I’ve noticed that the cost of CNC drilling increases significantly once the drilled holes reach a certain depth. This is because increased drilling depth makes CNC machining more difficult, requiring specialised equipment and stricter safety measures. When the hole depth exceeds five times the hole diameter, tool alignment, chip removal, and cooling become very challenging. Consequently, the cost of CNC drilling rises rapidly.

Table of Contents

Deep Hole Drilling Defined

What Is Deep Hole Drilling?

Deep hole drilling is a specialised method for creating holes that are significantly deeper than their diameter. This process differs from regular drilling in that it requires advanced tools and specialised skills. A hole is called “deep” if its length is more than three times its width. But most experts use five times the width as the real limit. When a hole gets this deep, it needs more careful work.

Machining helps keep the hole the right size and shape. It also makes the surface smooth and the hole straight. Advanced CNC systems and special tools are used for this job. These tools help control the process and ensure the results are always satisfactory. Many industries need this level of control for their parts.

Tip: To get the best results in deep hole drilling, pick a machining company that knows how to use advanced CNC machines.

Depth-to-Diameter Ratio Explained

The depth-to-diameter ratio shows how hard it is to drill a hole. For example, a hole that is 100 mm deep and 10 mm wide has a ratio of 10:1. Regular drilling works well up to a ratio of 3:1. If the ratio goes over 5:1, it is deep hole drilling.

Here is a table that helps explain the ratios:

| Depth-to-Diameter Ratio | Description |

|---|---|

| Greater than 20 | Defines a deep hole |

| Commonly 100 | Achievable ratio in practice |

| 200 to 300 | Possible depths in deep hole drilling |

When the ratio gets bigger, the job gets harder. CNC machining suppliers have to watch out for tool bending, chip removal, and cooling. Machining technology helps solve these problems with steady tool movement and good chip removal.

Industry Standards and Applications

Deep hole drilling is important in many fields. There are strict rules for straightness, smoothness, and strength. Here is a table that shows where deep hole drilling is used and what each field needs:

| Industry | Applications | Specifications Required |

|---|---|---|

| Defense & Firearm | Gun barrels, breech blocks | Straightness, surface finish, and high stress |

| Medical | Orthopedic implants, bone screws | High surface finish, accuracy |

| Automotive | Fuel rails, pump barrels, fuel nozzles | Accurate bores, fluid flow |

| Aerospace | Landing gear shafts, structural components | High precision, structural integrity |

| Oil & Gas | Shafts, downhole tools | Durability, depth accuracy |

| Die & Mold | Cooling holes, ejector pins | Enhanced cooling performance |

| Power Transmission | Copper electrodes, steel pins | Specialised in electricity and mechanics |

Machining service provided by AFI parts can meet these tough needs. It gives the accuracy, repeatability, and quality that industries want. When planning a project, I always look at the depth-to-diameter ratio and the job to choose the best machining method.

Key Challenges in Deep Hole Drilling

Tool Deflection Issues

Impact on Accuracy

When I drill deep holes, tool deflection is a big problem. As the drill goes deeper, it is harder to keep it straight. The tool can wobble or bend more as it goes in. This makes the hole bigger than planned or not straight. If the drill tip does not hit the workpiece precisely, the hole can deviate from its intended path. Even a small mistake at the start can turn into a big problem by the end.

As the hole gets deeper, it is much harder to stay accurate. Longer tools can bend more easily. This makes the hole drift and hard to keep within tight limits. In fields like aerospace and medical, even a small error can make the part fail inspection.

Machining Solutions

To fix these problems, I use special tools and advanced machines. We pick drills with long, strong shanks that do not bend much. These tools have special cutting edges to keep them steady. We also use CNC machines that watch and change the tool path as they work. This helps keep the hole straight and within the needed size.

For example, deep hole machining uses single- and double-tube systems. These can go up to 250 surface feet per minute for most materials. With these systems, we can keep the hole size within ±0.003 inches and straightness within ±0.002 to 0.004 inches per foot. These numbers show how advanced machining can keep holes accurate, even when they are very deep.

Chip Evacuation Difficulties

Limited Space for Chips

Another big problem in deep hole drilling is chip evacuation. As we drill deeper, the chips have a long way to go to get out. The space inside the hole is small, so chips can get stuck. When chips block the flutes, friction and heat go up. This can break the tool or hurt the workpiece. I have seen chip problems stop production and cause more scrap.

In printed circuit board making and deep hole tapping, chips that do not leave fast can wrap around the tool. This makes it more likely for the tool to break and for parts to be bad. Chip evacuation gets harder as the depth-to-diameter ratio goes up.

Advanced Machining Techniques

To help chips get out, we use advanced machining methods. Here is a table that shows some ways I use:

| Technique | Description |

|---|---|

| Gun Drilling | Uses a long, thin drill with coolant inside and one flute for good chip removal. High-pressure coolant helps even more. |

| Orbital Drilling | Spins the tool around the hole, which lowers cutting force and helps chips escape, especially in hard materials. |

| Through-Coolant Tools | Sends coolant right to the cutting edge, pushing chips out and stopping clogs. |

Gun drilling works well for deep holes. The tool shape and high-pressure coolant move chips out fast. Orbital drilling lowers the force on the tool, so chips can leave the cutting area. Through-coolant tools are needed to flush chips out of deep holes and keep things running well.

Cooling and Lubrication Problems

Heat Buildup Risks

Heat is a big issue in deep hole drilling. As the tool cuts deeper, friction makes more heat. Without enough cooling, the tool wears out fast and the workpiece can get damaged. Bad lubrication can cause rough surfaces, wrong hole sizes, and even cracks. In dry drilling, no cutting fluid makes these problems worse. The surface gets rougher, and the tool can break more easily.

Machining Technology for Cooling

To control heat, we use advanced machining technology. Most deep hole drills have channels inside to send cutting fluid right to the edge. This fluid cools the tool and workpiece and helps chips get out. Special boring bars with coolant channels keep the cutting edge cool and slippery. Advanced coatings on tools also help lower wear and heat, making tools last longer.

We always pick the right cutting fluid for the material and job. The right fluid takes away heat, lowers friction, and protects the tool. This is very important for keeping the hole the right size and making a smooth finish.

Tip: Cutting fluid is very important in deep hole drilling. It controls heat, lowers tool wear, and helps get the best results.

Deep hole drilling has special problems that need careful planning and the right machines. By knowing these problems and using advanced technology, I can make good parts, even when the holes are very deep.

Maintaining Hole Quality

Tolerance and Surface Finish

When I do deep hole drilling, I focus on two things. I want to keep tight tolerances and get a smooth surface finish. These are important because they decide if the part will pass inspection. They also make sure the part works well when used. As the hole gets deeper, it is harder to keep the diameter the same. It is also tough to keep the surface free from marks or rough spots.

I always watch out for these problems:

- When the hole is deeper, the tool can wander more. This can make the diameter change.

- Even small changes in tool size or how it is lined up can cause big mistakes at the end.

- If chips or heat build up, the surface can get rough or even damaged.

To handle these problems, I use advanced machining methods and strict process control. I use automatic control systems that change the tool path as the machine works. This helps keep the hole straight and the diameter correct. I also use special math to check the process and find problems early.

Here are some important things I learned from new studies:

- Using math and time checks helps me make holes straighter and smoother.

- Changing feed and speed does not change quality as much as tool size or setup.

- Automatic control systems make the holes better than doing it by hand.

- Using data models helps me pick the best drilling settings.

- Deep microdrilling needs very careful control of hole size and tool size.

We always check the surface finish with special tools. We look for a shiny, even surface with no scratches or marks. If I see a problem, I fix the process right away.

Machining for Precision

We use machining solutions to get high precision in deep hole drilling. These solutions help me keep tight tolerances and a smooth finish. They work even with hard materials or tricky parts. I pick the right tools, machines, and controls for each job.

Here is a table that shows how machining helps with tolerance and surface finish:

| Aspect | Details |

|---|---|

| Time Reduction | Regular machining can take over 30 hours. Deep hole machining cuts this to 7.5 hours (an 80% reduction). |

| Tolerance | 70% of holes have a round inner diameter with a typical tolerance of 0.2mm and a diameter tolerance of 20 microns. |

| Operational Efficiency | Deep hole machining lets me do the job in one setup, which makes production faster for big batches. |

| Example Application | Oil exploration parts with tricky shapes need tight tolerances and a great surface finish, which special techniques can give. |

We always use advanced CNC machines that watch the process in real time. These machines let me make changes while drilling. This keeps the hole size right and the surface smooth. I also use special cutting fluids and coated tools to lower friction and wear.

Tip: I always say you should work with a machining partner who knows deep hole drilling. This helps you get the best quality and precision for your parts.

Keeping hole quality good is not just about the tools. It is about knowing the process, checking every step, and making changes when needed. With the right plan, I can make holes that meet the highest standards for tolerance and surface finish.

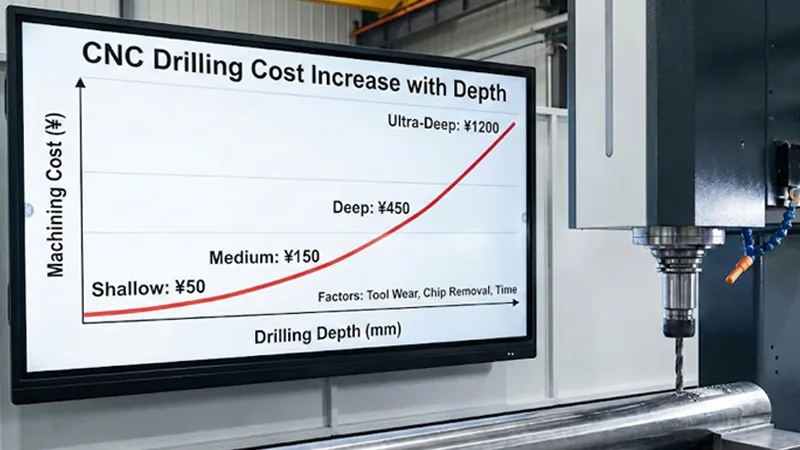

Why CNC Drilling Cost Rises with Depth

Slow Drilling Speeds

When we drill deep holes, I must slow down the drilling speed. The deeper the hole, the more careful I need to be. If I rush, the tool can bend or break. Slow speeds help me keep the tool straight and the hole accurate. This means each part takes longer to finish. As a result, the CNC drilling cost goes up because the machine spends more time on each hole.

I often see that deep hole drilling can take several hours for a single part. In comparison, shallow holes finish much faster. The extra time adds to labour and machine costs. When we plan a project, we always consider how slow speeds will affect the total CNC drilling cost. If I want to keep cost efficiency, I must balance speed and quality.

Note: Slower speeds are necessary for safety and accuracy, but they increase the total cost for each part.

Increased Tool Wear

As the drilling depth increases, the tool wear rate also accelerates. The longer the tool remains in the material, the more friction and heat it experiences. This extra wear means I need to apply more force to maintain good cutting performance. If the force becomes too great, I have to stop drilling and replace the tool. Each tool change increases the cost of CNC drilling.

Tool wear can also lead to increased cutting edge temperature. If the cutting fluid does not provide adequate cooling, the tool temperature will rise further, damaging both the tool and the workpiece. Tool wear also reduces accuracy, potentially preventing parts from meeting the required dimensions or shape, leading to more scrap and rework, and further increasing the cost of CNC drilling.

I’ve found that worn tools have a shorter lifespan and need to be replaced more frequently, which increases machining costs. In some cases, we have to use special coated tools or advanced machining strategies to reduce wear. These tools are more expensive, but they help maintain the stability of the machining process and ensure that part dimensions meet tolerance requirements.

Using advanced tool coatings and real-time monitoring technology during machining can extend tool life and reduce unexpected costs. This helps me control CNC drilling costs.

Need for Specialized Equipment

Deep hole drilling requires machines that can handle long, thin tools and high-pressure coolant systems. Standard CNC machines cannot always do this job. We need machines with special guides, supports, and coolant delivery systems. These features keep the tool steady and help remove chips from deep inside the hole.

Specialized equipment costs more to buy and maintain. We also need trained operators who know how to set up and run these machines. The setup time is longer, and the risk of mistakes is higher. All these factors add to the CNC drilling cost.

Here is a table that shows the difference between standard and specialized equipment:

| Equipment Type | Features Needed for Deep Holes | Impact on Cost |

|---|---|---|

| Standard CNC Machine | Basic spindle, standard coolant | Lower initial cost, not suitable for deep holes |

| Specialized Deep Hole Machine | Long tool support, high-pressure coolant, advanced controls | Higher purchase and maintenance cost, needed for deep holes |

When we use machining with the right equipment, we can achieve better results and reduce the risk of errors. This investment pays off in quality and reliability, but it does increase the CNC drilling cost for deep projects.

For more details on the cost impact of specialized equipment, industry sources like Modern Machine Shop and Production Machining provide further insights.

Deep hole drilling is a complex process. Each of these factors—slow speeds, tool wear, and specialized equipment—directly increases the CNC drilling cost. By using advanced machining solutions and careful planning, we can improve cost efficiency and deliver high-quality parts.

Labour and Setup Time

Labour and setup time are very important for the total CNC drilling cost of deep holes. Getting ready for deep hole drilling takes much longer than for shallow holes. We need to line up the workpiece very carefully. Setting up the machine and checking everything must be done before starting. Every step needs to be exact. If I make a mistake, the tool can break, or the part can fail.

We often use special fixtures and supports to keep the workpiece steady. These fixtures take extra time to put in and adjust. For deep holes, I cannot hurry this step. We check the alignment with gauges and sometimes use laser tools. This makes sure the hole is straight and meets the needed tolerance.

When we change from one part to another, we must do the setup again. Every new job means more time spent getting ready. In jobs with many different parts and small batches, setup time can be a big part of the total cost. For example, setting up for deep hole drilling can take hours, but drilling may only take one hour. This difference makes the CNC drilling cost higher, especially for small batches.

Skilled workers are needed for deep hole drilling. I trust machinists who know the process and can find problems early. Training new workers takes time and money. If I use less skilled workers, mistakes and scrap can happen more often. This adds to the total cost.

Here is a summary of how labor and setup time affect CNC drilling cost:

| Factor | Impact on Cost |

|---|---|

| Setup Time | Longer setup increases cost per part |

| Skilled Labor | Higher wages for experienced machinists |

| Fixture Preparation | Custom fixtures add time and expense |

| Job Changeover | Frequent changes increase downtime |

| Quality Checks | More inspections needed for deep holes |

Tip: I always say you should work with a machining partner who uses advanced CNC systems and standard setup steps. This helps lower setup time and stops costly mistakes.

Machining technology helps us control labor and setup costs. Automatic tool changers, digital setup sheets, and process monitors make preparation faster and cut down on errors. By using these tools, we can keep CNC drilling costs steady and fair, even for hard, deep hole jobs.

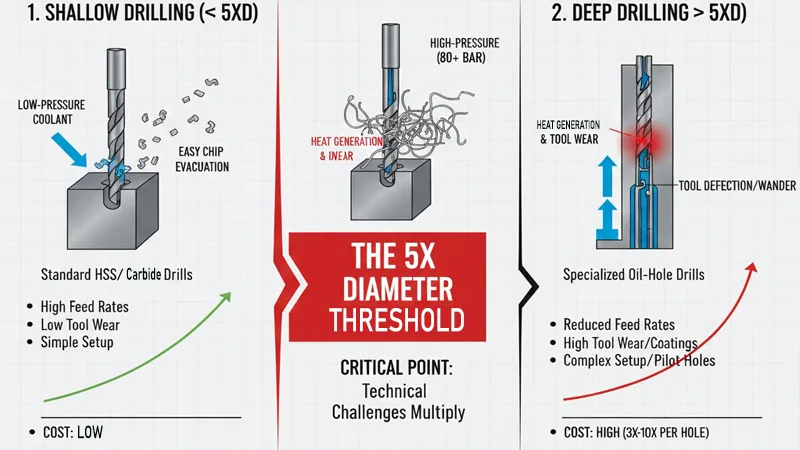

The Five-Times-Diameter Threshold

Exponential Cost Increase

When we drill a hole deeper than five times its diameter, we see costs rise much faster than before. This is not a small jump. The cost curve turns sharply upward. Industry research shows that after this threshold, the price per millimetre can double or even triple for each extra unit of depth. For example, a study from the International Journal of Advanced Manufacturing Technology found that tool wear, chip evacuation, and cooling challenges increase exponentially after the 5:1 ratio is passed (source). I have seen this in my own work. The deeper I go, the more I must slow down, change tools, and check the process. Each step adds time and expense.

Note: The five-times-diameter rule is not just a guideline. It is a proven limit where physics and engineering make the job much harder.

Comparing Shallow vs. Deep Drilling

We often compare shallow and deep drilling jobs to show clients why costs change so much. For a shallow hole, we can use standard CNC machines and basic drills. The process is quick. We can finish many parts in a short time. The risk of tool breakage is low. We do not need special cooling or chip removal systems.

When we drill a deep hole, everything changes. We need advanced machines with high-pressure coolant. We must use special drills that cost more. The setup takes longer. We must check the alignment many times. If I make a mistake, the part may become scrap. The time per part can be five to ten times longer than for a shallow hole.

Here is a simple comparison:

| Feature | Shallow Drilling (≤5xD) | Deep Drilling (>5xD) |

|---|---|---|

| Tool Cost | Low | High |

| Machine Requirement | Standard CNC | Specialized CNC |

| Cycle Time | Short | Long |

| Scrap Risk | Low | High |

| Cooling/Chip Removal | Basic | Advanced |

Real-World Cost Multipliers

In my experience, the cost jump is not just theory. I have seen real projects where the price per hole increased by three to five times once the depth passed the five-times-diameter mark. For example, drilling a 10 mm diameter hole to 50 mm depth might cost $10. Drilling the same diameter to 100 mm can cost $30 or more. If the depth reaches 200 mm, the price can exceed $100. These numbers match industry reports from Modern Machine Shop and Production Machining.

When I plan a job, I always warn clients about these multipliers. The deeper the hole, the higher the risk, time, and cost. After the five-times-diameter threshold, every extra millimeter adds much more to the total price.

I always recommend careful design review before committing to deep holes. Sometimes, changing the part design can save a lot of money. If deep holes are necessary, we use advanced machining solutions to control costs and deliver the best quality.

Machining Solutions for Deep Hole Drilling

Advanced CNC Technology

We use advanced CNC machines to solve hard drilling problems. These machines let me control every step closely. We can set the speed, feed, and tool path exactly. This helps me keep holes straight and within tight limits. Our machines have high-pressure coolant and special supports for long tools. These features keep the tool cool and steady, even for deep holes.

Switching to advanced CNC machines can change a project a lot. For example, an automotive supplier in Chennai used to drill with twist drills. They switched to a U-Drilling SPM. The cycle time dropped from 180 seconds to 80 seconds. The first-pass yield went up to 99.6%. The company got its money back in less than nine months. These results show that advanced CNC machines help with quality and cost.

- Cycle time goes down, and output goes up.

- Accuracy and first-pass yield get better.

- Investment pays off fast.

Material Selection and Heat Treatment

Picking the right material is very important for deep hole drilling. We always match the material to the job. If we choose wrong, the tools wear out faster, and the holes may not be good. This means higher costs and more downtime. We keep learning about new materials and treatments to get better results.

Heat treatment is also important. It changes how hard and tough the workpiece is. For tough materials like Ti6Al4V, we use special cooling methods. Cryogenic coolants work well. They are safer for workers and better for the environment than old fluids. These coolants help tools last longer and keep drilling stable. Using the right material and heat treatment means fewer tool changes and better holes.

- Good material makes drilling better and costs less.

- Advanced heat treatment and cooling help tools last longer.

- Learning about new materials helps me do better work.

Process Control for Quality

We use strict process control to keep quality high when drilling deep holes. Automation and robots help me stay consistent. Robots follow set rules and do not get tired or make mistakes. This means every hole meets the same high standard.

Here is a table that shows how process control helps:

| Evidence Description | Key Points |

|---|---|

| Role of Automation and Robotics | Makes drilling more accurate and consistent |

| Precision of Automated Systems | Robots stick to set rules |

| Consistency Over Manual Ops | No human error, good for making many parts |

| Faster Production Cycles | Less manual work, more parts made faster |

| Flexibility of Automation | Easy to change for new jobs |

We check every step with sensors and data tracking. If something goes wrong, we can fix it quickly. This keeps scrap rates low and quality high. We trust automation to help us get the best results for every project.

Tip: I always say you should use advanced process control and automation for deep hole drilling. This makes sure every part meets top standards.

Partnering with Machining Experts

I always say it is smart to work with machining experts for deep hole drilling. From my experience, these experts do more than just use fancy machines. They bring great skill and make sure the work is very reliable. When I team up with specialists, every step of the job gets better.

Machining experts use automated systems to keep holes straight and accurate, even when drilling very deep. They know how to pick the right tools and set up machines for each job. This skill means there are fewer mistakes and less wasted material. I trust their knowledge to help me avoid expensive errors and delays.

Here is a table that shows the main benefits of partnering with machining experts:

| Benefit | Description |

|---|---|

| Precision and Accuracy | Automated operations ensure precise depth-to-diameter ratios, crucial for industries like aerospace. |

| Improved Surface Finish | Specialized tools and setups provide superior surface quality, reducing friction and wear. |

| Enhanced Tool Life | Durable tools reduce the need for frequent changes, saving costs and increasing productivity. |

| Superior Straightness | Achieves straight holes at extreme depths, surpassing conventional drilling methods. |

| Versatility | Suitable for various applications with stringent requirements and unique challenges. |

I have seen these benefits make a big difference. For example, I worked with machining specialists on an aerospace project. We got holes that were straighter and smoother than normal drilling could do. The tools lasted longer, and the parts passed inspection the first time.

Tip: I always tell people to pick a machining partner who has done deep hole drilling before. Their experience helps you avoid mistakes and makes sure your project meets all the rules.

Machining experts are also very flexible. They can work with many types of materials and part shapes. This is important for projects with tough standards or special problems. We should count on their quick thinking to solve problems fast.

Planning for Deep Hole Drilling Projects

Equipment and Budgeting

When we plan a deep hole drilling job, I pick the right machine first. The machine we choose changes how good the work is and how much it costs. We look for machines that can drill as deep and wide as we need. We check if the machine has strong supports for long tools and high-pressure coolant. These things help keep drilling safe and steady.

We think about the total cost, not just the price we pay at first. We know regular maintenance is important. It keeps the machine working well and helps me find problems early. We make a schedule for checking the machine and use special tools to spot issues before they get worse. We also look at where the machine will be used. Dust, heat, and wet air can make machines wear out faster.

Here is a simple table I use to compare equipment choices:

| Equipment Option | Initial Cost | Maintenance Cost | Total Cost of Ownership |

|---|---|---|---|

| Option A | High | Low | Medium |

| Option B | Medium | Medium | Medium |

| Option C | Low | High | High |

We always pick the choice that saves money in the long run, not just the cheapest one.

Timeline and Risk Management

Making a good schedule is just as important as picking the right machine. We plan every step, from setup to checking the finished part. We know delays can cost a lot, so we add extra time in case something goes wrong.

Risk management is a big part of my plan. We use data about the ground and old jobs to find problems early. If a hole is dry or not in the right spot, we have a plan to stop and move on. This keeps my budget safe and lets me spend money on new jobs. We also keep track of all costs, even ones that are hard to see, like tool wear and machine breaks.

Here is a checklist we use for risk and timeline planning:

- Check the ground and material data before drilling.

- Add extra time for surprises.

- Track every cost, even hidden ones.

- Make a backup plan for bad holes or broken machines.

- Use tax rules to get some money back and keep cash steady.

Consulting Machining Specialists

When collaborating with experts, you can obtain advice on equipment setup, tool selection, and process control. They help clients develop quality control plans and provide solutions to improve work efficiency.

Tip: I always say you should talk to machining experts early when planning. Their advice can save time, cut costs, and help you meet all the rules.

By following these steps, you can control the budget for deep hole drilling projects, complete the work on time, and achieve high standards.

| Aspect | Benefit |

|---|---|

| Tool Design | Makes the bore hole better |

| Process Stability | Less shaking, drilling stays the same |

| Equipment | Advanced machines give better results |

Summary

In conclusion, CNC drilling costs are determined by a combination of factors, including material selection, design complexity, hole depth-to-diameter ratios, and production scale. While high precision and intricate designs naturally command higher prices, significant savings can be achieved during the design phase.

By implementing Design for Manufacturing (DFM) principles—such as standardising hole sizes, avoiding unnecessarily tight tolerances, and selecting materials with better machinability—you can achieve an optimal balance between performance and cost-efficiency. Ultimately, partnering with an experienced manufacturer who provides proactive technical guidance is the most effective way to ensure your project remains within budget without compromising on quality.

FAQ

The total cost typically consists of four main components: Setup Fees, Material Costs, Machining Time (hourly rate), and Post-Processing. According to industry standards, machine time is the primary driver, ranging from $30 to $100 per hour depending on machine complexity and labour rates. Larger production volumes significantly reduce the setup fee distributed per part

Several “cost drivers” can spike your quote:

- Deep-Hole Drilling: If the hole depth exceeds 4x the diameter, it requires multiple “peck” cycles to clear chips, doubling the machining time.

- Hard Materials: Materials like Stainless Steel or Titanium accelerate tool wear and require slower cutting speeds.

- Tight Tolerances: Demanding tolerances below ±0.05mm require high-precision equipment and frequent inspection, adding significant labour costs.

You can lower costs by implementing these three strategies:

- Use Standard Hole Sizes: Design for standard drill bit diameters so the factory doesn’t have to purchase or grind custom tooling.

- Minimise Setup Changes: Ensure all holes are on the same plane (or as few planes as possible) to reduce the time spent repositioning the workpiece.

- Avoid Deep Blind Holes: Opt for through-holes where possible, or keep blind hole depths reasonable to simplify chip removal.

Material choice has a massive impact. Aluminum (e.g., 6061) is highly machinable, allowing for fast cutting speeds and long tool life, making it the most cost-effective. In contrast, Stainless Steel or Tool Steel requires slower speeds and risks breaking expensive carbide drills. Choosing free-machining alloys is the fastest way to cut your budget if high strength isn’t critical.

This is due to Fixed Setup Costs. Whether you need 1 hole or 1,000, an engineer must spend time programming the CNC, installing tools, and calibrating the machine. In small batches, these fixed costs are borne by only a few parts; in mass production, they are diluted, drastically lowering the price per unit.

For high-precision, multi-hole, or complex parts, CNC is far more cost-effective. While the initial setup fee is higher, its speed, consistency, and extremely low scrap rate make it the superior choice for production runs exceeding 10–20 parts. Additionally, CNC can handle combined operations like tapping and countersinking in a single cycle.

The Aspect Ratio (L:D) is a critical quoting metric. Generally, a ratio below 4:1 is considered standard. Once the ratio exceeds 10:1, it is categorised as “Deep-Hole Drilling,” requiring specialised equipment (like gun drills) and high-pressure cooling systems, which causes the price to increase exponentially.