You see copper tubing used for many important jobs each day. You find it in your home’s plumbing. It carries water safely because it does not rust and stays strong for a long time. You also see it in HVAC systems, like air conditioners and heaters. Copper tubing moves heat well. Hospitals and factories use copper tubing too. It helps deliver gases and fluids in a clean and safe way.

- In plumbing, copper tubing is popular because it lasts long and fights germs. It makes up almost 43% of the market.

- In HVAC, more than 32% of copper tubes are used in air conditioning and heat exchangers. This is because they move heat very well.

- Copper tubing is used a lot in these areas. It is strong, does not rust, and fits modern building rules.

You can see why copper tubing is so important in homes, businesses, and factories.

Key Takeaways

- Copper tubing is strong and can last 70 to 80 years. This makes it a good choice for plumbing and HVAC systems. It does not rust or corrode. This keeps water clean and gas safe in homes and businesses. Copper tubing moves heat very well. This makes it great for air conditioning and heating systems. Hospitals use copper tubing for medical gas systems. It is safe and follows strict rules. Picking the right type of copper tubing is important. It helps stop leaks and makes it last longer. Putting in copper tubing needs skilled workers. They often use soldering, which is harder than other materials. Checking for leaks and cleaning helps copper tubing last longer. It also keeps systems working well. Copper tubing can be recycled. This helps the environment and is good for green projects.

Table of Contents

Uses of Copper Pipes

Plumbing Applications

Copper tubing is used in most new plumbing systems. When you use the sink, copper pipes bring water to you. These pipes do not rust, so your water stays clean. Germs do not grow easily inside copper pipes. Many homes and cities use copper pipes for water and gas lines. They are also used underground and for moving gas.

Here is a table that shows where copper tubing is used in plumbing:

| Application Type | Benefits |

|---|---|

| Underground water and gas services | Strong and works well for important jobs |

| Water distribution systems | Does not rust, lasts a long time |

| Chilled water mains | Keeps water moving, no need for bigger pipes |

| Drainage and vent systems | Smooth inside, water flows better |

| Heating systems (including solar) | Moves heat fast, saves energy |

| Fuel-oil systems | Safe, does not catch fire |

| Oxygen systems | Good for hospitals |

| Non-flammable medical-gas systems | Helps keep hospitals safe |

| General plumbing | Needs little care, follows building rules |

Copper pipes can last for many years. You do not have to worry about leaks or rust. The inside of copper pipes is smooth, so water moves quickly. You do not need bigger pipes to get a good water flow. This saves space and money. In heating, copper pipes move heat fast. This helps keep your house warm or cool. Solar heating systems use copper pipes because they move heat better than other metals.

Tip: If you want plumbing that lasts and keeps water clean, copper tubing is a good pick.

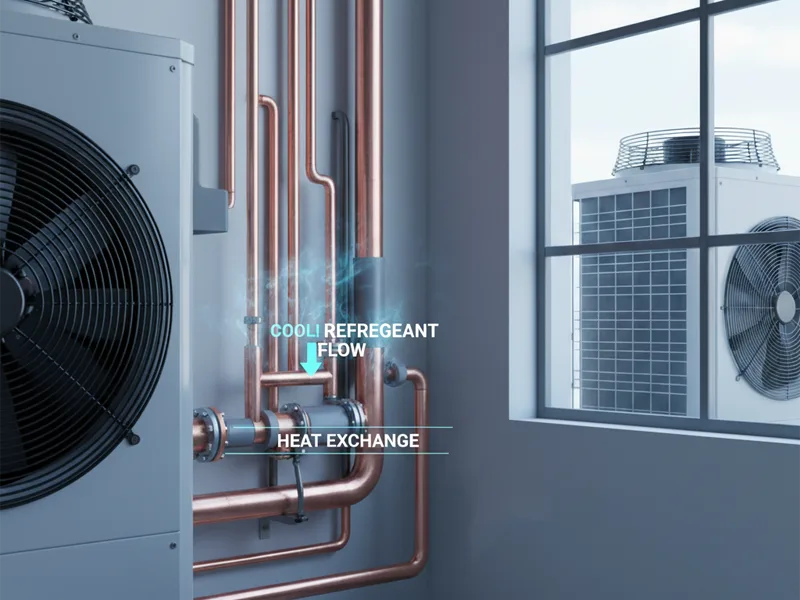

HVAC and Refrigeration

Copper tubing is very important in HVAC and refrigeration. Copper pipes move cool air in air conditioners and warm air in heaters. Copper moves heat much faster than other metals. It moves heat twenty times faster than stainless steel. It is more than twice as fast as aluminum. This means your air conditioner cools your house faster. Your heater also warms it up quickly.

You can bend copper pipes easily. This makes putting them in place simple. You do not need special tools. Copper pipes can handle high pressure and hot or cold temperatures. They do not break or leak, even when working hard. Copper has a layer that protects it from rust. It does not get damaged by refrigerants. Copper does not have the same problems as brass, so you do not have to worry about leaks.

Note: If you pick copper tubing for HVAC, your system will work well, be safe, and easy to fix.

Gas and Medical Systems

Copper tubing is very important for gas and medical systems. Hospitals use copper pipes to bring oxygen and other gases safely. These pipes must follow strict safety rules. For example, NFPA 99 is a rule in the United States for copper pipes in hospitals. ISO 7396-1 is another rule for medical gas pipes around the world. These rules make sure copper pipes give safe, clean gases to patients.

Here is a table of important rules for copper tubing in medical gas systems:

| Standard | Description |

|---|---|

| NFPA 99 | Rules for medical gas pipes in hospitals, including how to put them in and test them |

| ISO 7396-1 | Rules for making and testing medical gas pipes |

| European Pharmacopoeia | Make sure medical gases and pipes are safe and pure |

Copper pipes are also used for gas in homes and businesses. Copper tubing does not rust and keeps gas moving safely. It does not react with natural gas or propane. You do not have to worry about leaks or dirty gas. The inside of copper pipes is smooth, so gas keeps flowing well.

Safety Alert: Always use copper tubing that follows local rules for gas and medical systems. This keeps your family and patients safe.

Copper tubing is strong, safe, and works well. If you need clean water, good heating, or safe gas, copper pipes are a trusted choice for plumbing, HVAC, and medical systems.

Industrial and Electrical Uses

You can find copper pipes in many factories and power plants. These pipes help machines work safely. They also help move energy to the right places. In factories, copper pipes carry water, steam, oil, and chemicals. They do not rust, so they last a long time. Copper pipes work well even in tough places. They can handle high pressure and hot or cold temperatures. This makes them great for hard jobs.

Copper tubing is important in electrical work, too. You see it in wiring systems, transformers, and switchgear. Copper moves electricity very well. It keeps power loss low. This helps machines work better. Electric vehicles use more copper pipes and tubing now. This helps them work better. As more people use electric cars and green energy, the need for copper tubing grows.

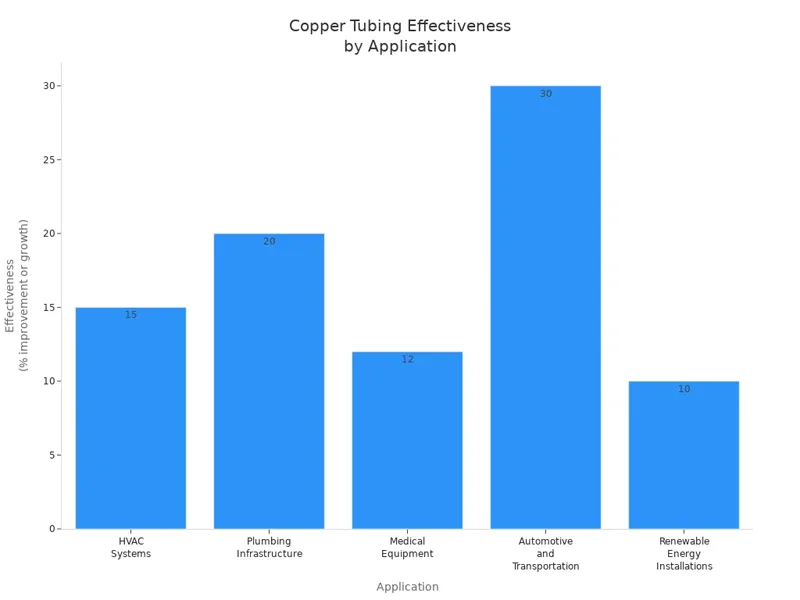

Here is a table that shows how copper tubing works in different industrial and electrical jobs:

| Application | Effectiveness Evidence | Adoption Metrics |

|---|---|---|

| HVAC Systems | Improved energy efficiency by up to 15% and reduced system downtime. | High adoption in green building projects. |

| Plumbing Infrastructure | Reduced leak incidences by over 20% compared to alternative materials. | Proven reliability in urban developments. |

| Medical Equipment | Rise of approximately 12% annually in healthcare settings, with fewer infections. | Increasing use in infection control. |

| Automotive and Transportation | EV manufacturers are increasing copper content by up to 30% for better performance. | Growing demand for electric vehicles. |

| Renewable Energy Installations | Projected growth of over 10% in the integration of copper tubes by 2025. | Driven by global sustainability goals. |

Copper pipes help keep factories safe. They do not make sparks. This is good in places where fire is a risk. You see copper tubing in oil refineries, chemical plants, and food factories. These pipes do not react with most chemicals. This keeps products pure and safe.

Copper pipes are important in renewable energy. Solar panels and wind turbines use copper tubing. It helps move heat and electricity. This saves energy and helps green building projects. The use of copper tubing in these areas will grow by more than 10% by 2025.

Copper pipes are trusted in many industries. They help lower costs and make things safer. They also help new technology work better. If you work in a factory, build machines, or care about clean energy, copper tubing is a smart pick. It keeps your systems strong and helps you meet new rules.

Tip: If you pick copper pipes for your next project, you get a material that is safe, reliable, and ready for the future.

Types of Copper Tubing

When you pick copper tubing, you should know the types. Each type has a different thickness and color. Each one is best for certain jobs. Picking the right type helps your system last longer. It also helps it work better.

Type K, L, M, and DWV

There are four main types of copper tubing. Each type has its own color and job.

| Type | Thickness | Typical Uses | Color Code | Price Comparison | Durability |

|---|---|---|---|---|---|

| K | Thickest | Commercial buildings, city water mains | Green | Most expensive | Extremely durable |

| L | Medium | Potable water, hot water, sprinkler systems | Blue | Cheaper than K | High durability |

| M | Thinnest | Residential plumbing, easy installation | Red | Cheapest | Less durable |

| DWV | Varies | Waste management, gravity-operated | Yellow | N/A | N/A |

- Type K copper tubing is the thickest. It is used for big jobs like city water pipes.

- Type L copper tubing is medium thick. It is good for home water and sprinklers. It is strong and not too costly.

- Type M copper tubing is the thinnest. It is used for light plumbing in homes. It is easy to put in and costs less.

- DWV means Drain, Waste, and Vent. It is for waste and vent pipes. It works with gravity, not pressure.

Tip: Check your local rules before picking a type. Some places do not allow Type M or DWV for some jobs.

Hard vs. Soft Temper

Copper tubing comes as hard or soft varieties. The difference is how it is made and used.

| Feature | Soft Copper Tubing | Hard Copper Tubing |

|---|---|---|

| Manufacturing Process | Heat-treated, sold in coils | Not heat-treated, sold in straight lengths |

| Flexibility | Very flexible, easy to bend and coil | Rigid, needs fittings for bends |

| Recommended Applications | HVAC, refrigeration, and natural gas lines | Plumbing, fire sprinkler, exposed piping |

- You can bend soft copper tubing by hand. It is great for tight spots, air conditioners, and gas lines.

- Hard copper tubing is stiff. You cut it and use fittings to turn corners. It is good for water pipes and places where you can see the pipe.

Note: If you need to go around corners or through walls, soft copper tubing saves time and parts.

Sizing and Identification

You must know the size and type before you install copper tubing. Each type has its own way to show size and use.

| Type of Copper Tubing | Identification Method | Joining Method |

|---|---|---|

| Threadless Copper Pipe (TP) | Gray stripe, manufacturer’s name, nation, ‘TP’, incised markings | Brazed socket-cup fittings; not for standard fittings |

| Copper Drainage Tube (DWV) | Incised mark, yellow stripe, manufacturer’s name, ‘DWV’ | Soldering with ASME/ANSI fittings |

| Seamless Copper Water Tube | Color stripe (green for K, blue for L, red for M), incised markings | Soldering, brazing, or press fittings |

- Look for color stripes and marks on the tubing. These help you pick the right type for your job.

- Always use the right way to join the pipes. This keeps your system safe and stops leaks.

Callout: Using the right size and type makes your job easier and safer.

Precision and Quality from Machining

Machining helps make copper tubing exact and strong. Modern machines, like CNC cutters, make tubing smooth and the right size. This helps pipes fit together well and last longer. Some copper, like C145 tellurium copper, is easier to machine. It is good for making lots of pipes. Copper is strong and bends well. This helps you cut and bend pipes without cracks.

If you want a system that works well and lasts, pick copper tubing made with high-precision machines.

Copper Tubing Advantages

Durability and Longevity

The advantages of using copper tubing are obvious in homes and businesses. It is known for being strong and reliable. Most copper pipes work well for 70 to 80 years. If you take care of them, they can last even longer. Many people pick copper tubing because it does not wear out like plastic pipes. Plastic pipes can start to fail after a few years. Copper tubing keeps working for many decades.

- Copper tubing does not rust or get damaged by sunlight or bad weather. This means your pipes will not wear out fast.

- Copper tubing is much stronger than plastic pipes. Annealed copper tubes can handle stress up to 200N/mm². PVC pipes only handle 42N/mm² at first and drop to 25N/mm² after 50 years.

- Copper pipes do not crack or leak easily, even when under pressure.

If you want pipes that last and need fewer repairs, copper tubing is a good choice. You save money because you do not have to replace pipes often.

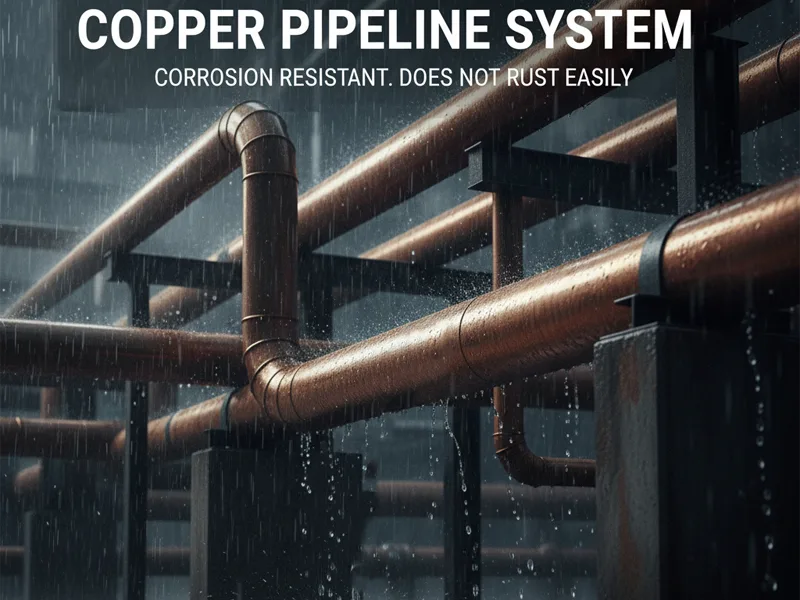

Corrosion Resistant

Copper tubing is good because it does not rust easily. This is important for plumbing. Water and other fluids can cause some pipesto break down. Copper tubing makes a natural layer that protects it from most chemicals and water.

- Studies show copper and its alloys do not rust in tough places.

- You can use special chemicals with copper tubing to make it even stronger.

- Both organic and inorganic chemicals help protect copper pipes.

You can use copper tubing where water is hard or chemicals are present. It enables a safe water supply. This is why it is used in homes, hospitals, and factories. Copper tubing means fewer leaks and less rust. Your plumbing stays safe and clean.

Health and Safety

Copper tubing helps keep water and air safe. It stops bacteria from growing inside the pipes. Hospitals and food businesses use copper pipes for this reason. You can trust copper tubing to keep water clean and free from germs.

| Health and Safety Benefits of Copper Tubing | Regulatory Evidence |

|---|---|

| Stops bacteria from growing inside pipes | EPA checks copper for safety in antimicrobial products |

| Used in food and healthcare to stop harmful bacteria like E. coli | OSHA sets rules to protect workers from copper dust and fumes |

| Does not rust and is strong, so plumbing stays clean | EPA has rules for safe use and exposure to copper |

There are strict rules to make sure copper tubing is safe. The EPA and OSHA set these rules to protect your health. Using copper tubing lowers the risk of dirty water and keeps people safe.

Tip: If you want safe, long-lasting, and healthy plumbing, copper tubing is a great choice. It is easy to install and trusted by many builders and homeowners.

Installation and Maintenance

If you pick copper plumbing pipes, you might wonder if they are easy to put in and take care of. Copper tubing is known for being strong and lasting a long time. But putting it in is not the same as other pipes.

A plumber must install copper plumbing pipes. The plumber cuts the pipes to the right size. Then, the plumber joins them by soldering. Soldering uses heat to melt a metal that fills the gaps. This keeps water from leaking out. The joints are strong and last a long time. But this way takes more time and skill than other pipes.

Let’s look at how copper tubing compares to PEX and PVC pipes:

| Material | Ease of Installation | Maintenance |

|---|---|---|

| Copper | Needs professional installation with soldering | Repairs may require opening walls |

| PEX | Flexible, easy to install with push-fit fittings | Repairs are less invasive |

| PVC | Lightweight, glued together quickly | Not used for hot water or high-pressure lines |

Copper plumbing pipes do not bend like PEX. You need more fittings to go around corners. This can make the job take longer. PEX pipes bend around things and fit in small spaces. This saves time and means fewer joints.

Fixing copper plumbing pipes can be harder. If there is a leak, you might have to cut into a wall. The plumber cuts out the bad part and soldered in a new piece. PEX pipes are easier to fix. You can use push-fit connectors and do not always need to open walls.

Copper tubing takes more work to put in, but it lasts for many years. The inside of copper pipes is smooth, so water keeps moving. Machining helps with this. Machines cut copper plumbing pipes to the right size and make them smooth. This helps the pipes fit well and not leak.

Tip: If you want plumbing that lasts and keeps water clean, copper plumbing pipes are a good choice. They may cost more to put in, but you save money on repairs later.

When you plan your next project, think about the future. Copper tubing gives you strong, safe pipes that last for years.

Choosing Copper Tubing

When you pick copper tubing, you want it to fit your project. The right type helps your system last longer and work better. Think about where you will use the tubing. Check what rules you need to follow. Look at how much it costs.

Matching Tubing to Application

You must pick tubing that fits the job. Each job has its own needs. Here are some things to think about:

- Pipe size and type: Make sure the fittings are the right size and type. This stops leaks and keeps your system safe.

- Application requirements: Some jobs need tubing for high pressure or special fluids. Refrigeration systems need tubing that works with certain refrigerants and pressures.

- Environmental conditions: If the tubing is in a tough place, pick fittings that do not rust.

- Longevity and durability: Pick tubing and fittings that last a long time.

- Installation expertise: Some jobs need a skilled plumber. If you are not sure, hire a pro to install the tubing right.

Tip: Always use connectors that match the refrigerant and pressure. Do not mix metals because this can cause rust. Follow the maker’s instructions for best results.

Codes and Standards

You must follow local rules when you put in copper tubing. These rules keep plumbing safe and working well. Here is a table with some important codes:

| Code Reference | Description |

|---|---|

| 903.2 Use of Copper Tubing | Sets weight rules for copper tubing in underground and aboveground drainage and vent piping. It does not allow copper tubing for chemical or industrial waste. |

| 1107.5.3 Copper tube | Lists requirements for seamless copper tube in refrigerant piping. Tubing must meet ASTM standards. |

| 605.3 Copper Pipe, Tubing, and Joints | Details how to make brazed and flared joints for soft copper water tubing. It also sets temperature rules for brazing alloys. |

Note: Always check your local rules before you start. Some places have extra rules for plumbing.

Cost and Availability

Cost and how easy it is to get copper tubing matter. Copper is popular because it lasts a long time and can be recycled. It also saves energy in HVAC systems because it moves heat well. Many builders use copper for green buildings.

- Copper tubing is needed in places like India and China. Cities are growing fast, and more people need HVAC systems.

- In the US and Japan, copper tubing is used in new and old buildings as cities fix their plumbing.

- Aluminum and PEX cost less and are lighter than copper. Many people use them in plumbing, especially when price matters.

- Copper tubing has to compete with these other materials. In some places, people pick aluminum or PEX because they are cheaper and easier to install.

If you need special copper tubing, talk to a machining expert. They can help you pick the right material and process. Adding tellurium to copper makes it easier to machine but keeps it strong. CNC milling and turning help make tubing with exact shapes and sizes. This is important for electrical, HVAC, and special factory jobs.

Tip: When you plan your project, think about the job, the rules, and your budget. If you need special tubing, ask an expert for help.

Installation

Cutting and Measuring

When you install copper tubing, you need to cut and measure it the right way. This helps you get a good fit and avoid leaks. You have several tools to choose from. Each tool works best for certain jobs. Here is a table to help you pick the right one:

| Tool Type | Description |

|---|---|

| Pipe Cutter | Most reliable for accurate cuts; features a cutting blade and adjustable grip for uniformity. |

| Hacksaw | Versatile and robust; suitable for tight spaces and can produce good results without a pipe cutter. |

| Tubing Cutter | Designed for copper; provides quick, smooth cuts and minimizes pipe deformation. |

A pipe cutter gives you a straight, clean cut. You turn the tool around the pipe and tighten it as you go. This makes the edge smooth and ready for joining. A tubing cutter works much like a pipe cutter but is made just for copper. It is fast and keeps the pipe round. If you do not have these tools, you can use a hacksaw. It works in small spaces, but you need to file the edges after cutting to remove any rough spots.

Before you cut, always measure the length you need. Use a tape measure or a ruler. Mark the pipe with a marker or a pencil. Double-check your measurement before you cut. This helps you avoid mistakes and wasted material.

Tip: Always wear gloves and safety glasses when cutting copper tubing. This keeps your hands and eyes safe from sharp edges and flying bits.

Joining Methods

After you cut and measure the tubing, you need to join the pieces together. There are several ways to do this. Each method has its own strengths and weaknesses. Here is a table to help you compare them:

| Joining Method | Advantages | Disadvantages |

|---|---|---|

| Brazing | Proven technique, durable when done correctly, meets low-lead requirements | Requires high heat, labor-intensive, limited warranty period |

| Press Fittings | Requires less labor, eliminates the need for hot permits, and often has warranties | More pipes may be needed, and specific tools for each manufacturer |

| Compression Fittings | Easy to install, reusable, suitable for confined spaces | May loosen under vibrations, requires precise tightening |

Brazing is a strong and trusted way to join copper tubing. You use a torch to heat the joint and melt a filler metal. This makes a tight, leak-proof seal. Federal rules say you must use brazing for any copper joints below ground. This keeps the system safe and up to code.

Press fittings are another good choice. You use a special tool to press the fitting onto the pipe. This method is fast and does not need heat. Many press fittings come with warranties. Compression fittings are easy to use and work well in tight spaces. You tighten a nut to make the seal. These fittings are reusable, but you must tighten them just right. If you do not, they can leak or loosen over time.

Note: Always follow the maker’s instructions for each joining method. This helps you avoid leaks and keeps your system safe.

Safety Tips

Safety is very important when you install copper tubing. You need to follow some key steps to keep yourself and others safe. Here is a table with important safety tips:

| Recommendation | Description |

|---|---|

| Review procedures for using mechanical couplings | Make sure you follow the manufacturer’s instructions for design and installation. |

| Review leak survey procedures | Check for leaks carefully, and think about the weather and other conditions. |

| Review personnel qualifications | Only let trained people check for leaks and do the work. |

| Use Category 1 fittings | Use these for certain pipe sizes to make sure you get a good seal. |

| Improve recordkeeping | Keep detailed records of all couplings, including type and maintenance. |

| Consider full replacement programs | If you have old or unknown couplings, think about replacing them. |

| Collaborate with safety representatives | Work with local and federal safety experts to solve any problems. |

You should always check your work for leaks before you finish the job. Use soapy water or a leak detector. If you see bubbles, you have a leak that needs fixing. Make sure you use the right fittings for the job. Only trained people should install or check copper tubing. Good records help you keep track of what you have done and make future repairs easier.

Safety Alert: Never skip safety steps. Careful work keeps you, your family, and your customers safe.

Maintenance

Keeping your copper tubing in top shape helps your plumbing and HVAC systems last longer. You can do this by checking for leaks, cleaning the pipes, and fixing any problems right away. Here are some simple steps you can follow.

Leak Detection

You should check your copper pipes for leaks often. Early leak detection saves you money and prevents water damage. Here are some best practices:

- Look for wet spots, green stains, or corrosion on the pipes.

- Listen for hissing sounds, which may mean a small leak.

- Use soapy water on joints and watch for bubbles.

- Try a leak detection spray for hard-to-see areas.

- Follow Method 21 requirements if you want to use advanced leak detection tools.

Many experts recommend using a leak detection and repair (LDAR) program. These programs help you find leaks quickly and fix them before they get worse. Always check your pipes after big temperature changes or if you notice a drop in water pressure.

Tip: Regular leak checks help you catch small problems before they turn into big repairs.

Cleaning and Care

Copper tubing stays clean and safe with regular care. You do not need harsh chemicals. In fact, mild cleaning works best. Here are some easy ways to keep your pipes in good shape:

- Wipe pipes with a damp cloth to remove dust and dirt.

- Use a mix of vinegar and salt to clean tarnish. Rinse well with water after cleaning.

- Avoid using strong chemical cleaners, as they can damage copper.

- Check pipes for signs of oxidation or green spots.

- Schedule regular visual inspections to catch early signs of corrosion.

Copper has natural antimicrobial properties. This means it helps keep water clean and stops bacteria from growing inside the pipes. Regular cleaning also prevents oxidation and keeps your pipes looking new.

Note: Routine care and cleaning help your copper pipes last longer and work better.

Repair Techniques

If you find a leak or damage, you can fix copper pipes in several ways. Always turn off the main water supply before starting any repair. Gather all your tools first. Here is a table that compares common repair methods:

| Repair Method | Pros | Cons |

|---|---|---|

| Permanent Soldering | Strong, long-lasting, good for most repairs | Needs skill and heat, takes more time |

| Press Fittings | Quick, no heat needed, easy for beginners | Needs special tools, may cost more |

| Temporary Fix (Tape) | Fast, easy, good for emergencies | Not a permanent solution, may leak later |

- Soldering gives a strong, permanent fix but needs practice.

- Press fittings are easy and safe, especially if you do not want to use a torch.

- Temporary fixes, like pipe repair tape, work in emergencies but should not be your final repair.

If you are not sure how to fix a pipe, call a professional plumber. They have the right tools and know-how to make safe, lasting repairs.

Safety Alert: Only trained people should repair copper pipes in important systems like medical gas or high-pressure lines.

Regular inspection, cleaning, and timely repairs keep your copper tubing system safe and reliable for years.

You have learned that copper tubing is used in many places. It is found in homes, hospitals, and factories. The table below explains why people like to use it:

| Benefit/Use | Description |

|---|---|

| Versatility | Good for water, gas, and heating systems |

| Durability | Stays strong in hard places and lasts long |

| Corrosion Resistance | Inside stays smooth, so water and gas move easily |

| Thermal Conductivity | Moves heat better than most other metals |

| Ease of Installation | Bends without much effort and needs fewer joints |

| Safety | Will not burn or make harmful gases |

| Recycling | It can be used again, which helps the planet |

It is important to pick the right type:

- The wrong pipe can leak or break.

- Each type (K, L, M, DWV) is made for a special job.

- Using the right flux and fittings keeps your system working well.

If you want pipes that are safe and last a long time, copper tubing is a good pick. For more information, check out these links:

- Copper tubing overview

- Benefits of using copper tubing

- Copper Tube Handbook: Joining Methods

- Copper Tube Handbook (PDF)

- Copper Tube & Fittings (PDF)

- Copper Water Supply & Drain Piping

- Basic Information about Copper in Drinking Water

FAQ

You use copper tubing most often for plumbing, heating, and cooling systems. It carries water, gas, or refrigerant safely in homes, hospitals, and factories.

Yes, you can bend soft copper tubing by hand. This makes it easy to fit around corners or through tight spaces. Hard copper tubing needs special tools for bending.

Check your project needs and local building codes. Use Type K for heavy-duty jobs, Type L for most homes, and Type M for light plumbing. Always look for color stripes and markings.

Yes, copper tubing is safe for drinking water. It does not rust or let bacteria grow inside. Many cities and homes use copper pipes for clean water.

You can join copper tubing by soldering, using press fittings, or compression fittings. Soldering gives a strong, leak-proof joint. Press and compression fittings are easier and faster to use.

You can join copper tubing by soldering, using press fittings, or compression fittings. Soldering gives a strong, leak-proof joint. Press and compression fittings are easier and faster to use.