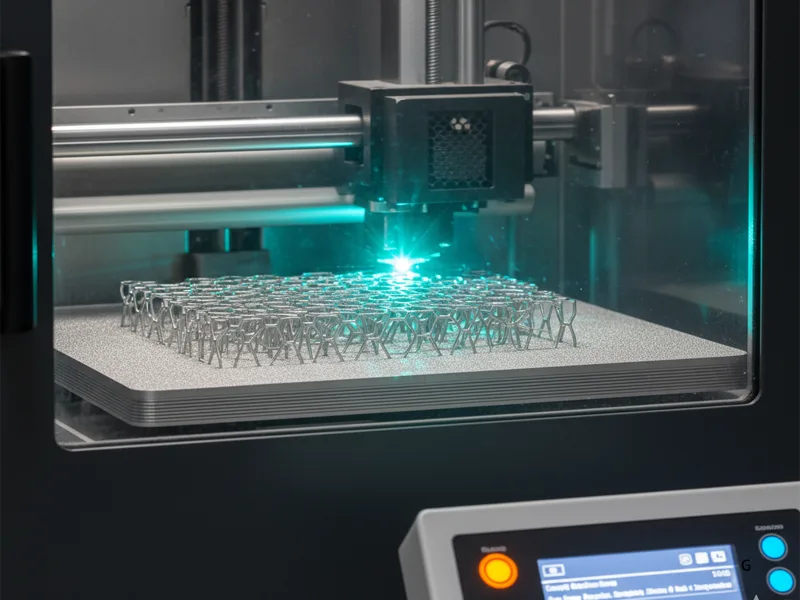

Direct metal laser sintering changes how people make things. You can make detailed metal parts faster and for less money. This method helps you go from idea to finished product quickly. It gives you high precision, complex shapes, and less waste than old ways.

| Advantage | Description |

|---|---|

| High Precision | Get fine detail and accuracy for hard parts. |

| Material Versatility | Use many metals and alloys for strong, tough results. |

| Complex Geometries | Make shapes that old methods cannot create. |

| Reduced Waste | Use less material and make less waste. |

- The DMLS technique made over USD 271.5 million in 2021.

- Experts think it will grow by 22% each year until 2030.

You can find this technology in many areas. AFI Industrial Co., Ltd is a leader and uses smart solutions to help with hard jobs. Think about how the DMLS process can fix your hardest problems and help your business grow.

Key Takeaways

- Direct Metal Laser Sintering (DMLS) helps make metal parts fast. It cuts down the time needed to make things by a lot.

- DMLS does not need pricey molds or tools. This saves money, especially for small orders and custom pieces.

- This technology lets people make shapes that old methods cannot do.

- DMLS uses only the material needed for each part. This means less waste and a greener way to make things.

- Aerospace, automotive, and medical fields use DMLS. They make parts that are lighter, stronger, and work better.

- DMLS lets people quickly make and test new designs. This helps new ideas and products come out faster.

- AFI Industrial Co., Ltd gives full help from design to making the parts. They make sure the parts are high-quality and fit what you need.

- As DMLS gets better, more industries will start using it. This will help meet the need for custom-made parts.

Table of Contents

DMLS Benefits

Cost Savings

Direct metal laser sintering helps you save money. You do not need pricey molds or tools. The process builds parts one layer at a time with lasers. This works well for low-volume parts and custom orders. You do not pay extra for setup or tooling. Metal additive manufacturing uses only the material needed for each part. You waste less and spend less money. AFI Industrial Co., Ltd helps you cut costs with advanced machining and metal additive manufacturing. You get strong parts without spending a lot.

| Benefit | How It Saves Money |

|---|---|

| No Tooling Needed | Skip expensive molds and dies |

| Less Waste | Use only what you need |

| Fast Setup | Start making parts quickly |

| Small Batches | Make small runs for less money |

Design Flexibility

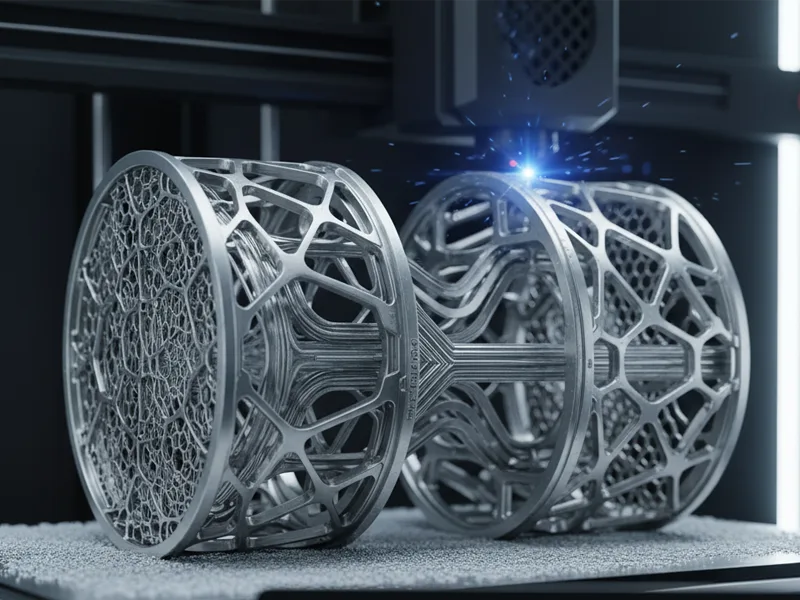

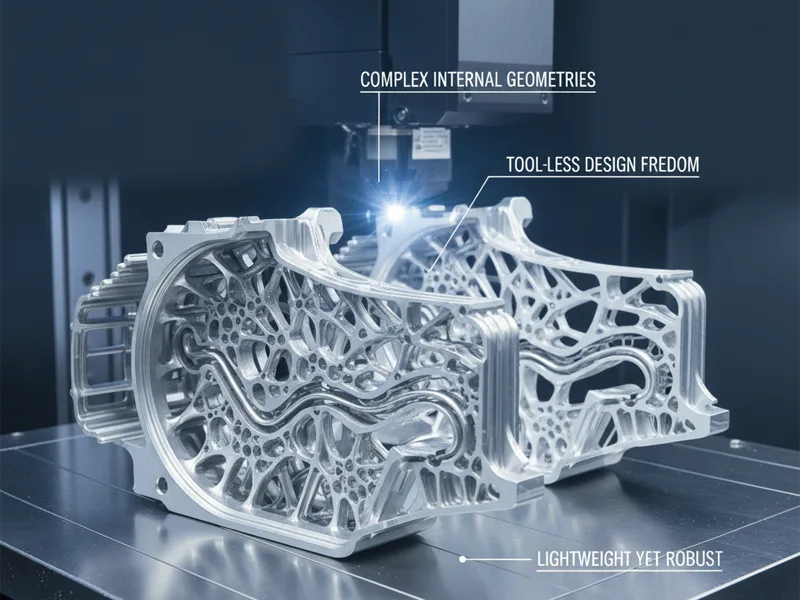

Direct metal laser sintering lets you make almost any shape. The process allows you to design parts with intricate and complex structures. Old ways of making things cannot do this easily. Metal additive manufacturing gives you the freedom to try new ideas. You can change parts for special jobs. 3d printing lets you change designs fast and test new ideas. AFI Industrial Co., Ltd helps you be creative with direct digital manufacturing and metal additive manufacturing.

- You can make parts with tiny details and hard shapes.

- You can design inside channels, lattice shapes, and light frames.

- You can change each part for your needs.

- You can make shapes that old ways cannot do.

Tip: Try direct digital manufacturing to test new ideas before making lots of parts. You can fix your designs without spending extra money.

Fast Turnaround

Direct metal laser sintering gets your parts to you faster. The process skips long setup steps. You send your CAD file, and the machine starts right away. Metal additive manufacturing cuts down on wasted material and tooling costs. You can get test parts in three to five days, depending on how hard the part is. Rapid prototyping helps you test and fix designs quickly. 3d printing lets you make changes fast and shortens wait times. AFI Industrial Co., Ltd gives you test parts and finished parts in seven days or less.

- You can make working metal test parts in less than a week.

- You can change designs and get new parts quickly.

- You can go from idea to finished part fast.

- You do not have to wait for tooling or setup.

Direct metal laser sintering and metal additive manufacturing help you stay ahead in making things. You save money, get more design choices, and get parts faster. AFI Industrial Co., Ltd offers direct digital manufacturing and rapid prototyping to help you do well.

Direct Metal Laser Sintering in Industries

Aerospace

Direct metal laser sintering is changing how people make airplane parts. This technology helps build strong and light pieces for aerospace parts. Lighter parts help planes use less fuel and fly better. You can now design shapes that were not possible before. The laser melts metal powder in layers to make detailed and lighter parts.

Some real examples in aerospace are:

- GE Aviation uses metal 3D printing for a fuel nozzle. This nozzle has a tricky shape. It is 25% lighter and helps engines save fuel.

- Airbus made a new partition for planes. This part is 45% lighter than the old ones. The plane weighs less and can carry more.

- Autodesk made a seat frame with a lattice design. The frame is much lighter but still keeps people safe.

These examples show how the technology meets tough aerospace rules. You get lighter parts, better fuel use, and safer flights. AFI Industrial Co., Ltd helps with precision machining and direct metal laser sintering for planes. You can trust them to make high-quality airplane parts that fit your needs.

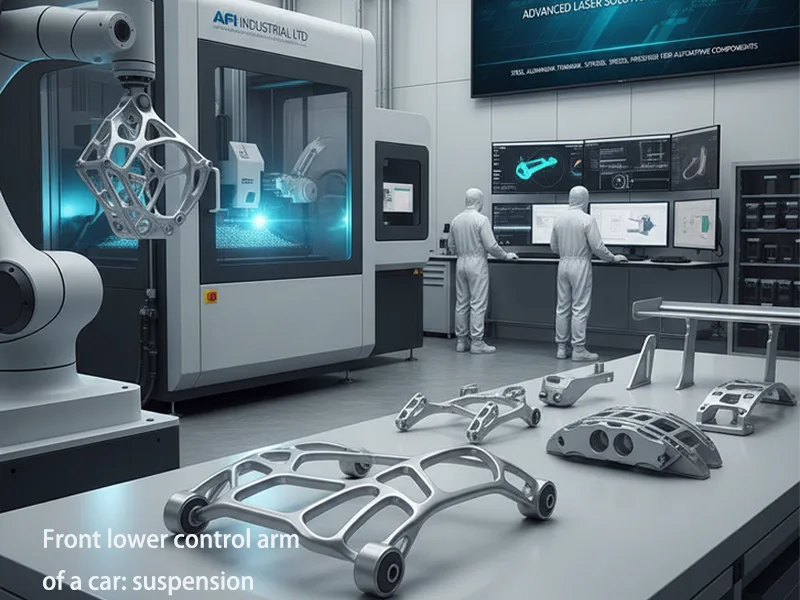

Automotive

Direct metal laser sintering gives new ways to make car parts. You can create tricky shapes and strong pieces that help cars work better. The laser builds each part from metal powder. This means you waste less and get parts faster.

| Advantage | Description |

|---|---|

| Design Freedom | You can make tricky shapes and hidden spots in car parts. |

| Speed | You get test parts fast and move to making them sooner. |

| Material Efficiency | You use only what you need, saving money and helping the planet. |

| Strength and Durability | You get tough parts that last a long time. |

| Wide Range of Materials | You can pick from many metals and alloys for different jobs. |

| Integration of Assemblies | You can make hard assemblies as one part, making building easier. |

You can use direct metal laser sintering to make strong and light car parts. These parts handle stress well. Engineers use metals like steel, aluminum, and titanium to make cars lighter and faster. You can also make special parts for race cars or custom vehicles. AFI Industrial Co., Ltd helps you get the right car parts with advanced laser tools and expert help.

Defense

You need strong and reliable parts for defense jobs. Direct metal laser sintering lets you make parts that meet strict rules for strength and detail. The laser process helps you make detailed pieces for defense, like light armor, custom brackets, and tricky housings.

You can make small batches of custom parts fast. This is good for special missions or quick fixes. On-demand manufacturing means you get parts when you need them. AFI Industrial Co., Ltd works with you to make defense parts that fit your needs, using advanced laser and machining tools.

Note: Direct metal laser sintering helps many industries by making custom parts easy. From planes to defense, you can count on this technology for fast, flexible, and high-quality parts.

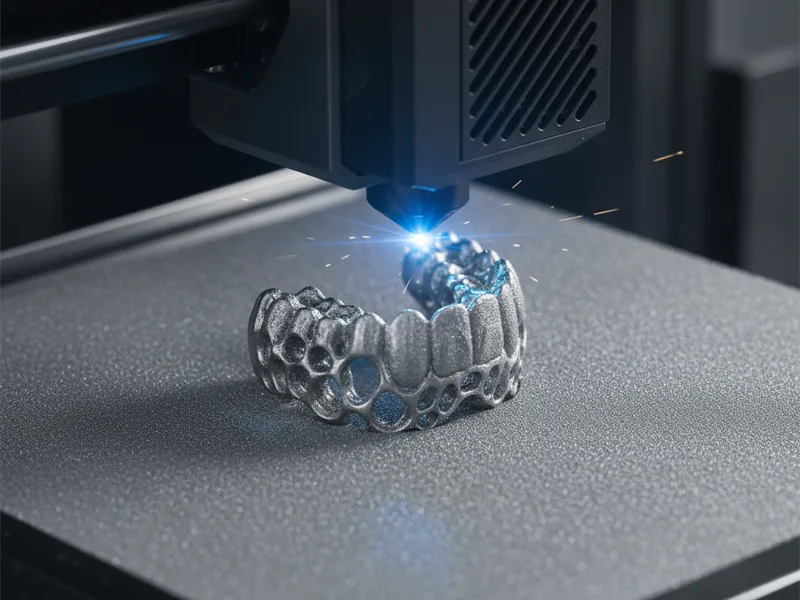

Medical and Dental

You see big changes in the medical field because of direct metal laser sintering. This technology lets you make custom medical implants and dental devices that fit each patient. You can design and produce parts with shapes that match a person’s body. The laser builds these parts layer by layer, so you get strong and safe results.

You can use titanium to make dental implants with a special porous surface. This surface helps the bone grow into the implant, making it stronger in the mouth. You control the size, shape, and placement of the pores. This helps the implant work better and last longer. You also waste less material and save money because you only use what you need.

- You can make custom medical implants for hips, knees, and jaws.

- You can design dental crowns, bridges, and orthodontic parts that fit perfectly.

- You can create parts with complex shapes that help doctors and dentists do their jobs better.

AFI Industrial Co., Ltd uses advanced laser technology to help you get the right medical parts. You get high-quality results that meet strict health standards. You help patients heal faster and feel better with these new tools.

Jewelry

You can now design and make jewelry in ways that were not possible before. Direct metal laser sintering lets you turn digital designs into real pieces with fine details. You can create rings, pendants, and bracelets with shapes that are hard to make by hand.

- You can make jewelry with tiny patterns and open spaces.

- You can use metals like stainless steel and titanium for strong and shiny pieces.

- You can test new designs quickly and change them before making the final piece.

Designers use this technology to make custom jewelry for special events or personal gifts. You can offer your customers more choices and faster service. AFI Industrial Co., Ltd helps you bring your creative ideas to life with expert laser work and careful finishing.

Turbomachinery

You need strong and complex parts for machines like turbines and compressors. Direct metal laser sintering helps you make these parts with high precision. You can design shapes that improve airflow and heat control. The laser builds each part so you get the best fit and performance.

Siemens Energy used this method to improve hot turbine guide vanes. These new parts help the machine run better and last longer. You can make parts that handle high heat and stress. You also save time because you do not need special tools or long setup steps.

- You can make blades, vanes, and housings for turbines.

- You can test new designs and improve them quickly.

- You can use strong metals that work well in tough jobs.

AFI Industrial Co., Ltd supports you with advanced laser and machining services. You get reliable parts that help your machines work better and save energy.

AFI Industrial Co., Ltd Solutions

Custom Parts

You need parts that fit your job. AFI Industrial Co., Ltd makes custom parts for many industries. You send your design to their team. They use lasers to build your part layer by layer. This way, you get strong parts with tricky shapes. You can pick metals like titanium, stainless steel, or aluminum. Their engineers work with you to match your needs. You get parts for planes, cars, medical tools, and more. Direct metal laser sintering helps you test ideas and change designs fast.

Tip: You can ask for special things, like inside channels or lattice shapes. The laser makes these details very carefully.

Quality Control

You want parts that work every time. AFI Industrial Co., Ltd checks each part with strict rules. The team uses smart tools to measure size, shape, and strength. You get reports that show your part meets all standards. Laser scanning finds tiny mistakes. You can trust your parts to last and work well. Engineers fix problems before you get your order. You save time and avoid errors.

| Step | Check | Result |

|---|---|---|

| Laser Scanning | Finds small flaws | Strong, safe parts |

| Measurement Tools | Checks size and shape | Exact fit |

| Material Testing | Tests metal strength | Reliable results |

One-Stop Service

You want everything in one place. AFI Industrial Co., Ltd gives you one-stop service for direct metal laser sintering and other machining. You get help from design to the finished part. The team helps with rapid prototyping, picking materials, and making the final product. You save time because you do not need many suppliers. The company helps you make tricky shapes and strong parts with lasers.

- Complex Geometries: You can make hard shapes that old ways cannot do.

- Material Versatility: You pick from many metals for your job.

- Time and Cost Efficiency: You get parts fast and save money.

- Design Iterations and Prototyping: You test new ideas quickly.

| Advantage | Description |

|---|---|

| Design Freedom | You make tricky shapes and inside features |

| Speed | You get parts fast with rapid prototyping |

| Material Efficiency | You waste less metal |

| Strength and Durability | Your parts are strong and last long |

| Wide Range of Materials | You pick from many metals and alloys |

You get help from start to finish. The team helps you fix problems and make your products better. AFI Industrial Co., Ltd uses lasers to give you strong parts and quick service.

DMLS vs. Traditional Methods

Speed

You want your parts fast. Direct metal laser sintering gives you a big speed advantage over traditional methods. You do not need to wait for special tools or molds. The laser builds each part layer by layer, starting from your digital design. This means you can go from idea to finished part in just a few days. Traditional manufacturing often takes weeks because you must set up machines and make tools first. DMLS works well for rapid prototyping and for making complex parts quickly. You can test new ideas and get working samples much faster than before.

Tip: If you need a part with tricky shapes or fine details, the laser can make it in less time than old methods.

Cost

You care about cost when you make parts. The price depends on how many parts you need and how complex they are. Here is how the two methods compare:

- DMLS costs more for each part because the machines and metal powders are expensive.

- Traditional methods cost less for big batches, but you pay extra for molds and setup.

- DMLS saves money for small runs and custom jobs because you do not need special tools.

- You get shorter lead times with DMLS, so you save time and money on urgent projects.

| Factor | DMLS | Traditional Methods |

|---|---|---|

| Tooling Cost | None | High for molds and dies |

| Best for | Prototyping, custom parts | Large production runs |

| Lead Time | Short | Long |

| Material Use | Efficient | More waste |

Note: If you want to test new designs or make only a few parts, DMLS is often the better choice.

Complexity

You can make more complex parts with direct metal laser sintering than with old methods. The laser builds parts one layer at a time, so you can design shapes that are hard or impossible to make with cutting or casting. You can add inside channels, lattice structures, or hollow spaces. Traditional manufacturing cannot do this easily because it needs tools that fit the shape.

- DMLS lets you create parts with special features inside.

- The laser does not need extra tools, so you can change designs quickly.

- You can make lighter parts that still stay strong.

| Property/Process | DMLS | Traditional Methods |

|---|---|---|

| Geometrical Capability | Very complex shapes | Limited by tools |

| Internal Features | Easy to add | Hard or not possible |

| Design Changes | Fast and simple | Slow and costly |

Did you know? The laser can make parts with tiny details and strong frames, helping you solve tough design problems.

Future of DMLS

Industry Trends

Direct metal laser sintering is growing in many fields. Companies want to make special parts in small amounts. They use digital tools to design and build these parts. More businesses pick additive manufacturing because it saves time and materials. Here are some important trends for the future:

- More companies use additive manufacturing for custom and small parts.

- New metal powders help make stronger and better parts.

- Digital design tools work with DMLS for easy production.

- Businesses care about the planet and want less waste.

- Industries like aerospace and healthcare lead with new ideas.

These trends will keep growing as technology gets better.

Innovation

There are many new ideas in direct metal laser sintering. The technology lets you make shapes that old ways cannot do. You do not need special tools, so you can test new designs fast. DMLS uses only the metal powder needed for each part. This means less waste. You can reuse extra powder, which saves money and helps the planet.

- DMLS makes complex and light parts for planes and cars.

- The process gives high precision for medical and aerospace jobs.

- New multi-laser systems make parts faster and help with bigger projects.

- Research on new alloys gives stronger and better parts.

These new ideas make DMLS more useful for many jobs. Laser technology keeps getting better and gives more choices.

Adoption

More companies choose DMLS every year. The market for this technology keeps growing. Here are some numbers:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 1.05 | 11.0 |

| 2033 | 2.40 |

Many things help this growth:

| Factor | Description |

|---|---|

| Advancements in Technology | New printers with stronger lasers and better software make DMLS more useful. |

| Demand for Customized Solutions | Industries want parts made just for them, like light airplane parts or custom implants. |

| Supportive Regulatory Environments | Governments help companies use DMLS by supporting new methods. |

DMLS helps companies make better products, save money, and meet new needs. As more people learn about the benefits, even more will use DMLS in the future.

You notice direct metal laser sintering is changing how things are made. This technology helps you make metal parts that are almost solid. You can create special shapes for planes, cars, and medical tools.

- You can use this method in planes, cars, medicine, art, jewelry, furniture, and fashion.

Experts say more people want tricky metal parts now. You get parts made faster, and they work better. AFI Industrial Co., Ltd gives you help with laser solutions. You can try new ideas and make your products better with this new technology.

FAQ

You use DMLS to build metal parts layer by layer with a laser. The laser melts metal powder to create strong, detailed shapes. You get parts quickly and with less waste.

You can choose metals like titanium, stainless steel, aluminum, and cobalt-chrome. Each metal gives you different strength and weight for your project.

You often receive test parts in three to five days. Finished parts usually arrive in less than a week. You save time compared to traditional methods.

You get the best results for custom designs and small batches. You do not need expensive molds or tools. You can change designs easily.

You use only the metal needed for each part. The process creates less scrap than cutting or casting. You save material and money.

You design parts with inside channels, lattice structures, and tricky features. The laser builds these shapes layer by layer. You get results that old methods cannot match.

You receive strict quality control for every part. The team uses laser scanning and measurement tools. You get reports to show your parts meet all standards.