Clear details help you get the right price for your custom metal fabrication project. Good communication helps you avoid surprises and delays. Picking a trusted supplier like AFI Industrial Co., Ltd. gives you peace of mind at every step.

Unclear plans and specifications are a common problem on small jobs. People often do not want to spend time drawing and listing every detail. But this can be a much more costly problem on big jobs where more money is involved.

Getting ready helps you succeed. With the right steps, you can start your project with confidence and get quotes that match your needs.

Key Takeaways

- Clear drawings and specifications help get correct quotes. Give detailed design and planning to stop mistakes and save time.

- Good communication with your fabricator stops surprises. Stay in touch during the project for smooth work.

- Picking the right materials changes quality and cost. Choose metals that fit your project and do not spend too much.

- Knowing your project timeline is important. Share deadlines early so your supplier can plan and avoid rush fees.

- Collect all technical documents before requesting a quote. This helps your fabricator give an accurate estimate.

- Build a strong relationship with your supplier. Trust and talking openly lead to better results and easier projects.

- Always check quotes for hidden costs. Look past the price to see what is included and avoid surprise expenses.

- Read contracts closely before signing. Make sure all terms are clear to protect yourself and set expectations.

Table of Contents

Custom Metal Fabrication Overview

What Is It

You might wonder what custom metal fabrication is. It means making metal products or structures just for you. These are not made in large amounts. They are designed to meet your specific needs. You get to choose how the product will look and work. Workers use special machines to cut, bend, roll, and join metals. Some metals used are carbon steel, stainless steel, aluminum, and copper. Sometimes, you need other metals for special jobs. Each step shapes the metal into the desired form.

AFI Industrial Co., Ltd. is a top company in this field. They have skilled workers and modern machines. They make high-quality parts for many businesses.

Here are some common metal fabrication processes you may use:

- Cutting: This means splitting metal sheets into smaller pieces.

- Folding: This process involves shaping metal at specific angles.

- Welding: This joins two metal parts using heat.

- Machining: This process removes material from metal to create shapes or holes.

- Punching: This makes holes in metal with a die and drill.

- Shearing: This cuts long pieces from metal sheets.

- Stamping: This raises parts of metal sheets for shapes or letters.

- Casting: This pours melted metal into molds for certain forms.

These steps help you make simple brackets or complex parts.

Why Quotes Matter

Getting a good quote for your project is very important. You want your needs to be clear and met. A detailed quote helps you avoid extra costs and surprises. If you give all the right information, you get a faster and better quote.

Tip: Always give correct drawings and details. This helps your fabricator give the best price.

To get a good quote, you should:

- Give correct and detailed drawings.

- Involve all needed experts for the job.

- Keep talking with everyone for smooth work.

Good quotes help you plan your money and time. They also let you compare choices and pick the best company.

Project Types

Custom metal fabrication is used for many kinds of projects. You see its value in design, building, and finishing work. Here is a table that shows the main types of projects using custom metal fabrication:

| Type of Project | Description |

|---|---|

| Design | First, you analyze and plan to make products that match needs. |

| Build | Next, you use methods to make the product after planning. |

| Secondary Fabrication | Last, you finish or put together parts to make the product better. |

You find custom metal fabrication in cars, planes, buildings, and electronics. The benefits are flexibility, accuracy, and meeting strict rules. Picking the right material is also very important. If you work with AFI Industrial Co., Ltd., you get CNC turning, milling, sheet metal work, stamping, bending, fast service, and strong quality checks. These skills help you get the results you want, no matter how big or small the job is.

Project Requirements

Design and Specs

Drawings

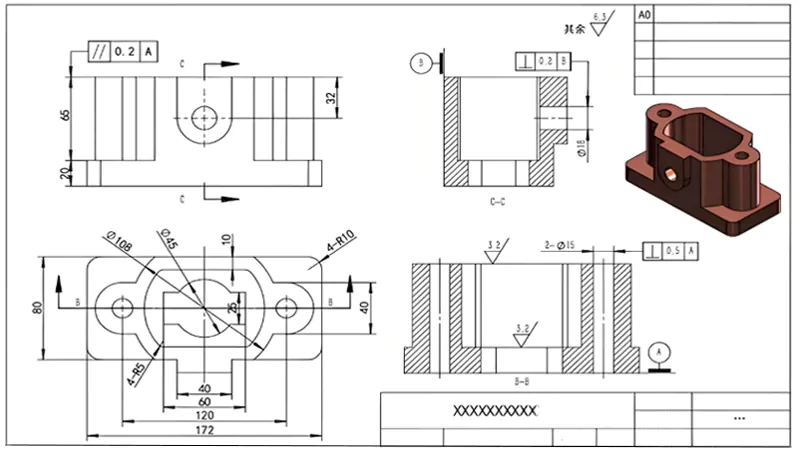

You start your project by making clear drawings. These drawings show what your part looks like. They also show the size and special features. When you give good drawings, your fabricator knows what you want. This helps stop mistakes and saves time.

- Good drawings tell how the part is used, its shape, angles, and what it is made of.

- More details in your drawings help get better cost guesses.

- Sending finished drawings lowers the chance of mistakes when making your part.

Studies say about 24% of CAD drawing mistakes are about making the part. Fixing these mistakes early saves time and money.

AFI Industrial Co., Ltd. can use any file type, like CAD, STP, or PDF. Their team checks your drawings to make sure every detail is right for you.

Functional Needs

You also need to say how your part will work. This means how strong it must be and how it fits with other parts. You should also say what weight or force it must handle. When you share this, your fabricator can pick the best way to make your part.

Here is a table with important design and spec details:

| Specification Detail | Importance |

|---|---|

| Detailed Drawings | Help make your part and check it meets your needs. |

| Material Specifications | The change in the process must match what you pick. |

| Collaboration with Fabricators | Helps you learn the best choices for your job. |

| Metal Thickness | Changes strength and bend; often from 0.5mm to 6mm. |

| The change in the process must match what you pick. | Good methods stop bending and keep parts strong. |

| Bending Techniques | Should match real work, not just perfect angles. |

| Welding Equipment Compatibility | Make sure your design works with the tools for the best results. |

| Finishing Options | Depend on your goals, like protection or looks. |

Giving final prints and specs is key for a good quote. The more details you give, the better your price guess will be.

Dimensions

You must list the exact size for each part. This means length, width, height, hole size, and space between holes. Good sizes help your fabricator plan and stop mistakes. If you miss a size, you may have delays or pay more. AFI Industrial Co., Ltd. checks your sizes to make sure your parts fit and work right.

Surface Treatment

Surface treatment keeps your parts safe and makes them look better. You can pick powder coating, painting, anodizing, or plating. The best treatment depends on what you need. You may want to stop rust, add color, or make it smooth. When you tell your fabricator what you want, they can plan the right steps and give a better price.

Tip: Talk about your surface treatment needs early. This helps your supplier pick the best way and materials for your custom metal fabrication project.

Materials

Types

You must pick the best material for your project. The metal you choose changes how strong and tough your part is. It also changes the price. Some common metals are carbon steel, stainless steel, aluminum, and copper. Each metal has good points. Aluminum is light and does not rust. This makes it great for outdoor use. Stainless steel is strong and looks clean. It is good for food or medical tools.

Picking the right metal is very important. Your choice affects how well your part works and how much it costs. It also changes how easy it is to make. If you pick a metal that fits your needs, you save money. You do not want to pay for more than you need. The right steel grade helps you meet your goals and spend less. Some people pick cheaper metals to save money at first. But this can cost more later if you need extra work.

Sourcing

You should think about where your metal comes from. Good sourcing means you get the same quality every time. It also means your order arrives on time. AFI Industrial Co., Ltd. uses trusted suppliers for its metals. They check each batch before they start making your parts. This helps stop problems and keeps your project on track.

Tip: Ask your fabricator how they get their metals. Good sourcing means fewer delays and better parts.

Quantity

How many parts you order changes the price. If you order more parts, each one costs less. This is because setup costs are shared over more pieces. If you only order one part, it costs more. The setup fee is the same no matter what. Even a small increase in your order can save you money. If you know you will need more parts soon, order them together.

- More parts mean a lower cost for each one.

- Setup and layout costs go down with bigger orders.

- One-off parts cost more.

- Small order increases can save money.

- Bulk orders are best if you need many parts soon.

AFI Industrial Co., Ltd. lets you order any amount you need. They work fast, so you can plan your project with ease.

Packaging

Good packaging keeps your parts safe when shipped or stored. Tell your fabricator if you need special packaging. You might want foam, shrink wrap, or custom boxes. Good packaging stops scratches and dents. AFI Industrial Co., Ltd. gives packaging that fits your needs. They make sure your parts arrive safely and ready to use.

Note: Give clear packaging instructions. This helps your supplier send you parts with no damage.

Timeline

Your project timeline is very important when getting a quote for custom metal fabrication. If you tell your supplier when you need your parts, they can plan better. This helps them use their workers and machines the right way. It also stops mistakes that can slow things down or cost more money.

If you want your parts fast, you might pay more. Rush jobs need workers to work extra hours. They also need to get materials faster and change their normal plans. All these things make the price go up. If you give your supplier more time, they can fit your job into their normal schedule. This often means you pay less and your parts are made without problems.

⏰ Tip: Always tell your supplier when you need your parts. This helps them give you the right price and timeline.

Your timeline can change your quote in these ways:

- Rush jobs cost more because they need to be done faster.

- Telling your supplier your timeline helps them plan and price your job right.

- If you can wait longer, you might get a better price.

- Telling your supplier early helps them get materials and plan.

To get the best results, do these things when talking about your timeline:

- Tell your supplier the date you need your parts when you ask for a quote. This gives them a clear goal.

- Ask for two quotes: one for normal timing and one for fast delivery. This helps you see the price difference and pick what works best.

- If your schedule changes, tell your supplier right away. This helps them change their plans and avoid delays.

- Make sure you agree on the production and shipping timeline before you say yes to the quote. This makes sure everyone knows what to expect.

AFI Industrial Co., Ltd. knows how important it is to meet your deadlines. Their team can finish jobs quickly, from 3 to 15 days, depending on how big or hard your order is. When you work with AFI, you get clear updates and a schedule you can trust from start to finish.

Note: Timelines change the price and how well your project goes. Plan early and keep your supplier updated so you do not have last-minute problems.

If you manage your timeline well, your project will go smoothly and stay on budget. Always tell your supplier what you need, and pick a company like AFI Industrial Co., Ltd. that cares about being on time and talking clearly.

Prepare Details

Before you ask for a quote, gather your technical papers. You also need to think about your budget. Doing this helps you avoid waiting and keeps your project on track. AFI Industrial Co., Ltd. can help with every step, from design to packaging. This lets you focus on what you want to achieve.

Documentation

Collect all your technical files and specs for your project. These papers help your fabricator know what you want. This stops mistakes that can cost a lot.

CAD Files

CAD files show what your part looks like. They have details about shape and features. You use these files to share your design with the team. CAD files help the team check every angle and size. This makes sure your part is just right.

STP Files

STP files are 3D models of your part. They let the team see your part from all sides. These files help with tricky shapes and big builds. Sending STP files makes it easier to plan how to make your part.

PDF files

PDF files are simple to open and send. You use them to show drawings and notes. PDF files are good for quick checks and getting approval.

Specs

You must add all specs to your papers. Specs tell the size, limits, materials, and finishes. Good specs help your fabricator pick the right tools. They also make sure your part works as you want.

Tip: Always add title blocks, key sizes, material types, and welding info to your drawings. Full drawings help check the work and keep quality high.

Budget

A clear budget helps you and your fabricator agree. Think about all the things that change your project cost. The table below shows what to look at:

| Factor | Description |

|---|---|

| Accurate Project Estimation | A good estimate sets clear goals and builds trust. This helps your project go well. |

| Material Costs | Knowing what materials you need and their price is key to a good estimate. |

| Labor Costs | Good drawings help guess labor hours and real costs. |

| Fabrication Techniques | Telling the methods helps the job go faster and saves money. |

| Project Timeline | Clear drawings help set real times for buying and making parts. This sets when the job will finish. |

| Clear Communication | Talking with your fabricator helps find problems early. This leads to better estimates. |

| Value Engineering | Looking at other ways can save money and keep your project strong. |

| Contingency Planning | Adding extra time or money helps if something goes wrong. This keeps your project on track. |

When you share your budget, your fabricator can suggest the best choices. This helps you plan and design your custom metal fabrication project better.

Special Needs

Some jobs need extra steps or special care. Tell your fabricator about any special needs early.

Finishing

If you want a certain finish, like powder coating or painting, say so in your papers. Special finishes protect your parts and make them look nice. AFI Industrial Co., Ltd. can do many finishes to fit your needs.

Compliance

You may need your parts to meet rules or standards. Tell your fabricator if you need things like ISO or SGS certification. AFI Industrial Co., Ltd. follows strict checks and has world certifications. You can trust your parts will meet top standards.

Note: Sharing your special needs early helps your supplier plan the right steps and avoid delays.

Find Fabricators

Research Providers

When you pick a metal fabrication company, you should look at a few key things. You want a company that gives good quality and is reliable. Value is also important. The table below helps you compare different companies:

| Criteria | Description |

|---|---|

| Experience | Choose companies that have worked for many years. They know how to pick and shape materials well. |

| Expertise | Look at their old projects. This shows their skills and how good their work is. |

| Work Area | Make sure they have enough room. A clean shop helps make better parts. |

| Equipment | Check if they use new machines. New tools help make more exact parts. |

| Location | Local companies can save you money on shipping. They also lower the chance of damage. |

| Price | Compare what you get for the price. Good quality is more important than just a low price. |

| Testimonials | Read what other customers say. This helps you see if they are reliable and give good service. |

Reviews

Reading reviews helps you learn how a company works. People who used the company shared whether they liked the quality and service. Look for things people say again and again. If many say the company talks well or works fast, you can expect that too. Reviews also tell you how the company fixes problems. Good companies answer quickly and solve issues. AFI Industrial Co., Ltd. gets good reviews for caring about details and helping customers.

Certifications

Certifications show a company follows high standards. Look for things like ISO 9001 or SGS. These mean the company uses strict rules for quality. Certified companies check their work at every step. This means you get parts that meet your needs each time. AFI Industrial Co., Ltd. has both SGS and ISO 9001 certifications. This shows they care about top quality.

Experience

Experience is very important in custom metal fabrication. Companies with many years know how to fix problems and stop mistakes. Here is what you get from an experienced company:

- Good quality and on-time delivery.

- Use of strong materials and good testing.

- Careful work for safe and reliable parts.

You also get good quality checks and skilled workers. A long history means you can trust them with any project.

Location

Location changes cost, speed, and how you talk to the company. Working with a local company can make shipping cheaper and faster. You can visit their shop to check the work or talk about changes. Local teams can help faster if you need something quickly. You also get better protection for your ideas and better following of local rules.

- Cheaper shipping and faster delivery.

- Easier visits to check quality.

- Fast changes for urgent jobs.

- Better teamwork and clear talks.

AFI Industrial Co., Ltd. works with clients all over the world. They keep high standards and deliver on time, no matter where you are.

Approach to Problem-Solving

When you pick a custom metal fabrication provider, see how they fix problems. Every project has some challenges. You want a team that finds answers fast and keeps things moving. Good fabricators follow simple steps to solve issues. They talk with you, listen to what you need, and give you choices.

A good problem-solving approach looks like this:

- The team answers your questions quickly.

- They give you new ideas if a design fails.

- They tell you about changes and keep you in the loop.

- They use their past work to stop common mistakes.

- They help you reach your goals by working with you.

AFI Industrial Co., Ltd. is known for helping before problems get big. Their experts check your project and suggest ways to make it better. If something goes wrong, they act fast and let you know. You get clear advice and easy-to-understand answers. This makes you feel sure about your project.

Tip: Ask your fabricator what they do when problems pop up. A good company will tell you stories and explain their steps.

When you choose a metal fabrication company, look at how they fix problems. This helps your project stay on track and meet your needs.

References

References from old clients help you see how a fabricator works. You learn how the company acts in real jobs. Talking to past customers gives you honest thoughts about quality, trust, and how they talk.

Here is a table showing what you can learn from references:

| Aspect | Insight |

|---|---|

| Performance | References show if the fabricator finishes work on time. |

| Reliability | Past clients share if the fabricator can be trusted. |

| Quality of Work | Talking to customers shows how good the work is. |

| Handling Challenges | You learn how the fabricator deals with problems. |

| Communication | You hear how well the fabricator talks during the job. |

You should ask for references before you pick a company. Listen to what other clients say about their jobs. This helps you avoid problems and choose a company that fits your needs.

AFI Industrial Co., Ltd. lets you check what their clients say. Their many good projects and happy customers show they care about quality and service.

Note: References give you real proof of a fabricator’s skills and trust. Always check them before you decide.

Request Quotes

Submit Info

When you ask for a quote, you need to collect all your documents. You must send these papers to the fabricator. This step helps make sure your quote is correct. Give lots of details about your project. This helps the fabricator know what you want. It also lowers mistakes and delays.

When you send an RFQ, add many details. Include materials, specs, certifications, and delivery needs.

AFI Industrial Co., Ltd. has a skilled team to check your info. Their experts help you not miss anything. They make sure your project starts well.

Online Forms

Most fabricators have online forms for quotes. AFI Industrial Co., Ltd. uses these forms too. The forms help you step by step. You can upload files and type in your project info. You can also say what you need. Online forms save time and keep things neat.

Use our Metal Fabrication RFQ Guide. It is a checklist for specs people forget. It has easy sections and covers important topics and questions.

Make sure you fill out every part of the form. If you miss something, your quote may be slow or wrong.

Complete Details

Giving full details helps you get a good quote. When you share all the info, the fabricator can plan better. This helps you get a fair price and a real timeline.

- Detailed specs and uses help fabricators know your needs.

- Full papers mean less back-and-forth talk.

- You get a correct quote when you give all the info, like finishes and assembly.

Attachments

Always add all technical files to your quote request. These files can be:

- CAD models of your assembly with hardware.

- Technical drawings in PDF or STP.

- Welding instructions for inside or outside welds.

- Tapped hole notes with size and depth.

- Any part numbers, finishes, or coatings.

Key Specs

Write your main specs clearly. Include:

- Material type and finish, like powder coating or silk screening.

- Certifications or rules you need.

- Delivery needs and timeline.

- Special instructions for assembly or packaging.

Tip: More details mean a faster and better quote.

AFI Industrial Co., Ltd. uses your full info for smooth work. Their team checks every detail to make sure your parts are just right.

Communicate

Contact Points

You need to know who to talk to when you start your custom metal fabrication project. Good communication helps stop mistakes and keeps your project going well. Pick a partner you can trust, like AFI Industrial Co., Ltd. Their team listens to what you want and gives helpful advice. You should set clear rules for quality and delivery from the beginning. This helps stop confusion and delays.

Talking early and often makes a big difference. You should share your goals and any problems you think might happen. If you talk openly with your fabricator and your own team, everyone knows what is happening. When you keep talking, you can change plans fast if something changes. This helps your project keep moving without surprises.

AFI Industrial Co., Ltd. likes open talks. Their experts answer fast and keep you updated at every step. You always know who to ask if you have questions or need news. This support helps you feel sure and in control of your project.

Clarify Questions

You should always ask questions before and during the quote process. Clear answers help you stop mistakes and save money. Here are some important questions to ask your fabricator:

- What are the project requirements and specifications?

- What is the project timeline?

- What are the quantity requirements?

- What are the budget constraints?

- Are there any known design or engineering challenges?

When you ask these questions, your fabricator knows what you need. You also make sure you both agree on the details. AFI Industrial Co., Ltd. wants you to ask questions at every step. Their team explains hard words and helps you understand the process. This way, you get the best results for your custom metal fabrication project.

Discuss Challenges

Every project has some problems. You should talk about these problems early with your fabricator. Working together from the start helps you fix issues before they get big. Talking openly during the project lets you fix things as they happen.

Focus on making things just for you and getting them right. These two things help you with special project needs. AFI Industrial Co., Ltd. works with you to find answers. Their team uses their skills and good tools to meet your needs.

When you talk about problems openly, you build trust. You also help your project stay on time and reach your goals. This teamwork gives you better results and makes the whole process easier.

Timeline Estimates

You need to know when your project will be done. A clear timeline helps you plan and stops delays. Many things can change how long your project takes. You should learn about these before asking for a quote.

Some main things that affect your timeline are:

- Design Complexity: Simple shapes are faster to make. If your part has special features, it takes more time.

- Availability of Materials: If the metal is ready, work starts soon. If not, you have to wait for it to arrive.

- Size and Quantity: Big jobs or lots of parts take longer. Small orders are finished faster.

- Location: If your fabricator is close, shipping is quick.

Tip: Tell your fabricator your deadline early. This helps them plan and meet your needs.

You can finish your project faster if your supplier is well organized. AFI Industrial Co., Ltd. uses good ways to keep projects moving:

- Strong Supplier Relationships: AFI works with trusted suppliers. This means they get metals fast and avoid waiting.

- Up-to-date Equipment: New machines help AFI work quickly and make fewer mistakes.

- Experienced Team: Skilled workers use tools well. They find problems early and keep things on track.

When you talk to your fabricator, ask how long each step will take. Make sure you know what happens from start to finish. If you need parts fast, tell your supplier. They may offer rush jobs or split deliveries.

AFI Industrial Co., Ltd. gives updates at every step. Their team works hard to meet your deadlines and keeps you in the loop. You always know when your parts will be ready.

Professional expertise

Professional expertise is very important for custom metal fabrication. You want a team that knows what you need and does good work. Skilled workers use smart tools and methods to make your parts right.

Here is how expertise helps your project:

- You get parts that match your design. Even small mistakes can cause big problems, so being exact is important.

- Experts use Computer-Aided Design (CAD) software. This tool helps everyone see the same plan and talk about changes.

- Skilled teams fix problems fast. They suggest better ways to make your parts or improve your design.

- You get good communication from start to finish. This keeps your project on track and stops surprises.

Note: Working with a company like AFI Industrial Co., Ltd. gives you a team with lots of experience. Their experts use new technology and proven ways to get the best results.

When you pick a fabricator with strong expertise, you get better quality and fewer mistakes. The process is smoother and easier. You can trust your project will meet your needs and industry rules. AFI Industrial Co., Ltd. is known for its skilled team and great work on every job.

Compare Quotes

When you get quotes for your custom metal machining project, do not just look at the price. You need to check everything carefully. This helps you pick the best company and avoid problems that cost more money. Here are ways to compare quotes with confidence.

Pricing

Materials

The metal you choose changes your project cost. Better metals cost more but last longer and work better. Check if the quote says the exact metal type and grade. Some suppliers use cheaper metals that may not fit your needs. Always ask where the metal comes from and how good it is. AFI Industrial Co., Ltd. uses trusted suppliers and checks every batch so you get the same results each time.

Labor

Labor costs change based on worker skill and experience. Skilled workers make sure your parts are made right. Look at the quote to see how much labor is needed and what skills are used. Shops with certified welders and skilled machinists may charge more. But they give you better quality. Pick companies that train their workers and use new machines.

Extras

Extras can be finishing, assembly, packaging, or special tests. Not every quote lists these extras, so check for them. Some suppliers add fees for rush jobs, special packaging, or meeting special rules. Make sure you know what is included and what costs more. This helps you avoid surprises later.

Scope

Scope means what the quote covers from start to finish. Check if the quote includes all steps, like design review, metal fabrication, finishing, and delivery. Some quotes only cover basic work. Others offer a full package. A clear scope helps you compare quotes fairly. AFI Industrial Co., Ltd. gives one-stop service, so you know what you get.

Value

Quality

Quality should always come first. You want parts that match your needs and last a long time. Look for companies with strong quality checks, like AFI Industrial Co., Ltd., which has SGS and ISO 9001 certifications. Ask how they check parts and fix mistakes. Good quality may cost more, but it saves you money later.

Service

Service means good communication, support, and fixing problems. Good service gives you quick answers and keeps your project moving. Check if the company gives updates, clear contact people, and helps with design or making parts. Companies that care about service make your project easier and better.

Tip: Always check quotes for accuracy, scope, and value—not just price. This helps you pick a good partner and get the best results for your project.

Hidden Costs

When you look at quotes, check more than the price. Hidden costs can make a cheap project expensive. These costs show up if details are missing or plans change. You can stop surprises by knowing what to look for and planning.

Most hidden costs happen when project details are not clear. If you do not give full drawings or specs, your fabricator may redo work or buy more materials. This means you pay extra. Always send detailed drawings and clear instructions in your RFQ. Include the size, weight, and volume of all materials. If you do this early, your supplier can give you the right price.

Talk about design problems before the project starts. If you wait until production, changes cost more. Good talks with your fabricator help you find problems early. AFI Industrial Co., Ltd. likes clear talks and checks every detail with you. Their team works with you to stop mistakes and keep your project moving.

Here is a table with smart ways to avoid hidden costs:

| Strategy | Description |

|---|---|

| Thorough Cost Estimation | Guess all costs to stay on budget. |

| Quality Equipment | Use good tools to stop repairs or delays. |

| Skilled Labor | Hire experts to lower mistakes and rework. |

| Clear Communication | Share all details to stop confusion. |

You can use these steps to protect your budget:

- Save extra money for surprise costs.

- Watch for changes in material prices.

- Mix supplier quotes with a backup plan.

Talking about every part of your project is important. If you forget the material size or weight, you may pay more for shipping or handling. You might also pay extra for special packaging or fast delivery. Always ask your supplier to list all possible charges in the quote.

To stop hidden costs, do these things:

- Give detailed drawings and specs in your RFQ.

- Tell the size, weight, and volume of materials clearly.

- Talk about design problems before production starts.

AFI Industrial Co., Ltd. helps you plan for every detail. Their team checks your project and gives you a clear, full quote. You get good prices and strong quality checks, so there are no surprises. Careful planning and open talks help you keep your project on budget and on time.

Finalize Agreement

Contract

You should read every contract term before signing. A clear contract keeps you safe and sets the rules for your custom metal fabrication project. Always check the contract details with your supplier. AFI Industrial Co., Ltd. gives contracts that show each step of the process.

Here is a table of important contract terms you should check:

| Essential Contract Term | Description |

|---|---|

| Quality Standards and Tolerances | Sets the exact quality and what small changes are allowed, using industry standards and certifications. |

| Cost Overages and Budget Changes | Tells how you will hear about and approve any extra costs. |

| Change Order Process | Lists the steps for making changes to the job, price, or timeline. |

| Right to Assert a Lien | Gives the right to claim a lien on products if payment is not made. |

| Intellectual Property Rights | Explains who owns the designs and who can use project ideas. |

| Tooling and Equipment | Says who owns special tools, molds, and dies made for the job. |

| Confidentiality | Keeps your business information private during the project. |

| Termination Rights | Tells how either side can end the contract and what happens to unfinished work or unpaid bills. |

| Inspection and Acceptance | Lets you check the products after delivery and tells you how to handle any problems you see. |

| Insurance | Make sure there is insurance and that you are named as an extra insured person. |

Payment

You must agree on how and when to pay before work starts. Most contracts ask for a deposit first, then more payments later or at delivery. Make sure you know when to pay and what ways you can pay. AFI Industrial Co., Ltd. has payment options to fit your needs.

Delivery

Delivery terms tell when and how your parts will be shipped. You should check the delivery schedule and who pays for shipping. Ask if you can track your order and what happens if it is late. AFI Industrial Co., Ltd. gives clear delivery dates and updates you during the process.

Warranty

A good warranty helps you feel safe. Check how long the warranty lasts and what it covers, like problems with materials or how it was made. Know how to ask for help if something goes wrong. AFI Industrial Co., Ltd. promises quality and stands by its products.

Milestones

Breaking your project into milestones helps you see progress. Each milestone is a big step, like design approval, starting production, or delivery. You should agree on these steps in your contract. Milestones help you know if the project is on time and on budget. AFI Industrial Co., Ltd. uses milestones to keep you updated and involved.

Tip: Set clear milestones so everyone knows what to expect and your project keeps moving.

Confirm Details

Check every detail before the project starts. Look over drawings, materials, finishes, and delivery dates with your supplier. Make sure both sides agree on everything. This step helps stop mistakes and saves money later. AFI Industrial Co., Ltd. wants you to confirm all details so your project turns out right.

Note: Checking details now helps you avoid problems and extra costs later.

Start Project

You have checked the contract and made sure all details are right. You also set clear steps for your project. Now, you can begin your custom metal fabrication project. This is when you move from planning to making your parts. Doing things the right way now helps your project go well and meet your needs.

Here’s how you can start your project with confidence:

- Send Your Approval

Tell your supplier you are ready to start. You can send an email or sign a paper. This lets your fabricator know they can begin making your parts. - Schedule a Kickoff Meeting

Plan a meeting with your project manager or main contact. Talk about the timeline and ask any last questions. Make sure everyone knows what happens next. Good talks at the start help stop problems later. - Share Key Contacts

Make sure everyone knows who to call or email for updates. Give names, phone numbers, and emails for your team and the supplier’s team. This helps everyone get answers fast and keeps things moving. - Monitor Progress

Ask your supplier to give you updates often. You can get weekly reports or photos of your parts being made. If you see a problem, talk about it early. - Stay Flexible

Sometimes, things change while making your parts. Be open to ideas from your fabricator. Their skills can help fix problems and make your project better.

Tip: Keep all your project papers in one place. Use folders or cloud storage for contracts, drawings, and emails. This helps you find what you need quickly.

AFI Industrial Co., Ltd. helps you at every step. Their team gives clear updates and answers your questions fast. You can trust them to follow your instructions and deliver good parts on time.

Starting your project with a good plan and clear talks helps you do well. You stay in control, make smart choices, and get the results you want. When you work with a trusted partner like AFI Industrial Co., Ltd., you feel calm, and your project goes smoothly from start to finish.

Remember: How you start your project affects the results. Take action, stay involved, and watch your custom metal fabrication project come to life.

Tips for Custom Metal Fabrication

Be Proactive

You do better when you start early. Gather your drawings, 3D models, and specs before asking for a quote. Adding a 3D model and clear sizes helps your supplier see your design fast. Always say what material and thickness you want. If you need a special finish, write it clearly. Giving lots of details stops confusion and saves time.

Answer your supplier’s questions quickly. Try to reply in one day. Fast replies keep your project moving and show you care about their time.

Say if you want delivery or will pick up your order. This stops surprises and helps your supplier plan shipping.

Stay Organized

Being organized makes things easier. Keep your files, drawings, and notes together. Use folders or cloud storage so you can find things fast. When you make your RFQ, check that you have all the details. List sizes, material specs, and any special needs at the start.

A simple checklist helps you remember:

- Did you add all technical drawings?

- Did you say the material and thickness?

- Are the finishing needs clear?

- Did you list how many parts and delivery needs?

Good prep means fewer mistakes and faster quotes.

AFI Industrial Co., Ltd. takes many file types and helps if you have questions about your papers.

Build Relationships

Strong relationships with your supplier help you get better results. Pick a reliable partner like AFI Industrial Co., Ltd., who cares about clear talks and good quality. Working with the same team helps them learn what you like and suggest ways to make your project better.

Keep talking during the project. Share updates and ask for advice. If you have a problem, talk openly with your supplier. Good talks build trust and help you fix problems fast.

Working with a trusted supplier makes your custom metal fabrication projects go well now and later.

You have learned the main steps to get a good quote for your custom metal fabrication project. Get your details ready before you ask for a quote. Talk clearly with your supplier so there are no mistakes. Pick a trusted company like AFI Industrial Co., Ltd. This helps you avoid problems and keeps things on time. If you follow these steps, you will see how custom metal fabrication helps your project. Begin your next job feeling sure and work well with your team from beginning to end.

FAQ

We offer a wide range of material capabilities to meet various industrial applications. Our commonly used materials include Aluminum, Stainless Steel, Carbon Steel, Copper, and Brass. Whether your project requires high-strength structural steel or corrosion-resistant medical-grade stainless steel, we can provide the right material solution along with the appropriate surface treatments.

The cost of custom metal fabrication primarily depends on the following dimensions:

- Material Cost: The type of metal selected, its thickness, and current market prices.

- Processing Complexity: Whether it involves complex laser cutting paths, multiple bends, or high-precision welding.

- Order Quantity: Large-scale production typically lowers the unit price by amortizing setup costs.

- Surface Finishing: Extra processes such as powder coating, anodizing, or plating.

- Tolerances: Extremely tight tolerances require more advanced equipment and rigorous inspection, which increases cost.

We provide comprehensive services ranging from single-piece prototyping to large-scale mass production. We understand that rapid prototyping is critical for testing during the R&D phase. Therefore, we have no strict minimum order quantity (MOQ) requirements, aiming to help our customers transition smoothly from design validation to market launch.

To ensure accuracy in quoting and manufacturing, we recommend providing 3D files in STEP, IGES, or X_T formats, along with 2D vector files such as DXF or DWG (especially for laser cutting). If you only have a concept or a rough sketch, our engineering team can provide DFM (Design for Manufacturing) guidance to help optimize your design and convert it into production-ready CAD drawings.

Lead times depend on project complexity and our current factory schedule. Generally:

- Simple laser-cut or bent parts: Usually completed within 3–7 business days.

- Complex assemblies or parts requiring finishing: May take 2–3 weeks. If you have an urgent deadline, please let us know during the inquiry phase, and we will do our best to accommodate your timeline through optimized scheduling.

To enhance corrosion resistance, durability, or aesthetics, we offer one-stop surface treatment services, including:

- Powder Coating: Provides a wide range of colors and a durable protective layer.

- Anodizing: Commonly used for aluminum parts to improve hardness and appearance.

- Plating: Including zinc plating, chrome plating, and nickel plating.

- Polishing & Brushing: To improve the metal texture and surface finish.

- Bead Blasting: To achieve a uniform matte surface.

Quality is our core priority. We ensure every product meets your specifications through the following process:

- Advanced Equipment: Utilizing high-precision CNC laser cutters and press brakes.

- In-Process Inspection: Conducting first-article inspections and random checks during cutting, bending, and welding.

- Final Quality Control: All parts undergo strict dimensional verification and visual inspection before shipping. We can also provide Material Test Reports (MTR) and Certificates of Conformance (CoC) upon request.