You want your custom machined parts project to move smoothly from prototype to production. You achieve this by following a structured process that encourages early collaboration and clear communication between your design and manufacturing teams. When you engage with your machining partner at the design stage, you uncover potential challenges early and find practical solutions. This approach leads to better material choices, improved manufacturability, and even cost savings. For example, a simple design adjustment suggested during early discussions can cut machining time by 30%. The Ultimate Guide to Custom Machined Parts Services: From Prototype to Production shows you how these steps turn manufacturing into a strategic advantage. As you read, consider how each stage could shape your own project’s success.

Table of Contents

Custom Parts Manufacturing Overview

What Are Custom Machined Parts?

You encounter custom machined parts every day, whether you realize it or not. These are components made to your exact specifications, often using advanced CNC machines. Unlike mass-produced items, custom parts are designed for unique applications, precise fits, or specialized functions. You see them in industries ranging from automotive to aerospace, medical devices, and industrial equipment. The global custom parts manufacturing market is growing rapidly, expected to reach over $12 billion by 2031, with a strong annual growth rate. This surge reflects the increasing demand for tailored solutions in modern manufacturing.

Here’s a quick look at where you find custom machined parts in today’s industries:

| Industry | Applications |

|---|---|

| Automotive | Engine components (pistons, cylinder heads, crankshafts), exterior parts (door handles, grilles) |

| Medical Device | Implants, surgical instruments, and diagnostic equipment with high precision and biocompatibility |

| Aerospace | Turbine blades, fuel injectors, structural parts for aircraft, spacecraft, and satellites |

| Industrial Equipment | Gears, shafts, bearings, robotic arms for automation systems, and heavy machinery |

Why Choose Machining for Custom Parts?

You choose machining for custom parts because it delivers unmatched versatility and precision. Machining allows you to work with almost any material, from metals to plastics, and create parts with complex shapes and tight tolerances. Unlike casting or forming, machining does not restrict you to extreme molding design constraints. You can produce a wide variety of shapes and sizes, making it ideal for prototypes, one-off components, or low-to-medium volume production.

Here are the main reasons manufacturers like you prefer machining for custom parts:

| Advantage | Description |

|---|---|

| Versatility | Machining applies to nearly any material and achieves precision accuracy for complex parts. |

| Cost-effectiveness | You get precise parts at a lower cost compared to casting or forging, especially for small runs. |

| Precision | Machining achieves extremely tight tolerances, often better than other methods. |

| Minimal Waste | The process generates little waste, and you can recycle or reuse excess material. |

- Custom CNC machining improves product accuracy and production efficiency.

- It decreases waste during the manufacturing process.

- Machined parts can have a wide variety of shapes and sizes.

- They are not subject to extreme molding design constraints.

Key Features and Advantages of Machining

When you select machining for your custom parts manufacturing needs, you gain several key advantages. Precision machining achieves standard tolerances as tight as 0.005 inches, ensuring your parts fit and function perfectly. You benefit from high repeatability, which is crucial when you need consistent quality across many parts. CNC machines offer flexibility, allowing you to adjust designs quickly for prototyping or customization.

| Advantage | Description |

|---|---|

| Tight Tolerance | Precision machining typically achieves a standard tolerance level of around 0.005 inches. |

| High Repeatability | The process allows for consistent replication of parts, crucial for high-demand industries. |

| High Accuracy and Consistency | Precision machining achieves and maintains high accuracy across numerous parts, minimizing human error. |

| Versatility | CNC machines can work with various materials, allowing adaptability across different projects. |

| Complex Geometries | Enables the creation of intricate designs with high accuracy, essential for industries like aerospace. |

| Flexibility | Adjustments to designs can be made quickly, reducing time and cost for prototyping and customization. |

Tip: When you need reliable, high-quality custom parts, machining stands out as the most scalable and precise solution in custom parts manufacturing.

Why choose different manufacturing processes for custom metal parts?

When selecting a manufacturing process for custom metal parts, you face numerous choices. Each process—such as CNC machining, casting, forging, stamping, or additive manufacturing—offers unique strengths. Your decision depends on your project’s requirements, including cost, lead time, material properties, and part complexity.

You should start by considering your project’s priorities. If you require high precision and tight tolerances, CNC machining is the ideal choice. When you want to produce large quantities at a lower cost per part, stamping or casting may be more suitable. For complex shapes or rapid prototyping, additive manufacturing can save you time and allow for design flexibility.

Cost and lead time play a major role in your decision. The following table highlights how different factors impact these two aspects:

| Factor | Description |

|---|---|

| Order volume and complexity | Complex projects require more setup and inspection, increasing lead time and cost. |

| Production model | High-mix, low-volume jobs face longer lead times due to frequent changeovers. |

| Supply chain and seasonality | Raw material availability can fluctuate, affecting scheduling and delivery. |

| Capacity and scale | Manufacturers with bulk inventory can shorten lead times and reduce costs. |

| Process efficiency | Lean, optimized processes enable quicker turnarounds and lower expenses. |

You also need to weigh several other factors:

- Raw Material Choice: Some metals cost more than others. Stainless steel, for example, offers better corrosion resistance but comes at a higher price than mild steel.

- Labor Costs: Complex parts require more skilled labor, which increases your total project cost.

- Design Complexity: Simple designs are easier and cheaper to manufacture. Intricate features or tight tolerances add to both cost and lead time.

- Order Quantity: Larger orders reduce the per-unit cost because setup time is spread across more parts.

- Finishing Processes: Additional steps like powder coating or brushing improve appearance and durability but add time and expense.

You can compare options using the table below:

| Factor | Option A (Cost-Effective) | Option B (Premium) | Implications |

|---|---|---|---|

| Material/Grade | DC01/SPCC | 304 SS | Stainless steel costs more, resists corrosion |

| Strength/Hardness | HRB 60–80 | HSS/DP steel | Harder steels increase tool wear, raise cost |

| Corrosion Resistance | Zinc 8–12 µm | Powder 70 µm | Powder coating adds time, improves durability |

| Tolerance | ISO 2768-mK | Custom ±0.05 mm | Tighter tolerances require more inspection |

| Surface Finish | Ra ≤ 3.2 µm | Brushed/2B | Brushed finish adds steps and time |

Tip: Always match your process to your project’s goals. If you need fast delivery, choose a process with short setup and high efficiency. For critical parts, prioritize precision and material performance, even if it means higher costs.

You make the best choice by balancing these factors. When you understand how each process affects your timeline, budget, and part quality, you set your project up for success.

The Ultimate Guide to Custom Machined Parts Services: From Prototype to Production

Steps for Custom Metal Parts Machining

You begin your journey with a clear process. The ultimate guide to custom machined parts services: from prototype to production helps you understand each step, so you can plan with confidence. Here’s a typical workflow you will follow:

| Step Number | Step Description |

|---|---|

| 1 | Design |

| 2 | Choosing a manufacturing method |

| 3 | Quoting and picking a supplier |

| 4 | Tooling |

| 5 | Casting |

| 6 | Heat treat or shake out |

| 7 | Machining |

| 8 | Inspection |

| 9 | Polishing |

| 10 | Finishing |

| 11 | Shipping |

You start by understanding your materials and determining the right manufacturing processes. You identify the use cases for your part. You collaborate with your supplier to select the best approach for your needs. This step-by-step method ensures a smooth transition from prototype to production.

Design and Engineering for CNC Machining

CAD Modeling and Design for Manufacturability

You lay the foundation for success with strong design and engineering. The ultimate guide to custom machined parts services: from prototype to production emphasizes the importance of CAD modeling. You use computer-aided design (CAD) software to create detailed blueprints. These blueprints define every feature, tolerance, and surface finish for your part.

You work with engineers to establish strength requirements and cost targets. You optimize part geometry to reduce material waste and machining time. You minimize complexity to decrease programming time and avoid specialized tooling. You align features with standard tooling capabilities, which helps you save on costs and lead times.

| Design Consideration | Explanation |

|---|---|

| Optimize part geometry | Reduces material waste and machining time |

| Minimize machining complexity | Decreases programming time and the need for specialized tooling |

| Align features with tooling | Ensures compatibility with common tools, reducing costs and lead times |

| Specify appropriate tolerances | Balances function and manufacturability, avoiding unnecessary complexity |

| Avoid sharp internal corners | Enables the use of standard tooling, reducing programming complexity |

| Limit complex curves | Reduces manufacturing complexity and machining time |

| Manage tight tolerances | Tolerances below ±0.002″ require specialized equipment and increase timelines |

Note: When you design for manufacturability, you avoid costly mistakes and delays. You make it easier to move from prototype to production.

Converting part drawings to CNC machine language

You convert your CAD drawings into CNC machine language. This step is critical in the ultimate guide to custom machined parts services: from prototype to production. You use CAM (computer-aided manufacturing) software to translate your designs into instructions that CNC machines can follow.

You ensure that every feature, hole, and contour is programmed accurately. You check the tool paths for efficiency and collision avoidance. You select the right cutting tools and set the speeds and feeds for each operation. This careful preparation allows your CNC machining process to run smoothly and produce high-quality custom parts.

Iterative Design and Feedback

You improve your design through iteration and feedback. After reviewing your prototype, gather input from your team and machining partner. You look for ways to enhance performance, reduce cost, or simplify manufacturing.

You update your CAD model based on this feedback. You repeat the process as needed, refining your design until it meets all requirements. This iterative approach, highlighted in the ultimate guide to custom machined parts services: from prototype to production, ensures your part is ready for efficient CNC machining and reliable production.

Material Selection for Machining

Metals, Plastics, and Composites

You choose from a wide range of materials for CNC machining. Your options include metals like aluminum, steel, and titanium; plastics such as ABS and PEEK; and advanced composites. Each material offers unique properties for strength, weight, and durability.

Create a list of material options that meet your requirements, including design specifications. Choose the most appropriate material, prioritizing quality over cost when necessary.

You consider the function of your part, the environment it will face, and the performance you expect. You select a material that matches your needs for mechanical strength, thermal stability, and surface finish.

Factors Affecting Material Choice

You start with must-have requirements and work down to nice-to-have features. This process helps you narrow down your material options. You focus on the functional requirements of your part, not just cost or availability.

- Will your part endure mechanical stress or impact?

- Will it operate in high temperatures?

- Will it face exposure to chemicals, UV, or moisture?

You define the material requirements, including mechanical, thermal, and other specifications. You consider the intended use and environmental conditions of the parts. This careful selection process, as described in the ultimate guide to custom machined parts services: from prototype to production, ensures your custom part will perform as expected.

Assessing and verifying material compliance

You assess and verify that your chosen material meets all necessary standards. You check certifications, test reports, and supplier documentation. You confirm that the material’s properties align with your design and regulatory requirements.

You may request sample testing or third-party verification for critical applications. You document your findings and keep records for traceability. This step protects your project from costly errors and ensures your custom parts meet quality expectations.

Tip: Always verify material compliance before you move to CNC machining. This step helps you avoid delays and ensures your prototype and production parts meet all requirements.

Prototyping with CNC Machining and 3D Printing

Process selection for small-batch manufacturing of metal parts.

You face a critical decision when choosing the right process for small-batch manufacturing of metal parts. Your choice directly impacts cost, speed, and the quality of your prototypes. CNC prototype machining and 3D printing stand out as the most effective options for rapid prototyping and low-volume production. Each method offers unique strengths, and your selection depends on your project’s requirements for accuracy, material, and turnaround time.

You should consider the following when selecting a process:

- Part complexity: 3D printing excels at producing intricate geometries without extra tooling. CNC prototype machining is ideal for parts that require high accuracy and precision.

- Material selection: CNC prototype machining supports a wide range of metals and engineering plastics. 3D printing offers flexibility but may have limitations with certain metals.

- Tolerance and finish: If your project demands tight tolerances and a superior surface finish, CNC prototype machining delivers better results.

- Lead time and cost: 3D printing provides fast setup for one-off parts. CNC prototype machining becomes more cost-effective as the batch size increases.

You can compare the two methods using the table below:

| Factor | CNC Machining | 3D Printing |

|---|---|---|

| Tolerances | ± 0.001″–0.005″ (high precision) | ± 0.004″–0.02″ (depends on tech) |

| Production Speed | Slower setup, faster for batches | Faster setup, slower for large parts |

Tip: For small batches of custom-made parts that require high accuracy and precision, CNC prototype machining is often the preferred choice. For complex shapes or quick design iterations, 3D printing can accelerate your prototyping stage.

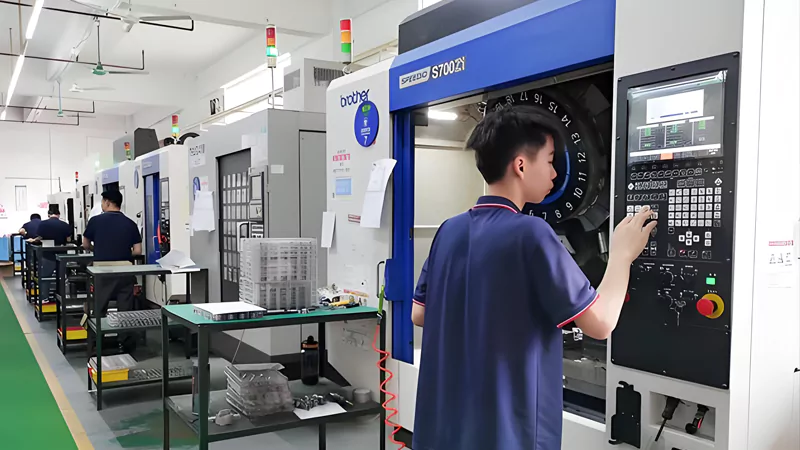

CNC Prototype Machining

You rely on CNC prototype machining to produce functional prototypes that closely match your final production parts. This process uses advanced CNC machines to cut, drill, and shape raw materials into precise components. You benefit from the ability to create parts with tight tolerances, excellent repeatability, and a wide range of materials.

Industries that use CNC prototype machining include aerospace, automotive, medical devices, and electronics. You can produce everything from engine components to surgical tools and custom enclosures. CNC prototype machining supports both metal and plastic parts, making it versatile for many applications.

Key advantages you gain from CNC prototype machining:

- Consistent quality across multiple prototypes

- Ability to test fit, form, and function before committing to mass production

- Fast turnaround for urgent projects

- Direct path from CAD model to finished part

You can use custom CNC milling, turning, and multi-axis machining to achieve complex geometries and fine details. This flexibility allows you to refine your design and ensure your prototype meets all requirements.

CNC Machining for Prototyping

You use CNC machining for prototyping when you need to validate your design under real-world conditions. This approach gives you production-grade parts that you can test for strength, durability, and performance. You can make quick design changes and produce new iterations rapidly, reducing your development cycle.

The CNC machining process ensures that your prototypes match the specifications of your production parts. You can evaluate assembly, fit, and function with confidence. This step is essential for prototype manufacturing, as it bridges the gap between concept and full-scale production.

Note: CNC prototype machining allows you to identify and resolve design issues early, saving you time and money during the transition to production.

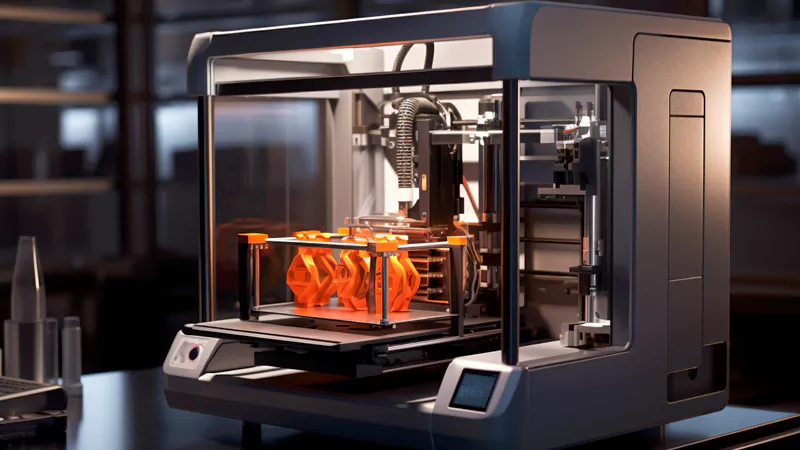

3D Printing Integration

You integrate 3D printing into your prototyping workflow to accelerate design iterations and explore complex geometries. 3D printing enables you to create models quickly, test new ideas, and visualize your concepts before investing in tooling or machining. You can combine 3D printed parts with CNC prototype machining to optimize both speed and accuracy.

For example, you might use 3D printing to produce a quick-fit prototype for ergonomic testing, then switch to CNC prototype machining for a functional prototype that requires tight tolerances. This hybrid approach leverages the strengths of both technologies, giving you flexibility and control over your prototype manufacturing process.

You benefit from:

- Reduced lead times for initial prototypes

- Lower costs for early-stage design validation

- Ability to test multiple design options in parallel

By combining CNC prototype machining and 3D printing, you streamline your prototyping stage and set the foundation for successful production parts.

CNC Machining Technologies and Capabilities

CNC Machining Processes

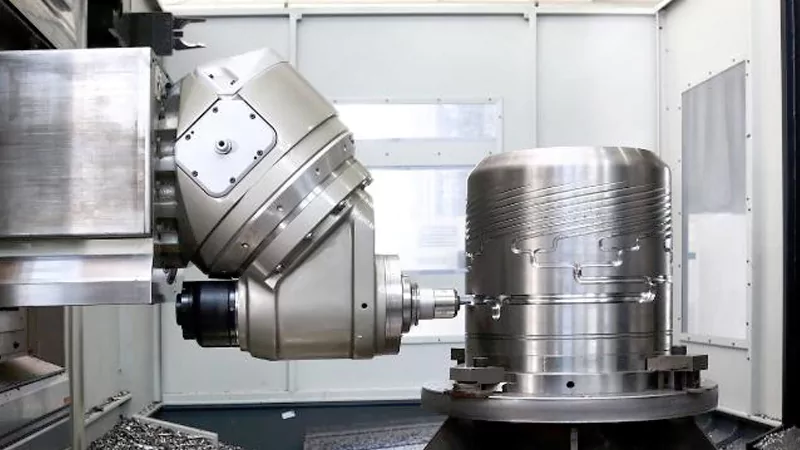

Milling, Turning, and Multi-Axis Machining

You rely on CNC machining to produce custom parts with high accuracy and repeatability. The most widely used CNC machining processes include:

- CNC milling: You use computerized controls to cut and shape materials. The machine moves the cutting tool along multiple axes, allowing you to create flat surfaces, slots, holes, and complex 3D shapes.

- CNC turning: You rotate the workpiece while a stationary cutting tool shapes it. This process is ideal for producing cylindrical parts like shafts, bushings, and threaded components.

- Multi-axis machining: You take advantage of machines with three, four, or even five axes. These machines allow you to create intricate geometries and reduce the number of setups, improving efficiency and part quality.

CNC machining gives you the flexibility to work with metals, plastics, and composites. You can achieve tight tolerances and smooth finishes, making this technology essential for industries such as aerospace, automotive, and medical devices.

Advanced Machining Methods

EDM, Laser, and Waterjet Cutting

You expand your capabilities with advanced CNC machining methods. These include EDM (Electrical Discharge Machining), laser cutting, and waterjet cutting. Each method offers unique benefits for custom parts manufacturing.

| Feature | Description |

|---|---|

| Precision | Achieve high dimensional accuracy and low surface roughness, ideal for close-fitting parts. |

| Complexity | Create intricate designs and complex shapes without custom tooling. |

| Versatility | Perform cutting, marking, drilling, and welding on a wide range of materials. |

| Material Processing | Machine hard-to-cut materials, including hardened steels and exotic alloys. |

| Minimal Tool Wear | EDM uses electrical sparks, reducing tool wear and increasing efficiency. |

| Non-Contact Erosion | Remove material without physical force, perfect for delicate or thin parts. |

| Applications | Use in aerospace, medical, and electronics for high-tolerance, complex components. |

You use EDM to cut intricate shapes and hard materials with exceptional accuracy. Laser cutting provides clean edges and fine details, while waterjet cutting handles thick or heat-sensitive materials without thermal distortion. These advanced CNC machining methods help you meet demanding requirements for precision and complexity.

Additive Manufacturing and Hybrid Approaches

3D Printing for Prototyping

You integrate 3D printing into your CNC machining workflow to accelerate prototyping and design validation. 3D printing allows you to create models quickly, test new ideas, and visualize concepts before committing to full-scale production. You benefit from reduced lead times, lower costs for early-stage prototypes, and the ability to test multiple design options in parallel.

Combining Machining and Additive Methods

You combine additive manufacturing with traditional CNC machining to unlock new possibilities. This hybrid approach offers several advantages:

| Benefit | Description |

|---|---|

| Efficiency | Reduce inventory and minimize waste by producing only what you need. |

| Design Flexibility | Create molds and patterns with complex geometries, improving thermal distribution and reducing mold-making time. |

| Material Optimization | Produce parts with intricate designs that are difficult to achieve using conventional methods. |

| Tool Performance | Manufacture custom tools with internal cooling channels, extending tool life and performance. |

| Customization | Produce jigs and fixtures faster, tailored to your specific needs. |

| Multi-material Use | Combine different materials in a single part for enhanced functionality. |

| Maintenance | Use 3D printing for quick repairs, extending the life of tools and components. |

You gain the ability to produce complex, high-performance parts while optimizing your manufacturing process. By integrating CNC machining with additive manufacturing, you improve efficiency, reduce costs, and deliver innovative solutions for your customers.

Other Manufacturing Process Options

You have more choices than CNC machining when you need custom parts. Each process brings unique strengths to your project. You can select the best method based on your production volume, part complexity, and material requirements.

- Injection molding works well for high-volume production. You can create complex shapes with detailed features. This process becomes cost-effective when you need many identical parts.

- 3D printing gives you rapid prototyping. You can produce parts quickly and at a lower cost. This method allows you to test designs and make changes before full-scale production. You can also create complex structures and customize each part easily.

You should consider your project’s needs before choosing a process. For example, injection molding is ideal for thousands of parts with tight tolerances. 3D printing is better for prototypes or small batches that require design flexibility. By understanding these options, you can make informed decisions and achieve the best results for your custom parts.

Surface Finishing and Quality Control

You want your custom machined parts to look good and last long. Surface finishing techniques help you achieve both goals. These processes improve appearance, increase durability, and enhance performance. You can choose from several finishing methods, each with its own benefits.

| Technique | Description | Impact on Quality |

|---|---|---|

| Anodizing | Creates a protective oxide layer on aluminum and titanium parts. | Increases corrosion resistance and adds aesthetic appeal. |

| Powder Coating | Electrostatic application of dry powder, cured in an oven. | Provides a tough, uniform coating that is durable and resistant to damage. |

| Electropolishing | Chemical process to smooth and brighten surfaces. | Enhances corrosion resistance and provides a clean, polished appearance. |

| Brushed Finish | Creates a uniform pattern of fine lines on the surface. | Offers a decorative satin-like sheen, often used for visible components. |

| Passivation | Uses acid baths to enhance the corrosion resistance of stainless steel. | Improves longevity in corrosive environments without altering appearance. |

| Electroplating | Deposits a thin layer of metal onto the surface. | Enhances corrosion resistance, wear resistance, or electrical conductivity. |

You should select the finishing process that matches your part’s function and environment. For example, anodizing works well for aluminum parts exposed to moisture. Powder coating adds a durable layer for parts that face frequent handling. Electropolishing and passivation improve corrosion resistance for stainless steel components.

Quality control is essential at every stage. You need to inspect parts for surface defects, measure critical dimensions, and verify that finishes meet your specifications. Consistent quality checks ensure your parts perform as expected and meet industry standards.

Tip: Always include surface finishing and quality control in your project plan. These steps protect your investment and help you deliver reliable, high-quality custom parts.

Cost and Quality in Custom Parts Manufacturing

When you plan a custom parts project, you need to balance cost and quality. Understanding what drives expenses and how to maintain high standards helps you get the most from your precision machining service.

Factors Influencing Cost

Design Complexity and Material Choice

You will notice that several factors shape the cost of your custom parts. The most important include:

- Equipment used for machining

- Materials selected for the part

- Design complexity

- Production volume

- Required tolerances

- Surface treatments

If your design has intricate features or tight tolerances, you will pay more. Choosing premium materials or adding special finishes also increases costs. For example, a part made from titanium with a mirror finish will cost more than one made from aluminum with a standard finish. The more complex your design, the more time and resources your precision machining service will need to achieve the required precision.

Batch Size and Production Planning

Batch size plays a big role in your total cost. Producing a single prototype costs more per unit than making a batch of 100. Larger orders allow you to spread setup and programming costs across more parts. Careful production planning, such as grouping similar parts, can further reduce expenses.

Cost Optimization Strategies

Design for Manufacturability

You can lower costs by working with your precision machining service to simplify your design. Here are some proven strategies:

- Simplify geometry to speed up machining

- Use standard tolerances where possible

- Minimize setups by aligning features

- Consolidate components to reduce assembly

- Prototype early to catch design issues

Selecting cost-effective materials, like 6061 aluminum instead of 7075, can also help. Sourcing materials in bulk or comparing global suppliers may lead to better pricing.

Efficient Use of Machining Resources

You can optimize costs by:

- Increasing batch sizes to lower the cost per part

- Grouping orders to share setup costs

- Negotiating long-term contracts for regular needs

Choosing the right material and keeping designs simple reduces machining time. Using advanced techniques, such as CNC machining and 3D printing, improves efficiency and precision.

Quality Assurance and Inspection

Standards, Certifications, and Testing

Your precision machining service should follow strict quality assurance methods to ensure every part meets your requirements. Common methods include:

| Quality Assurance Method | Description |

|---|---|

| Surface Roughness Testers | Measure and inspect the surface quality of parts. |

| Hardness Testing Equipment | Assess the hardness of materials, ensuring suitability. |

| Non-Destructive Testing (NDT) Methods | Identify internal and surface defects without damaging the part. |

| Statistical Process Control (SPC) | Monitor data in real time to maintain consistent quality. |

| Tool Condition Monitoring | Track tool wear and performance during machining. |

| Environmental Monitoring Equipment | Ensure optimal temperature and humidity for precision machining. |

| Geometric Dimensioning and Tolerancing | Verify geometric tolerances of machined parts. |

| Visual Inspection Tools | Visually inspect parts for quality control. |

Continuous Improvement in Machining

You benefit when your precision machining service uses continuous improvement. Regular reviews, feedback, and process upgrades help maintain high precision and quality. Your supplier should invest in training, new equipment, and updated standards. This commitment ensures your parts meet the latest industry requirements and perform reliably in the field.

Tip: Partner with a machining provider to prioritizes both cost efficiency and precision. This approach helps you achieve the best value and quality for your custom parts.

Choosing the Right CNC Machining Partner

Selecting the right CNC machining partner shapes the outcome of your custom parts project. You want a provider who understands your needs, delivers consistent quality, and supports you from design to delivery.

Evaluating Machining Service Providers

Capabilities, Experience, and Support

You should start by evaluating each provider’s strengths. Look for these qualities:

- Ability to meet your part requirements, including material, tolerances, surface finish, and complexity.

- Expertise in handling your chosen materials and part designs.

- Access to advanced equipment and a range of CNC machining solutions, such as milling, turning, and EDM.

- Strong quality control systems that ensure precision and consistency.

- Surface treatment options that match your finishing needs.

- Reliable lead times and flexibility to adapt to your schedule.

- Transparent quoting and clear cost structures.

A provider like AFI Industrial Co., Ltd. brings years of experience, a skilled team, and state-of-the-art technology to every project. You benefit from their ability to handle complex parts and deliver high-quality CNC machining services.

Requesting Quotes and Comparing Offers

When you request quotes, you set the stage for a successful partnership. Follow these steps:

- Define your project requirements, including material, dimensions, and quantity.

- Choose a CNC machining partner with proven experience and capacity.

- Provide detailed drawings or 3D models of your part.

- Specify any secondary operations, such as finishing or assembly.

- Communicate your timeline and delivery expectations.

Compare offers not just on price, but also on value. Consider lead time, support, and the provider’s ability to meet your technical requirements. A clear, detailed quote helps you avoid surprises and ensures your project stays on track.

Building a Collaborative Relationship

Communication and Project Management

You build a strong partnership through open communication and effective project management. Choose a provider who listens to your needs, responds quickly, and keeps you informed at every stage. Regular updates, clear documentation, and a single point of contact help prevent misunderstandings.

Tip: Establish regular check-ins and use project management tools to track progress and address issues early.

Managing Revisions and Feedback

You improve results by sharing feedback and managing revisions together. A reliable partner welcomes your input and adapts to changes. Look for a team that treats your project as a priority, offers personalized attention, and values long-term collaboration.

You achieve the best outcomes by working with a partner who puts your interests first, adapts to your requirements, and builds trust through consistent performance.

Common Challenges and Solutions in Custom Machining

No credibility, price adjustments after prepayment

You may encounter suppliers who change prices after you have already made a prepayment. This situation can damage trust and disrupt your project timeline. When a machining partner lacks credibility, you risk unexpected costs, missed deadlines, and even project failure. To avoid these issues, always choose a supplier with a proven track record and transparent pricing policies. Ask for detailed quotes and written agreements before making any payments. Reliable partners, like AFI Industrial Co., Ltd, provide clear communication, honor their commitments, and help you avoid unpleasant surprises.

Tip: Protect yourself by requesting references and checking reviews before selecting a machining service. A trustworthy partner will always be upfront about costs and timelines.

Design and Tolerance Issues

You face design and tolerance challenges in almost every custom machining project. If you set tolerances too tightly, you increase costs and make manufacturing more difficult. Over-tolerancing can lead to higher expenses and longer lead times without improving part performance. On the other hand, loose tolerances may result in parts that do not fit or function as intended.

Machining tolerances define how much a part’s dimensions can vary. Not every feature needs to be exact. By setting realistic tolerances, you allow for efficient manufacturing while ensuring your parts work as required. Tolerance standards are essential, especially when parts must fit together. They help reduce waste and control costs.

Successful design means balancing precision with manufacturing realities. You must consider how tight tolerances affect both cost and production time. Designers who work closely with machinists can find the right balance, ensuring parts are both functional and affordable.

Note: Always review your design with your machining partner. This step helps you avoid unnecessary expenses and ensures your parts meet performance requirements.

Production Delays and Lead Times

You may experience production delays and extended lead times for several reasons:

- Part Complexity: Complex designs take more time to machine. If you do not plan for this, your project may fall behind schedule.

- Equipment Failures: CNC machine breakdowns or poor maintenance can halt production and cause unexpected delays.

- Raw Material Supply Issues: Delays in receiving materials or problems with material quality can disrupt your timeline.

- Inadequate Production Scheduling: Poor scheduling leads to mismanaged tasks and missed deadlines.

- Internal Production Management Problems: Lack of communication and coordination within the team lowers efficiency and increases the risk of delays.

To minimize these risks, you should work with a machining partner who uses robust scheduling systems, maintains equipment regularly, and communicates clearly.

Tip: Ask your supplier about their contingency plans for equipment failures and material shortages. A prepared partner can adapt quickly and keep your project moving forward.

Quality Control and Inspection Challenges

You face several quality control and inspection challenges when managing custom machined parts projects. These issues can affect the performance, reliability, and appearance of your final products. Understanding these challenges helps you take proactive steps to maintain high standards.

Here is a table summarizing the most frequent quality control and inspection challenges in custom machined parts manufacturing:

| Challenge | Description |

|---|---|

| Dimensional Inaccuracies | Deviations from specified dimensions can compromise part functionality. |

| Surface Finish Defects | Imperfections can negatively impact appearance and performance. |

| Material Defects | Inconsistencies in raw materials can lead to part failures. |

| Tool Wear | Worn tools result in inaccurate dimensions and poor surface finishes. |

| Machine Tool Errors | Mechanical issues in CNC machines can cause defects in the final product. |

| Programming Errors | Incorrect programming can lead to parts that do not meet specifications. |

You may encounter dimensional inaccuracies if your process does not control tolerances tightly. Surface finish defects, such as scratches or roughness, can reduce the visual appeal and function of your parts. Material defects, like internal cracks or inconsistent hardness, often result from poor supplier quality or inadequate material testing.

Tool wear is another common challenge. As cutting tools degrade, they produce parts with less accuracy and rougher surfaces. Machine tool errors, such as misalignment or vibration, can introduce defects that are hard to detect until final inspection. Programming errors in your CNC code may cause features to be out of place or missing entirely.

To address these challenges, you need a robust quality control process. Start by verifying that all materials meet the required mechanical properties, such as hardness and tensile strength. Use supplier certifications and material testing to confirm compliance. Regularly inspect your tools and machines to catch wear or mechanical issues early. Process design plays a crucial role in quality control. Create rational process flows based on your product’s characteristics, and select suitable materials, tools, and machining parameters for each job.

Tip: Consistent quality checks at every stage of production help you catch problems before they reach your customer. Use precision measuring tools and maintain detailed inspection records to ensure every part meets your standards.

Solutions and Best Practices

You can overcome common machining challenges by adopting proven solutions and best practices. Start by using advanced CAD/CAM software to simulate and refine your designs before production. This step helps you address complex geometries and reduce the risk of programming errors.

Regularly calibrate your CNC machines and use high-quality cutting tools to maintain tight tolerances. Adjust cutting parameters and reinforce critical areas to prevent deformation, especially when machining thin walls. For difficult materials like titanium, select appropriate cutting tools and optimize your machining strategies.

Implement precision measuring tools, such as coordinate measuring machines (CMMs) and surface roughness testers, to verify part quality. Adopt modular design principles to make your parts easier to integrate with other components. Conduct regular inspections of your tools to detect wear early and replace them before they affect part quality.

Use high-grade materials for your tools to enhance durability and reduce wear. Employ advanced software to simplify programming and minimize errors. Adopt modular fixturing systems for greater flexibility in your production setups. Preventive maintenance on your machines reduces repair costs and extends equipment lifespan.

- Utilize advanced CAD/CAM software for design simulation and error reduction.

- Calibrate CNC machines and use high-quality tools for precision.

- Adjust machining parameters for thin walls and difficult materials.

- Implement precision measuring tools and modular design principles.

- Inspect tools regularly and use high-grade materials for durability.

- Employ modular fixturing and preventive maintenance for efficiency.

Note: At AFI Industrial Co., Ltd, you benefit from a comprehensive quality management system. The team uses advanced inspection equipment, regular tool maintenance, and strict process controls to deliver reliable, high-quality custom machined parts for every project.

Future Trends in CNC Machining and Custom Parts Manufacturing

Advances in Machining Technology

You see rapid changes in CNC machining technology. New tools and smarter machines are shaping the future of custom parts manufacturing. You now have access to 5-axis CNC machining, which lets you create complex shapes with fewer setups. This technology improves efficiency and expands your design options. You can produce intricate parts that were once impossible or too costly.

You also benefit from digital twin technology. This innovation allows you to simulate machining processes before production. You can optimize parameters, reduce errors, and save time. Predictive maintenance powered by artificial intelligence helps you avoid unexpected downtime. Your machines alert you to potential issues, so you can fix them before they cause problems.

Here are some key trends you should watch:

- 5-axis CNC machining for complex geometries and fewer setups

- Digital twin technology for process simulation and optimization

- Predictive maintenance using AI to reduce downtime

- Rapid prototyping and agile manufacturing for faster product development

- Enhanced customization and personalization for unique customer needs

Note: You can now deliver parts with higher precision and complexity, meeting the demands of modern industries.

Digital Manufacturing and Industry 4.0

You are entering the era of Industry 4.0. Digital manufacturing connects your machines, systems, and people. You use sensors and the Internet of Things (IoT) to collect real-time data from your CNC machines. This data helps you monitor performance, track production, and make better decisions.

You can integrate your CAD designs directly with your manufacturing workflow. This seamless connection reduces errors and speeds up production. Smart CNC machining uses AI and robotics to automate tasks, improve accuracy, and boost efficiency. You can respond quickly to changes in demand and customize products for your customers.

Key features of digital manufacturing include:

- IoT-enabled machines for real-time monitoring

- AI-driven analytics for smarter decision-making

- Seamless CAD-to-machine integration for faster workflows

- Robotics and automation to increase throughput and reduce errors

Tip: Embracing digital manufacturing helps you stay competitive and deliver high-quality custom parts on time.

Sustainable Materials and Green Manufacturing

You play a vital role in building a sustainable future. Environmental concerns are driving the adoption of green manufacturing practices in CNC machining. You choose energy-efficient machines and processes to reduce your carbon footprint. You select sustainable materials that meet performance requirements while minimizing environmental impact.

You also focus on waste reduction. CNC machining produces minimal scrap, and you can recycle or reuse excess material. You use advanced software to optimize tool paths and material usage, further reducing waste. Many manufacturers now prioritize eco-friendly coolants and lubricants to protect workers and the environment.

Here are some ways you can support green manufacturing:

- Use energy-efficient CNC machines and processes

- Select sustainable and recyclable materials

- Optimize tool paths to minimize waste

- Choose eco-friendly coolants and lubricants

- Implement recycling programs for scrap material

By adopting sustainable practices, you help protect the environment and meet the expectations of customers who value green solutions.

AFI Industrial Co., Ltd. leads these trends by investing in advanced machining technology, digital manufacturing systems, and sustainable practices. You can rely on their expertise to deliver innovative, high-quality custom parts that meet the demands of tomorrow’s industries.

Automation and Smart Machining

You see automation and smart machining transforming the CNC industry. These technologies help you achieve higher productivity, better quality, and lower costs. You use automation to streamline repetitive tasks, reduce manual errors, and speed up your workflow. Smart machining brings intelligence to your shop floor, allowing machines to make decisions and adapt in real time.

You benefit from several key advances in automation and smart machining:

- Robotic Integration: You use robots to load and unload parts, manage tool changes, and handle materials. This reduces downtime and keeps your machines running around the clock.

- Automated Tool Monitoring: You rely on sensors and software to track tool wear and breakage. The system alerts you when a tool needs replacement, preventing defects and reducing scrap.

- Smart Scheduling: You use advanced software to schedule jobs, balance workloads, and optimize machine usage. This helps you meet tight deadlines and maximize efficiency.

- Real-Time Data Analytics: You collect data from your machines and analyze it instantly. This gives you insights into performance, energy use, and maintenance needs.

Tip: Embrace automation early. You will see faster turnaround times, fewer mistakes, and more consistent part quality.

Smart machining uses artificial intelligence and machine learning to improve your processes. Machines learn from past jobs and adjust parameters for better results. You can program machines to detect anomalies, predict failures, and even suggest process improvements.

Here is how automation and smart machining impact your operations:

| Benefit | How You Gain Value |

|---|---|

| Increased Throughput | Machines run longer with less downtime |

| Improved Quality | Automated checks catch errors before they reach you |

| Lower Labor Costs | Fewer manual tasks mean you need less direct labor |

| Predictive Maintenance | Machines alert you before breakdowns occur |

| Flexible Production | You switch between jobs quickly and efficiently |

Note: Automation and smart machining are not just for large factories. You can implement these solutions in shops of any size. Start small, scale up, and watch your productivity soar.

You achieve success in custom machined parts projects by following a clear process. Start with strong planning and open communication. Choose a machining partner who understands your needs and delivers consistent quality. Prepare your design files and reach out to a trusted provider. Stay informed about new machining technologies and trends. This approach helps you deliver high-quality parts and keeps your business competitive.

Tip: Take the first step today—review your project requirements and connect with a machining expert for guidance.

FAQ

You should provide a detailed drawing or 3D model, specify material, quantity, tolerances, surface finish, and any special requirements. Clear information helps your machining partner deliver an accurate quote and avoid delays.

You can often receive prototypes in as little as 3–7 business days. Production parts may take longer, depending on complexity, order size, and finishing needs. Ask your provider for a specific timeline.

You can choose from metals like aluminum, steel, titanium, and copper, as well as plastics such as ABS, PEEK, and nylon. Composites are also available for specialized applications.

You benefit from strict quality control. Providers use advanced inspection tools, material certifications, and in-process checks. They verify dimensions, surface finish, and material properties before shipping your parts.

You can request changes, but it may affect cost and lead time. Communicate updates as early as possible. Your machining partner will review the impact and advise you on the best approach.

You can select from anodizing, powder coating, electropolishing, passivation, and more. Each finish improves appearance, durability, or corrosion resistance. Your provider can recommend the best option for your application.

Choose CNC machining for tight tolerances, strength, and production-grade materials. Use 3D printing for rapid prototyping, complex shapes, or low-volume runs. Your project goals determine the best process.