What materials can be used in cnc? Makers typically select CNC machining materials from three main groups. These are metals, plastics, and prototyping materials. Each group has special features for different cnc jobs. For example, engineers use stainless steel because it does not rust and is strong. Aluminum alloys are light but strong and are easy to shape. The table below shows some common metals and their main features:

| Material | Defining Properties |

|---|---|

| Stainless Steel (316 SS) | Does not rust, is strong, handles stress and wear well, good for medical and aerospace uses. |

| Aluminum Alloys | Light but strong, easy to shape, can be anodized, keeps its size under stress. |

| Carbon Steel | Tough, hard, resists scratches and wear, good for heavy jobs. |

| Brass | Easy to shape, conducts electricity, does not rust, good for fittings and valves. |

| Titanium | Light and strong, does not rust, handles heat well, used in planes and medical parts. |

| Copper | Great at moving heat, conducts electricity, used in heat sinks and parts that need to lose heat. |

What materials can be used in cnc? The answer depends on what the part needs. What materials can be used in cnc? Picking the right one helps the part work well and last longer. What materials can be used in cnc? Knowing the features helps make good choices. What materials can be used in cnc? Smart choices make better parts that last longer.

Key Takeaways

- CNC machining works well with metals, plastics, and prototyping materials. Each material has special features for different jobs.

- Picking the right material is important. Aluminum is good for light parts. Stainless steel is good for strong parts. This helps make sure the product is strong and works well.

- Plastics like ABS and PEEK are good for CNC. They are light, cheap, and resist chemicals. This makes them useful for many things.

- When you pick materials, think about strength, heat resistance, and cost. This helps make sure the part fits the project.

- Prototyping uses materials like MDF and acrylic. This lets you test and change designs quickly. It saves time and money when designing.

Table of Contents

CNC Machining Materials Overview

What Materials Can Be Used in CNC?

CNC machining works with many materials. People often pick metals, plastics, or prototyping materials. Each group has special traits for different jobs. The table below lists the main types and what they are like:

| Material Type | Description |

|---|---|

| Metals | Has steel and aluminum, used for many parts. |

| Plastics | Cheaper, strong, and light, good for many uses. |

CNC machines can cut steel, aluminum, and plastics. These materials make parts for planes, cars, and electronics. Picking the right material helps the part work well and last long.

Tip: Choosing the best cnc material can make parts better and save money.

Metals vs. Plastics

Metals and plastics are the most used cnc materials. Each has good and bad points. The table below shows how they compare:

| Feature | Plastics | Metals |

|---|---|---|

| Strength and Durability | Light but not as strong | Strong and lasts longer |

| Weight | Much lighter | Heavier |

| Cost Efficiency | Cheaper for testing new ideas | Good for making many parts |

| Corrosion Resistance | Does not rust easily | Needs extra care to stop rust |

| Precision and Tolerances | Good, but can change | More steady and exact |

| Industry Applications | Used in medical and electronics | Used in planes, cars, and defense |

Plastics are light and resist chemicals, so they are good for parts that do not hold weight. Metals are strong and can be made very exact, which is needed for frames and supports. Picking metals or plastics changes how long cnc takes, how fast tools wear out, and the cost. For example, aluminum is quick to cut and does not wear tools fast. Titanium is tough and lasts in hard jobs. Finding the right balance of price and strength gives the best cnc results.

Common Metals for CNC Machining

Aluminum

Aluminum is a top metal for cnc machining. Engineers pick aluminum alloys because they are light and easy to shape. These alloys do not rust since they make a protective layer. Many industries use aluminum for special cnc parts. Aerospace and car makers use it a lot. The table below shows important facts and uses:

| Mechanical Property | Description | Typical Applications |

|---|---|---|

| Machinability | Aluminum is simple to cut and needs less power. This helps make parts more exact. | Used in many cnc metal parts. |

| Strength-to-weight Ratio | Aluminum is light but strong. It works well for cars and planes. | Car and plane parts. |

| Corrosion Resistance | Aluminum does not rust, even near the sea. | Used in boats and sea buildings. |

| Performance at Low Temperatures | Aluminum stays strong in cold places. | Used for cold area parts. |

| Electrical Conductivity | Aluminum carries electricity well. Different alloys change this. | Used for electric parts. |

| Recyclability | Aluminum can be recycled easily. This helps the environment. | Used in green factories. |

Steel

Steel is used for cnc parts that need to be tough. Makers use cnc machining with steel for frames, gears, and tools. Steel is very strong and does not rust easily. But steel can get harder when cut and wear out tools. The table below shows good and bad points:

| Advantages | Limitations |

|---|---|

| Very strong | Gets harder when cut |

| Does not rust easily | Wears out tools |

| Lasts a long time | Does not move heat well so it gets hot |

Stainless Steel

Stainless steel is great for cnc because it does not rust and is clean. Types like 316 and 304 are common. 316 stainless steel does not get tiny holes and works in tough places. Medical and food machines use stainless steel for cnc parts. 316 is easier to cut than 304, which needs tool changes more often.

Note: Stainless steel is strong and does not rust, so it works well for hard jobs.

Brass

Brass is strong and bends without breaking. People use brass because it is easy to cut and does not rust. C300 brass is good for pipes and valves. Brass is easy to shape and cut, so it makes tricky parts.

Copper

Copper is great at carrying electricity and heat. Electric, car, and medical companies use copper for heat parts and connectors. Copper does not rust, so it works in tough places.

- Carries electricity very well

- Moves heat very well

- Lasts long and does not rust

Titanium

Titanium alloys are strong but light and safe for people. Planes and medical tools use titanium for cnc parts that must be tough and light. Titanium bends well and lasts long. Cutting titanium is hard because it gets hot and needs strong tools, but it is worth it.

Tip: Titanium alloys do not attract magnets and are safe for people. This makes them good for special cnc jobs, like using cobalt chromium.

Plastics for CNC Machining

CNC machining with plastics helps make strong and exact parts. Engineers pick plastics because they are light, cheap, and resist chemicals. The next parts talk about the most used plastics in cnc and why they are good for different jobs.

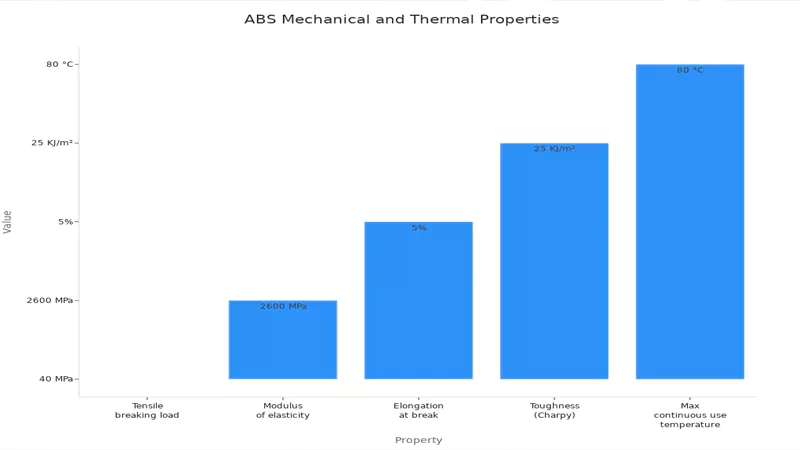

ABS

ABS is a top pick for cnc. Makers like ABS because it is tough and easy to cut. It keeps its shape and does not scratch easily. This makes it good for parts that need to last. The table below shows some main facts:

| Property | Value |

|---|---|

| Tensile breaking load | 40 MPa |

| Modulus of elasticity | 2600 MPa |

| Elongation at break | 5% |

| Toughness (Charpy) | 25 KJ/m² |

| Maximum continuous use temperature | 80 °C |

ABS also slides well and does not wear out fast. It can take hits and its hard surface stops damage.

PEEK

PEEK is a strong plastic for hard jobs. It stands up to chemicals and heat. PEEK works up to 260°C and melts at 343°C. It does not bend in heat and works in hot water or steam. Planes, cars, and hospitals use PEEK for tough parts.

- PEEK works well above 250°C (480°F).

- It stays strong in very hard places.

- Good for making parts for rough jobs.

Delrin (Acetal)

Delrin, or acetal, is used for exact cnc parts. It keeps its shape and does not soak up much water. Delrin stands up to many chemicals, like fuel and oil. It is hard and stiff, so it does not bend easily. The table below lists its good points:

| Advantage | Description |

|---|---|

| Superior Mechanical Properties | Strong, stiff, and does not change shape. |

| Excellent Wear Resistance | Slides well and does not wear out fast. |

| Outstanding Dimensional Stability | Does not soak up water, so it stays the same size. |

| Chemical Resistance | Stands up to many fuels and solvents. |

| Electrical Insulation | Stops electricity from leaking out. |

Polycarbonate

Polycarbonate is tough and does not break easily. It can take hits and does not crack. Polycarbonate stays strong from -20°C to 140°C. It is clear and lets a lot of light through, so it is good for windows and lenses.

- Very tough and does not break.

- Works well in hot and cold.

- Lets lots of light through for clear parts.

Nylon

Nylon is bendy and strong for cnc. It is good for parts that hold weight. Nylon slides well and does not wear out fast. The table below shows some facts:

| Property | Value |

|---|---|

| Tensile Strength (PA66) | 80-90 MPa |

| Wear Resistance | Good |

| Friction Coefficient | 0.25 |

Nylon PA11 bends well, takes hits, and stands up to chemicals. Cutting PA11 needs care because it is special.

Acrylic

Acrylic is easy to cut and looks nice. It is simple to polish, so it is good for clear cnc parts. You can make acrylic shiny by flame, buffing, or using chemicals. Cutting acrylic is easier and cheaper than polycarbonate, which needs more work.

- Easy to cut and polish.

- Very clear for nice-looking parts.

- Saves money on cnc jobs.

Prototyping and Other CNC Machining Materials

MDF

Medium-density fiberboard is often used for cnc prototyping. It lets engineers make detailed parts fast and cheap. CNC routers can carve cool shapes on MDF. This helps test ideas before making the real thing. MDF has many good points:

- Makes very exact and neat engravings.

- Gives the same results every time.

- Works quickly, so jobs finish faster.

- Wastes less material, which saves money.

- Easy to change designs if needed.

- Can use thick or thin pieces for different tests.

| Advantage | Description |

|---|---|

| Precision And Accuracy | CNC routers can engrave MDF with great detail. |

| Repeatability And Consistency | CNC routers make the same part over and over. |

| Complex Design | CNC routers can carve tricky patterns and textures in MDF. |

Not all MDF is the same. Some kinds make bad dust or have uneven spots. This can hurt the quality of the part. Picking better MDF helps stop these problems, but it costs more.

Note: Operators should use the right speed and feed. This keeps the MDF and cnc machine safe.

Acrylic (for Prototyping)

Acrylic is a top pick for cnc prototypes. Designers like acrylic because it is cheap and easy to cut. Its clear look helps teams see how parts fit together. Acrylic also lets people change designs quickly, which helps work go faster.

| Advantage | Description |

|---|---|

| Cost-effectiveness | Acrylic does not cost much, so it is great for testing. |

| Ease of machining | It is simple to cut and change. |

| Transparency | Acrylic is clear, so you can see the part well. |

- Light and easy to move.

- Strong enough to last through tests.

- Good for making neat and exact shapes.

Acrylic helps teams make new versions fast. It does not need much care, so it is used a lot in cnc projects.

Other Rigid Plastics

Many hard plastics are good for cnc prototypes. Each kind has special features for different jobs. The table below shows some common plastics and what they do:

| Plastic Type | Distinguishing Features | Machinability and Applications |

|---|---|---|

| ABS | Strong and tough | Smooth finish, good for testing and small batches |

| Polycarbonate (PC) | Very strong, tough, clear | Used for medical tools, covers, and cases |

| Polyethylene (PE) | Bendy, comes in many types | Easy to cut, good for lots of parts |

| Polypropylene (PP) | Stands up to chemicals, does not soak up water | Easy to cut, used for chemical boxes |

| Acetal (POM) | Strong, slides easily | Great for exact parts that must fit tight |

| Nylon (PA) | Tough, does not wear out fast | Good for strong parts, but soaks up water |

| PEEK | Very strong, stands up to chemicals and heat | Used for hard and important cnc jobs |

| PVC | Cheap, tough, stands up to chemicals | Used in pipes, connectors, and many other parts |

These plastics help engineers make test parts that are close to the final ones. They work for many cnc jobs, from simple tests to tricky, exact pieces.

Tip: Picking the best material for cnc tests gives better parts and makes moving to full production easier.

CNC Machining Material Selection

Picking the right material is very important for cnc projects. Engineers and designers must think about many things when they choose a material. Each thing changes how well the part works, how much it costs, and how long it lasts.

Mechanical Strength

Mechanical strength tells if a material can take stress and weight without breaking. Metals and alloys are very strong and last a long time. They are good for parts that hold things up. Some plastics are strong too and do not wear out fast. These are good for lighter parts. The table below shows the main types:

| Material Type | Key Properties |

|---|---|

| Metals | High tensile strength, good durability |

| Alloys | Enhanced mechanical properties |

| High-strength Plastics | Good wear resistance and endurance strength |

Titanium is very strong and does not rust, so it is used for medical and airplane parts. Nylon keeps its shape well, so it is good for bearings and parts that hold weight.

Thermal Resistance

Thermal resistance means how well a material can take heat. Some metals and alloys, like titanium, work well in hot places. Plastics like PEEK can take heat and chemicals, so they are good for tough jobs. Engineers must pick materials that can handle the heat where they will be used. This stops parts from bending or breaking.

Tip: Always check how hot a material can get before using it in cnc.

Cost

The material you pick changes how much the cnc job costs. Metal alloys like titanium or Inconel cost a lot, but they are special for important jobs. Some plastics, like PEEK or Ultem, also cost more but work very well. For early tests, designers use cheaper materials like MDF or acrylic to save money.

- Metal alloys can make projects cost more.

- Special plastics cost more but have good features.

- Cheaper materials help save money when testing.

Surface Finish

Surface finish changes how a cnc part looks and works. Different materials can have different finishes. The table below shows some finishes and what they work with:

| Finish Type | Description | Material Compatibility |

|---|---|---|

| As machined | Small tool marks, normal roughness (3.2 μm) | Any material |

| Bead Blasting | Matte look, makes parts look better | Many metals |

| Anodizing Type II | Stops rust, adds color | Aluminum, Titanium |

| Anodizing Type III | Thicker, stronger layer | Aluminum, Titanium |

| Powder Coating | Strong finish, many colors | Many metals |

Engineers pick finishes for rust protection, less friction, less wear, stopping electricity, and looks. For example, anodizing keeps aluminum from rusting. Powder coating adds color and makes parts last longer.

Application Needs

What the part does helps pick the material for cnc. Engineers look at what the part must do, how strong it needs to be, and if it needs to carry electricity. Light materials are good for planes. Strong metals are best for heavy jobs. How easy it is to cut the material changes how fast the job goes and how long tools last. Finishes, material features, cost, how easy it is to get, and how long it takes to get all matter too.

- Think about what the part must do.

- Pick materials that fit the job.

- Think about how easy it is to cut and finish.

- Remember cost, how easy it is to get, and wait time.

Note: Picking the right cnc material helps parts work well and meet project goals.

Factors to Consider in Material Selection

The table below shows the most important things to think about when picking cnc materials:

| Factor | Description |

|---|---|

| Part Application | Pick materials that fit what the part must do. |

| Operating Environment | Make sure the material can take heat and chemicals. |

| Dimensional Stability | Pick materials that keep their size for exact parts. |

| Electrical Conductivity | Pick for carrying or stopping electricity if needed. |

| Machinability | Pick materials that are easy to cut to save time and money. |

| Physical Appearance | Think about looks for parts people will see. |

| Tolerances | Make sure the material can be cut very exactly. |

Engineers and designers should always match the material to what the project needs. Picking the right one helps make strong, cheap, and good cnc parts.

CNC machining can use many materials. These include metals, plastics, and prototyping choices. Each material has special benefits for different parts. Picking the right material helps make strong and reliable parts. Engineers should look at what the project needs. They should think about weight, strength, heat resistance, and cost before picking.

- Think about how the part will be used

- Check if it needs to be light or strong

- See if it is easy to cut and looks good

- Make sure the price matches how well it works

If the cnc job is tricky, ask an expert or do more research to get the best results.

FAQ

Engineers pick metals like aluminum, steel, and titanium. Plastics such as ABS and PEEK are good too. Each material has special benefits for cnc jobs.

CNC machines can cut metals and plastics well. Operators use the right tools for each material. This helps make parts that fit just right.

Picking the material changes how strong and tough the part is. Metals are strong, but plastics are light. The best choice makes sure the part works for the project.

Teams use cnc machining to make test parts. MDF and acrylic help test ideas and change designs fast. This way, work goes quicker and costs less

Engineers look at strength, heat resistance, cost, and finish. They match the material to what the part needs to do. Planning well helps make good cnc parts.