heavy force/shrink fit |

Functions and Use Cases

You use interference fit when you want a joint that will not slip. This fit is used in:

- Cars: wheel bearings, gears, bushings.

- Planes: engine parts, landing gear, strong joints.

- Factory machines: shaft-hub links, bearing setups, gear mounting.

AFI Industrial Co., Ltd uses careful machining. This makes sure your interference fit meets tight rules. You get strong, safe assemblies.

Clearance Fit

Clearance fit lets one part move inside another. The shaft is always smaller than the hole. This leaves a gap so parts can turn or slide easily. This fit is good for easy assembly and smooth movement.

Tolerance Ranges

| Type of Clearance Fit | Common Applications in Industry |

|---|---|

| Running Fits | Rotating shafts in bearings, sliding mechanisms |

| Sliding Fits | Machine tool guides, automotive pistons |

| Loose Fits | Assembly jigs, temporary fixturing |

Functions and Use Cases

You use clearance fit in:

- Journal bearings

- Engine parts

- Machine tool spindles

- Conveyor systems

This fit is best for parts that must move or be changed often. AFI Industrial Co., Ltd’s skill in machining gives you the right gap for smooth work and long life.

Transition Fit

Transition fit is a mix of clearance fit and interference fit. Sometimes there is a small gap. Other times, there is a small overlap. This fit is good when you want parts to line up well, but may need to take them apart later.

Tolerance Ranges

| Fit Type | Description | Example |

|---|---|---|

| Transition fit | May result in clearance or interference | H7/k6 |

Functions and Use Cases

Transition fit helps you:

- Line up parts during assembly

- Limit movement without making things too hard to put together

- Stop putting too much stress on the parts

You find a transition fit where you need both accuracy and the option to take things apart. This is common in locating assemblies or light press fits.

Note: AFI Industrial Co., Ltd uses advanced machining. This helps you get the exact transition fit your design needs. It supports both good assembly and easy repairs.

| Fit Type | Definition | Context/Use |

|---|---|---|

| Clearance Fit | The shaft is always smaller than the hole. | Free movement; rotating or sliding parts. |

| Transition Fit | May result in clearance or slight interference. | Accurate location, possible disassembly. |

| Interference Fit | The shaft is always larger than the hole. | Permanent, high-strength connections. |

Picking the right fit is very important for your machine design. AFI Industrial Co., Ltd’s careful machining makes sure you get the fit you need for every job.

Interference Fit Tolerance in Machining

When you build strong machines, interference fit tolerance is very important. This tolerance shows how tightly two parts press together. It helps make joints that do not move or shake. These joints can hold heavy loads. Picking the right interference fit tolerance helps your parts last longer and work better. If you pick the wrong value, your parts may wear out fast, get misaligned, or even break.

Best Practices

Material Selection

You need to think about material properties when using interference fit tolerance. Materials change size at different rates. For example:

- Steel needs a closer fit because it is hard.

- Aluminum can have a looser fit since it is soft.

- Heat can make materials grow or shrink, changing the fit.

- Wetness and chemicals can change how stable materials are.

- Shaking can affect how parts line up and work.

Match the interference to the strength of your materials. Use charts to help pick the right fit. Always check if your materials work well together. This helps stop problems when you put parts together or use them.

Manufacturing Capabilities

Getting tight interference fit tolerance needs special machines. You need good tools to keep close limits. Here is a table that compares regular and high-precision needs:

| Component | Standard Precision | Tight Tolerance Requirements | Quality Impact |

|---|---|---|---|

| Cutting Tools | Standard carbide inserts | Ground carbide or diamond tools | ±0.002mm improvement |

| Tool Holders | Standard collets | Precision shrink-fit holders | Reduced runout by 50% |

| Workholding | Standard vises | Precision fixtures with repeatability | ±0.005mm repeatability |

| Measurement | Dial indicators | Coordinate measuring machines | 10:1 accuracy ratio |

Your measuring tools should be ten times more accurate than your needed tolerance. This rule helps you avoid mistakes when checking quality. Using process control and real-time checks keeps your work steady. AFI Industrial Co., Ltd uses advanced CNC machines and inspection tools. This gives you better precision for all fits, including interference.

Assembly Methods

There are different ways to put together interference fit joints. Each way works best for certain jobs:

| Assembly Method | Description |

|---|---|

| Force | Use a hammer or press to join parts. |

| Thermal Expansion/Contraction | Heat one part to make it bigger or cool another to make it smaller. |

| Shrink Fit | Cool a part to shrink it, fit it in place, then let it warm up to hold tight. |

Pick the method that matches your part size, material, and needed interference. For example, use a shrink fit for big gears or a press fit for small bushings.

Common Pitfalls

Overly Tight Tolerances

Interfering fit tolerance too tight can cause trouble:

- It costs more because you need better machines and tools.

- You waste more parts and need extra checks.

- Putting parts together gets harder and takes more time.

- Tighter fits can cost two to four times more than loose fits.

Always balance a strong fit with what is possible in making and putting together parts. Do not make tolerances tighter than you need.

Thermal Expansion

Heat can change how well your interference fit works. If two parts grow at different rates, the fit may get loose or too tight. For example, a steel bearing in an aluminum case may not hold as well when hot. In engines or gearboxes, uneven growth can jam parts or cause cracks. Always think about temperature changes when you design.

Surface Finish

How smooth a surface is affects how strong and stable the joint is. A rough surface can make the joint weak and not hold well. Aim for a smooth finish to keep the fit steady. This stops slipping and keeps the joint strong when loaded.

Design Strategies

Calculating Press Fit Forces

You need to figure out the right force for your press fit. Use these formulas:

| Interference Type | Formula | Purpose |

|---|---|---|

| Maximum Interference | Max Shaft Diameter – Min Hub Diameter | Stops material from breaking |

| Minimum Interference | Min Shaft Diameter – Max Hub Diameter | Make sure the joint holds |

You also need to know:

- F: The force needed to press parts together

- P: The pressure between the parts

- A: The area where parts touch (A = π × d × L, d is diameter, L is length)

- μ: The friction between the parts

These calculations help you avoid breaking parts and make sure the fit is secure.

Using Standard Tolerance Tables

Standard tables help you pick the interference fit tolerance for your drawings. They show the difference between hole-basis (like H7) and shaft-basis (like h7) fits. Use these tables to choose the right fit for your job. For example, an H7 hole with a T6 shaft gives a strong interference. Always use the correct fit name to stop mix-ups.

Service and Maintenance Considerations

When you design with interference fit tolerance, think about how the assembly will be used and fixed:

- Pick tolerances based on how fast parts move and how much load they carry.

- Think about how much shaking the joint will get.

- Choose how to add grease or oil.

- Make sure the fit lets you put parts together and fix them later.

- Plan for size changes from heat.

If tolerances are too loose, parts may shake and wear out fast. If they are too tight, heat can build up and damage materials. Good machining and fit choices stop these problems.

When parts get hot, they grow. If there is not enough space, they may touch and make heat. This can hurt materials and break machines.

You can make strong, long-lasting assemblies by following these tips for interference fit tolerance. AFI Industrial Co., Ltd gives you tight precision and steady quality for all fits. Your assemblies last longer, work better, and need less fixing.

Applications of Interference, Clearance, and Transition Fits

When you build machines, you must pick the right fit. The fit you choose changes how your parts work. It also affects how long your machine lasts. Some fits make fixing things easier. Let’s see where you use interference fit, clearance fit, and transition fit. AFI Industrial Co., Ltd can help you get the fit you need.

Interference Fit Applications

An interference fit makes a strong, lasting joint. You use this fit when parts must stay together under heavy force or shaking. This fit is important for safety and strength.

Shafts and Bearings

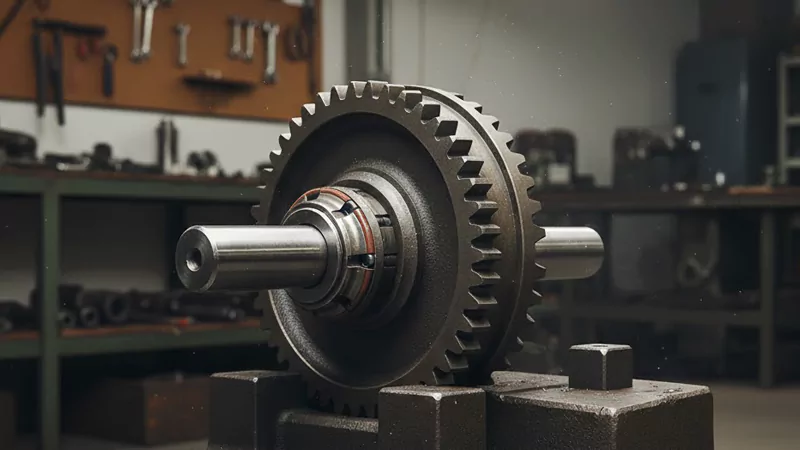

Interference fit joins shafts and bearings tightly. This stops the bearing from spinning or slipping. For example, you press a bearing onto a shaft in a motor or conveyor. The tight fit keeps the bearing in place, even at high speed.

Gears and Couplings

Gears and couplings need an interference fit to work well. When you put a gear on a shaft, you want no movement. This fit lets the gear turn without slipping. In cars, interference fit is used in wheel hubs and axles. In planes, it is used for bushings in the landing gear.

| Application | Description |

|---|---|

| Wheel Hub in Train Suspension | The hub fits tightly on the axle, stopping movement under heavy loads. |

| Metal Bushing in Aircraft Landing Gear | The bushing is cooled, inserted, and then expands to lock in place. |

Tip: Use interference fit when you need a joint that stays tight.

Clearance Fit Applications

Clearance fit lets one part move inside another. You use this fit for easy assembly and smooth movement. Clearance fit is good for machines that need fixing often or have moving parts.

Sliding Assemblies

Sliding assemblies use a clearance fit so parts can move easily. You see this fit in drawer slides, conveyor rollers, and machine guides. The gap lets parts slide or roll without sticking.

Removable Parts

Clearance fit is used for parts you take out or change often. Bolts in holes, pins in jigs, and shafts in bushings use a clearance fit. This fit makes putting together and taking apart parts quick.

- Clearance fit works best for:

- Rotating shafts in bearings

- Sliding parts in machines

- Assembly jigs and fixtures

Note: AFI Industrial Co., Ltd can machine your parts for the right clearance.

Transition Fit Applications

Transition fit is a mix of clearance and interference. Sometimes there is a small gap. Other times, there is a small overlap. You use transition fit for good alignment, but also want to take parts apart later.

Locating Assemblies

Transition fit helps you line up parts exactly. You use this fit for shafts and hubs in machines. The fit keeps parts straight but lets you take them apart if needed.

Light Press Fits

Light press fits use a transition fit for easy assembly. You see this fit in sockets for electronics or bearings in engines. The fit holds parts together but does not make taking them apart too hard.

- Transition fit is used for:

- Cylindrical parts that need to line up and carry weight

- Precision machines where you want both accuracy and easy fixing

Remember: Transition fit gives you a tight hold and lets you fix things later.

| Fit Type | Best Use Cases |

|---|---|

| Clearance fit | Sliding parts, removable pins, rotating shafts |

| Transition fit | Permanent joints, gears, couplings, heavy-duty shafts, and bearings |

| Interference fit | Permanent joints, gears, couplings, heavy-duty shafts and bearings |

Picking the right fit helps your machine work well. AFI Industrial Co., Ltd gives you precise machining for every fit type. Your assemblies will work well in any industry.

Quick Reference: Types of Fit and Applications

When you design machines, you need to compare fit types fast. This part gives you easy tables and short explanations. Use these tables to pick the best fit for your project. You will also see where each fit works best.

Types of Fits Comparison Table

This table helps you see the big differences between the fits. It shows how each fit uses tolerances and where to use them.

| Fit Type | Tolerance Values | Application Scenarios |

|---|---|---|

| Interference fit | Shaft size is equal to or greater than hole size (shaft ≥ hole) | Use when you need a secure hold. Disassembly needs high force and may damage parts. |

| Transition fit | Tolerance is between clearance and interference. Fit can be tight or loose. | Use when you want a secure hold but still need to take parts apart if needed. |

| Clearance fit | Always leaves a gap between parts. The shaft is smaller than the hole. | Use for smooth sliding or rotation, like in bearings or guide rails. |

Tip: Always check your tolerance values before you start machining. This helps you avoid mistakes and saves time during assembly.

Application Summary Table

This table matches each fit type with common uses. It helps you pick the right fit for your design.

| Fit Type | Typical Applications | Key Benefits |

|---|---|---|

| Interference fit | Wheel hubs, gears, couplings, heavy shafts | Strong, permanent connection |

| Transition fit | Locating pins, light press fits, bushings | Accurate alignment, easy removal |

| Clearance fit | Bearings, sliding guides, and removable pins | Smooth movement, easy assembly |

- An interference fit is best when you want parts to stay together under heavy loads. You see this fit in train wheel hubs and aircraft bushings.

- Transition fit helps you line up parts just right. You use this fit for locating assemblies or light press fits in machines.

- Clearance fit is good for moving parts. You find this fit in bearings, guide rails, and parts you need to take out often.

Note: AFI Industrial Co., Ltd can help you get any of these fits with high-precision machining. You get reliable results for every application.

If you keep these tables close, you can pick the right fit type fast. This saves you time and helps you build machines that last longer and work better.

You need to know how interference, clearance, and transition fits are different. Interference fits make joints that stay together and are very strong. Clearance fits let parts move easily and are simple to put together. Transition fits help parts line up and can be taken apart if needed. Picking the right fit and using the right tolerance helps machines work well and last longer. AFI Industrial Co., Ltd uses careful machining so each fit works for you. Always look at the rules and tips before you choose a fit or a transition fit for your design.

FAQ

You create an interference fit when you make the shaft slightly larger than the hole. You press or shrink the parts together. This fit gives you a strong, permanent joint.

You look at how the parts will work. If you need movement, use a clearance fit. If you want a tight hold, use an interference fit. For easy alignment, use transition fit.

A smooth surface helps you get a strong, stable joint. Rough surfaces can weaken the fit and cause slipping. Always aim for a fine finish.

Usually, you cannot reuse them. Removing the parts can damage them. If you need to take parts apart often, use a clearance or transition fit.

You need high-precision tools like coordinate measuring machines (CMMs), micrometers, and calipers. These tools help you check if your parts meet the required tolerances.

Temperature changes can make parts expand or contract. This can loosen or tighten the fit. Always consider how hot or cold your machine will get during use.

AFI Industrial Co., Ltd provides precision machining. You get parts that meet strict fit tolerances. This ensures your assemblies are strong, reliable, and long-lasting.