You may ask, what are CNC turning parts? These are special pieces made by machines. The machines use computer numerical control, or CNC, to shape things very accurately. You can find these parts almost everywhere. Many industries need them for important products. Different fields use CNC turning parts, like:

- Automotive

- Aerospace

- Medical and healthcare

- Consumer electronics

- Defense and military

- Marine and shipbuilding

- Energy

Computer numerical control helps make parts that follow strict rules. This technology gives you parts that are always reliable and the same each time.

Key Takeaways

- CNC turning parts are made with machines controlled by computers. This helps make sure they are very exact and always the same.

- These parts are very important in many fields like cars, planes, and medicine. People use them because they work well and are very accurate.

- CNC turning helps make shapes that are simple or very detailed. It is good for making both easy and hard designs.

- Using CNC turning can make things faster and cost less money. This makes it a smart way to make lots of parts.

- Picking the best material for CNC turning is very important. You can use metals or plastics. Each one has special uses for different jobs.

Table of Contents

What are CNC Turning Parts?

Definition and Key Characteristics

CNC turning parts are special pieces made by spinning a workpiece. A sharp tool shapes the piece as it turns. Computers control the machine to make sure it works right. This helps you get shapes that are hard to make by hand. CNC turning makes sure every part is made the same way. The process is very accurate.

- Turning parts are made by spinning material and cutting it.

- CNC turning uses computers to make parts more exact.

- You can make easy or hard shapes with CNC turning.

Here is what makes CNC turned parts different from other parts:

| Characteristic | Description |

|---|---|

| Symmetry and Geometry | CNC turning works best for parts with even shapes. You get the same shape every time. |

| Cylindrical & Round Shapes | Most CNC turned parts are round. This helps them fit in many machines. |

| Material Starting Form | You start with a bar or cylinder. This means less waste and easier work. |

| Complexity and Features | You can add things like threads and grooves with CNC turning. |

| Material Compatibility | CNC turning works with metal and plastic. You can use many materials. |

| Production Volume and Efficiency | CNC turning is good for making lots of parts fast. |

| Tooling and Setup Requirements | You need only a few tools, and setup is simple. This saves time. |

| Secondary Operations Integration | You can drill or tap holes in the same step. This saves time and money. |

| Surface Finish Requirements | CNC turned parts can be very smooth. This is important for cars, planes, and medical tools. |

Why CNC Turning Parts Matter

Why are CNC turning parts important? They help you make products that work well and last long. CNC turned parts give you many good things:

- CNC machining makes your products better.

- You can make things quickly and easily.

- You can make shapes that are hard to do by hand.

- CNC turning parts are very exact.

- You can use many materials for CNC turned parts.

- Makers can build things that fit your needs.

Here is a table that shows how CNC turned parts help your products:

| Benefit | Description |

|---|---|

| Precision Accuracy | CNC turned parts are very exact. This makes your products better. |

| Efficiency in Production | Computers help you make parts faster and cheaper. |

| Consistent Quality | CNC keeps every part the same. Your products are always reliable. |

Tip: If you pick CNC turned parts, your products will be high quality and reliable. Many industries use CNC turning for their most important parts.

CNC turning parts are very important in making things today. You see them in cars, planes, and medical tools. Using CNC turned parts makes your products strong, exact, and ready for new ideas.

CNC Turning Process Overview

How CNC Turning Works

You may wonder how the CNC turning process shapes material into exact CNC turned parts. The process uses advanced CNC turning machines and follows clear steps. Here is what happens:

- Design & Programming: First, you make a 3D model of the part on a computer. Then, you turn the design into a special code called G-code. This code tells the CNC lathe machine how to move.

- Machine Setup: Next, you get the CNC lathe machines ready. You put a bar or cylinder of material inside the lathe machine. This step keeps the material in place while turning.

- The Turning Operation: The CNC turning machines spin the material very fast. A sharp tool moves along the spinning part. The tool cuts the material into the right shape. You can make simple or hard shapes this way.

- Finishing & Quality Control: After shaping, you clean the part and check its size. You use tools to make sure the CNC turned parts are correct.

Note: The cnc turning process is special because the workpiece spins and the tool stays still. This is not like milling, where the tool spins and the part does not move. Drilling makes holes, but turning makes round and smooth surfaces.

Machining and CNC Turned Parts

Machining is the main part of the CNC turning process. You use CNC turning machines for high accuracy, speed, and flexibility. These machines use digital programming to control every move. This means you can make CNC-turned parts with tight tolerances and smooth finishes.

- CNC turning machines help you make easy or hard parts.

- You can use metals or plastics, so the process works for many things.

- Automation lowers mistakes and keeps every CNC turned part the same.

When you use CNC lathe machine technology, you get parts that match your design. The process uses the right material, speed, and tool path for the best results. CNC machining gives you speed, accuracy, and trust. This is why many industries use CNC turning for important parts.

Tip: If you need many cnc lathe machining parts, cnc turning machines help you make them fast and with the same good quality every time.

CNC turning machines have changed how you make parts. They let you try new ideas and meet strict quality rules. With machining as a key part, you can trust your CNC-turned parts will be exact, fast, and ready for any job.

Features of CNC Turning Parts

Precision and Accuracy

You want your products to work well every time. Precision CNC turning helps you trust your parts. CNC turned parts are special because they are very exact. They can be made with very small errors and smooth surfaces. You can count on these parts for jobs that need perfect sizes. The CNC process uses smart machines and computers to shape each part carefully. You get the same part every time, even if you need a lot.

Here is a table that shows the usual tolerances and surface finishes for CNC turned parts:

| Parameter | Tolerance | Surface Finish Description |

|---|---|---|

| Diameter | ±0.001″ (0.025 mm) to ±0.002″ (0.051 mm) | Ranges from rough to very shiny, smooth finishes are possible with fine tools. |

| Length | ±0.005″ (0.127 mm) | |

| Roundness | ±0.002″ (0.051 mm) | |

| Surface Finish RMS | Up to 16 RMS |

You see these good CNC turned parts in places where accuracy is important, like planes, cars, and medical tools. Machining with CNC makes sure every part is just right.

Material and Design Flexibility

CNC turning lets you pick from many materials and make hard shapes. You can use metals like stainless steel, aluminum, carbon steel, brass, titanium, copper, and bronze. Each metal has its own good points. For example:

- Stainless steel does not rust and is used in medical and plane parts.

- Aluminum is light and strong, good for cars and planes.

- Brass and copper are easy to cut and do not rust.

- Titanium is strong and light, used for implants and planes.

- Bronze lasts a long time because it needs less oil and stays cool.

You can also use plastics and other materials for CNC turned parts. This means you can design parts for almost any job.

CNC turning uses special tools that move in different ways. You can make simple round parts or hard shapes. Smart software turns your ideas into machine steps. Multi-axis machines help you make CNC turned parts with tiny details. Machining lets you make parts fast and exactly, even for special or tricky designs.

Tip: CNC machining helps you get cnc turned parts that fit what you need, whether you want a simple pin or a detailed connector.

You can trust CNC turning for good CNC turned parts that meet tough rules and help with your most important work.

Applications of CNC Turning Parts

Automotive and Aerospace

CNC turning parts are used a lot in cars and planes. These industries need parts that are strong and exact. In cars, CNC-turned parts help your car work well and stay safe. Here are some ways they are used:

- Drive axles move power from the engine to the wheels. They need to be tough and made with care.

- Gearboxes use CNC turning to make gears that fit together. This helps your car shift easily and last longer.

- Electrical parts use CNC turned pieces to stay safe and work properly.

- Transmission parts, like gears and clutches, must handle stress and keep working.

- Cylinder heads and blocks need careful cutting so engine parts work well and stay cool.

- Exhaust system parts, like headers and catalytic converters, use CNC turning to help exhaust flow and follow rules.

- Starter motors use CNC turned parts to help engines start every time.

In planes, CNC turned parts are even more important. You need parts like shafts, rings, and bushings to be very exact. These parts must be round and fit just right. Advanced CNC machines help you reach these high standards. Some machines can do turning and milling at once. This lets you make hard parts in one step. It saves time and keeps every part the same.

Note: In cars and planes, cnc turning gives you the accuracy and repeatability needed for safety and performance.

Medical and Industrial Uses

CNC turned parts are also used in hospitals and factories. In hospitals, CNC turning makes parts for tools, implants, and machines. These parts must be clean, smooth, and exact to keep people safe. You can trust CNC to make parts that fit and work every time.

In factories, CNC-turned parts help machines run. You find them in pumps, valves, and connectors. These parts must handle heavy use and still work well. CNC turning lets you use many materials, so you can pick what works best. You get parts that last longer and need less fixing.

CNC turning helps you make parts for many jobs. Whether you need a tiny implant or a big machine part, CNC turned parts help you get the job done right.

Advantages of CNC Turning

Efficiency and Cost-Effectiveness

You want to make more parts in less time. CNC turning helps you do this. The machines run fast and do not need much stopping. You can set up the machine, load your material, and let it work. CNC machines can run all day and night. This means you get more parts without waiting.

Here is a table that shows how much faster CNC machinists work compared to manual machinists:

| Method | Output Rate |

|---|---|

| CNC Machinist | 4 times higher |

| Manual Machinist | Lower output |

You also save money with CNC turning. The process is great for making many parts at once. You do not have to stop and change tools often. This lowers setup costs and keeps the machine working. When you make a lot of parts, your cost for each part goes down. You can use CNC turning for big orders and save even more.

Note: CNC machines can do complex jobs with high precision. They run at higher speeds than old tools. This means you finish jobs faster and deliver your products sooner.

- CNC machines provide incredible precision and repeatability.

- This leads to higher-quality parts with tighter tolerances.

Consistency and Quality

You want every part to be the same. CNC turning gives you this power. Once you program the machine, it makes each part just like the last one. You do not have to worry about mistakes from handwork. The machine follows your design every time.

- CNC machining excels in keeping the quality the same for thousands or even millions of parts.

- CNC turning services give you results you can count on, batch after batch.

- Once you set up the program, the machine makes identical parts with almost no change.

You get fewer defects and better customer satisfaction. Your products look and work the same, no matter how many you make. This is important for industries that need high standards, like cars, planes, and medical tools.

Tip: If you want your products to be reliable and trusted, choose CNC turning. You will see the difference in every part.

CNC Turning Manufacturer Selection Methods

Define Your Requirements and Specifications

Before you pick a manufacturer, know what you need. Make a list of your part’s needs. Think about size, shape, and material. Also, think about how you will use the part. Here are some things to check:

- Cutting speed: How fast the tool moves.

- Cutting feed: How far the tool moves each spin.

- Spindle speed: How fast the part spins.

- Feed rate: How quickly the tool moves.

- Axial and radial depth of cut: How deep the tool cuts.

- Tool geometry and material: The tool’s shape and type.

- Workpiece material: What the part is made of.

- Coolant flow: How the part stays cool.

- Chip control: How the machine handles cut pieces.

- Machine rigidity: How strong the machine is.

Write down these details. This helps you talk clearly with the manufacturer.

Assess Manufacturer Capabilities and Qualifications

You want a manufacturer who can do the job. Look for these signs:

- They follow industry standards.

- They meet all rules and laws.

- They have special certificates for your field.

- They hold ISO 9001 or AS9100 certifications.

- They use a strong Quality Management System.

These points show the manufacturer cares about quality and safety.

Evaluate Quotation and Cost Structure

Manufacturers set prices in different ways. Some use fixed pricing, which stays the same. Others use time and material pricing, which changes. Cost-plus pricing adds profit to the cost. Labor and material costs also change the price. Some countries have lower labor costs. This can make the price lower. Always ask for a clear quote so you know what you pay for.

Review Delivery and Supply Chain Management

Getting your parts on time is important. Here are some good steps:

- Use more than one supplier to avoid delays.

- Keep talking with your suppliers.

- Check your suppliers often to make sure they are good.

- Manage your inventory so you do not run out.

- Work with good shipping partners for global orders.

These steps help you get your CNC parts when you need them.

Prototyping and Production Validation

Prototyping lets you test your design before making many parts. You can use CNC technology to make a prototype quickly. This helps you find problems early and fix them. Prototyping also lets you get feedback from users. You can test how the part fits and works. This step lowers the risk of mistakes in full production.

Contracts and Legal Terms

When you work with a manufacturer, you need a contract. The contract should cover important points. Here is a table to help you know what to include:

| Clause Type | Explanation |

|---|---|

| Scope of Work | Lists the tasks, who does them, and the standards to follow. |

| Indemnification Clause | Explains who pays for damages or losses. |

| Confidentiality and IP Rights | Protects your designs and secrets. |

| Compliance with Laws | Makes sure everyone follows the rules. |

| Quality Control | Sets standards to keep parts high quality. |

| Force Majeure Clause | Tells what happens if something stops the work, like a natural disaster. |

| Communication and Reporting | Explains how you and the manufacturer will talk and share updates. |

| Dispute Resolution | Describes how to solve problems if you disagree. |

Tip: Always read your contract carefully. Make sure you understand every part before you sign.

Material Choices and Design Tips

What materials are suitable for CNC turning?

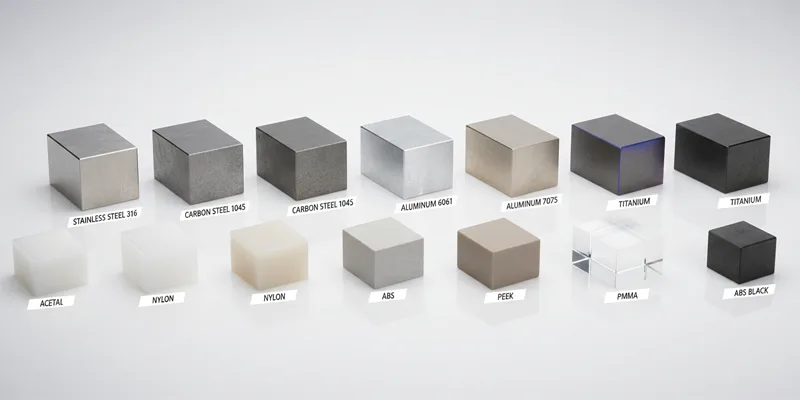

You can pick from many materials for CNC turning. The right choice helps your project work well. Some materials are easy to cut. Others are strong or resist rust. Here is a table to help you compare common choices:

| Material | Mechanical Properties | Machinability Characteristics |

|---|---|---|

| Stainless Steel 316 | Resists rust, used in cars and boats | Easy to cut, good for strong parts |

| Carbon Steel 1045 | Tough, strong, can be made harder | Easy to cut and weld, good for small parts |

| Aluminum 6061 | Light, strong, does not rust | Very easy to cut, used for many things |

| Aluminum 7075 | Very strong, used in planes and cars | Easy to cut, strongest aluminum type |

| Titanium | Very strong, safe for the body, used in planes and medicine | Harder to cut, good for special jobs |

| Acetal | Strong, slippery, does not soak up water | Easy to cut, good for food machines |

| Nylon | Strong, bends, does not break easily | Easy to cut, used instead of metal |

| ABS | Tough, does not break, used for test parts | Easy to cut, good for quick tests |

| PEEK | Very strong, stays the same, used for special jobs | Harder to cut, good for special uses |

| PMMA | Hard, does not scratch, used for clear parts | Easy to cut, used for screens and lenses |

Tip: Pick a material that fits your part’s job. Aluminum and steel are strong and easy to cut. Plastics like acetal and nylon are good if you need parts that resist chemicals or slide easily.

Design Considerations for CNC Turned Parts

When you design CNC turned parts, make them easy to cut and strong. Here are some tips:

- Use even shapes. This makes cutting easier and more exact.

- Keep the part short compared to its width. Long, thin parts can bend or shake.

- Only add features the part needs. Extra details are not helpful.

- Give clear drawings and notes. This helps the machinist make your part right.

- Set fair size limits. Very tight limits can cost more.

- Avoid tiny details. Small features need special tools and slow things down.

- Think about how the part will be held. Make it easy to grip.

- Use common shapes if you can. This helps the machinist work faster.

Note: The material you pick changes the price, cutting time, and how your part works. Plan your design with these ideas for the best results.

Quality control of CNC turning parts

You want every CNC turned part to be correct. Quality control helps you check each part. Here are ways to do this:

- Check the material before you start. Make sure it is right.

- Watch the parts’ size and shape while cutting.

- Check the first part against your design.

- Look at all the finished parts for problems.

- Use special machines to measure hard shapes.

- Test the part without breaking it.

- Use data to watch for problems early.

- Set clear rules and check parts often.

| Defect | Prevention Strategy |

|---|---|

| Dimensional Inaccuracy | Use heat treatment between steps to keep parts the right size. |

| Poor Surface Finish | Set good cutting speeds and use the right tools. |

| Chatter Marks | Use short, strong tools and test cutting to stop shaking. |

| Burrs and Sharp Edges | Plan to smooth edges so parts are safe and ready. |

| Warping and Deformation | Use rough cuts, heat treatment, and finish cuts to keep the right shape. |

Tip: Good quality control means fewer mistakes and better parts. You can trust your cnc turning process if you follow these steps.

CNC turning parts are very important for making things today. These parts help you make products that are exact and fast. CNC turning lets you create shapes that are just right. Many industries use these parts to stay ahead.

| Key Takeaway | Why It Matters |

|---|---|

| Precision | Your parts fit well and work every time. |

| Efficiency | You save time and spend less money making things. |

| Versatility | CNC turning parts work for many different jobs. |

If you want to learn more, you can visit the Complete CNC Machining Resource Center. You can also read about tricky CNC machining. For more help, check out learning websites about CNC technology.

FAQ

You get parts with high precision and repeatability. CNC turning makes sure every part matches your design. This helps your products work better and last longer.

Yes! You can use CNC turning for metals like steel, aluminum, and brass. You can also use it for plastics such as nylon and acetal.

Think about what your part needs to do. Use strong metals for heavy-duty jobs. Pick plastics for lightweight or chemical-resistant parts. Ask your manufacturer for advice.

Industries trust CNC turning because it gives you reliable, exact parts every time. This process helps you meet strict safety and quality standards.

Tip: Always check the material, measure the parts, and inspect the surface. Use quality control steps at every stage. This helps you catch problems early and keep your parts perfect.