When you look at Delrin vs acetal, the main differences are in their structure, properties, and how they are used. Delrin is a homopolymer acetal. It is strong and does not wear out easily. Acetal is usually a copolymer. It handles chemicals better and is easier to shape in different ways. These differences are important. Picking the right material can change how well a product works and how easy it is to make.

The world market for acetal copolymer was $576.5 million in 2023. It will likely get bigger, mostly in cars and electronics.

| Property | Acetal | Delrin |

|---|---|---|

| Chemical resistance | Great, especially to acids/solvents | Not as good, not for acids/bases |

| Mechanical properties | Good, gets better with glass filling | Very good at not wearing out |

| Applications | Insulin pens, gears, toothbrushes | Conveyor parts, bearings, rollers |

Key Takeaways

- Delrin is a homopolymer. It is strong and tough. It works well for parts that need to be very sturdy.

- Acetal is usually a copolymer. It resists chemicals like acids and solvents. This makes it good for wet places.

- Think about what you need before picking a material. Delrin is best for strong, moving parts. Acetal is better if there are chemicals.

- Both materials do not soak up much water. They keep their shape and size in humid air.

- Delrin does not get tired or break easily. It is great for parts that get used a lot.

- Acetal copolymer is simple to cut and shape. It also keeps its size well. You can use it for many things.

- If you need parts for food or medical tools, both are safe. They follow FDA rules and can touch food.

- Talk to a machining expert before you choose. Pick the best material for your project and budget.

Table of Contents

Delrin vs Acetal Overview

What Is Acetal?

Acetal is a plastic used in many machines and products. It is strong and does not rub away easily. Acetal keeps its shape well. You can get acetal as a homopolymer or a copolymer. Most people use the copolymer type. Copolymer acetal handles chemicals better. It also works well when things are wet. Acetal does not soak up much water. It does not wear out fast. You can find acetal in gears and medical tools.

Acetal copolymer has a structure that is less packed than the homopolymer. This makes it stand up to chemicals, even in hot water. Acetal copolymer has fewer weak spots inside. This means it is stronger in the middle. Companies pick acetal when they need a tough plastic. It is good for parts that touch water or chemicals.

What Is Delrin?

Delrin is a special kind of homopolymer polyolefin made by DuPont. Delrin has a very regular and packed structure. This makes Delrin strong and hard to break. It also handles heat well for short times. Delrin’s chains are all the same. This gives Delrin better strength than most acetal copolymers.

People use Delrin for parts that must be exact and strong. Delrin is good for things that need to last a long time. It can have some small weak spots inside. But Delrin does not wear out easily. You see Delrin in gears, bearings, and fasteners that need to be tough.

Note: Delrin is always a homopolymer pom. Acetal can be a homopolymer or a copolymer. This changes how they work in real life.

Structure and Branding Comparison

Here is a table to show the main ways Delrin and acetal plastics are different:

| Feature | Delrin (POM) | General Acetal Plastics |

|---|---|---|

| Brand | DuPont (Delrin) | Many brands and types |

| Chemical Structure | Semi-crystalline homopolymer | Homopolymer or copolymer |

| Mechanical Props | High strength, stable | Changes with each type |

| Applications | Exact, strong parts | Used for many things |

You can also look at their structures and how they act:

| Property | Delrin (Homopolymer) | Acetal Copolymer |

|---|---|---|

| Structure | More packed | Less packed |

| Fatigue Resistance | Better | Not as good |

| Heat Resistance | Higher for short times | Better for long times |

| Chemical Resistance | Not as good in hot water | Better in hot water |

When you compare Delrin and acetal, Delrin is stronger and lasts longer. Acetal copolymer is better with chemicals and has fewer weak spots. You should pick the one that fits your needs best.

Delrin vs Acetal Key Properties

Mechanical Properties

Strength and Stiffness

Delrin and acetal have different mechanical strengths. Delrin is very strong and stiff. It is good for parts that must not bend. Acetal, especially the copolymer, is also strong. But it is not as strong as Delrin. Both are part of the pom family. This means they are tough and last a long time.

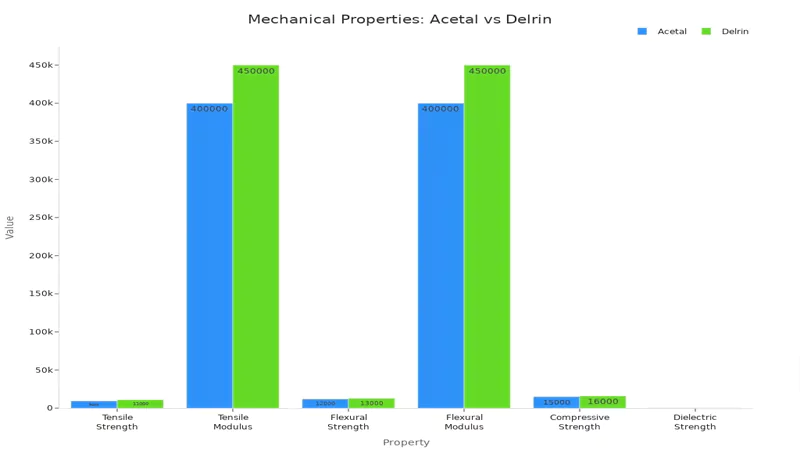

Here is a table that compares their mechanical properties:

| Property | Acetal | Delrin® |

|---|---|---|

| Density (lb/in³) | 0.051 | 0.051 |

| Water Absorption @24 Hours | 0.2% | 0.2% |

| Tensile Strength (psi) | 9500 | 11000 |

| Tensile Modulus (psi) | 400,000 | 450,000 |

| Elongation at Break | 30% | 30% |

| Flexural Strength (psi) | 12000 | 13000 |

| Flexural Modulus (psi) | 400,000 | 450,000 |

| Compressive Strength (psi) | 15000 | 16000 |

| Hardness, Rockwell | M88/R120 | M89/R122 |

| Dielectric Strength (V/mil) | 420 | 450 |

You can see the differences in this chart:

Delrin has higher tensile and flexural strength. This makes it great for gears and levers. These parts need to be tough. Acetal copolymer is easy to shape. It works for many things. But if you want the best strength, pick Delrin.

Fatigue and Creep Resistance

You want your parts to last a long time. Delrin is very good at handling repeated bending. It does not lose its shape or strength easily. You can make thinner and lighter parts with Delrin. This can help save money. Acetal copolymer is still tough. But it is not as good as Delrin for these uses.

Tip: Pick delrin for moving parts or parts under stress. It will last longer and work better.

Chemical Resistance

Chemical resistance is important when picking a plastic. Both Delrin and acetal resist many chemicals. But acetal copolymer is better in harsh places. It stands up to acids, bases, and solvents. Delrin does not do as well in hot water or high pH. This matters if your parts touch cleaners or strong chemicals.

Here is a table that shows their chemical resistance:

| Material | Chemical Resistance Characteristics |

|---|---|

| Delrin (POM-H) | Not as good with hydrolysis and oxidation, especially in heat or acid. |

| Acetal Copolymer | Better with acids, bases, and solvents, good for chemical use. |

| Works well in hot water and high pH, stops cracking in delrin. |

- Delrin is best for parts that do not touch many chemicals.

- Acetal copolymer is good for plumbing and food machines.

- Use acetal copolymer for parts cleaned with strong chemicals or hot water above 60°C.

ASTM D543 tests show acetal copolymer is better in hot water and high pH. This helps stop problems in tough chemical places.

Thermal Performance

Thermal performance tells how parts act in heat or cold. Delrin works in temperatures from -40 °C to 90 °C. It stays strong and tough even when it is very cold. It only loses about 20% of its impact strength at -40 °C. Acetal copolymer also works well in most temperatures. But Delrin is a bit better for short times in heat.

| Property | Delrin |

|---|---|

| Operating Temperature Range | -40 °C to 90 °C |

| Tensile Strength | 2,000 psi |

| Flexural Modulus | 180,000 |

| Impact Resistance Loss | 20% at -40 °C |

Both Delrin and acetal are good for most uses inside and outside. If you need strong parts in cold weather, choose Delrin. For parts in hot water or chemicals, acetal copolymer is better for long-term use.

Moisture Absorption

You should think about how much water a material can absorb. Delrin and acetal copolymer do not soak up much water. This helps your parts stay the right size. Delrin’s moisture absorption is between 0.2% and 0.3%. This low amount means your parts will not get bigger or change shape a lot, even if it is humid. You can keep sizes very close, within ±0.02 mm. This is important when you need parts to fit just right.

Here is a quick comparison:

| Material | Moisture Absorption Rate | Dimensional Change Impact |

|---|---|---|

| Delrin | 0.2–0.3% | ±0.02 mm accuracy control |

| Acetal Copolymer | N/A | N/A |

Both materials are good at keeping water out. This keeps your parts strong and working well. If you need parts that stay the same size and work every time, Delrin and acetal copolymer are great picks. They are good for gears, valves, and other parts that get wet.

Note: Low moisture absorption means your parts will not swell or bend. They will keep their shape and work as they should.

Machinability in Machining

Machining is important when you use Delrin or acetal. Both are easy to machine, but they are a little different. Delrin is very hard and stiff. It gives a smooth finish and keeps its shape well, especially with CNC machines. Delrin’s low friction means tools do not wear out fast.

Here is a table to help you compare machinability:

| Property | Delrin | Acetal |

|---|---|---|

| Surface Finish | Outstanding tensile strength, better for CNC applications | Good machinability, suitable for various applications |

| Tool Wear | Excellent wear resistance | Moderate wear resistance |

| Dimensional Stability | High rigidity maintains dimensions well | Good dimensional stability |

When you pick Delrin for machining, you get:

- Very hard and stiff parts

- Low friction for a smooth finish

- Great wear resistance, so tools last longer

Acetal copolymer is also easy to machine. It works well when you want good quality and a fair price. It stands up to chemicals and water, so your parts last longer.

When you choose a material, think about what you need most. Delrin is better if you want less wear and more accuracy. Acetal copolymer is good if you want strong chemical resistance and easy machining. Both help you make parts that fit well and work right.

Delrin vs Acetal Applications

Typical Uses for Delrin

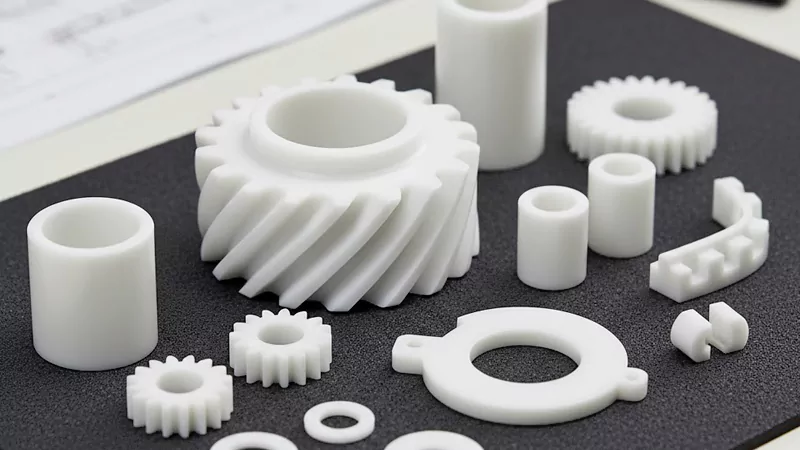

Delrin is used for parts that need to be strong. It works well when things must last a long time. Delrin is tough and does not wear out fast. It also has low friction, so parts move smoothly. You can trust Delrin for important jobs.

Some common uses for Delrin are:

- Car parts like gears and bushings

- Airplane pieces such as safety locks and doors

- Medical tools like valves and pumps

- Sports gear, glasses frames, and food boxes

- Electrical parts that work in wet places

Delrin is good for gears and moving parts. It is strong and does not get damaged by chemicals. Delrin does not soak up much water. It is dense, so parts stay the right size.

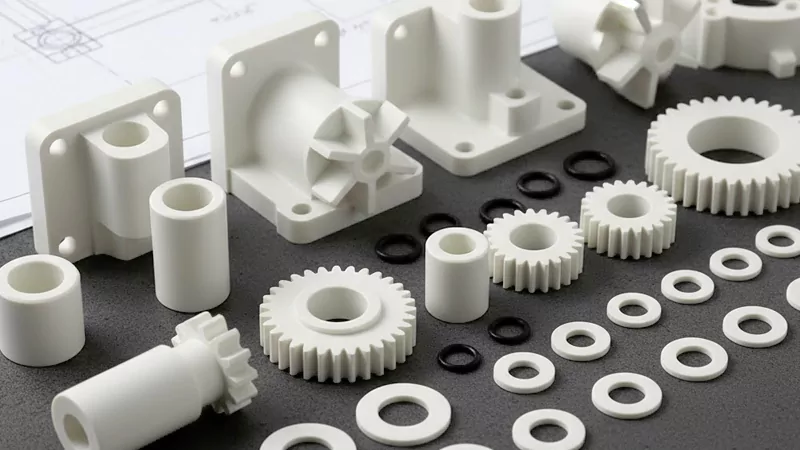

Typical Uses for Acetal Plastic

Acetal plastic is used in many ways. The copolymer type is best for tough jobs. Acetal stands up to chemicals and works in lots of places. It is great for parts that touch water or cleaners.

Some common uses for acetal are:

- Pump and valve parts for moving fluids

- Connectors for plumbing and food machines

- Gears and rollers for smooth movement

- Bushings and bearings that need chemical strength

- Everyday items like insulin pens and toothbrushes

Acetal does not break down with acids or bases. It is a good choice for hard jobs. Acetal costs less but still works well.

Choosing the Right Material for Machining

You need to pick the right material for your project. Both Delrin and acetal are easy to machine. Delrin is better if you need parts that last longer. It is strong and handles stress well.

Acetal is good if you want chemical resistance and a lower price. It fits more jobs and is used in many places. Acetal is best for fluid systems and everyday products.

Machining experts use both Delrin and acetal. They look at how strong and tough each one is. They also check how each material handles heat. Always choose the one that fits your needs and budget.

Tip: Talk to your machinist before you decide. They can help you pick the best material for your job.

Delrin is more expensive but lasts longer. Acetal costs less and fights chemicals better. Knowing what each one does helps you make the right choice.

Acetal vs Delrin Comparison Table

Side-by-Side Comparison

It helps to compare Acetal and Delrin side by side. This way, you can see what makes each one different. The table below shows their main features. It lists things like strength, chemical resistance, heat performance, and how easy they are to machine.

| Property | Acetal Copolymer | Delrin (Acetal Homopolymer) |

|---|---|---|

| Density | 1.42 g/cm³ | 1.41 g/cm³ |

| Tensile Strength | 8,500–12,000 psi | 10,000–13,000 psi |

| Flexural Yield Strength | 9,500 psi | 11,000 psi |

| Elongation at Break | 10–75% | 0.1–0.75% |

| Fatigue Resistance | Good | Excellent |

| Creep Resistance | Good | Excellent |

| Abrasion Resistance | Good | Higher than acetal |

| Chemical Resistance | Excellent (acids, bases, solvents) | Good (less resistant to acids/bases) |

| Heat Resistance | Better for long-term use | Good for short-term heat |

| Max Service Temperature | Up to 100°C | Up to 90°C |

| Melting Temperature | 162–175°C | 175°C (uniform structure) |

| Moisture Absorption | Very low | Very low |

| Machinability | Easy to machine | Excellent surface finish |

| Typical Applications | Fluid handling, medical devices, consumer products | Gears, bearings, fasteners, precision parts |

Tip: Use this table to help pick the right material for your project. If you need strong chemical resistance and good heat performance over time, acetal copolymer is a good pick. If you want more strength, better fatigue resistance, and a smoother finish, Delrin is the better choice.

Both materials have many things in common. But each one is best for certain jobs. Acetal copolymer works well with chemicals and water. Delrin is great for parts that move and need to last.

Looking at this comparison helps you choose the best material for your next project.

Material Selection Tips

Factors to Consider

There are a few things to think about before you pick Delrin or Acetal. First, think about where your part will be used. If it will be around strong chemicals, hot water, or lots of moisture, you need a material that can handle that. You should also think about how much weight or movement your part will face. Some parts need to stay strong even when used a lot. If your part needs to fit just right, you want a material that keeps its shape.

Here is a quick table to help you compare:

| Factor | Delrin (POM-H) | Acetal (POM-C) |

|---|---|---|

| Chemical Resistance | Moderate, less for acids/bases | High, better for acids/alkalis |

| Mechanical Strength | High strength and stiffness | Slightly lower, but still strong |

| Hydrolysis Resistance | Less in wet environments | Better for humid or wet conditions |

| Centerline Porosity | Possible, may affect sealing | None, more uniform properties |

Tip: Make sure the material you pick matches what your project needs. If you are not sure, ask a material expert or supplier for help. This can help you avoid mistakes that cost money.

When to Choose Delrin

Pick Delrin if you need a part that is very strong and stiff. Delrin is great for gears, bushings, and other parts that move a lot or carry heavy things. It does not wear out fast. Delrin also has low friction, so parts move smoothly. It keeps its shape well, which is good for parts that must fit just right. After machining, Delrin looks smooth and nice.

- Use Delrin for:

- Parts that carry heavy loads or bend a lot

- Gears and bearings that must be exact

- Projects where parts need to slide easily

- Jobs where a smooth look is important

Remember, Delrin can have centerline porosity. This might cause problems with sealing or color. Delrin does not like strong acids or bases, so do not use it with those.

When to Choose Acetal

Choose acetal if your part will touch chemicals, hot water, or be in damp places. Acetal stands up to acids, alkalis, and solvents better than Delrin. It is the same all the way through, so you do not have to worry about holes inside. Acetal is good for plumbing, medical tools, and parts that move liquids.

- Use acetal for:

- Parts that touch strong chemicals

- Things used in wet places

- Jobs where medium strength is enough

- Projects that need good sealing and color

Acetal is not as strong as Delrin, but it is better with chemicals and keeps its shape in tough places.

Note: Both delrin and acetal can be recycled and used again. This helps cut down on waste. Delrin also comes in eco-friendly types for green projects.

When you look at Delrin and acetal, you notice some big differences. Delrin is harder and stronger. It does not wear out fast. This makes Delrin good for tough jobs. Acetal fights chemicals well and costs less money. To pick the best one, think about what you need. Do you need strong parts or smooth movement? Pick Delrin. Do you need parts that handle chemicals or have fewer holes inside? Pick acetal. If you are not sure, talk to a machining expert. Picking the right material helps you make better parts for your project.

FAQ

Delrin is a homopolymer. Acetal is usually a copolymer. Delrin is stronger and lasts longer. Acetal copolymer fights chemicals better. It also has fewer weak spots inside.

You can use regular tools to machine both. Delrin makes smoother parts with tight sizes. Acetal copolymer also works well for most jobs.

Pick an acetal copolymer for parts that touch acids or bases. It stands up to chemicals better than Delrin. Delrin is best for dry places with little chemical contact.

Moisture does not cause problems for these plastics. Both Delrin and acetal take in very little water. Your parts will stay the same size, even if it is wet.

Delrin costs more because it is stronger and a brand name. Acetal copolymer is cheaper but still works well for many uses.

You can use Delrin and acetal copolymer for food equipment. They follow FDA rules for food safety. Always ask your supplier about special certificates.