You use the galvanizing of metal parts process to cover them with zinc. First, you clean the metal. Then you pickle and flux the surface. Next, you dip each part in hot, melted zinc. This step gives the metal a strong zinc layer. The zinc helps stop rust and makes the metal tougher. The zinc coating can protect for up to 50 years. It works well on edges and in small spaces. Many industries use the galvanizing of metal parts to make them last longer. AFI Industrial Co., Ltd helps these industries with careful machining. They make sure every step of the galvanizing process works well.

| Year | Market Size (USD Billion) | Projected Growth (USD Billion) | CAGR (%) |

|---|---|---|---|

| 2023 | 14.5 | 22.8 | 5.1 |

Key Takeaways

- Galvanizing keeps metal safe by putting zinc on it. Zinc stops rust and makes metal last longer.

- Cleaning metal well is very important. Good cleaning helps the zinc stick for many years.

- Pickling takes away rust and dirt. This makes the metal clean so that zinc can stick better.

- Fluxing stops the metal from getting rusty. It helps zinc cover the metal evenly. This makes the coating strong.

- Hot-dip galvanizing dips clean metal in melted zinc. This gives the metal a hard, protective layer.

- Cooling with air or water helps the zinc set. It keeps the coating strong.

- Checking the coating often makes sure it is even and strong. It also checks if it meets rules for quality.

- Galvanizing protects metal and helps the environment. It means fewer repairs are needed.

Table of Contents

Preparation

You need to get the metal ready before you galvanize it. This step helps the zinc coating stay strong and last a long time. If you skip this part or do it too fast, the coating can be weak. It might not stick well and could fail early.

Cleaning Methods

Cleaning comes first. It takes away dirt, oil, and things that stop zinc from sticking. There are many ways to clean metal. The table below lists some good choices:

| Cleaning Method | Description |

|---|---|

| SSPC-SP 8 | Chemical cleaning standard for acid cleaning before painting. |

| Acid Chemical Cleaning | Uses acids like sulfuric or hydrochloric with inhibitors and rinsing steps. |

| Acidic Flux Treatment | Removes oxides and prevents new oxidation before galvanizing. |

| Performance-Based Standards | Focuses on the final quality of galvanizing, not just the cleaning method. |

Degreasing

Degreasing is the first step to fight contamination. You use degreasers to get rid of grease, oil, and other stuff on the metal. This step matters because:

- Degreasers remove both organic and inorganic substances.

- Clean metal lets the zinc coating stick everywhere.

- If oil or dirt stays, zinc can peel off.

- Contaminants can cause pits, holes, or color changes.

You must make sure every piece is clean before you go on.

Rinsing

After degreasing, you rinse the metal parts. Rinsing washes away leftover cleaners and loose bits. This step keeps chemicals from causing problems later. Use clean water and check for soap, acid, or dirt. Rinsing well gets the metal ready for pickling and fluxing.

Importance of Galvanizing

You cannot get a good galvanized finish without cleaning and degreasing. These steps help the zinc coating stick tight and cover all the metal. If you leave dirt or oil, you may get weak spots. These can rust, peel, or fail early.

Tip: Always look at the metal after cleaning. Check for oil, dirt, or anything left behind. If you see any, clean it again.

AFI Industrial Co., Ltd cares about surface preparation. The company uses a strong quality control system for machining and cleaning. They inspect parts many times during each step. AFI Industrial Co., Ltd follows global standards to make sure every piece meets tough rules. This careful work gives you metal parts that are ready for galvanizing and made to last.

Pickling

Once you finish cleaning and rinsing, you start pickling. This step uses acid to take off rust and scale. Pickling gets the metal ready for the zinc coating. It makes sure the surface is clean and active.

Acid Bath

An acid bath takes away leftover rust, oxides, or scale. This step shows fresh metal. Fresh metal is needed for a strong zinc bond.

Rust Removal

The acid bath melts away rust and scale that cleaning missed. Hydrochloric acid is used for big batches. Sometimes, you use sulfuric, nitric, or phosphoric acid for special metals. Inhibitors are added to keep the base metal safe from too much acid. They also help use less acid. Wetting agents and detergents help the acid reach every part. They work even in small cracks or corners.

- Acid baths take off unwanted scale from metals and alloys.

- Hydrochloric acid is used for big jobs.

- Other acids like nitric, phosphoric, and sulfuric are for special needs.

- Inhibitors lower metal loss and keep acid safe at high heat.

- Wetting agents and detergents help acid clean better.

Tip: Always check the metal after pickling. If you see rust or dark spots, do the process again to get a clean surface.

Safety

You must be careful when using acids. You need to protect yourself and your team from burns and fumes.

- Wear gloves and eye protection with acids.

- Keep first aid supplies close, like calcium gluconate gel for burns.

- Store acids in their own acid-safe containers, upright and away from alkalis.

- Make sure there is good airflow, with 5-10 air changes each hour, to lower fumes.

- Never use acids in small, closed rooms without good airflow or masks.

- Clean up spills fast and throw away waste safely.

Note: Safety is always important. Always follow your company’s safety rules and local laws.

Surface Activation

After pickling, you activate the metal surface. This step helps the zinc coating stick better and last longer. Surface activation makes tiny spots on the metal for zinc to bond. You often use special chemicals, like colloidal titanium phosphate, to start this.

- Surface activation helps the phosphating reaction, which is important for zinc sticking.

- Colloidal titanium phosphate makes the first layer of crystals, so the zinc layer is finer and smoother.

- The process makes more crystals and makes them smaller, so zinc covers the metal evenly.

When you activate the surface, you help make a strong, even zinc coating. This step is very important for good galvanizing, especially for parts with tricky shapes or tight spaces.

Fluxing

Fluxing is the next step after pickling and surface activation. You use flux to prepare the metal for zinc coating. This step is important because it keeps the metal clean and ready for the hot-dip process. You want every part to have a strong, even zinc layer. AFI Industrial Co., Ltd uses advanced fluxing methods to support high-quality galvanizing.

Applying Flux

You apply flux to the metal surface to stop oxidation. Oxidation can happen fast after pickling. If you let the metal sit in the air, it can form a thin layer of rust. This rust blocks the zinc from sticking well. You need to use the right flux to prevent this problem.

Preventing Oxidation

Flux acts as a shield. It covers the metal and keeps oxygen away. You want to choose a flux that works best for your parts. The table below shows two common flux types and how they help:

| Flux Type | Role in Preventing Oxidation |

|---|---|

| Zinc Chloride | Acts as a protective layer to prevent oxidation. |

| Ammonium Chloride | Removes iron oxide and reacts with zinc oxide, aiding in oxidation prevention. |

Zinc chloride forms a barrier on the metal. Ammonium chloride reacts with any leftover oxides and helps keep the surface clean. You use these fluxes together in many galvanizing plants. They work well for steel and other metals.

Preparing for Zinc

You need to make sure the flux covers every part of the metal. You dip or spray the flux solution on the surface. The flux dries and leaves a thin film. This film helps the zinc stick during the hot-dip step. If you miss a spot, you may get weak coating or bare metal. Always check that the flux covers all edges, corners, and holes.

Tip: Use fresh flux solution and keep it at the right temperature. Old or cold flux does not work as well.

Role in Galvanizing

Fluxing does more than just stop oxidation. You use flux to make sure the zinc coating is even and strong. Here is how fluxing helps you get the best results:

- Removal of residual oxides. Fluxing agents clean the surface, so zinc touches the base metal directly.

- Prevention of secondary oxidation. Flux forms a protective film, stopping new rust before dipping.

- Promotion of zinc wetting. Flux lowers the surface tension of zinc, helping it spread and stick.

- Activation of the substrate surface. Active ingredients in flux react with the metal, exposing iron atoms for better zinc alloy formation.

You want every part to have a smooth, shiny zinc layer. Good fluxing helps you reach this goal. It also lowers the risk of coating defects, like bare spots or peeling. AFI Industrial Co., Ltd uses strict process controls to make sure fluxing is done right. You get metal parts that are ready for zinc and built to last.

Note: Always inspect the fluxed parts before moving to the hot-dip step. Look for dry, even coverage and no missed areas.

Galvanizing of Metal Parts

When you use the galvanizing of metal parts, your products get a strong shield. This shield lasts a long time. The process is not just dipping metal in zinc. You must follow the steps in order. This makes sure every part gets good protection. Many industries trust the galvanizing process. It works for all shapes and sizes. You can use it for small fasteners or big beams.

Hot-Dip Process

The hot-dip process is the main part of galvanizing. You put each metal part into hot, melted zinc. This makes a strong bond between zinc and the metal. The zinc coating helps the metal last in tough places.

Immersion in Zinc

First, you lower the clean metal parts into melted zinc. The zinc is very hot, about 450°C (842°F). The zinc covers every part, even holes and corners. This full coverage is why the galvanizing of metal parts works so well.

- The zinc and steel react to make alloy layers.

- The top layer is pure zinc. The inside layers are zinc-iron alloys.

- This makes the coating tough and tightly stuck to the metal.

Tip: Always check the zinc bath. Make sure it is clean and hot enough. This helps the coating go on smooth and stick well.

Temperature Control

You must keep the right temperature during hot-dip galvanizing. If the zinc is too cool, the coating is thin or patchy. If it is too hot, the coating gets too thick or breaks easily. The right temperature gives you a smooth, even finish.

- Keeping the same temperature makes the coating the right thickness.

- Good control stops problems like drips or rough spots.

- You get a finish that meets industry rules.

Coating Formation

The galvanizing of metal parts makes a special bond. The zinc and steel form layers together. Each layer adds strength and protection. The outside zinc keeps out water, air, and chemicals. If the coating gets scratched, the zinc still protects the steel. The zinc will corrode first. This is called sacrificial protection.

You get many benefits:

- The zinc coating stops rust in many places.

- The tight layers slow down rust a lot.

- A zinc patina forms over time for more defense.

- The coating is stuck to the metal, so it will not peel or flake.

- If the coating is damaged, the zinc protects the steel and stops rust from spreading.

AFI Industrial Co., Ltd helps you at every step of the galvanizing process. Their machining makes sure your parts are cut and finished right. They use advanced cutting tools and check quality with special machines. You get parts that fit well and have smooth surfaces. They are ready for galvanizing. This careful work means your zinc coating will be strong and even.

The galvanizing of metal parts gives you a simple but powerful way to protect metal. The coating lasts for many years, even in hard places. When you pick AFI Industrial Co., Ltd, your parts meet high standards for quality and strength.

Key Steps in the Hot-Dip Galvanizing Process:

- Degreasing: Take off oil and grease from the metal.

- Rinsing: Wash away the degreasing stuff.

- Pickling: Remove rust and scale.

- Rinsing After Pickling: Clean the surface again.

- Pre-Fluxing: Put on a flux coating.

- Galvanizing: Dip in melted zinc.

- Finishing: Check and finish the galvanized part.

Galvanization is not just a coating. It is a full process that makes your metal parts stronger and better protected.

Cooling and Inspection

After you finish the hot-dip galvanizing step, you need to cool the metal parts. Cooling helps set the zinc coating and keeps it strong. You have a few ways to cool galvanized metal. Each method works best for different part sizes and shapes.

Cooling Methods

Air Cooling

Air cooling is the simplest way to cool galvanized parts. You take the metal out of the zinc bath and let it cool in the open air. This method works well for most small and medium parts. Air cooling gives you a smooth finish and helps avoid cracks.

- You place the parts on racks or hang them.

- Air moves around the parts and lowers the temperature slowly.

- This method works best for thin or small items.

Tip: Use air cooling when you want to keep the coating even and avoid sudden changes in temperature.

Water Quenching

Water quenching cools metal parts much faster. You dip the hot galvanized parts into a water tank right after they leave the zinc bath. This stops any more reactions between the zinc and steel.

- Quenching quickly drops the temperature and locks in the coating.

- For large or thick steel tubes, quick cooling helps prevent the zinc from peeling.

- If you cannot use a full quench, you can spray a fine mist of water on the parts at a steep angle.

Note: Always check if your parts need fast cooling. Some shapes or sizes may need special care to avoid damage.

Quality Checks

You need to check every galvanized part before you send it out. Quality checks make sure the zinc coating is strong, even, and ready for use. You use different tests to look for problems and measure how well the coating will last.

| Quality Control Check | Description |

|---|---|

| Appearance Inspection | You look for a smooth, shiny finish. Check for bubbles, cracks, or peeling. |

| Coating Thickness Measurement | Use a gauge to see if the zinc layer meets the right thickness. |

| Adhesion Test | Try the grid or pull-out test to see if the coating sticks well. |

| Corrosion Resistance Test | Use salt spray or immersion to test how the coating fights rust. |

| Chemical Composition Analysis | Use spectral tools to check the zinc and other elements. |

| Mechanical Properties Test | Test the strength and flexibility of the part. |

| Hardness Test | Use Rockwell or Vickers tests to see how tough the coating is. |

Tip: Always keep records of your quality checks. Good records help you track performance and solve problems fast.

You get the best results when you follow each step with care. AFI Industrial Co., Ltd uses strict cooling and inspection steps to make sure your galvanized parts meet high standards. You can trust that every part will be strong, safe, and ready for your needs.

Benefits of Each Step

Corrosion Protection

Galvanizing helps stop rust at every step. Each part of the process gets the metal ready for a zinc layer. This layer keeps out water and air. Water and air cause rust. The zinc makes a shield between the steel and the outside. If the coating gets scratched, the zinc will rust first. This saves the steel under it. This is called sacrificial protection. Zinc is more likely to rust than steel. So, even if the coating is damaged, the steel stays safe.

- Galvanizing puts a shield on steel to stop rust.

- Zinc rusts before steel, so it protects the metal.

- Zinc is more active than steel, so it keeps working if scratched.

- The coating keeps out water and air, which slows rust.

Hot-dip galvanizing keeps steel safe from many kinds of rust. It works in air and water. Zinc and zinc alloy coatings are used when you need extra rust protection.

Galvanizing gives long-lasting safety and peace of mind, even in tough places.

Durability

You want your metal parts to last a long time. Galvanizing makes them strong and tough. Hot-dip galvanized steel is used in hard places like bridges and factories. The coating covers every part, even inside hollow spots. This means you do not have to worry about hidden rust.

- Hot-dip galvanized steel lasts in rough places.

- The coating is tough and covers all sides.

- Galvanized steel rusts much more slowly than plain steel, so you fix it less.

Hot-dip galvanizing also helps steel parts last longer under stress. This process makes your equipment last longer, even where there is lots of water or chemicals.

You save time and money on repairs because the coating lasts for years.

Performance

Galvanizing makes your metal parts work better. It does more than just look shiny. The coating slows down rust a lot. Steel with zinc rusts about 30 times slower than plain steel. This means your parts stay strong and safe for a long time. Many industries use galvanizing because it works well.

| Aspect | Detail |

|---|---|

| Corrosion Cost | Rust costs the U.S. about $297 billion each year. |

| Corrosion Rate | Zinc rusts about 30 times slower than steel. |

| Applications | Used in many industries for over 100 years. |

| Longevity of Protection | Hot-dip galvanizing protects for many years without fixing. |

You get strong protection, lower costs, and better results. Galvanizing is the best choice for anyone who needs metal parts to last.

Common Questions

Process Time

You might ask how long the galvanizing process takes. The time depends on part size and order amount. Each step has its own time. Cleaning and getting ready can take a few minutes or up to an hour. The hot-dip step also takes minutes or up to an hour. Most orders are finished in about three days. If you need parts fast, some companies can finish in 24 hours.

| Step | Time Estimate |

|---|---|

| Preparation | A few minutes to 1 hour |

| Hot-dip Galvanizing | Minutes to 1 hour |

| Overall Turnaround Time | Typically around 3 days |

| Fast-Track Completion | Can be arranged within 24 hours |

AFI Industrial Co., Ltd works quickly and plans well. You get your parts on time, even for big or tricky orders.

Suitable Metals

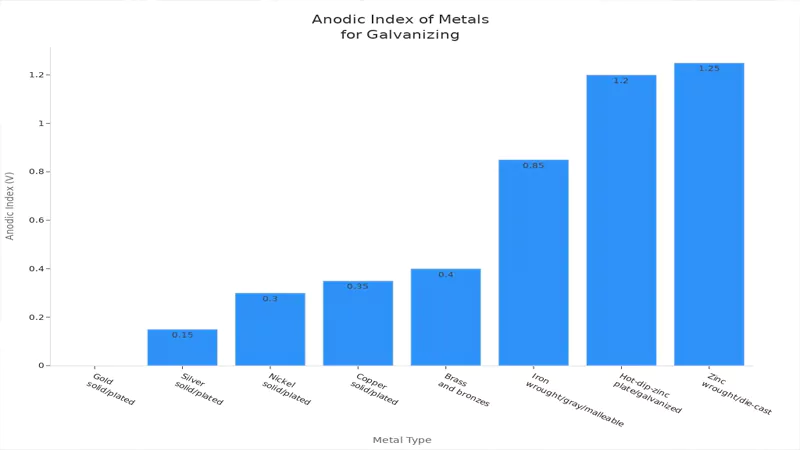

You may wonder which metals are best for galvanizing. Steel and iron are used most often. Zinc sticks well to these metals and keeps them safe. Some alloys can be galvanized, but you must check if they work. Copper and brass can rust fast when touching galvanized steel, especially if it is wet. Stainless steel and aluminum can be used in some places, but need extra care near the sea.

- Steel and iron: Best for galvanizing. Zinc sticks tight and protects.

- Copper and brass: Can rust fast if touching galvanized steel.

- Stainless steel and aluminum: Work sometimes, but need protection in tough places.

Rust can happen when two different metals touch and let electricity flow. You should design your parts to stop this problem. AFI Industrial Co., Ltd helps you pick the right metals and designs for your needs.

Coating Thickness

You want your galvanized parts to last a long time. The thickness of the zinc layer is important. Rules like ASTM A123/A123M say how thick the coating must be. There is no rule for the thickest coating. The finish should look smooth and even. You should not see bare spots or problems. The coating must stick well for the whole life of the part.

- ASTM A123/A123M sets the least thickness for coatings.

- No rule for the thickest coating.

- The finish should be smooth and even.

- No bare spots or problems allowed.

- The coating must stick strongly.

AFI Industrial Co., Ltd checks the thickness with special tools. You get parts that meet or beat the rules. Their careful checks make sure every part is ready for hard jobs.

Tip: Always ask for records of coating thickness. This helps you know the quality and how long your parts will last.

Environmental Impact

You might ask how the galvanizing process affects nature. When you pick galvanizing, you protect metal from rust. But you should also think about the Earth. Most impact happens when making galvanized metal. This step uses lots of energy and produces waste. You see this when heating zinc and cleaning metal.

But there is more to the story. Hot-dip galvanized steel lasts a long time. After you install it, you do not need to paint or fix it for years. This saves energy and lowers pollution over time. Studies show hot-dip galvanized steel can last over 70 years. You do not need to replace or fix these parts often. This means you make less pollution and use fewer new materials. You help the planet by saving energy and cutting waste.

AFI Industrial Co., Ltd cares about the environment in every job. They use smart machining and galvanizing to make less waste. Their energy recovery systems catch and reuse heat. They also recycle water. By cleaning and using water again, AFI Industrial Co., Ltd uses less fresh water and stops pollution.

Tip: Ask your supplier about their green habits. Companies that recycle water and save energy help you reach your own eco goals.

Here are some ways to make your galvanizing projects better for the earth:

- Pick suppliers with energy-saving machines.

- Find companies that recycle water and handle waste safely.

- Choose designs that use less material but still work well.

- Plan for long-lasting galvanized parts so you do not replace them often.

You help nature when you choose galvanizing. By working with AFI Industrial Co., Ltd, you get strong parts and help make the world cleaner and greener for everyone.

You get great results when you do every step in order. Each part of the galvanizing process helps make metal stronger and last longer. Galvanization puts a tough shield on your metal parts. This shield stops rust and damage. You do not need to fix galvanized metal often, so you save money. If you want even better protection, you can use special surface methods like profiling or laser cleaning.

| Technique | Purpose |

|---|---|

| Profiling | Makes the coating stick better and improves texture |

| Laser cleaning | Gets the surface ready for the best coating |

AFI Industrial Co., Ltd gives you expert help with machining and galvanizing. Learn more about advanced ways to protect surfaces so your parts work well for a long time.

FAQ

You can use galvanizing on steel and iron. Zinc sticks well to these metals. Some alloys might work, but you should ask your supplier. Stainless steel and aluminum need extra care if you want to galvanize them.

The zinc coating is usually 50 to 100 microns thick. The thickness depends on the steel type and how long it stays in zinc. You can get a test report to check the thickness.

Galvanized steel lasts from 30 to 70 years. How long it lasts depends on the place and coating thickness. If the steel is near the sea or in factories, it may not last as long.

Yes, you can weld or paint galvanized steel. You need to take off the zinc where you want to weld. For painting, use special primers made for galvanized metal.

Galvanizing uses zinc, which is found in nature. The process makes very little waste. Many factories clean and reuse water and save heat. Picking galvanized parts helps the earth because they last a long time.

Yes, you can weld or paint galvanized steel. You need to take off the zinc where you want to weld. For painting, use special primers made for galvanized metal.

Galvanizing uses zinc, which is found in nature. The process makes very little waste. Many factories clean and reuse water and save heat. Picking galvanized parts helps the earth because they last a long time.

Galvanized parts are used in building, cars, farming, and energy. These industries pick galvanized steel because it is strong and does not rust easily.

You check how thick the coating is and look for smooth spots. You also test if the coating sticks well. Some companies use salt spray tests to see how well it fights rust. Always ask your supplier for records about quality.