You want to find the best printable drill and reliable tap hole size chart for your shop. Accurate charts make your work faster and more precise. When you use a chart that is easy to read, you avoid mistakes and save time.

- The precision of tapping depends on the correct hole size.

- Industry research shows that even small errors in hole diameter can change machining results.

- Reliable chart recommendations help you get the right hole every time.

- A Drilling and threading comparison table also helps you select the best option for each job.

Download and print your chart today to keep your shop running smoothly.

Key Takeaways

- Drill and tap size charts help you work faster and more accurately.

- You can find free or paid charts online; pick one that works for your shop.

- Print a chart and keep it in your work area for easy use, even if you do not have a computer.

- Use a drilling and threading comparison table to help you pick the right tools for each job.

- Download charts as PDFs so they are clear and last longer; cover them with plastic to keep them safe.

- Update your charts often to show new tools and materials for the best results.

- Check sizes twice and use a tap guide to avoid mistakes when working.

- Mobile apps can help you find drill and tap sizes fast, making your work easier.

Table of Contents

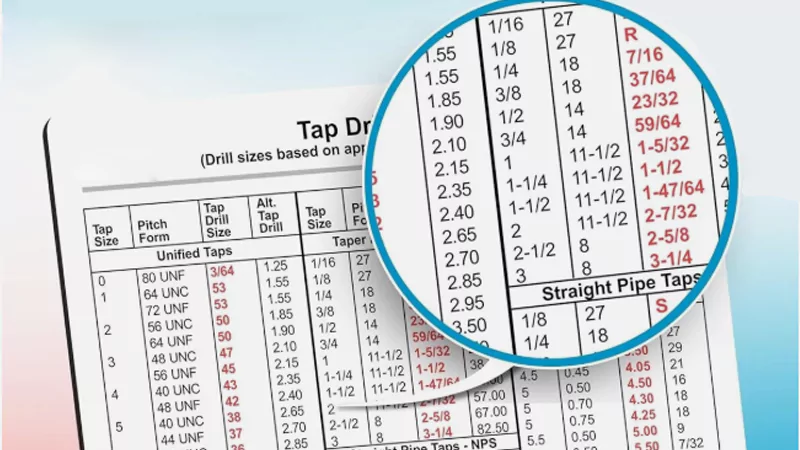

Top Tap Drill Chart Downloads

Picking the right tapping drill size chart helps you work better. You need a chart that is simple to read and easy to print. The best free and paid charts are listed below. You will also find tips for downloading and printing your chart.

Best Free Printable Tap Drill Charts

There are many free printable charts online. These charts help you pick the right tap drill sizes for different threads and materials. Using a printable chart lowers mistakes and makes setup faster.

- Little Machine Shop gives a popular tap and drill chart. Many machinists get this chart with their tools. They also have an online calculator for tap drill sizes and clearance drills.

- Starrett lets you get tap drill charts from their website. You can make an account and download a printable chart for your shop.

- MSC Industrial Supply and Allied Machine give free charts too. These charts show many tap drill sizes and thread standards.

Tip: Keep a printed chart at your workstation. This helps you find tap drill sizes fast, even if your computer is not close.

Here is a quick look at popular sources:

| Source | Recommendation Details |

|---|---|

| Little Machine Shop | Gives a tap and drill chart with tool orders; also has an online calculator for tap drill sizes. |

| Starrett | The website has tap drill charts after you make an account. |

Premium and Interactive Tap Drill Chart Options

If you want more features, you can get premium or interactive charts. These charts may show extra details like speeds, feeds, and tap drill sizes for each material. Some interactive charts let you enter your thread type and material for quick answers.

- Starrett and Allied Machine both have premium chart options. These may have interactive tools or mobile app access.

- Little Machine Shop has an online calculator that works like an interactive chart. It helps you find the right tap drill sizes for any job.

Premium charts are helpful if you use many materials or need more machining data.

Note: Interactive charts save time by cutting down on manual math and help you avoid mistakes in machining.

Download and Print Tips

When you download a printable chart, you want to avoid printing problems. Here are some common issues and how to fix them:

| Issue | Description | Solution |

|---|---|---|

| Slow print speeds | Errors happen when the print spooler does not handle jobs correctly. | Check the document type and make sure printer settings are set for fast printing. |

| Spooling errors | Errors happen when the print spooler does not handle jobs right. | Ask your system admin for help, and do not hit print many times. |

| Print driver issues | Old or wrong drivers can cause printing problems. | Update printer drivers often to keep things working well. |

| Paper jams | Jams can happen from objects or bad paper loading. | Make sure the paper is straight, clean, and loaded right in the tray. |

To get the best results:

- Download the chart as a PDF if you can. PDF files keep the chart clear and easy to read.

- Use good paper for your printable chart. This makes the chart last longer in your shop.

- Put your chart in a plastic sleeve or laminate it. This keeps it safe from oil, coolant, and dirt.

A good tapping drill chart is important for any shop. It helps you pick the right tap drill sizes, lowers mistakes, and keeps your work moving. No matter if you use a free or premium chart, print and protect your chart for daily use.

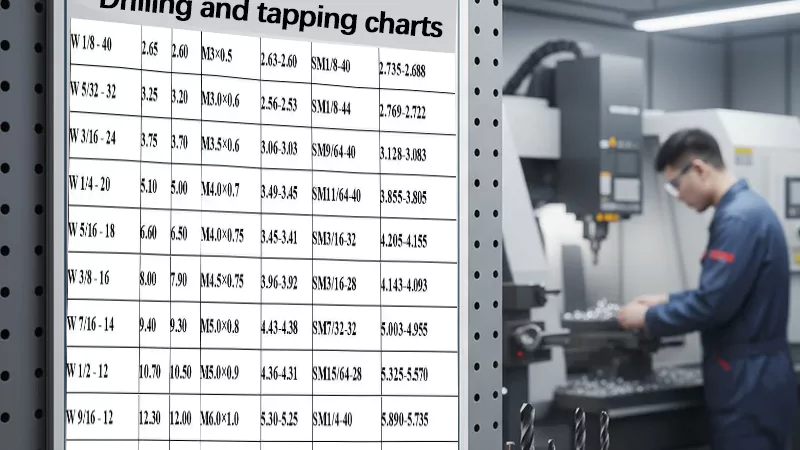

Drilling and Threading Comparison Table

A drilling and threading comparison table helps you pick the right drill size. It also helps you choose the best threading method for your job. You use this table to look at different thread types, materials, and hole depths. The table gives you important facts about tap drill sizes and thread types. It also tells you about the machine setup. When you have this information close by, you can pick the right tools fast. This helps you avoid expensive mistakes. In machining, a good reference like this table saves time. It also makes your work more accurate. You can change your plan for each job. This is helpful when you need a certain thread depth or must work with deep holes.

How to Read a Drilling and Threading Comparison Table

When you look at a drilling and threading comparison table, you will see many parts. Each part helps you make a good choice for your work. Here is a quick guide to what you should check:

| Key Element | Description |

|---|---|

| Material Type | Check if the material is hard or brittle. This changes if you use thread milling or tapping. |

| Hole Depth | Look at how deep the hole is. Deep holes may need special threading. |

| Thread Quality and Precision | See what thread quality and tolerance you need for your job. |

| Thread Type | Find out if you need a standard or special thread. |

| Machine Setup and Adaptability | Think about what your machine can do and how it handles different threading. |

| Chip Removal | Check how each method removes chips, especially in deep holes. |

| Cycle Time and Efficiency | Compare how fast and efficient each method is for your work. |

| Tool Cost and Availability | Look at how much the tools cost and if you can get them easily. |

Tip: Always use the drilling and threading comparison table before you start a new job. This habit helps you avoid mistakes and keeps your work smooth.

Where to Find Reliable Comparison Tables

You can find up-to-date drilling and threading comparison tables online. These websites have charts, calculators, and tables for metric and imperial threads. Here are some good places to get your reference:

| Resource Description | Link |

|---|---|

| Theoretical Machinist Website News | Visit |

| Calculators for Threads and Drilling | Calculators |

| Unified Imperial Thread Sizes | Threads Unified Imperial |

| Metric Thread Profile | Threads Metric: M Profile |

| Tap Drill Size Calculators | Tap Drill Size |

| Common Imperial Thread Sizes | Common Imperial thread sizes |

| Common Metric Thread Sizes | Common Metric thread sizes |

| Basic Tap Drill Sizes | Basic Tap Drill Sizes |

| National Pipe Thread Tap Drill Size | National Pipe Thread Tap Drill Size |

| British/ISO Pipe Thread Tap Drill Size | British/ISO pipe thread Tap Drill Size |

| Updated Metric Thread Calculator | Metric thread calculator |

You can use these resources as your main reference for any drilling and threading comparison table you need. Keeping a printed or digital copy at your workstation means you always have the information ready for any job.

Note: Having quick access to a drilling and threading comparison table helps you spend less time looking for data and more time working with confidence.

Tap Hole Size Chart Essentials

Tap Hole Size Chart vs. Drill Bit Size Chart

You might ask how a tap hole size chart is different from a drill bit size chart. Both charts help you pick the right tool, but they are used for different jobs. The tap hole size chart is for threading. The drill bit size chart is for regular drilling.

| Chart Type | Application Description |

|---|---|

| Tap Drill Chart | Used to find the right drill size for making threads inside a hole. |

| Drill Bit Size Chart | Shows many drill sizes for different jobs, not just threading. |

If you want to make threads in a hole, use the tap hole size chart. This chart tells you which drill bit you need before you tap. If you only use the drill bit size chart, you might pick a drill that does not fit your thread. This can make weak threads or break your tool.

Using Tap Hole Size Charts in Machining

A tap hole size chart helps you work more accurately and quickly. You use this chart to match the drill size to your tap. This makes sure your threads fit well and stay strong. Experts say a good tap hole size chart is important for many reasons:

- Getting the right hole size is key for tapping. It affects how well your threads fit and how fast you work.

- Old tap/drill charts may not show new drilling methods. This can cause broken taps and slow work.

- New drill technology needs exact hole sizes. This helps you make better threads and improves your work.

Keeping a tap hole size chart at your station helps you avoid mistakes. Here are some errors you can stop:

| Mistake | Explanation |

|---|---|

| Incorrect Tap Drill Size | Using the wrong drill size can make threads too tight or too loose. |

| Misunderstanding Pitch | Mixing up pitch and TPI can make threads not fit right. |

| Choosing the Wrong Tap for Material | Some materials need special taps. Using the wrong one can damage your work. |

| Not Accounting for Tolerance | Not thinking about tolerance can change how your threads fit. |

Check your tap hole size chart before every tapping job. This habit helps you avoid big mistakes and keeps your work steady. Following the chart lowers the chance of breaking taps, making bad threads, or wasting material.

Tip: Always look at your tap hole size chart before you start a new thread. This easy step saves time and stops you from doing work over.

A tap hole size chart is more than a guide. It helps you work better, faster, and get good results every time.

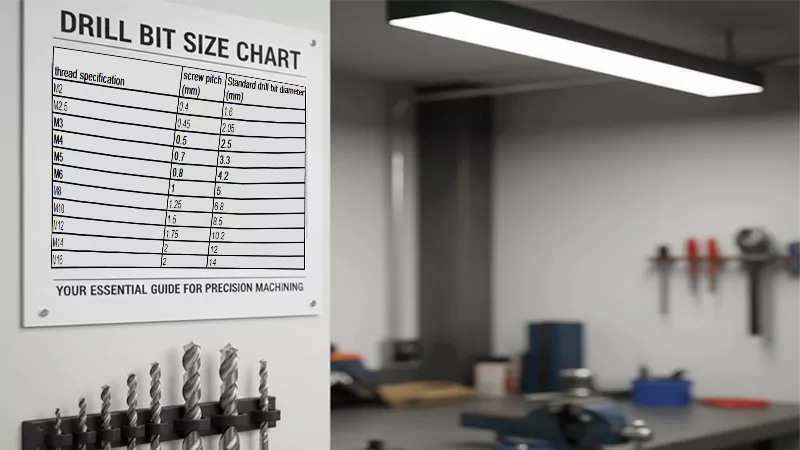

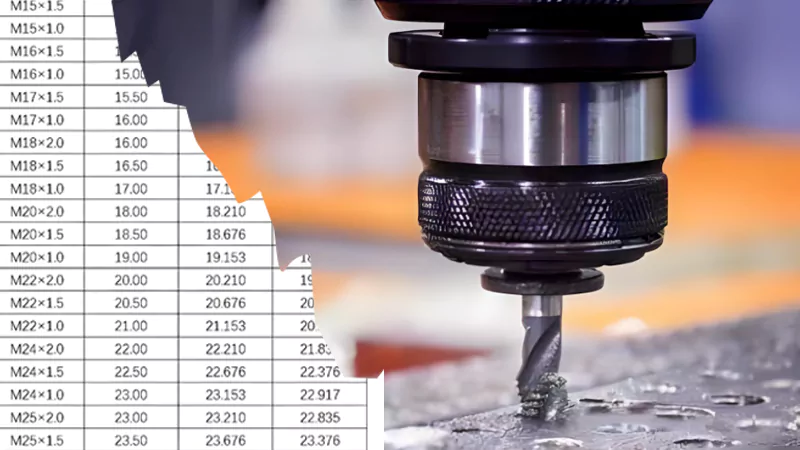

Drill Bit Size Chart for Machinists

A drill bit size chart is one of the most important tools you can keep in your shop. You use this chart to match the right drill bit sizes to your machining needs. The chart helps you work with both metric and imperial sizes, so you can handle any job that comes your way. When you look at a drill bit size chart, you will see a table that lists the measurement system, the drill bit size, and the required screw tap size. This structure makes it easy for you to find the right size quickly, whether you are working with metric and imperial sizes.

Metric and Imperial Drill Bit Size Charts

You will find that a drill bit size chart includes both metric and imperial sizes. This means you can switch between systems without confusion. For example, you might see a table like this:

| Measurement System | Drill Bit Size | Required Screw Tap Size |

|---|---|---|

| Metric | 3.0 mm | M3 |

| Imperial | 1/8 inch | #30 |

This format lets you compare metric and imperial sizes side by side. You can use the chart to select the correct drill bit sizes for any fastener or thread standard. If you work with international parts or need to follow specific machining standards, having both metric and imperial sizes on your drill bit size chart is essential. You avoid mistakes and keep your work accurate.

A drill bit size chart is not just a list. It is a reference that helps you make the right choice every time. You can use it for tapping, drilling, or matching fasteners. The chart gives you confidence that your holes will fit the screws or bolts you plan to use.

Quick Reference Tips for Shop Use

You can get the most out of your drill bit size chart by following a few simple tips:

- Understand fractional and metric bit sizes. Keep a conversion chart handy so you can switch between metric and imperial sizes without delay.

- Consider the hole depth before you pick your drill bit sizes. Use the shortest bit that will do the job for better stability.

- Size pilot holes for precision. Drill a small pilot hole first to keep your bit from wandering.

- Always consult your drill bit size chart. Check the workpiece material and the fastener size before you start drilling.

You need to choose the correct drill bit sizes for every job. The size of the drill bit affects the diameter of the hole. If you pick the wrong size, the screw may not fit, or the connection may be weak. Using a drill bit size chart helps you avoid these problems.

A drill bit size chart is especially important when you work with different materials and thread standards. You want clean, functional holes every time. The chart helps you match the drill bit sizes to the material and the thread, so your work stays strong and reliable.

Tip: Keep your drill bit size chart close to your workstation. Laminate it or put it in a plastic sleeve to protect it from oil and dirt. This way, you always have the information you need at your fingertips.

A drill bit size chart is more than a tool. It is your guide to better machining. You can handle metric and imperial sizes with ease, make precise holes, and keep your shop running smoothly.

Using Tap Drill Charts in Machining

Step-by-Step Guide

You can make your machining process smoother by following a clear method for using a tap drill chart. Here is a simple guide you can use every time:

- Identify the material and fastener you plan to use. Write down the diameter, thread pitch, and material type.

- Find the fastener size on your tap drill chart. Match it to the correct drill diameter. This ensures your threads will fit well.

- Select the right tap for internal threads. Make sure it matches the fastener and the drill size you chose.

- Double-check your choices. Review the chart and your notes before you start drilling or tapping.

Tip: Always keep your tap drill chart close by. This habit helps you avoid errors and keeps your workflow efficient.

Common Mistakes to Avoid

Even experienced machinists can make mistakes when using a tap drill chart. You can prevent most problems by watching for these common issues:

- Using the wrong drill size for the tap. This can lead to threads that are too tight or too loose.

- Forgetting to use a tap guide. Without it, your tap may not go in straight.

- Skipping oil during tapping. Oil helps keep the tap cool and makes cutting easier.

- Not using a center drill. This step helps align larger bits and prevents misalignment.

- Applying too much force. Excess pressure can break the tap or damage the workpiece.

- Failing to peck when drilling or tapping. Pecking helps remove chips and keeps the tool cool.

| Cause | Fault Codes |

|---|---|

| TAP DRILL SIZE INCORRECT | O-B |

Note: Take your time to set up each job. Rushing increases the chance of mistakes and tool damage.

Shop Organization Tips

You can boost your machining accuracy and speed by organizing your workspace around your tap drill chart. Here are some practical tips:

- Place a printed tap drill chart at every workstation. Laminate it or use a plastic sleeve to protect it from oil and dirt.

- Store your charts near your drill bits and taps. This makes it easy to check sizes before you start.

- Update your charts when you get new tools or work with new materials. Outdated charts can cause errors.

- Train everyone in your shop to use the tap drill chart as part of their daily routine. Consistent use leads to fewer mistakes.

- Keep a backup digital copy on your shop computer or tablet. This ensures you always have access, even if the printed chart gets damaged.

Keeping your tap drill chart accessible at all times helps you make quick, accurate decisions. This practice supports efficient machining and reduces costly errors.

By following these steps and tips, you make your shop safer and more productive. A well-used tap drill chart is a key tool for any machinist who values precision and efficiency.

Choosing the Right Chart for Your Shop

Picking the right drill and tap chart is important. You need more than just a piece of paper. The chart should last a long time and be easy to read. It must fit what you do in your shop. Let’s look at what you should check.

Material and Durability

Your chart should not fall apart in a busy shop. Oil, coolant, and metal shavings can mess up weak charts fast. Try to get charts printed on thick paper or ones that are laminated. Some shops use plastic sleeves to keep charts clean.

When picking a chart, think about these things:

- Accuracy of drill sizes: You need the right info for good threads.

- Type of material being drilled: Some materials need different drill and tap sizes.

- Thread engagement requirements: The right chart helps your threads stay strong.

- Hole depth: Deep holes need care so taps do not break.

- Tool compatibility: Make sure your tools fit the sizes on your chart.

Tip: Laminate your chart or put it in a plastic sleeve. This keeps it clean and helps it last longer.

Readability and Size

A chart is only helpful if you can read it fast. Look for charts with big letters and bold headings. A clear layout helps you find sizes quickly. Large print is good if your hands are dirty or you wear gloves. Some charts use colors to show metric and imperial sizes. This makes it easier to switch between them.

The size of the chart matters too. If it is too small, it is hard to read. If it is too big, it may not fit at your station. Pick a size that works for your space. Many machinists like charts that fit in a binder or hang on the wall.

| Feature | Why It Matters |

|---|---|

| Large Print | Easier to read in shop conditions |

| Clear Layout | Find sizes and info quickly |

| Color Coding | Switch between metric and imperial |

Specialty Charts for Advanced Machining

Sometimes, regular charts are not enough for your work. If you use special materials or threads, you may need specialty charts. These charts have extra info, like speeds, feeds, and tap drill sizes for tough alloys. Some charts show pipe threads or fine threads.

Specialty charts can also help with advanced jobs, like thread milling or forming taps. Some even give tips for fixing problems, like broken taps or bad threads.

Note: Specialty charts are great if you do many types of jobs or use high-performance materials. They help you avoid mistakes and keep your shop working well.

Picking the right chart means thinking about how strong it is, how easy it is to read, and what you need for your work. The right chart saves you time, helps you make fewer mistakes, and lets you do good work every day.

Additional Resources for Machinists

You want your shop to run well and stay modern. The right resource can help you work faster and with fewer mistakes. Here are some helpful resources that give you important machining data, quick math tools, and the latest news.

Mobile Apps and Digital Tools

Mobile apps and digital tools are very helpful for machinists. You can use these apps to check drill and tap sizes fast. They also help you figure out feeds and speeds. You do not need to look through paper charts.

| App Name | Features |

|---|---|

| Theoretical Machinist Charts | Custom charts, Drill Point Calculator, Cutting Tap drill size chart, works on iOS and Android. |

| Machinist Buddy | Free calculator with many useful tools, but it has some limits. |

| Machinist Journeyman | Advanced Milling Calculations, Drill Chart References, works on Android. |

You can put these apps on your phone or tablet. They help you get answers fast and check your work. Many machinists use these tools to make fewer mistakes and work quickly.

Tip: Try a few different apps to see which one you like best. Some apps have more features for tough jobs. Others are simple and quick to use.

Printable Charts for Shop Calculations

Printable charts are also great for your shop. You can use these charts for more than just drill and tap sizes. Many shops keep charts for speeds, feeds, and other math near each machine. These charts help you set up jobs fast and stop big mistakes.

- Use these charts to help set up your machines.

- Keep printed charts at each workstation so you can find them fast.

- Laminate your charts or put them in plastic sleeves to keep them clean.

Note: These printable charts show basic cutting speeds and average numbers. They help you practice programming and make quick choices in the shop.

Staying Updated

Machining changes quickly. You need good resources to learn about new tools, charts, and tips. Many machinists sign up for newsletters, visit trusted websites, or join online groups to stay up-to-date.

- Check company websites like Starrett, Little Machine Shop, and Allied Machine for new charts and tools.

- Visit machining forums and online groups to learn about new things and share ideas.

- Sign up for emails from your favorite resources. This way, you hear about new charts, app updates, and machining news.

Staying connected with your favorite resources helps you find new ideas and keep your shop doing well.

By using mobile apps, digital tools, and printable charts, you make your shop better and more accurate. Keeping your resources up-to-date means you always have the best info for every job.

You need the right drill and tap size charts for good machining. Updated charts help you pick the correct tool sizes. This makes your work faster and helps you waste less. Using new data helps you avoid mistakes. It also makes your work better.

| Tap Drill Size Charts | Description |

|---|---|

| Use updated charts | Needed to pick the right drill size and stop tap breakage. |

| Downloadable charts | You can get them in metric and imperial. They cover screw sizes from 0 to 1″. |

| Keep your charts close and look at them often. Download a new chart now to help your shop work better. |

FAQ

A tap drill chart helps you choose the correct drill size before tapping threads. You use it to match the tap size and thread pitch to the right drill bit. This chart prevents mistakes and broken taps.

Laminating your charts protects them from oil, coolant, and dirt. You keep the information readable and extend the chart’s life. Laminated charts also resist tearing and stains in busy shop environments.

Some charts show both metric and imperial sizes. You can use these charts for any job that needs either system. Always check that your chart covers the sizes you need before starting your work.

Update your charts when you get new tools, work with new materials, or see changes in industry standards. Keeping your charts current helps you avoid errors and ensures you use the best machining practices.

A tap drill chart shows the correct drill size for tapping threads. A drill bit size chart lists all drill sizes for general drilling. Use the tap drill chart for threading jobs and the drill bit size chart for other drilling tasks.

You can find reliable charts on trusted websites like Starrett, Little Machine Shop, and Allied Machine. These sites offer free downloads. You can also use mobile apps or digital tools for quick access.

Print a new chart as soon as possible. Keep a digital backup on your computer or phone. Laminating or using a plastic sleeve helps prevent future damage.