Hard Turning vs Grinding have different benefits for making hard steel parts. The optimal method depends on the part’s shape, the desired smoothness, and the production volume. Hard turning with CBN inserts can introduce beneficial compressive stress while maintaining microhardness. In contrast, grinding can inadvertently soften the part if not executed properly. The table below illustrates how each method impacts the sub-surface area:

| Sub-surface Effect | CBN Hard Turning | CBN Grinding |

|---|---|---|

| Residual Stress | Can add high beneficial compressive stress | Can be compressive; might turn tensile if not careful |

| Microhardness | Usually remains stable; can slightly increase or decrease | Typically stays the same; can become significantly softer with burn |

| White Layer | Lower chance if controlled well; can occur with worn tools | Higher chance if grinding is too aggressive (grinding burn) |

AFI Industrial Co., Ltd. utilizes advanced machinery and equipment to produce precision components with exceptional accuracy and efficiency.

Key Takeaways

- Hard turning offers faster speeds than grinding, making it particularly suitable for small-batch part production.

- Grinding makes the surface smoother, so it is good for parts that need to look shiny like a mirror.

- Choose hard turning If the part geometry is simple and rapid switching between machining tasks is required; it works well and saves time.

- Grinding works best when a large number of parts need to be processed, and all parts must have identical dimensions and appearance.

- Check your tools and the surface while working to make things better and keep parts good.

- Use the right tools and machine settings to help tools last longer and make less waste.

- Think about the part’s shape and how smooth it must be before you pick hard turning or grinding.

- New machines and robots can help both ways work better and make fewer mistakes.

Efficiency in Machining Hardened Steel

Table of Contents

What Is Efficiency in Machining?

Efficiency in machining means making parts with little waste. It shows how well a process turns raw material into finished parts. Efficiency is not only about working fast. It also means being accurate, saving money, and keeping quality steady. These factors are particularly important when processing work-hardened steel. This steel is very hard, so it is harder to machine. Good efficiency ensures that every step is effective and avoids wasting time or money.

AFI Industrial Co., Ltd uses smart machines to make work better at every step. Their equipments are very precise and uses automation to lower mistakes and boost output. This helps makers get better results, even with tough materials like hardened steel.

Key Metrics: Time, Cost, Quality, Tool Life

There are several ways to measure efficiency when machining hardened steel. These ways help compare different tools and methods.

| Metric | Description |

|---|---|

| Machinability Index (MI) | Comparative testing of cutting speeds between test materials and standard materials |

| Taylor Tool Life Equation | Connects cutting speed to how long a tool lasts. |

| Specific Cutting Energy | Tells how much energy is needed to cut a certain amount of material. |

Other things also change how efficient machining is. The table below shows how each one matters:

| Factor | Impact on Machining Efficiency |

|---|---|

| Tool Life | If tools last longer, there is less downtime and fewer replacements. |

| Material Hardness | Harder materials wear out tools faster, which can lower efficiency. |

| Cutting Force | More force can cut more material but may wear out tools quicker. |

| Surface Quality | Better surface quality means less extra finishing, which saves time and money. |

AFI Industrial Co., Ltd uses these ways to plan their machining. They focus on tool life and surface quality to help customers get the best results.

Why Efficiency Matters for Hardened Steel

Hardened steel is used for parts that need to last and work well under stress. Machining this steel can be slow and expensive if not done well. Poor efficiency wastes tools, takes more time, and costs more money. It can also hurt the quality of the part.

Manufacturers must balance speed, cost, and quality. Achieving high productivity requires the coordinated operation of every step in the process. Efficient machining means fewer tool changes, less scrap, and every part meets strict rules. AFI Industrial Co., Ltd’s smart machines help companies reach these goals. Their technology helps make strong, accurate, and affordable parts, even with hard materials.

Tip: Always check tool wear and surface quality while machining. Small changes can make a big difference in efficiency.

Hard Turning Efficiency Factors

Hard Turning Process Overview

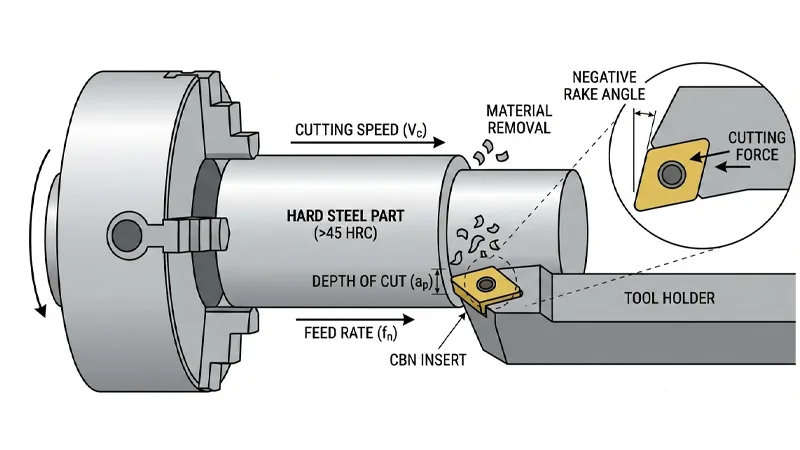

Hard turning is a way to shape hard steel parts. It uses special cutting tools to remove material. Most of the time, it uses CBN inserts. These inserts work well with steel that is very hard, above 45 HRC. Hard turning can take the place of grinding in many cases. It is good when you need smooth surfaces and high accuracy. You can use hard turning for both steady and interrupted cuts. This makes it useful for many part shapes.

The hard turning process has several main steps. The table below shows common operations, tool choices, and cutting settings:

| Operation | Tooling Example | Cutting Speed (Vc) | Feed Rate (fn) | Depth of Cut (ap) |

|---|---|---|---|---|

| Continuous Finishing | Low-Content CBN Insert | 120-180 m/min | 0.05-0.12 mm/rev | 0.1-0.25 mm |

| Interrupted Cutting | High-Content CBN Insert | 90-140 m/min | 0.08-0.15 mm/rev | 0.15-0.3 mm |

The shape of CBN inserts is critical. A negative rake angle helps control the cutting force. It also protects the edge of the tool. This design pushes force into the tool holder. It stops damage and keeps turning stable.

Drivers of Efficiency in Hard Turning

Cutting Parameters and Tooling

Cutting settings are very important in hard turning. The right speed, feed rate, and depth help remove material fast. They also give a good surface finish. CBN tools are best for hard steel. They last long and resist wear. Carbide tools work well for steel that is not as hard. They are precise and strong.

Machine and System Optimization

Machines must be strong and steady for hard turning. A solid setup stops vibration and makes surfaces smoother. The entire system, including the tool holder and workholding fixtures, must be robust and durable. This lets you cut faster and repeat the process well. AFI Industrial Co., Ltd uses advanced CNC machines. Their machines have strong frames and accurate controls. These systems lower mistakes and make turning more efficient.

Automation and monitoring make hard turning even better. Automatic tool changers and real-time feedback keep quality steady. They also cut down on downtime. These features help a lot when making many hard steel parts.

Machining Applications for Hard Turning

Hard turning works well for many steel parts. It is good for:

- Shafts and spindles

- Bearing races

- Gears and gear blanks

- Rollers and pins

- Precision bushings

CBN tools are best for steel above 45 HRC. Carbide tools are good for steel that is not as hard. Hard turning gives high accuracy and smooth surfaces. It also saves time and works for both small and large batches.

AFI Industrial Co., Ltd uses hard turning to make precise parts. Their skills help every part meet strict rules for size and quality. This makes them a trusted choice for tough jobs.

Tip: Always pick the right tool material and shape for the part’s hardness and form.

Hard Turning Limitations

Hard turning helps make hard steel parts. But it has some limits that are important to know. Knowing these limits helps people pick the best way to make each part.

One big problem is the surface finish. Hard turning can make parts smooth. But it does not always make them as shiny as grinding. If a part needs a mirror-like look or very tight sizes, grinding might be better.

Part shape is another limit. Hard turning works best on simple shapes like cylinders or flat faces. It is hard to make deep grooves or small holes while turning. Grinding can reach areas that turning tools cannot access.

Tool wear is also something to think about. CBN inserts are very hard and last long. But they can still wear out fast when cutting very hard steel. If the machine is not steady, tools wear out even more quickly. Tool life depends on how strong the setup is and how hard the steel is.

The table below shows how CBN inserts help with some problems in hard turning:

| Advantage | Description |

|---|---|

| Exceptional Hardness | CBN is very hard, so it can cut tough steel well. |

| Outstanding Thermal Stability | CBN stays hard even when it gets hot, so you can cut faster. |

| Superior Wear Resistance | CBN does not wear down quickly, so tools last longer. |

Even with these good points, hard turning has size and batch limits. Big parts or lots of parts may need grinding to keep things even and fast. Hard turning makes more heat at the cutting edge. Too much heat can hurt the surface. It can cause burns or tiny cracks.

Here are some times when hard turning is not the best:

- The part needs a surface roughness below Ra 0.2 μm.

- The design has deep or thin grooves.

- The part is very large or has thin walls, it will vibrate.

- The steel is super tough or has hard spots.

Note: Always check the machine and tool before you start hard turning. A strong setup and sharp tool help you get good results.

Hard turning offers quick and flexible machining, suitable for a wide range of processing needs. It saves time and can make tricky shapes easier than grinding sometimes. But knowing its limits helps ensure every part is made well and works properly.

Grinding Efficiency Factors

Grinding Process Overview

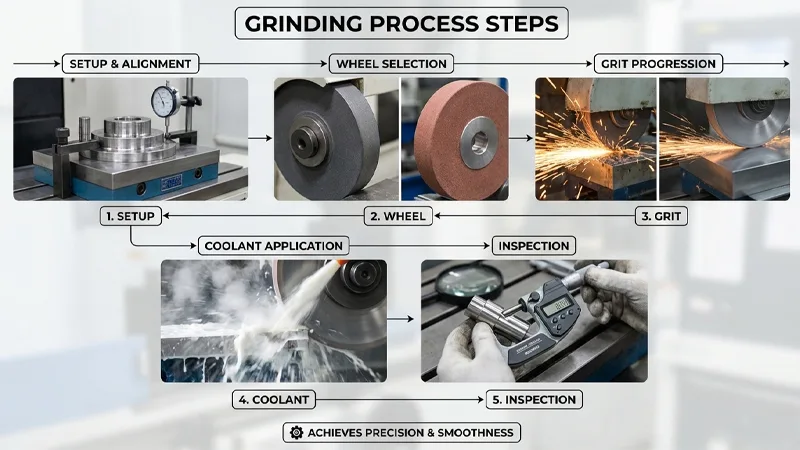

Grinding is important for making steel parts very precise. It uses abrasive wheels to take off small bits of material. This helps get exact sizes and smooth surfaces. People choose grinding when parts must be very smooth or the right size. The steps in grinding are simple and follow a set order:

- 1. First, put the workpiece on the machine and make sure it is lined up.

- 2. Next, pick a grinding wheel, usually made from tungsten carbide or aluminum oxide.

- 3. Start with a rough grit to remove more material, then use finer grits to finish.

- 4. Use coolant all the time to keep things cool.

- 5. Check the part often to see if it meets the needed size and smoothness.

The unique feature of grinding is that it can make parts smoother and more precise than other methods.

Efficiency Drivers in Grinding

Abrasive Selection and Coolant Use

Choosing the right abrasive wheel is very important for grinding hard steel. The wheel type and grit size change how smooth the part is and how fast you can work. For example, aluminum oxide wheels work well for carbon and alloy steels. Flap discs are better for blending and finishing stainless steel.

Combo wheels can cut and grind at the same time, so they are good for quick jobs. Coolant is also very important in grinding. It keeps the part and wheel cool and stops burns or cracks. The method of using coolant affects heat accumulation. Good coolant flow helps keep the part strong and extend the tool’s life.

Grinding wheels that resist wear keep their shape and save time. Tough abrasives stop cracks and help when grinding requires a lot of energy. The right coolant can change how much power is needed and how hot things get.

Machine Precision and Setup

A precise machine is needed for the best grinding results. A steady and lined-up machine makes sure the wheel touches the part evenly. This stops shaking and helps keep tight sizes. Workers must check the machine’s setup before starting. Settings like wheel speed and feed rate also matter for grinding well. Changing these can help control cutting forces and make tools last longer. Regular inspection and maintenance of machinery is key to ensuring smooth grinding operations.

Machining Applications for Grinding

Grinding is best for parts that need to be very exact and smooth. It is used for:

| Grinding Wheel Type | Description | Best Suited For |

| Aluminum oxide grains are versatile for many tasks | Aluminum oxide grains, versatile for many tasks | Carbon steel, structural steel, alloy steels |

| Flap Discs | Overlapping layers for blending and finishing | Stainless steel, structural steel |

| Combo Wheel | Cuts and grinds in one, efficient for quick tasks | Rebar, pipe, light grinding |

| Bench Grinding Wheels | Tool sharpening and general-purpose grinding | Sharpening steel tools like chisels |

Grinding is the top choice for jobs that need tight sizes and smooth surfaces. AFI Industrial Co., Ltd uses advanced machines to make sure every part is made right. With their masterful craftsmanship, they ensure that every component meets stringent dimensional and quality requirements.

Tip: Be sure to select the appropriate grinding wheel and coolant based on the job and material.

Grinding Limitations

Grinding is strong for finishing hardened steel parts, but it has limits. One big problem is grinding burn. This happens when too much heat builds up. Heat alters the internal structure of steel. It may cause color changes, make the steel softer, or make it brittle. If the grinding burn is not stopped, tiny cracks can form. These cracks can get bigger over time. They make the part weak and easier to break.

To stop grinding burn, workers use the right coolant. They also keep the grinding wheel in good shape. Sometimes, they cut less deeply or use very cold cooling for special steel. These steps help keep steel strong. But they can slow down work and make it cost more.

Grinding also has trouble balancing quality and speed. Achieving a perfect surface typically requires a slower grinding speed. Special coolants are sometimes needed. Workers may need to grind the part many times to get it just right. This takes more time and costs more money. For some jobs, this is not a good trade, especially if many parts are needed fast.

The table below shows how creep-feed grinding helps with some problems. But it still needs careful control:

| Aspect | Description |

|---|---|

| Process | Creep-feed grinding removes lots of material in one go. |

| Tolerance | Keeps sizes tight and surfaces smooth, good for hard steel. |

| Productivity | Makes many tough parts, but slower speeds may be needed for best finish. |

| Tool Life | Lower cutting force helps tools last longer and stops bending. |

Grinding needs machines set up just right. If the machine is not lined up or steady, it can shake. This makes the surface uneven. It is hard to maintain precise dimensions. Workers must check machines often and change settings for the best results.

Other limits are the cost of special abrasives and coolants. These help make smooth surfaces and tight sizes. But they cost more money. Straight oils, for example, make a slippery layer that cuts heat and friction. They help stop grinding burn and clear chips better. But they cost more than simple coolants.

Here are some important things to remember about grinding limits:

- Grinding burn can hurt steel parts and make them break.

- Getting the best surface often means slower work and higher cost.

- Machines must be set up correctly to stop shaking and keep tight sizes.

- Special abrasives and coolants help, but they cost more.

Note: Always watch heat and surface quality when grinding. Small changes in settings can stop damage and help parts work better.

AFI Industrial Co., Ltd uses smart machines to fix these problems. Their grinding skills help customers get strong, high-quality parts, even with tough steel.

Hard Turning vs Grinding: Direct Comparison

Cycle Time and Throughput

Cycle time measures how long it takes to finish one part. Throughput shows how many parts a shop can make in a set time. Hard turning achieves high machining speeds because the tool removes more material with each cutting pass. This means shorter processing times for each part. Turning machines can switch between parts quickly. They do not need long setup times. For small and medium batches, hard turning often wins in speed.

Grinding takes longer. The wheel removes less material with each pass. Operators must check the surface often. Grinding machines need careful setup. This setup can take extra time. For large batches, grinding can keep a steady pace. It works well when every part must be the same. Still, for most jobs, hard turning vs grinding shows that turning is faster for short runs.

Note: If you need to finish many parts quickly, hard turning is often the better choice. For very large orders, grinding can match the pace with less variation.

Surface Finish and Accuracy

Surface finish means how smooth the part feels and looks. Accuracy is how close the part is to the right size. Grinding is the top choice for the best surface finish. It can make parts with a mirror-like shine. Grinding also holds very tight size limits. This is important for parts that must fit together perfectly.

Hard turning gives a good finish, but not always as smooth as grinding. It can reach a surface roughness of Ra 0.2–0.4 μm. For many parts, this is enough. Turning can also hold tight sizes, but not as tightly as grinding. If a part needs a super smooth surface or the tightest size, grinding is the best pick. For most other jobs, hard turning vs grinding shows that turning gives enough accuracy and finish.

Tip: Always check the part’s needs before picking a process. If the job needs a perfect shine or the tightest fit, grinding is best. For most other parts, turning works well and saves time.

Tooling and Consumable Costs

Tooling and consumable costs are important for every shop. These costs include the price of tools, wheels, and how often they need to be replaced. Hard turning uses CBN or carbide inserts. These inserts cost more than basic tools, but the setup is simple. Grinding uses special wheels. These wheels can be expensive, but they last a long time.

The table below compares the costs for each process:

| Process | Initial Setup Cost | Tooling Cost | Production Volume Cost Effectiveness |

|---|---|---|---|

| Hard Turning | Lower | Higher tool cost but offset by lower setup costs | More economical for small batches due to shorter cycle times |

| Grinding | Higher | Grinding wheels can be expensive but last long | More cost-effective for large volumes due to consistency and reduced rework |

For small batches, hard turning is often cheaper. Although tooling costs are relatively high, they can save setup time and costs. For big batches, grinding can be better. The wheels last longer, and the process is steady. When comparing hard turning vs grinding, always look at how many parts you need and how much you want to spend.

Tip: Shops can save money by matching the process to the job size. Turning is best for quick jobs and small runs. Grinding is better for long runs and when every part must be perfect.

Flexibility and Setup

When choosing between hard turning and grinding, flexibility and setup time are critical. Hard turning is very flexible. Workers can change parts’ shapes and sizes fast. CNC lathes let you change programs quickly. This helps make small batches or custom parts with little wait. Changing tools is easy, and setup is quick. Shops can switch jobs without long stops.

Grinding is not as flexible. It needs special fixtures and careful setup. Switching parts takes more time. Grinding wheels must be fixed and balanced for each job. If a shop makes many kinds of parts, the setup time gets longer. Grinding works best for big batches of the same part. The setup stays the same for a long time.

The table below shows how flexible and easy to set up each method is:

| Feature | Hard Turning | Grinding |

|---|---|---|

| Setup Time | Short | Long |

| Changeover Speed | Fast | Slow |

| Fixture Requirements | Simple | Complex |

| Batch Size Suitability | Small to Medium | Medium to Large |

Tip: If a shop makes many different parts or changes jobs often, hard turning is usually better. Grinding is good for making lots of the same part.

Environmental Impact

Machining affects the environment in many ways. Both hard turning and grinding use CNC machines that need lots of electricity. Most electricity comes from fossil fuels. These give off carbon dioxide. This adds to greenhouse gases.

Other things that hurt the environment are:

- Making and moving raw materials uses energy and produces carbon emissions.

- Both methods make scrap metal, use coolant, and wear out tools. These must be recycled or thrown away. This can pollute the earth.

- Changing tools and fixing machines uses more energy and resources.

Grinding uses more coolant and makes more waste. Old cooling methods can hurt the environment if not handled properly. Hard turning needs less coolant, especially with new methods like minimum quantity lubrication. This cuts waste and saves energy.

Modern shops use new technology to help the environment:

- Nanofluids and minimum quantity lubrication save energy and lower emissions.

- Better coolants and lubricants help machines run cooler and cleaner.

- Sustainable machining tries to use less energy and produce less waste.

When comparing hard turning vs grinding, hard turning usually hurts the environment less. It uses less coolant and makes less waste. Grinding can be greener with good coolants and recycling, but it often needs more resources.

Note: Picking the right process and using new technology can help protect the environment and save money.

Improving Efficiency in Machining Processes

Best Practices for Hard Turning

Hard turning is a strong way to shape hard steel parts. To get the best results, workers must use smart methods. AFI Industrial Co., Ltd follows these steps to make sure every part is made well.

Optimizing Parameters and Tool Life

Good hard turning needs careful control of settings and tool care. These steps help tools last longer and keep the process steady:

- Keep tools sharp to cut better and stay cool. Sharp tools work longer and make cleaner cuts.

- Use the right speeds and feeds to stop rubbing. Good settings help remove metal faster and make smoother parts.

- Do not use spring passes to stop the part from getting too hard. This keeps the part strong and stops bad changes.

- Use coolant-fed tools to keep things cool. Cooling helps protect both the tool and the part.

- Do not let the tool stay in one spot. Keep it moving to stop heat from building up.

- Feed the tool at a steady rate when drilling. This helps stop heat and keeps the tool from wearing out.

Tip: Check tools often and change them before they get too worn. This helps the process work well and keeps making good parts.

System Rigidity and Setup

A strong setup is very important for hard turning. A solid machine stops shaking and helps make parts more exact. AFI Industrial Co., Ltd uses CNC lathes with tough frames and good controls. These machines help keep sizes tight and surfaces smooth.

- Hold the part tight so it does not move.

- Use strong tool holders that do not bend.

- Check the machine’s setup before each job.

- Pick fixtures that fit the part’s shape for the best support.

A sturdy setup lets you cut faster and deeper. This helps make more parts in less time.

Best Practices for Grinding

Grinding is needed to make parts very smooth and the right size. Good grinding depends on picking the right tools, keeping them in shape, and using the right settings.

Abrasive and Coolant Optimization

Picking the best wheel and coolant is key for grinding. These tips help keep grinding working well:

- Match the wheel type and size to the job. This helps cut better and makes smoother parts.

- Use tools the right way to make them last. Do not push too hard or the wheel can break.

- Plan work to stop delays. Quick-change systems help switch wheels fast.

- Keep wheels clean and sharp. Check them often to make sure they work well.

- Change machine settings to fit the tool and part. Good settings help make better parts and stop mistakes.

- Teach workers the best ways to grind. Skilled workers make more parts and stay safe.

- Use new wheel types for better results and longer tool life.

Note: Always watch coolant flow and wheel shape when grinding. Good cooling stops burns and keeps parts strong.

Automation and Monitoring

Modern grinding machines use robots and sensors to work better. AFI Industrial Co., Ltd uses these tools to maintain high quality and minimize errors.

- Automatic tool changers help make more parts faster.

- Sensors check heat, shaking, and tool wear. They help workers fix problems fast.

- Data helps workers set the best machine settings for each job.

Automation helps make the same good parts every time and cuts down on waste.

Choosing the Right Process for Machining

Picking between hard turning and grinding depends on what the part needs. The table below shows how each method works:

| Criteria | Hard Turning Capability | Grinding Capability |

|---|---|---|

| Dimensional Tolerances | ±0.01mm | Stricter than ±0.01mm |

| Surface Finish | Ra 0.8μm | Finer than Ra 0.8μm |

| Heat Treatment Impact | Limited | Necessary for warping correction |

Other things to think about are stress and how strong the part is. Grinding gives helpful compressive stress, from -100 to -500 MPa. Hard turning gives tensile stress, from +200 to +800 MPa. For parts that must not break, compressive stress from grinding helps stop cracks.

If a part needs to be harder than HRC 50, grinding is needed. Heat treatment can bend parts a little, even if you cannot see it. For example, parts cut to size before heat treatment can still change shape. Grinding is needed to fix these small bends.

Tip: Look at the part’s shape, size needs, and surface finish before picking a method. Hard turning is fast and flexible for many jobs. Grinding is best for very smooth and exact parts.

AFI Industrial Co., Ltd uses both hard turning and grinding to fit each job. Their skills help every part meet tough rules for size, strength, and how well it is made.

Matching Process to Application Needs

Picking the right way to machine hardened steel parts takes careful thought. You need to consider the shape of the parts, the required quantity, and the precision requirements. When deciding between hard turning and grinding, every factor is critical. AFI Industrial Co., Ltd uses smart machines to help with these choices. They ensure every component operates efficiently and fulfills its intended function.

Part Geometry and Complexity

The shape and complexity of a component influence the selection of the optimal machining method. Some shapes are easier to make with one process than another. Think about these things when looking at the part:

- Tight tolerances often need grinding or EDM. These ways give the exact size needed for important parts.

- How hard the material is can change how it reacts to cutting. Some steel types work better with hard turning, while others do better with grinding.

- Surface finish matters more when the part is complicated. Grinding helps make the surface smoother and more exact, especially for detailed shapes.

Parts with deep grooves, tiny holes, or small details usually need grinding. Hard turning is good for simple shapes like rods or flat pieces. Knowing the shape helps engineers pick the way that gives the right size and look.

Production Volume Considerations

How many parts you need also helps you choose the process. Hard turning is flexible and lets you switch jobs fast. This is great for small batches or custom pieces. Shops can change from one job to another quickly, which helps with short runs or test parts.

Grinding is best for making lots of the same part. After setting up, grinding machines can make many parts that all look the same. The process stays steady, which is important when every part must match. For big orders, grinding makes up for its longer setup by keeping a steady pace.

Tip: Look at your work schedule and how many parts you need before picking a method. Hard turning is good for quick changes and small jobs. Grinding is better for big, repeat batches.

Quality and Tolerance Requirements

The precision requirements for components and the accuracy of dimensional matching are key factors in determining the machining method. Parts that need very tight sizes or a shiny finish often need grinding. Grinding gives the best size and smoothness. Hard turning can meet many needs, but may not get the smoothest finish or the tightest size for some jobs.

AFI Industrial Co., Ltd uses both ways to fit each project. Their skills make sure every part meets the needed size, whether it needs the speed of hard turning or the exactness of grinding.

Note: Always match your choice to the part’s shape, how many you need, and how good it must be. This helps make parts fast, strong, and at a good price.

Getting the most out of machining hardened steel parts takes planning. Here are some important steps:

- Use special heat treatment and change the steel’s structure to make cutting easier

- Use computer-controlled machines to help tools last longer and make smoother parts

- Use smart models and set rules to help with cutting

- Use green methods to save energy and produce less trash

New ideas like spinning tools, nitro-milling, and checking parts during work help make things better. To get the best results, use good ways for hard turning and grinding, and try advanced machining from AFI Industrial Co., Ltd. As technology gets better, even more improvements will come.

FAQ

The choice depends on the part’s geometry and production volume. Hard turning is generally preferred for complex geometries that require multiple operations in a single setup, such as contours or boring. It offers faster cycle times and lower tooling costs. However, precision grinding remains the gold standard for extremely tight tolerances (sub-micron level) and when the material is too brittle or hard for a single-point cutting tool.

While hard turning can achieve impressive surface finishes (typically $Ra$ 0.4 to 0.8), cylindrical grinding is still superior for high-aesthetic or high-friction applications requiring a mirror finish. Grinding can consistently produce finishes of $Ra$ 0.1 to 0.2 or better. If your custom CNC components require a specific cross-hatch pattern for oil retention, grinding is often the technically necessary choice.

In many cases, yes. Hard turning reduces costs by eliminating the need for specialized grinding wheels and reducing setup times. Since it is performed on a standard CNC lathe, you can often complete the turning, facing, and threading of a hardened part in one operation. This “one-hit” machining reduces labor costs and lead times compared to the multi-stage process of traditional grinding.

- Hard Turning: Can reliably hold tolerances within ±0.005 mm to ±0.01 mm. It is excellent for most industrial applications including gears and shafts.

- Precision Grinding: Can achieve tolerances as tight as ±0.001 mm to ±0.002 mm. If your custom metal parts require aerospace-grade precision or extremely tight fitments, grinding is the safer bet to ensure compliance with strict engineering specifications.

Both processes have different thermal effects. Grinding uses coolant to manage heat, but if not controlled, it can cause “grind burns” or surface cracks. Hard turning is typically a dry process; the heat is carried away by the chips. However, hard turning can induce beneficial compressive residual stresses on the surface, which may improve the fatigue life of the machined metal part in high-stress environments.

Hard turning is often preferred for sustainable custom metal manufacturing because it is usually performed without coolants (dry machining). This eliminates the cost and environmental impact of disposing of contaminated grinding sludge and coolant. Additionally, the chips produced in hard turning are easily recyclable compared to the messy waste produced by abrasive grinding wheels.