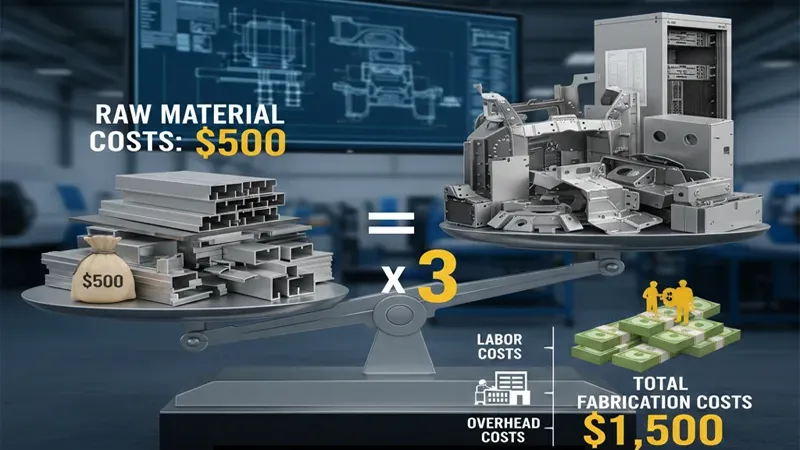

You need to understand both design and production costs before starting your project. The design and production costs of custom metal parts depend on the complexity and scale of the project. Prototype development typically costs between $100 and $5,000; however, projects involving large-scale production, due to the inclusion of expensive tooling costs (such as stamping or casting molds), may have starting costs ranging from $2,000 to $50,000+. Market rates for design services (2D drafting or 3D modeling) typically range from $30 to $150 per hour. The final price is directly influenced by the type of material, tolerance requirements, tooling costs, and manufacturing processes.

Table of Contents

Cost of Custom Metal Part Design and Production

Precision CNC Machining: Our Quotation Logic

At AFI Industrial, we believe in transparent pricing. For high-precision components, such as aluminum lens housings or stainless steel bushings, the cost is not a flat fee but a strategic calculation based on four key pillars:

1. Non-Recurring Engineering (NRE) & Setup Costs

Every precision job begins with technical preparation. This is a fixed cost per batch, which explains why unit prices drop significantly as volume increases.

- Programming: Developing the CAM (Computer-Aided Manufacturing) toolpaths.

- Machine Setup: Calibrating the 3-axis, 4-axis, or 5-axis centers and installing specific fixtures.

- First Article Inspection (FAI): Ensuring the first part meets +/- 0.005mm tolerances before the full run begins.

2. Material & Machining Cycle Time

- Material Utilization: We calculate the raw block size required (e.g., AL6061, SUS304) plus current market premiums.

- Cycle Time: The most critical factor. This is the “spindle time” required to complete the part. Complexity, wall thickness, and deep-hole drilling all add to the cycle time.

- Machine Hourly Rates: Our rates vary based on the equipment used (e.g., standard CNC turning vs. high-speed 5-axis milling).

3. Tooling & Specialized Finishing

High-precision parts often require specialized diamond-coated tools or micro-drills, especially for hardened metals.

- Tool Wear: Consumables are factored into the unit price based on material hardness.

- Surface Treatment: Costs for anodizing, sandblasting, laser engraving, or electroplating are calculated per batch or per square inch to ensure aesthetic and functional consistency.

4. Quality Assurance (QA) Requirements

For industries like automotive or optical electronics, “close enough” isn’t an option.

- Standard QA: Included in our base rate.

- Premium QA: If your project requires 100% CMM (Coordinate Measuring Machine) inspection reports, material certifications (CoC), or Salt Spray Testing, these are itemized to give you full control over your quality budget.

Price Breakdown Example (just for indicative)

| Project Phase | Prototype (1-5 pcs) | Mid-Batch (100-500 pcs) | Mass Production (2000+ pcs) |

| Setup Fee | High (Primary driver) | Medium (Amortized) | Minimal (Spread across volume) |

| Unit Price | $150 – $300 / pc | $15 – $45 / pc | $5 – $12 / pc |

| Lead Time | 3-7 Days | 2-3 Weeks | Scheduled Deliveries |

Pro Tip for Engineers: Providing a 3D model (STEP/IGS) alongside a 2D PDF with clearly marked tolerances allows us to provide a firm quote within 24 hours.

Understanding the Cost of Sheet Metal Fabrication

The cost of sheet metal fabrication is rarely a “flat rate.” It is a dynamic calculation driven by raw material fluctuations, geometric complexity, Minimum Order Quantities (MOQ), and secondary finishes. In the 2025 manufacturing landscape, the integration of AI-driven nesting and robotic automation has made cost structures more precise than ever.

1. Core Cost Breakdown (Estimated)

To help you budget effectively, the table below provides current industry benchmarks for professional-grade sheet metal fabrication:

| Cost Element | 2025 Estimated Unit Price (USD) | Notes |

| Raw Material (per sq. ft.) | $4.50 – $24.00 | Aluminum ($6–$14) / SS304 ($12–$24) / Galv. Steel ($4–$9) |

| Laser Cutting (per inch) | $0.15 – $0.85 | Varies by material thickness (Standard 1/8″ is approx. $0.35) |

| Bending/Folding (per bend) | $1.20 – $6.00 | Simple bends are cheaper; complex sequences require setup time |

| Professional Welding (per hour) | $75 – $160 | Certified TIG/MIG welding including labor and consumables |

| Powder Coating (per sq. ft.) | $2.50 – $18.00 | Certified TIG/MIG welding, including labor and consumables |

2. Key Factors Influencing Your Quote

- Material Utilization (Nesting): Modern software in 2025 can achieve over 85% material utilization. High-efficiency nesting significantly reduces the “scrap cost” passed on to the customer.

- Setup & Engineering Fees: For custom low-volume runs, programming and machine setup fees (ranging from $75 to $350) are the biggest price drivers. Increasing your order from 1 to 50 units can often reduce the per-unit cost by up to 80%.

- Tolerance Requirements: Standard industrial tolerances (±0.005″) are the most cost-effective. Requesting high-precision tolerances (±0.001″) typically results in a 30%–50% price premium due to increased inspection time and higher scrap rates.

The most effective way to lower costs in 2025 is through Design for Manufacturing (DFM). Simple choices—like maintaining a uniform bend radius across the part or avoiding complex internal cutouts—can reduce your final quote more effectively than switching to a cheaper material.

Cost of Precision Stamping

Precision stamping is the go-to process for achieving large-scale, high-consistency production. However, its cost structure is characterized by being “front-heavy.” Entering 2025, influenced by global raw material fluctuations and automation upgrades, the cost of precision stamping is primarily driven by three core dimensions:

- Initial Tooling & Die Costs: This is the largest upfront expense. For standard complexity single-hit dies or simple compound dies, costs typically range between $5,000 and $20,000. For high-precision, multi-station progressive dies, 2025 market quotes generally fall between $30,000 and $100,000+, depending on geometric complexity and required tool life (e.g., SPI Class 101).

- Raw Material Costs: Materials usually account for 30% to 50% of the unit price. According to market monitoring in the first half of 2025, Hot Rolled Coil (HRC) prices have stabilized at approximately $940 per short ton. High-precision parts often require stainless steel, aluminum alloys, or phosphor bronze, which carry higher procurement costs and involve a 20%-40% scrap rate during processing.

- Per-Unit Production Cost: The advantage of stamping lies in its extreme production speed. Once the break-even point is reached (typically 3,000 to 5,000 units), the per-unit processing fee drops significantly. For mass production (100,000+ units), the pure processing cost per part (excluding material) can be as low as $0.01 to $0.20.

2025 trends show that miniaturized electronic components (thickness <2.5mm) require even higher die precision. By implementing DFM (Design for Manufacturing) analysis early in the design phase to optimize nesting and reduce strip waste, you can directly reduce total costs by 10%-15%.

Key Factors Affecting Custom Metal Fabrication Cost

Material Selection and Impact

You make a critical decision when you select materials for custom metal fabrication. The choice affects the cost, durability, and performance of your part. Stainless steel provides durability and long-term benefits, but the initial cost may not fit every budget. Materials that resist wear and corrosion can lower operational costs by reducing repairs and replacements. You must balance upfront material costs with savings in maintenance and efficiency.

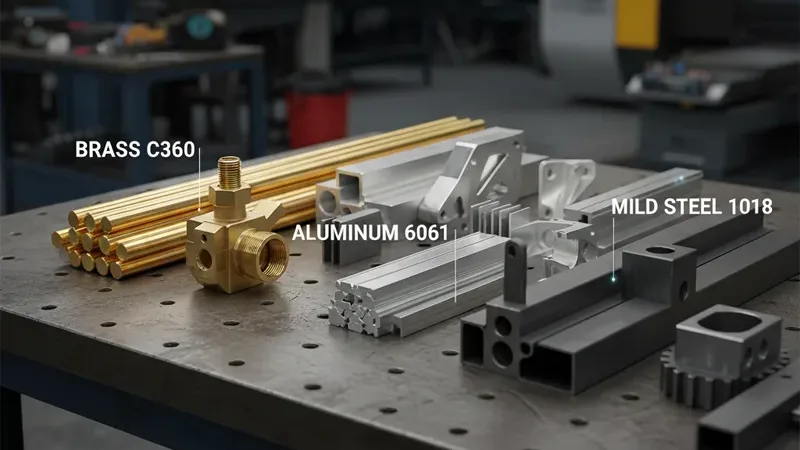

You can compare common materials for custom parts using machinability and cost-effectiveness:

| Material | Machinability Rating | Cost-Effectiveness | Notes |

|---|---|---|---|

| Brass C360 | 100% | High | Best for machinability, minimal tool wear, and high-speed machining. |

| Aluminum 6061 | Very Good | Cost-effective | Strength-to-weight ratio, corrosion resistance. |

| Mild Steel 1018 | Good | Affordable | Consistent quality, widely available for structural applications. |

You often choose aluminum for CNC machining because of its machinability and low raw material cost. Brass offers high machinability and a good scrap return, though the raw material cost is slightly higher. Mild steel remains affordable and available for many production runs.

Design Complexity and Tolerances

You influence the cost variables of your project through design choices. Complex designs require more time and resources to manufacture. Tighter tolerances increase production costs because you need specialized equipment. Scrap and rework rates rise when tolerances leave less room for error. You also face longer production times and higher labor costs. Additional tooling and maintenance become necessary to achieve tight tolerances.

Consider these impacts:

- Intricate designs demand more time and resources.

- Advanced machinery may be needed for complex parts.

- Balancing tolerances helps maintain functionality and control costs.

The tolerance you define in engineering drawings affects the manufacturing method and total cost. Smaller allowable deviations make it harder to achieve precise dimensions. This leads to higher chances of rejection and rework, which raises costs.

You can see typical cost increases for tighter tolerances:

| Tolerance Level | Cost Increase Factor |

|---|---|

| Rough Machining (0.76 mm) | 1x |

| Precision (0.025 mm) | 4x |

| Ultra-Precision (0.0025 mm) | 24x |

| Tolerance Change | Cost Increase (%) |

|---|---|

| ±0.2mm to ±0.05mm | 400-600% |

| ±0.05mm to ±0.01mm | 200-500% |

| Material | Cost Increase (%) |

|---|---|

| Aluminum | Base Cost |

| Stainless Steel | 40% more |

You must review your design and tolerance requirements to receive accurate quotes and manage your budget.

Machining Methods and Technology

You select machining methods based on the part design and required precision. CNC machining and electrical discharge machining (EDM) offer high precision for custom metal fabrication. CNC machines use computer programming for accurate cuts. EDM uses electrical sparks for fine details. The complexity and tolerances of your part affect the cost of these methods.

The number of axes on CNC machines changes the cost. Three-axis CNC machines are more affordable than five-axis machines. You can see typical hourly rates:

| Machine Type | Cost per Hour |

|---|---|

| Three-axis CNC | $10 – $20 |

| Five-axis CNC | $20 – $40 |

You also consider finishing processes. Anodizing and polishing add to the final price and improve durability. Waterjet cutters can reduce the need for additional finishing work, which impacts overall cost.

You compare CNC machining, laser cutting, and traditional fabrication methods for custom parts. CNC machining works well for complex 3D shapes and low to medium production runs. Sheet metal fabrication suits medium to high volume production. Laser cutting offers high speed for sheet metal, but setup costs are higher.

| Method | Cost per Part | Setup Cost | Production Speed | Ideal Use Case |

|---|---|---|---|---|

| Laser Cutting | $0.7 | Higher | 300 parts/hour | High-volume sheet metal production |

| CNC Machining | $1.62 | Lower | 40-60 parts/hour | Heavy materials, low-volume runs |

You must evaluate the machining method and technology to optimize cost and achieve the required part quality.

Quantity and Order Size

You influence the cost of each part when you decide how many to order. The first part of a production run carries the highest cost. This happens because machine setup and handling take time. When you increase the order size, you spread these setup costs over more parts. This leads to a lower cost per part.

- Ordering larger volumes of components leads to a decrease in the price per component due to reduced machine setup times and efficiencies in production.

- The first part of a production run incurs the highest cost due to setup and handling, while subsequent parts see a price drop, with discounts starting from the second part and potentially reaching up to an 86% reduction for large bulk orders.

You should consider your project needs and storage capacity before choosing a large order. Bulk orders work well for sheet metal fabrication projects that require many identical parts. You can achieve significant savings by planning your order size.

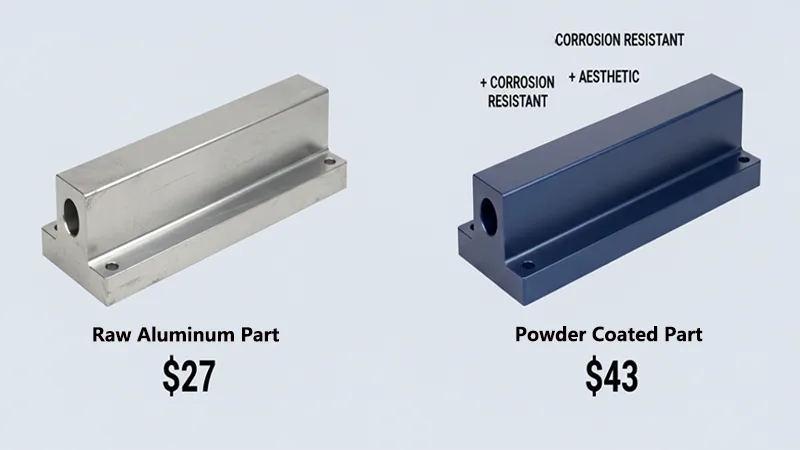

Finishing and Surface Treatments

You add value to your custom part with finishing and surface treatments. These processes change the appearance, durability, and function of the part. Each finishing option comes with a different cost. The choice depends on the base material and the performance you need.

| Finishing Option | Cost |

|---|---|

| Raw Aluminum Part | $27 |

| Powder Coated Part | $43 |

- Surface treatment options vary widely, each with unique advantages and limitations.

- The choice of treatment depends on the base material and performance requirements.

- Outsourcing surface treatment can introduce additional costs and risks.

You see that a raw aluminum part costs $27, while powder coating increases the cost to $43. You must decide if the added benefits of a finish justify the extra cost. Sheet metal fabrication often includes finishing steps to meet industry standards or customer requests. You should discuss your needs with your manufacturer to select the right finish for your part.

Custom Metal Part Design Process

You follow a structured process when you create a custom metal part. Each stage shapes the outcome and influences the design cost and metal fabrication prices. Here is a typical workflow:

- Initial Consultation: You meet with the manufacturer to discuss your needs. For example, you may need a steel bracket with specific dimensions for an assembly line.

- Design Specifications: You define measurements, tolerances, and material type. You might specify a 4-inch by 2-inch bracket made from cold rolled steel.

- Blueprint Development: The engineering team creates technical drawings or 3D models. These blueprints show hole locations, bends, and thickness.

- Material Selection: You choose the metal based on strength, weight, and cost. Cold rolled steel may be selected for its availability and price.

- Metal Fabrication Process: The manufacturer cuts, bends, and forms the part. For a bracket, this could involve laser cutting and press brake bending.

- Welding and Assembly: If the part has multiple pieces, the team welds or fastens them together.

- Finishing: The part receives a surface treatment, such as powder coating, to meet your requirements.

- Packaging and Delivery: The finished part is packaged and shipped to your location.

Note: Each step can affect the total cost. Accurate requirements and clear communication help you avoid changes that increase expenses.

Consultation and Requirements

You start with a consultation. You describe the function and environment for the part. The manufacturer asks questions to clarify your needs. This step helps prevent mistakes that could lead to extra costs later. For example, if you need a bracket for outdoor use, you specify corrosion resistance at this stage.

| Step | Impact on Pricing |

|---|---|

| Initial Consultation | Helps avoid mistakes that could lead to additional costs later |

| Design Specifications | Accurate specifications lead to better cost estimation |

CAD Design and Prototyping

You move to the design phase. Engineers use CAD tools to create digital models. These tools allow for real-time changes and precise measurements. Design automation increases efficiency and reduces material waste. You can request a prototype to test fit and function before full production. For example, a 3D-printed prototype of your bracket can confirm hole placement.

- Advanced CAD tools ensure high precision in metal fabrication.

- Automation lowers labor costs and speeds up production cycles.

- Enhanced communication between design and production teams leads to fewer errors.

Design Approval and Revisions

You review the design and approve the final drawings. If you see issues, you request changes. Each revision can add to the design cost and extend the timeline. Once you approve the design, the manufacturer starts production. For a steel bracket, you might adjust the hole size or add a bend. Final approval locks in the specifications and price.

Tip: Review all details before approval to avoid costly changes during fabrication.

You control the outcome and cost of your custom part by following each step closely. Using advanced CAD and machining tools helps you reduce errors and optimize the process.

Machining and Custom Metal Fabrication Methods

CNC Machining for Custom Parts

You rely on CNC machining when you need a custom part with precise dimensions. CNC machines use programmed instructions to shape metal. You achieve tight tolerances, which means your part matches your specifications every time. This repeatability matters in industries where accuracy is important. CNC machining operates without breaks, so you get faster production and lower labor costs. Automation reduces supervision, which helps you manage your budget. You can produce parts with tolerances as close as ± 0.00025”. This level of accuracy supports reliability and efficiency in your operations.

- CNC machining delivers consistent results for each part.

- You benefit from reduced production time and lower overall cost.

- Automation allows you to scale up production without increasing labor.

CNC machining works best for high-volume runs. When you order more than 1,000 units, the setup cost spreads across all parts, lowering the price per part. You see rapid execution for standard shapes, which limits waste and supports cost control.

Sheet Metal Fabrication Techniques

You use sheet metal fabrication when you need a custom part with simple shapes or standard features. This method includes cutting, bending, and forming metal sheets. You can lower your cost by choosing standard materials and finishes. Simpler designs reduce production time and limit labor. You avoid welding when possible, which saves money. You select optimal bend radii to use existing tools. Readily available materials help you avoid delays and extra fees.

Tip: Careful planning and clear specifications help you avoid last-minute changes and shipping expenses.

If your design is complex, you spend more time and money. Intricate shapes increase labor and slow down production. You keep your part affordable by aiming for simplicity.

- Simpler designs reduce production time.

- Standard materials and finishes help you manage expenses.

- Planning limits unexpected costs.

Casting, Welding, and Other Methods

You choose casting when you need a custom part with complex geometry or a large size. Casting lets you create shapes in one step, which limits assembly and manual labor. You use materials like aluminum, iron, bronze, or zinc. Casting suits both low and high production volumes. You get medium to rough surface quality and tolerances between 0.5 and 2.0 mm. This process works well for engine blocks, tool structures, and pipes.

Welding joins metal parts together. You use welding for pipelines, shipbuilding, and machinery. The cost varies with skill and equipment. Welding produces rough surfaces and tolerances from 0.5 to 3.0 mm. You rely on welding for assembly, not for creating parts from scratch.

| Process | Materials | Production volume | Typical tolerance (mm) | Surface quality | Cost | Example Applications |

|---|---|---|---|---|---|---|

| Casting | Aluminum, Iron, Bronze, Zinc | Low-high | 0.5–2.0 | Medium-rough | Low-medium | Engine blocks, pipes, sculptures |

| Welding | Most metals | Variable | 0.5–3.0 | Rough | Variable | Pipelines, shipbuilding, machinery |

Casting often costs less for large components than welding. You minimize waste and cycle times with casting. You prefer casting over welding for integrated features. Welding works best for joining parts, not for making them.

You select the right fabrication method based on your part’s design, production volume, and required accuracy. CNC machining supports high precision and repeatability. Sheet metal fabrication offers flexibility for simple shapes. Casting and welding suit large or complex parts. You manage your costs by matching your needs to the right process.

Managing and Reducing the Cost of Custom Metal Parts

Simplify Your Design

You can lower expenses and improve manufacturability by simplifying your custom metal part design. When you reduce complexity, you make production faster and more efficient. Here are strategies you can use:

- Remove unnecessary features and keep the geometry straightforward.

- Maintain uniform wall thickness and avoid deep pockets.

- Apply tight tolerances only where they are essential.

- Select metals that are easy to machine.

- Design parts that require minimal setups during machining.

- Use standard tool sizes and avoid custom tooling.

- Specify only the surface finishes that are necessary for the function.

- Optimize toolpaths with computer-aided manufacturing software.

- Break down complex parts into modules or use interchangeable designs.

- Work with engineering teams early in the process.

Tip: Early collaboration with engineers can help you identify design changes that save time and resources.

Choose Standard Materials

You can achieve savings by selecting standard materials for your custom metal parts. Standardization helps you benefit from economies of scale and simplifies inventory management. The table below outlines strategies and their descriptions:

| Strategy | Description |

|---|---|

| Standardization | Using standard materials leads to economies of scale and easier inventory management. |

| Bulk Purchasing and Negotiation | Buying materials in bulk can secure discounts and lower expenses. |

| Waste Reduction and Recycling | Choosing materials that minimize waste or can be recycled reduces overall material expenses. |

You should check with your manufacturer to see which materials are readily available. This approach helps you avoid delays and extra charges.

Optimize Order Quantity

You can reduce the price per part by optimizing your order quantity. Larger orders spread setup and programming time over more units. This practice leads to savings and greater efficiency. Here are some best practices:

- Order higher quantities of the same part to lower the unit price.

- Keep part designs consistent to reduce machine reprogramming and setup time.

- Avoid mixing many different parts in one order, as this increases programming and setup time.

Note: You should balance your order size with your storage capacity and project needs.

When you use these strategies, you manage your project more effectively and keep your costs under control.

Communicate with Your Manufacturer

You improve your project results when you communicate clearly with your manufacturer. Early and open discussions help you avoid misunderstandings and keep your project on track. You share your requirements and expectations, which allows your manufacturer to provide accurate feedback and suggestions.

You benefit from engaging your manufacturer early in the design process. When you involve them from the start, you receive input on feasibility and production methods. This approach helps you identify potential issues before fabrication begins. You also gain insight into cost drivers, which allows you to make informed decisions.

You should ask questions and request feedback during each stage of your project. You can use the following strategies to strengthen communication:

- Share detailed drawings and specifications.

- Ask for feedback on design choices and tolerances.

- Request updates on production progress.

- Discuss finishing options and delivery schedules.

- Clarify any uncertainties before approving the final design.

You reduce the risk of costly mistakes when you maintain regular contact. Timely feedback from your manufacturer ensures that your parts meet specifications. You avoid delays and rework by addressing concerns early.

A vendor who reviews your drawings and flags potential issues early can save 10x the cost of the cheapest quote.

You should encourage your manufacturer to review your designs and highlight possible challenges. This practice leads to better outcomes and helps you control expenses.

You can see how effective communication impacts your project:

- You understand design requirements, which influence the quality of your parts.

- You receive timely feedback, which prevents errors and keeps production efficient.

- You gain advice on feasibility, which leads to solutions that fit your budget.

You build a strong partnership when you communicate openly. You create trust and reliability, which supports long-term success. You should document all agreements and changes to avoid confusion. You can use email, phone calls, or project management tools to keep everyone informed.

You achieve better results and manage your costs when you work closely with your manufacturer. You ensure that your custom metal parts meet your needs and support your goals.

When to Request a Custom Quote

Unique or Complex Requirements

You should request a custom quote when your project involves unique or complex requirements. Proper preparation helps you present clear documentation to your supplier. Timing matters because complex projects often need longer quoting periods. You need to define your requirements, including the part’s purpose, quality standards, quantity, and deadlines. If you provide complete information, you help fabricators deliver accurate estimates. Missing details at the quoting stage often cause delays and changes in pricing later.

- Prepare clear documentation for your project.

- Allow extra time for complex requirements.

- Specify the purpose, quality, quantity, and deadlines for your part.

One of the main reasons for delays in custom metal projects is incomplete information during the quoting process. You can avoid changes in quotes by providing detailed specifications from the start.

Comparing Suppliers and Services

You need to compare suppliers and services before choosing where to request a quote. Several factors influence your decision. You should look at the quality of work and the supplier’s experience. Communication and customer service play a role in your project outcome. Equipment and technology affect production capabilities. Transparency in processes and reputation in the industry also matter.

- Quality of work

- Experience and expertise

- Communication and customer service

- Equipment and technology

- Transparency in processes

- Reputation in the industry

You benefit from engineering collaboration early in the process. Advanced equipment and modern manufacturing technology support your project goals. Consistent quality control and inspection systems ensure reliable results. Suppliers who can scale from prototype to production offer flexibility. Communication and planning aligned with your expectations help you achieve your objectives.

Value of a Tailored Estimate

You gain value from a tailored estimate when your project has specific needs. A personalized quote reflects your requirements and helps you understand the total cost. Suppliers use your documentation to calculate accurate pricing. You receive details about materials, machining, finishing, and delivery. A tailored estimate helps you plan your budget and avoid unexpected expenses.

| Benefit of Tailored Estimate | Description |

|---|---|

| Accurate Pricing | Reflects your specific requirements |

| Clear Scope | Defines materials and processes |

| Budget Planning | Helps you manage project expenses |

| Fewer Surprises | Reduces risk of hidden costs |

You should contact your supplier for a detailed, project-specific estimate. Early communication helps you clarify requirements and receive accurate quotes.

You improve your project outcome when you request a custom quote for unique or complex metal parts. Comparing suppliers and seeking tailored estimates helps you manage your budget and meet your goals.

You influence the cost of custom metal parts through your choices in material, design, machining, quantity, and finishing. You control your budget by reviewing each step and using standard options. You improve results when you communicate with your manufacturer and plan your order size.

Use these tips to manage your project. For a quote that fits your needs, contact your supplier today.

FAQ

There is no fixed “unit price” for custom metal parts because every project is unique. The total cost is primarily determined by material selection, machining time (e.g., CNC milling or sheet metal bending), and initial setup fees. A simple bracket may cost only a few dollars, while high-precision components with complex geometries and tight tolerances can cost hundreds or even thousands. The best way to get an accurate price is to provide a CAD file for a formal quote.

Aluminum (such as 6061) is generally considered the most cost-effective choice for many applications. It is lightweight, offers excellent machinability (which reduces labor time), and has a moderate material cost. If high strength is required but corrosion resistance is less critical, Carbon Steel (1018 or A36) is often cheaper than Stainless Steel. For projects requiring durability on a budget, we recommend prioritizing Aluminum over high-grade Stainless Steel alloys.

This is due to “Setup Costs.” Every order requires engineering time for CNC programming, machine setup, and custom fixturing. These fixed costs are high for a single piece. In mass production, these costs are distributed across thousands of units, significantly lowering the price per part. Typically, increasing an order from 1 unit to 100 units can reduce the unit price by 50% to 80%.

Following Design for Manufacturing (DFM) principles can significantly lower expenses:

Use Standard Sizes: Design your parts to fit standard sheet thicknesses or round bar diameters to avoid extra material preparation fees.

Simplify Geometries: Avoid deep holes, sharp internal corners (use radii instead), and extremely thin walls.

Relax Non-Critical Tolerances: Only specify tight tolerances (e.g., $\pm 0.01mm$) where absolutely necessary for the part’s function.

Surface treatments typically add between 10% to 30% to the total manufacturing cost. Most finishing shops also have a “Minimum Charge” per batch. Anodizing and Powder Coating are cost-effective options for protection and aesthetics. Specialized processes like Electroless Nickel plating or Gold plating will increase the cost more significantly.

The tighter the tolerance, the higher the cost. Achieving extreme precision requires slower cutting speeds, more frequent tool changes, specialized inspection equipment, and carries a higher risk of scrap. Moving from a standard tolerance ($\pm 0.125mm$) to a high-precision tolerance ($\pm 0.01mm$) can easily double the machining cost of the part.

Beyond the quote for the parts themselves, consider these potential “hidden” costs:

Design Revision Fees: Frequent changes to the CAD file after the project has started can lead to extra engineering charges.

Shipping & Logistics: Metal parts are heavy, and international freight can be a significant portion of the budget.

Packaging: Delicate or cosmetic-critical parts may require custom foam or protective packaging.

Tariffs & Duties: For international sourcing, ensure you account for import taxes.