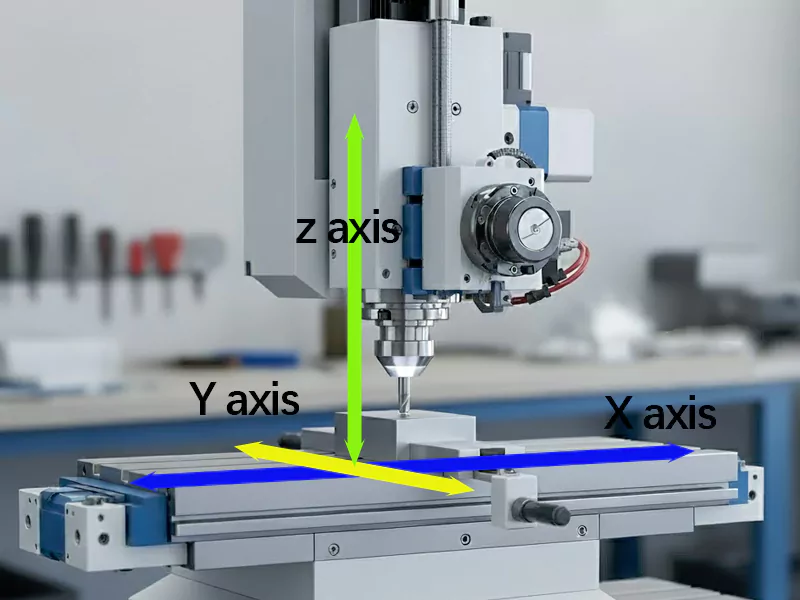

When you use cnc machines, you work with three main directions called the x, y, and z axes. These axes help you move a tool or part in different ways. The X-axis lets you move left and right. The Y-axis moves things forward and backward. The Z-axis moves up and down. Imagine sliding a box across a table: side to side is X, front to back is Y, and lifting it up is Z. Knowing What are the XYZ axes for CNC? helps you control machining jobs with confidence and accuracy.

Key Takeaways

- The X, Y, and Z axes move CNC machines. X moves side to side. Y moves forward and backward. Z moves up and down.

- Knowing these axes helps you use CNC machines well. Each axis is important for making parts that fit right.

- Always check your axis settings before you start. This helps stop mistakes and keeps your cuts correct.

- Multi-axis CNC machines make harder shapes and work faster. They cut from different sides without moving the part.

- Mistakes can happen if the Z axis is not set right. Always measure tool heights so you do not cut too deep or too shallow.

- Pictures, labels, or colored stickers help you remember each axis. Practice moving each axis to get better at it.

- Good axis control makes your parts look and fit better. It lowers mistakes and makes your work smoother.

- Learning about CNC axes can help you get more skills and jobs. The more you learn, the easier it is to use new machines.

Table of Contents

What Are the XYZ Axes for CNC?

When you work with CNC machine axes, you control movement in three main directions. These directions are called the X, Y, and Z axes. Understanding what the XYZ axes are for CNC? helps you use CNC machines with confidence and accuracy. Each axis has a special job in machining, and knowing how they work together is key to making precise parts.

Think of the axes like directions on a map. The X axis moves left and right, the Y axis moves forward and backward, and the Z axis moves up and down. When you use all three, you can reach any point in space on your cnc machine.

To help you see the official definitions, here is a table that shows how each axis works in CNC machine axes:

| Axis | Definition | Movement Orientation |

|---|---|---|

| X | Represents the horizontal axis | Side to side |

| Y | Represents the vertical axis | Up and down |

| Z | Represents the depth | Back and forth |

X Axis

Left-Right Movement

The X axis is the direction that moves side to side on your CNC machine. When you slide a part or tool from left to right, you use the X axis. This axis is very important in machining because it sets the base for all other movements. If the X axis is not set correctly, your part may not come out right. Even a small error in the X axis can cause problems in the final product. You need to check the X axis often to make sure your CNC machine axes stay accurate.

Y Axis

Forward-Backward Movement

The Y axis lets you move things forward and backward. Imagine pushing a box away from you or pulling it closer. That is the Y axis in action. In machining, the Y axis works with the X axis to help you reach any spot on a flat surface. When you use both the x and y axes, you can cut shapes, drill holes, or engrave patterns with high precision. The Y axis is just as important as the X axis for making sure your CNC machine axes follow the right path.

Z Axis

Up-Down Movement

The Z axis controls up and down movement. When you lift the tool or lower it into the material, you use the Z axis. This axis is what gives your CNC machine the power to cut deep or shallow. The Z axis is crucial for controlling the depth of your cuts. If you want to engrave a design or drill a hole, you need the Z axis to set how deep the tool goes. Many CNC machine axes errors happen when the Z axis is not set correctly. Here are some common Z axis issues and how you can fix them:

| Error Description | Possible Cause | Corrective Action |

|---|---|---|

| Incorrect tool height offsets | Z command exceeds machine limits | Clear tool offsets and re-measure tools |

| Z axis height exceeded | Tools not measured during tool changes | Measure tools correctly before starting |

| Tool height offset mismatch | Wrong tool or offset selected | Set the correct tool height offset |

| Shallow cuts over program length | Excessive load or lost motion | Use a ramp or lead-in for pockets, not vertical cuts |

Tip: Always check your Z axis settings before you start machining. This helps you avoid mistakes and keeps your cnc machine axes working smoothly.

The Z axis also lets you create multi-layered designs. By moving up and down, you can cut different levels and add details to your parts. Tools like Z axis setters help you measure and control the vertical position, making sure every cut is just right.

When you understand what the XYZ axes are for CNC, you can use your CNC machine to its full potential. Each axis—X, Y, and Z—plays a special role in machining. Together, they let you make parts that are accurate, detailed, and high quality.

CNC Machine Axes Explained

Axis Movements

When you use CNC machines, you control movement along three main directions. These directions follow the xyz plane. The X-axis moves left and right. The Y-axis moves forward and backward. The Z-axis moves up and down. You can think of the XYZ plane as a map that helps you find any point in space. The origin is the starting point, and each axis gives you a way to reach different spots on your workpiece.

- X-axis: Moves the tool or table left and right.

- Y-axis: Moves the tool or table forward and backward.

- Z-axis: Moves the tool or spindle up and down.

This system lets you cut, drill, or engrave on different sides of a part. You can reach any position on the flat surface by moving in the XYZ plane. When you add the Z-axis, you can also control how deep the tool goes. This is important for making parts with different levels or layers.

Tip: Always check your machine’s reference point before you start. This helps you avoid mistakes and keeps your cuts accurate.

Axis Roles in Machining

Each axis in the XYZ plane has a special job during machining. The X and Y axes work together to move the tool across the surface. This lets you shape the outside of a part or create holes in the right spots. The Z-axis controls the depth of each cut. When you want to make a groove or pocket, you use the Z-axis to set how deep the tool goes.

You will find that most CNC machines use three axes for basic jobs. These machines can handle many tasks, such as milling, drilling, and tapping. The table below shows how different machines use the axes:

| CNC Machine Type | Axes Involved | Capabilities |

|---|---|---|

| 3-Axis | X, Y, Z | Good for simple parts and single-direction cuts |

| 4-Axis | X, Y, Z, A | Adds rotation for more complex shapes |

| 5-Axis | X, Y, Z, A, B | Can reach any angle for intricate designs |

Three-axis machining is common for making mechanical parts. It lets you remove material in three directions. This works well for parts that are not too deep. If you need to make more complex shapes, machines with more axes can help you reach more sides without moving the part.

You use the XYZ plane to plan every move. This helps you make sure each cut is in the right place and at the right depth. When you understand how each axis works, you can create parts that fit together perfectly and meet your design goals.

Axis Analogies

Understanding axis movement can feel confusing at first. Analogies make it easier for you to picture how each axis works. When you use analogies, you connect new ideas to things you already know. This helps you remember the directions of the X, Y, and Z axes when you work with cnc machines.

3D Graph Analogy

Imagine you stand in the corner of a room. The floor and two walls meet at this point. You can use this corner to picture how the axes move. The X axis runs along the floor to your left. The Y axis runs along the floor to your right. The Z axis goes straight up where the two walls meet. This setup matches the way axes work in a 3D graph.

Here is a simple table to help you see this analogy:

| Axis | Description |

|---|---|

| X | Horizontal line along the wall to your left and the floor intersect. |

| Y | Horizontal line along the wall to your right and the floor intersect. |

| Z | Vertical line along which the walls intersect. |

Tip: When you think about the axes like lines in a room, you can quickly remember which way each one moves.

This 3D graph analogy helps you see how the axes work together. You can move left or right, forward or backward, and up or down. Every point in the room can be reached by moving along these three lines.

Everyday Object Analogy

You can also use everyday objects to picture axis movement. Think about a shoebox sitting on a table. If you slide the box from side to side, you move it along the X axis. If you push the box away from you or pull it closer, you move it along the Y axis. If you lift the box or set it down, you use the Z axis.

- X axis: Slide the box left and right.

- Y axis: Push or pull the box forward and backward.

- Z axis: Lift the box or lower it down.

Note: Using simple objects like a box helps you remember axis directions when you work with machines.

These analogies make it easier for you to understand how CNC machines move. When you picture the axes as lines in a room or as ways to move a box, you can plan your machining steps with more confidence.

How Axes Work Together

Coordinated Movements

When you use multi-axis CNC machines, you move in more than one direction at once. This teamwork lets you make parts that are both exact and tricky. You can move the tool on the X, Y, and Z axes altogether. This means you can cut curves, angles, and 3D shapes without stopping to move the part.

- Multi-axis CNC machines let you work on many sides of a part in one setup.

- You save time because you do not need to move the part by hand.

- You make fewer mistakes since the machine keeps things lined up.

- You can make parts with deep cuts, undercuts, and special features that 2-axis CNC machines cannot do.

When you use multi-axis cnc machines, you finish jobs faster and with better accuracy. That is why many companies pick these machines for important work.

Multi-Axis Machining

Multi-axis CNC machines include 3-axis, 4-axis, and 5-axis CNC machines. Each type gives you more ways to move and more control. The more axes you have, the harder and cooler your parts can be.

3-Axis vs. 5-Axis

You might wonder how a 3-axis machine is different from a 5-axis machine. Here is a table to help you see the main differences:

| Factor | 3-Axis | 5-Axis |

|---|---|---|

| Cutting tool movement | X, Y, Z axes | X, Y, Z, plus A and B rotation |

| Efficiency | Good | Excellent, very quick |

| Tool changes | Multiple setups | Minimal, works from many angles |

| Capabilities | Simple shapes | Deep cuts, undercuts, complex shapes |

| Accuracy | Good | Excellent |

| Ease of operation | Simple | Needs special training |

| Cost | Lower | Higher |

| Applications | Flat parts, basic shapes | Aircraft, medical, complex parts |

A 3-axis CNC machine is good for flat parts and easy shapes. You move the tool left-right, forward-backward, and up-down. This works for many jobs, but you must stop and move the part if you want to cut from a new angle.

A 5-axis machine adds two more ways to move. You can tilt and spin the tool or the part. This means you can reach almost any spot in one try. You do not need to stop and move the part, so you finish faster and make fewer mistakes.

Multi-axis CNC machines give you:

- Better precision. You can keep tight limits and make sure every detail is right.

- More efficiency. You save time by cutting from many angles without stopping.

- The ability to make tricky shapes. You can make parts with curves, holes, and features that 2-axis and 3-axis CNC machines cannot do.

- Multi-axis CNC machines help you do lots of work quickly.

- You get great accuracy because you do not need to move the part again.

- You can meet the needs of jobs in aerospace, cars, and medical devices.

If you want to make parts that are both detailed and exact, multi-axis cnc machines are the best pick. They let you do more work in less time and with fewer mistakes.

Importance of Precision

Knowing the X, Y, and Z axes is very important. It helps you make parts with high precision. When you understand each axis, you can move your CNC machine the right way. This makes you feel sure about every step. You can make parts that fit well, look nice, and work as they should.

Accuracy in Machining

You must control the axes well to get good results. If you set the axes right, the tool goes to the exact spot. Your cuts, holes, and shapes will match your plan. If you do not know the axes, you might make mistakes and ruin your part.

Studies show that using the axes well lowers errors a lot. Look at the table below to see how many mistakes drop when you control the axes:

| Metric | Reduction (%) |

|---|---|

| Maximum tool tip position contour error | 77.78 |

| Average tool tip position contour error | 83.90 |

| Maximum tool orientation contour error | 79.05 |

| Average tool orientation contour error | 86.66 |

You can see that knowing the axes means fewer mistakes and better accuracy.

Part Quality

When you use the axes correctly, your parts get better. Here are some ways axis control helps you:

- Keeping the tool at the right angle makes the surface smoother and the size more exact.

- Moving the tool the best way makes the part look and feel better than with basic three-axis moves.

- Fewer setup mistakes and keeping the part in place help features line up just right.

You can get tight fits, like ±0.01–0.05 mm, and smooth surfaces as low as Ra 0.8–25 µm. These things matter for parts that must fit or move well.

Avoiding Mistakes

Mistakes in machining waste time and material. If you know the axes, you can stop problems like cutting too deep, missing the spot, or making rough surfaces. Here are some tips to help you avoid mistakes:

- Always check your axis settings before you start.

- Use the right reference points to keep cuts correct.

- Watch for tool wear or drift, which can change axis moves.

Tip: Take your time to set up each axis before you start. Careful setup means fewer mistakes and better parts.

When you focus on axis control, your parts meet high standards. You also save money by making less scrap and fixing fewer errors. Learning the axes is the key to getting the best from your CNC machines and making great parts every time.

CNC Machines: Troubleshooting Axes

Common Confusions

You might feel confused when you first set up or use CNC machines. Many people mix up the X, Y, and Z axes, especially when looking at the machine from different angles. Sometimes, you may wonder which way the tool will move when you press a button. You may also get mixed up if you switch between machines with different layouts.

Here are some common questions and issues you might face:

- Which axis moves left and right, and which one goes up and down?

- Why does the tool move in the opposite direction from what you expect?

- How do you know if the tool or the table is moving?

- What should you do if your cuts are not in the right place?

You can solve many of these problems by following a few simple steps. When you notice that your machine is not cutting where you want, check the axis settings first. Sometimes, the machine may have lost its reference point. You should always rehome the machine before starting a new job. This step helps the machine know exactly where it is.

If you see that the tool is not moving smoothly, check for backlash or loose parts. Backlash means there is a small gap in the movement, which can cause errors. You can adjust compensation settings in the control software to fix this. Also, inspect and tighten motor mounts to keep everything stable. Examine the drive system for worn or faulty parts. Replace worn bearings and linear guides if you notice any wobble or rough motion. Let the machine warm up before cutting to manage thermal expansion and keep your cuts accurate.

Tip: If you follow a checklist before each job, you can catch most axis problems early and avoid mistakes.

Tips for Remembering

Remembering which axis is which can be tricky at first. You can use some easy tricks to help you keep them straight.

- Think of the X axis as left and right, like sliding a drawer.

- Picture the Y axis as forward and backward, like pushing a chair under a table.

- Imagine the Z axis as up and down, like raising or lowering a flag.

Many machinists use standard tool orientations to reduce confusion. Always set up your tools the same way, so you know which direction is which. Understand the difference between radial and axial tools by looking at the tool tip direction. Use clear programming conventions that show how the tool is mounted and which way it points.

You can also label your machine or workspace with arrows and letters for each axis. Some people use color-coded stickers or tape to mark the directions. This visual aid helps you remember the axes quickly, especially when you are learning.

Note: Practice moving each axis one at a time and watch how the tool or table moves. This hands-on approach helps you build confidence and avoid mistakes.

If you keep these tips in mind, you will find it much easier to set up and run CNC machines without confusion. With practice, you will remember the axes automatically and focus more on making great parts.

You have learned how the X, Y, and Z axes control CNC machines. Knowing how to move along each axis helps you make parts that fit well. It also helps your work go smoothly. Here are some important things to remember:

- Knowing the axes helps you work faster and more accurately.

- Lining up and setting the axes right stops expensive errors.

- Being good with axes can help you get better jobs and earn more money.

- Learning new things about axes keeps you ready for changes in technology.

Keep trying and look for new ways to learn. The more you know about cnc machines, the better your work and confidence will be.

FAQ

You use the X, Y, and Z axes to move tools or parts in three directions. X moves left and right. Y moves forward and backward. Z moves up and down.

You can picture a shoebox. Slide it left or right for X. Push or pull it for Y. Lift it up or down for Z.

You need to know axis directions to make accurate cuts. If you mix them up, your part may not match your design.

If you set the wrong axis, your tool may cut in the wrong place. This can ruin your part or waste material.

Yes. Some cnc machines have four or five axes. These extra axes let you make more complex shapes and reach more angles.

Check your machine’s reference point. Make sure all settings match your plan. If you see mistakes, rehome the machine and check for loose parts.

You can use axis setters, reference marks, and color-coded labels. These tools help you set up and check each axis before you start.