In the high-stakes world of international precision manufacturing, the margin between a successful product launch and a budgetary failure often hinges on “The Hidden Cost of the Cut.” For mechanical engineers, product designers, and procurement leads, the primary focus is usually on material selection, tolerance stacking, and surface finishes. However, there is a silent driver of both cost and lead time that is frequently overlooked during the CAD phase: Cutting Tool Geometry.

At AFI Parts, we have spent decades refining our CNC milling and turning processes. We’ve observed that projects utilising standardised tooling can be 20% to 40% more cost-effective than those requiring custom-ground implements. It makes CNC machining cost reduction, and helps our customers reduce their purchase cost.

This article aims to explore the technical and economic impacts of CNC machining standardized Tooling and to help engineers design parts optimised for modern machining workshops.

Table of Contents

Cutting Tool: the Hidden Economics of the Machining Manufacturer

Why are standardised cutting tools cheaper? The answer lies in the CNC machining supplier supply chain. Every CNC machine, whether a 3-axis mill or a sophisticated multi-axis turning centre, is only as effective as the “business end” of the spindle: the cutting tool.

The Cost of Customization(NRE Charges)

When a design requires a non-standard radius, a unique thread pitch, or an ultra-deep narrow slot, the manufacturer cannot simply pull a tool from the crib. We must order a “Special.” Custom tools involve:

- Engineering Time: Designing the tool geometry to ensure chip evacuation and heat dissipation.

- Grinding Fees: Specialized tool-and-die shops charge a premium to grind carbide blanks into specific shapes.

- Minimum Order Quantities (MOQs): Tooling vendors rarely grind just one cutter; you often pay for a batch of five or ten.

- Non-Recurring Engineering (NRE): These costs are passed directly to the client, often appearing as a “Setup Fee” or “Tooling Charge” that can range from $500 to $5,000.

Ordering Cycle

In the current global supply chain, a standard carbide end mill is available for “Next Day Delivery.” A custom-ground form tool typically carries a 3 to 6-week lead time. For an engineer facing a tight prototype deadline, this delay can be catastrophic. At AFI Parts, our massive inventory of standard tools allows us to begin production the moment the CAD file is approved.

Risk of Damage

If a standard tool breaks during a production run at our facility, we replace it in minutes. If a custom tool breaks and there is no spare, the entire production line stops for weeks. This “Single Point of Failure” adds a risk premium to your per-part price.

Technical Design Strategies for Tooling Optimization

Optimizing for standardized tooling isn’t about compromising your design; it’s about Strategic Geometry. Here are the deep-dive technical areas where engineers can make the most impact.

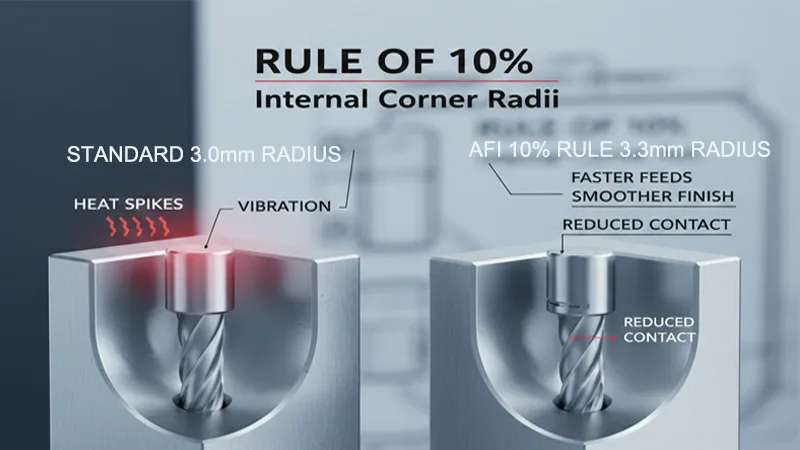

1. Internal Corner Radii: The “Rule of 10%”

One of the most common “cost increases” is the interior vertical angle. Engineers often design it with a specific radius, such as 3.0 mm, because they consider this to be the standard size. If you design a corner with a 3.0mm radius, a machinist must use a 6mm diameter end mill. Because the tool radius matches the corner radius exactly, the tool experiences “full engagement” as it turns the corner. This leads to:

- Tool Chatter: High vibration that ruins surface finish.

- Heat Spikes: Increased friction because the tool cannot “breathe.”

- Tool Deflection: The tool bends slightly, causing dimensional inaccuracies.

The AFI Solution: Always follow the Rule of 10%. If you want a 3.0mm radius, design it as 3.3mm. This allows a standard 6mm tool to navigate the corner without maintaining 100% contact, enabling faster feed rates and a much smoother finish. At AFI Parts, we maintain a vast library of standard metric and imperial cutters; designing for these “breathing room” clearances ensures we can use them effectively.

2. The Physics of the L:D Ratio (Length to Diameter)

Every tool has a limit to its rigidity. In CNC machining, this is measured by the Aspect Ratio or L : D Ratio.

- A standard end mill typically has a cutting length of 3x its diameter.

- “Long reach” tools exist up to 5x the diameter.

- Anything beyond 5:1 requires specialized, ultra-expensive carbide extensions or “tapered neck” tools.

As a tool gets longer relative to its thickness, its stiffness decreases exponentially. A 10:1 tool will deflect significantly, requiring the machine to run at 10% of its normal speed to maintain tolerance. You aren’t just paying for the tool; you are paying for the machine hours lost to slow cycle times.

3. Standardizing Hole Diameters and “Flat Bottoms”

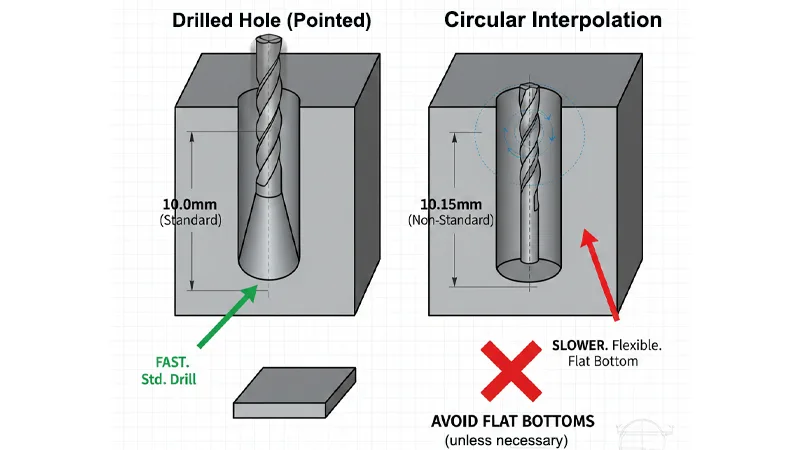

International procurement teams often overlook the difference between a drilled hole and an interpolated hole.

- Drilling: Fast, uses a standard twist drill.

- Interpolation: The machine moves a smaller end mill in a circular path to create a larger hole. It is slower but more flexible.

If your design specifies a hole diameter of 10.15mm (non-standard), we must interpolate it. If you change it to 10.0mm (standard), we can use a high-speed carbide drill.

Furthermore, avoid flat-bottomed holes unless necessary. Standard drills have a 118° or 140° point angle. Forcing a hole to be perfectly flat at the bottom requires a secondary operation with an end mill, doubling the labour for that feature.

4. Threading: The Global Language of Standards

While AFI Parts is capable of machining any thread profile, sticking to ISO Metric (M) or Unified National (UNC/UNF) standards is vital for cost control.

- Avoid Custom Pitches: A “fine” thread that isn’t on the standard chart requires a custom tap or a single-point threading operation. Single-pointing is precise but takes significantly longer than tapping.

- Thread Depth: Never design a thread deeper than 2x the diameter. Beyond this depth, the risk of tap breakage increases, and the extra threads provide no additional holding power according to mechanical engineering principles.

AFI Parts’ Technical Superiority: CNC Machining Standardized Tooling

Why choose AFI Parts as your manufacturing partner? It is because we bridge the gap between “Design” and “Delivery” through our integrated technical ecosystem.

1. Comprehensive DFM (Design for Manufacturability)

When you submit an RFQ (Request for Quote) to AFI, you don’t just get a price. You get a technical audit. Our engineers use advanced software to identify “tooling traps.” Example: If your 3D model contains a deep pocket that our standard 5-axis mills can’t reach without custom tooling, we will flag it and suggest a minor geometry change. This proactive approach saves our clients an average of 15% on their annual machining spend.

2. The Synergy of Multi-Process Capabilities

AFI Parts is not just a CNC shop. We operate:

- CNC Lathes and Milling Centres: For high-precision components.

- 15 – 2000 Ton Punch Presses: For high-volume sheet metal and stamping.

- Die Casting and Powder Metallurgy: For complex geometries.

Because we have this breadth of equipment, we can advise you when a part has become “too complex for CNC.” If a part requires so much custom tooling that the price skyrockets, we might suggest a hybrid approach—stamping a base blank and using CNC only for the final critical tolerances. This cross-disciplinary expertise is why procurement officers for major industrial brands trust us.

3. Surface Finish and Tooling Choice

Standardized tooling also affects surface roughness ($Ra$). Using standard “High-Feed” inserts allows us to achieve superior surface finishes without the need for secondary grinding or polishing operations. By designing for these standard inserts, you essentially get a “free” upgrade in part aesthetics and performance.

A Guide for International Procurement Professionals

1. Reducing “Piece Price” through Tooling Longevity

Standard tools are engineered for maximum tool life. When we use standard cutters, we can predict exactly when a tool will dull. This allows for Lights-Out Manufacturing, where machines run unattended overnight. This high efficiency translates into a lower hourly rate for the customer.

2. Speed to Market

In the current competitive landscape, being first to market is everything. By eliminating the 3-week wait for custom tools, AFI Parts can often deliver finished, nickel-plated copper or stainless steel parts before our competitors have even received their tooling.

3. Simplified Quality Control

Standard tools produce predictable results. When using a standard M6 tap, the Go/No-Go gauge results are consistent. Custom tools often require specialised inspection protocols, which add another layer of cost to your quality department’s workload.

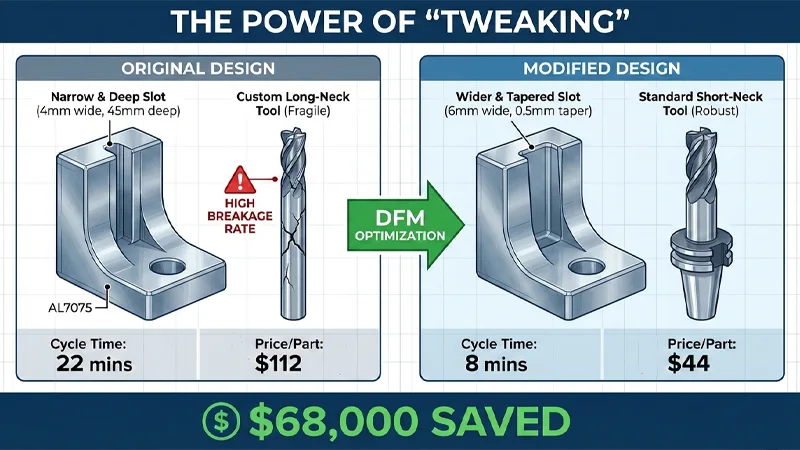

Case Study – The Power of the “Minor Tweak”

In early 2024, a North American robotics startup needed 1,000 brackets made of AL7075 aluminum alloy. The client’s design included an internal groove 45mm deep and only 4mm wide. This required a custom-made extended-neck end mill. Due to the fragility and high breakage rate of such custom tools, a local machining plant quoted $112 per part.

Our DFM team noticed that the slot was for weight reduction, not for a specific mating part. We suggested widening the slot to 6mm and adding a 0.5mm taper. The Result: We were able to use a standard 6mm stubby end mill with a long-reach holder.

- The cycle time dropped from 22 minutes to 8 minutes.

- The price per part dropped to $44.

- The customer saved $68 per unit across a 1,000-unit run—a total saving of $68,000 on a single component.

Partner with the Experts at AFI Parts

Standardisation is not a limitation; it is a strategic advantage. By aligning your design with the physical realities of the machine shop floor, you unlock faster lead times, higher quality, and significantly lower costs. At AFI Parts, we don’t just manufacture metal; we solve engineering challenges. Whether you are working on a complex CNC-turned shaft or a heavy-duty stamped bracket using our 2000-ton presses, our goal is to ensure your design is as efficient as it is functional.

Take the Next Step: Don’t let custom tooling fees drain your R&D budget. Let our team of experts review your next project. Contact us, and Learn how our integrated manufacturing capabilities—from CNC to Pipe Bending and Die Casting—can streamline your entire supply chain.

g well for a long time.

FAQ

Using standardized tooling eliminates the need for “specialized” or custom-made cutting tools, which often carry high surcharges. By utilizing a custom metal parts manufacturer that leverages a vast inventory of standard CNC cutters, you save on upfront engineering costs and reduce the “price per part,” especially for low-to-medium volume production runs.

Absolutely. High-quality precision CNC machining relies on the accuracy of the machine and the grade of the tool, not necessarily its “custom” status. Our standardized carbide and diamond-coated tools are capable of maintaining tolerances as tight as $\pm$0.01mm, ensuring that your custom metal components meet rigorous aerospace or medical standards.

Lead time is significantly shortened. Since we do not have to wait for custom tool fabrication or specialized shipping, production can often begin the same day the design is finalized. For clients seeking rapid prototyping or quick-turn custom metal fabrication, standardized tooling is the most efficient path to delivery.

While standardized tools are versatile, they do have fixed radii and lengths. To maximize cost-efficiency, we recommend designing internal corners to match standard end mill diameters. If your design requires a unique geometry, our engineers can provide Design for Manufacturing (DfM) feedback to help you adapt the part for standard tooling without sacrificing functionality.

We use a wide array of standardized high-performance tools optimized for various materials, including:

- Aluminum Alloys (6061, 7075)

- Stainless Steel (304, 316)

- Titanium & Carbon Steel

- Copper & Brass Our inventory ensures that regardless of the metal, we have the right “off-the-shelf” precision tool ready for your CNC machining services.

It is highly beneficial for both. For prototyping, it keeps the initial investment low. For mass production, it ensures “tooling consistency”—if a tool wears out, it can be replaced instantly with an identical standard tool, preventing downtime and ensuring every batch of your custom metal parts is identical.