In the world of precision manufacturing, the difference between a high-performing product and a pile of scrap metal often comes down to a few microns. For mechanical engineers and procurement specialists, understanding CNC machining tolerances is not just a technical requirement—it is a critical factor in controlling costs, ensuring part functionality, and managing supplier relationships.

Whether you are designing a complex aerospace component or sourcing simple brackets, this guide will walk you through everything you need to know about standard machining tolerances.

Table of Contents

Machining Tolerances Defined

What are Machining Tolerances

In manufacturing, tolerance is the allowable limit of variation in a physical dimension. No machine, no matter how advanced, can produce a part with 100% mathematical perfection every single time. When you design or make a part, you deal with machining tolerances. Machining tolerances show how much a part’s size can change from the plan. In CNC manufacturing, these tolerances set how far a part can be from its planned size. ISO 2768 gives a clear meaning and rules for general mechanical tolerances. This standard helps you keep quality and accuracy the same for every project. If you follow these rules, you make fewer mistakes, and each part matches the design.

Machining tolerances are very important for how parts fit and work. You need them to make sure parts go together and work right. When you pick tolerances, you decide how exact each part must be.

Common Types of Machining Tolerances

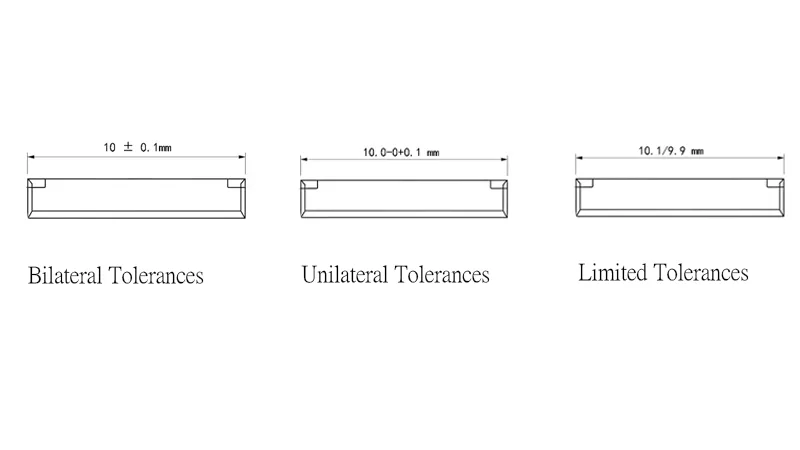

Bilateral Tolerances

The deviation is permitted in both positive and negative directions from the basic size (e.g., 25±0.1mm)

Unilateral Tolerances

Deviation is permitted in only one direction(e.g., 25+0.05/0.00mm). These are common for “hole and shaft” fits.

Limited Tolerances

Instead of a ± symbol, the drawing shows the maximum and minimum allowable dimensions(e.g., 24.95-25.05mm)

GD&T(Geometric Dimensioning and Tolerancing)

A more sophisticated system that defines the geometry of the part, including flatness, concentricity, and parallelism.

Typical Ranges in CNC Machining

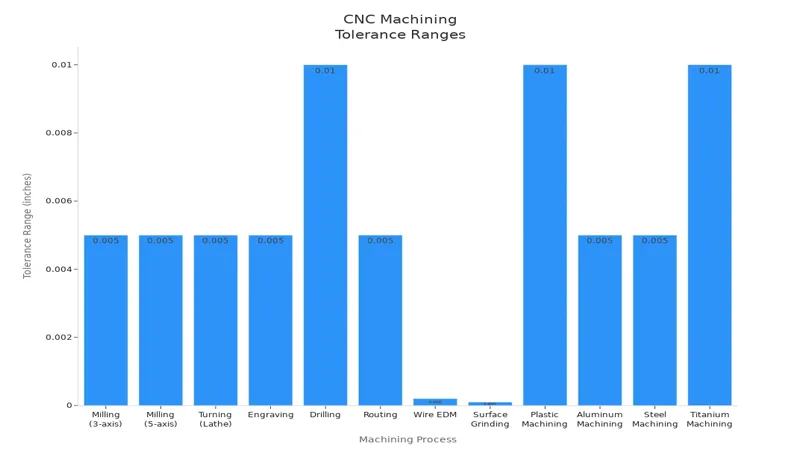

CNC machining uses many different tolerances, based on the job and material. Standard CNC tolerance values change with each process. For most jobs, you use standard machining tolerances like ±0.005″ (0.13 mm). Some jobs, like surface grinding or wire EDM, need much tighter tolerances.

Here is a table with common tolerance ranges for CNC processes:

| Process | Tolerance Range | Notes |

|---|---|---|

| Milling (3-axis) | ±0.005″ (0.13 mm) | Good for most normal machining jobs. |

| Milling (5-axis) | ±0.005″ (0.13 mm) | More exact for tricky shapes. |

| Turning (Lathe) | ±0.005″ (0.13 mm) | Best for round parts and making many at once. |

| Engraving | ±0.005″ (0.13 mm) | Used for small details and marks on parts. |

| Drilling | ±0.010″ (0.25 mm) | Tolerance changes with hole size and depth. |

| Routing | ±0.005″ (0.13 mm) | Used for cutting flat materials. |

| Wire EDM | ±0.0002″ (0.005 mm) | Very exact for tiny shapes and hard stuff. |

| Surface Grinding | ±0.0001″ (0.0025 mm) | Super tight tolerances and smooth surfaces. |

| Plastic Machining | ±0.010″ (0.25 mm) | Changes because plastic bends and grows with heat. |

| Aluminum Machining | ±0.005″ (0.13 mm) | Can use tighter tolerances. |

| Steel Machining | ±0.005″ (0.13 mm) | Needs strong tools and slower speeds. |

| Titanium Machining | ±0.010″ (0.25 mm) | Hard to machine; tolerances may be wider. |

You pick CNC machining tolerances based on the job, material, and how exact you need to be. Standard CNC tolerance values help you keep quality and save money. If you know the usual ranges, you can make better choices and not spend too much.

Importance of CNC Machining Tolerances

Impact on Quality and Fit

Tolerances help parts fit and work as planned. Setting the right limits stops problems when putting things together. Loose tolerances can make parts not line up or move well. Tight tolerances can make parts not fit at all. Good tolerances help products work better and make assembly easier.

- Proper tolerances help parts move and fit right. They make things work smoothly.

- You save money by cutting machining time and fewer checks. Tools last longer when you do not need extra precision.

- Assembly is more reliable. Parts fit as expected, so you need fewer fixes.

If you make mistakes in your drawings, products may not meet quality goals. You might have to fix or throw away parts. This costs more and makes customers unhappy. If you forget about tolerance stackups, production can fail. A prototype may work because you built it carefully. But in mass production, small changes can add up and break the design.

Performance and Reliability

You want products that last and work well. Tolerances help parts work for a long time. Following standards makes sure parts can be swapped. This is important in cars and other big industries. It also helps make things faster and cuts down on checking time. This means better quality and fewer mistakes.

| Aspect | Explanation |

|---|---|

| Ensuring Interchangeability | Standard tolerances let you swap parts, which is key for cars. |

| Improving Efficiency | Using tolerance standards makes production faster and better. |

| Minimizing Costs | Tolerance standards help you balance cost and precision for good results. |

Products work well and make customers happy when tolerances are right. You avoid expensive problems and keep your good name.

Cost Considerations

You need to balance how exact you want with how much you spend. Tighter tolerances take more time and special tools. This makes things cost more. Machines run slower, and you check parts more often. For example, a part may take 10 minutes with normal tolerances. It could take 30 minutes or more if you need it to be very exact.

- Tight tolerances slow down making parts and take longer.

- Special tools cost more because regular ones may not work.

- More parts get thrown away with tight tolerances. Normal parts may have less than 2% waste, but tight ones can go up to 10% or more.

If tolerances are too strict, you waste time and materials. Costs go up, and you wait longer for parts. Knowing how tolerances change quality, fit, and cost helps you make better choices for every CNC job.

Classification of CNC Machining Tolerances

General Tolerances

Industry Standards (ISO 2768-1)

When you design parts, you often use general tolerances first. The ISO 2768 standard gives clear rules for these tolerances. This standard helps you set limits for most parts without listing every detail. Using the iso 2768 standard keeps your work the same and stops confusion.

Here are the tables that show common general tolerance classes:

Table 1: Linear dimensional tolerances (ISO 2768-1)

This is the core table, covering length, height, center distance, etc. unit: mm

| Tolerance Class | 0.5 – 3 | 3 – 6 | 6 – 30 | 30 – 120 | 120 – 400 | 400 – 1000 | 1000 – 2000 | 2000 – 4000 |

| f (fine) | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | – |

| m (medium) | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2.0 |

| c (coarse) | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2.0 | ±3.0 | ±4.0 |

| v (very coarse) | – | ±0.5 | ±1.0 | ±1.5 | ±2.5 | ±4.0 | ±6.0 | ±8.0 |

Table 2: Chamfer and fillet radius tolerances (ISO 2768-1)

Applicable to external chamfers (bevel height or external fillet radius). unit: mm

| Tolerance Class | 0.5 – 3 | 3 – 6 | above 6 |

| f (fine) | ±0.2 | ±0.5 | ±1.0 |

| m (medium) | ±0.2 | ±0.5 | ±1.0 |

| c (coarse) | ±0.4 | ±1.0 | ±2.0 |

| v (very coarse) | ±0.4 | ±1.0 | ±2.0 |

Table 3: Angular dimensional tolerances (ISO 2768-1)

Applicable to angular deviations of parts, expressed in “degrees” and “minutes”.

| Tolerance Class | short side length≤10 | 10 – 50 | 50 – 120 | 120 – 400 | above 400 |

| f (fine) | ±1° | ±0°30′ | ±0°20′ | ±0°10′ | ±0°5′ |

| m (medium) | ±1° | ±0°30′ | ±0°20′ | ±0°10′ | ±0°5′ |

| c (coarse) | ±1°30′ | ±1° | ±0°30′ | ±0°15′ | ±0°10′ |

| v (very coarse) | ±3° | ±2° | ±1° | ±0°30′ | ±0°20′ |

You pick these classes based on what your project needs. Fine and medium classes are good for most mechanical parts. Coarse and very coarse classes work for bigger or less important items.

Common Applications

General tolerances are used in many industries, like automotive, consumer goods, and machinery. You see them in things like housings, brackets, and structural parts. These tolerances help keep costs down but still meet quality needs. In aerospace and medical devices, you must use strict tolerances for safety and reliability. Using general tolerances from the ISO 2768 standard helps you avoid mistakes and facilitates easier assembly.

Precision Tolerances

Typical Values (±0.001″, ±0.0005″)

When you need more accuracy, you use precision tolerances. These tolerances are tighter than the general ones. You often see values like ±0.001″ (0.025 mm) or ±0.0005″ (0.013 mm). Precision tolerances are used in mechanical assemblies, gears, and moving parts.

| Tolerance Classification | Range | Typical Applications | Industry Standards |

|---|---|---|---|

| General Purpose | ±0.5 mm to ±0.13 mm | Structural components, housings | ISO 2768, ASME Y14.5 |

| Precision | ±0.13 mm to ±0.05 mm | Mechanical assemblies, gears | DIN 7168, ISO 286 |

| High Precision | ±0.05 mm to ±0.013 mm | Optical components, gauges | VDI/VDE 2617 |

| Ultra Precision | <±0.013 mm | Semiconductor equipment, research | ASME B89 |

You find these tolerances in places where every detail matters. Aerospace, medical devices, and electronics all need precision tolerances. For example, engine parts, surgical tools, and RF shielding need this level of control.

Tight Tolerances

When Tight Tolerances Are Needed

You use tight tolerances when parts must fit together perfectly or move with little friction. These tolerances are much stricter than general or precision levels. You see tight tolerances in aerospace, medical, automotive, and industrial automation. For example, aerospace parts need very tight tolerances to keep people safe. Medical implants and tools need tolerances as close as ±0.005 mm. Automotive and automation parts often need tolerances between ±0.01 mm and ±0.02 mm.

| Industry | Tolerance Requirement | Description |

|---|---|---|

| Aerospace | Extremely tight | Ensures safety and performance in manufacturing. |

| Medical | ±0.005 mm | Needed for implants and tools to work and stay clean. |

| Automotive | ±0.01-0.02 mm | Balances precision with making lots of parts. |

| Industrial Automation | ±0.01-0.02 mm | Makes sure moving parts work well every time. |

You must use tight tolerances when failure is not an option. These tolerances keep your products safe, reliable, and long-lasting.

Challenges and Costs

Tight tolerances bring many challenges. You need special machines, skilled workers, and more time. The cost of making parts goes up fast as tolerances get tighter. For example, if you go from ±0.005″ to ±0.001″, your costs can double or even quadruple. At the tightest levels, costs may rise to 24 times more than standard work.

| Tolerance Level | Cost Increase Factor |

|---|---|

| ±0.005″ | 2x |

| ±0.001″ | 4x |

| ±0.0001″ | Up to 24x |

You also spend more time checking parts and may throw away more parts. Quality checks for tight tolerance parts can add 15-25% to your costs. You may spend hours checking each part to make sure it meets the requirements. Tight tolerances need careful planning and expert knowledge.

⚠️ Note: Always check if you really need tight tolerances. Using them everywhere can waste time and money. Save tight tolerances for parts where they matter most.

Factors Affecting Tolerance Selection

Material Influence

You have to think about the material when picking tolerances for CNC machining. Every material acts in its own way when you cut it. Hardness, thermal stability, and ductility all change how close you can get to the right size.

| Material Property | Influence on Tolerances |

|---|---|

| Hardness | Affects tool wear and machining speed, impacting precision. |

| Thermal Stability | Influences the ability to maintain tolerances under heat. |

| Ductility | Affects the ease of machining and the ability to hold tight tolerances. |

- Aluminum is softer and easier to machine than stainless steel. You can get tighter tolerances with less work.

- Titanium is harder and wears out tools faster. You have to change tools more, which costs more money.

- Softer materials let you cut faster. Harder ones need slower speeds to keep tools safe.

- Some materials, like wood or some plastics, can grow or shrink with heat. This makes it hard to keep parts the right size.

If you do not pick the right tolerance for the material, you might get more mistakes or spend more money.

Application Requirements

How you use a part tells you how tight the tolerances should be. Some parts need to fit together just right. Others can have more space between them.

- Functional Requirements: The main reason for a tolerance is how the part works. High-precision jobs need tight tolerances. Parts that are not as important can have looser ones.

- Cost Implications: Tighter tolerances cost more money. You need better machines and more checks.

- Material Properties: Some materials bend or break easily. This changes how close you can make the part to the plan.

- Manufacturing Process Capabilities: Each process has its own limits for how exact it can be.

- Surface Roughness and Finishing: The finish can change how parts fit and move.

- Inspection and Quality Control: You need the right tools to measure and check the parts.

You have to balance what the part needs with what you can actually make and measure.

Machine Capabilities

The CNC machine you use decides how tight your tolerances can be. New machines can make parts more exact. Old machines may not be as good. You also need to think about the size of the part and what kind of cutting tools you use.

| Tolerance Type | Prototype CNC Machining | Production CNC Machining |

|---|---|---|

| Standard Tolerance | +/- 0.005” | Varies, typically looser |

| Precision Tolerance | +/- 0.001” or less | Often not specified |

| Factors Influencing | Material, Machine, etc. | Production volume, cost |

- For prototypes, you often use tighter tolerances to see if things fit and work.

- In production, you might use looser tolerances to save time and money.

- You need to check parts while making them and after they are done. This means checking the first part, checking during the process, and checking at the end.

If you know what your machine can do, you can pick tolerances that work and do not cost too much.

Specifying Machining Tolerances

Communicating on Drawings

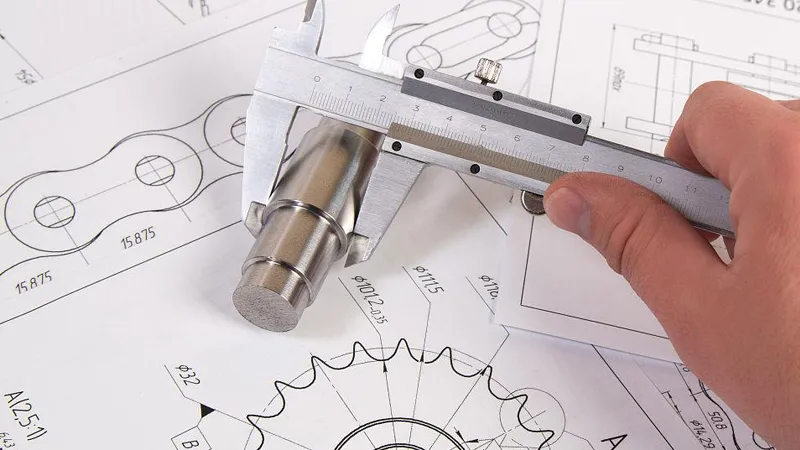

You need to show machining tolerance specifications clearly on technical drawings. This helps machinists know what you want and stops mistakes. Use Geometric Dimensioning and Tolerancing (GD&T) to explain form, orientation, and position. GD&T uses special symbols so every feature is easy to understand. Mark important tolerances and use clear notes. Put tolerances in the main view to show what changes are allowed. Always check your drawings before sending them to production.

| Best Practice | Description |

|---|---|

| Use GD&T | Show form, orientation, and position with standard symbols. |

| Define Tolerances | Put tolerances in the main view for easy reading. |

| Conduct Reviews | Look over drawings to catch mistakes and avoid confusion. |

Tip: Use bilateral or unilateral formats for tolerances. This helps others know what you mean and stops mix-ups during machining.

Balancing Tightness and Manufacturability

You must balance tight tolerances with how easy it is to make parts. High-precision CNC tolerances are needed for important parts, but they cost more and take longer. If tolerances are too tight, you need extra steps, slower speeds, and special tools. These things make costs go up and can cause more waste. For features that do not matter much, do not use tight tolerances. Use standard tolerances unless the part needs more precision.

| Factor | Description |

|---|---|

| More machining steps required | Tight tolerances need extra work. |

| Reduced feed rates | Slower cutting makes jobs take longer. |

| Specialized tooling and fixtures | Precision needs special, expensive tools. |

| Higher scrap and rework risk | Less room for error means more wasted parts. |

| Cost structure for precision | Longer jobs and more waste make projects cost more. |

- Only mark tolerances that affect fit or how the part works.

- Talk to your supplier early to find ways to save money.

- Use standard tolerances for features that are not important.

Avoiding Over-Specification

Setting tolerances too tight can cause problems. You may pay more, wait longer, and have trouble putting parts together. For example, using ±0.005 mm on a simple aluminum bracket can make costs go up by 25-35% because it takes longer and wastes more material. Set tolerances based on what the part does. Check each feature and ask if tight tolerances are really needed.

| Consequence | Over-Specifying Tolerances | Under-Specifying Tolerances |

|---|---|---|

| Increased Costs | Extra costs and harder work | Parts might not fit right |

| Production Delays | Makes manufacturing harder | Delays from fixing or changing parts |

| Assembly Failures | Parts may not go together | Problems with how the product works |

- Do not use tight tolerances for features that do not matter.

- Too many tight tolerances make checking harder and slow things down.

- Set tolerances for what is needed, not just guesses.

⚠️ Note: Always balance being exact with being practical. Tolerances that are too tight or too loose can waste time, cost more, and make products work badly.

Choosing the Right CNC Machining Tolerances

Selection Process

You need to follow the steps when picking CNC machining tolerances for a new part. Each step helps you make sure your part works and meets your goals. Here are the steps you should use:

- Understand the Functionality of the Parts

First, think about what the part does. Ask how it moves, fits, or supports other parts. - Select Appropriate Tolerances

Pick tolerances that match the part’s job. Use tighter tolerances for parts that need to fit close or move smoothly. - Perform Tolerance Analysis

Check how all the tolerances add up. Make sure small changes do not cause big problems in the final assembly. - Choose the Right Fit Type

Decide if you need a loose fit, a tight fit, or something in between. The fit type affects how the part works and how easy it is to put together. - Measure and Inspect Parts

Plan how you will check the parts. Use tools that can measure the tolerances you set. - Analyze Results

Look at the inspection data. See if the parts meet your needs. Change your tolerances if you find problems.

💡 Tip: Always test your design with a prototype before making lots of parts. This helps you find mistakes early and avoid expensive changes later.

How We Ensure Precision at AFI Industrial Co., Ltd.

At our facility, we combine Expertise with Advanced Technology to meet your most demanding specifications:

- State-of-the-art 5-Axis CNC Centers for reduced setups and higher accuracy.

- In-house Quality Control utilizing CMM and optical comparators

- DFM (Design for Manufacturing) Feedback: Our engineers review your drawings to suggest tolerance adjustments that can help you save money without compromising quality.

Conclusion

Standard CNC machining tolerances are the language that connects design intent with manufacturing reality. By understanding ISO standards and the factors that influence precision, you can design better products and optimize your production costs.

FAQ

In the custom metal manufacturing industry, the standard tolerance for most CNC machined components is typically ±0.005 inches (0.127 mm). At AFI, we follow ISO 2768 standards as a baseline for “medium” precision. These standard tolerances are cost-effective because they allow for efficient production speeds without requiring specialized inspection tools for every single dimension.

There is a direct correlation between dimensional precision and production cost. Achieving tight tolerances (such as ±0.001” or tighter) increases the price of custom metal parts due to:

- Increased Machining Time: Slower feed rates are required to maintain accuracy.

- Specialized Tooling: High-precision bits wear out faster and cost more.

- Frequent Inspection: Parts must be checked more often using CMM (Coordinate Measuring Machines).

- Higher Scrap Rates: The margin for error is much smaller, increasing the risk of wasted material.

For high-precision industries like aerospace or medical device manufacturing, we can achieve tolerances as tight as ±0.0001 inches (0.0025 mm) depending on the geometry and material. However, maintaining such high levels of dimensional accuracy requires climate-controlled environments and advanced CNC equipment. We recommend specifying these “super-tight” tolerances only for critical mating surfaces to keep your project within budget.

Material stability is a critical factor in precision machining. Metals like Aluminum 6061 are easier to machine to tight tolerances because they are stable and dissipate heat well. In contrast, harder materials like Stainless Steel 316 or specialized alloys may expand or contract during the cutting process due to heat, making it more challenging to maintain consistent CNC machining tolerances across a large production run.

Over-specifying (requesting tighter tolerances than the application actually requires) is one of the most common causes of “budget creep” in custom metal parts manufacturing. If a part is a simple bracket that doesn’t fit into a complex assembly, a standard tolerance is sufficient. By optimizing your design for realistic tolerances, you can significantly reduce lead times and manufacturing costs without sacrificing part functionality.

To guarantee that every CNC machined component meets your specifications, we employ a rigorous quality control process. This includes First Article Inspection (FAI), in-process monitoring, and final validation using calibrated tools such as digital micrometers, bore gauges, and CMM technology. We provide full inspection reports upon request to ensure transparency and compliance with your engineering requirements.