Chrome plated brass fittings are strong and shiny. They are good for plumbing jobs. Chrome on brass stops rust and helps fittings last longer. These fittings work well in kitchens and bathrooms. They are also good for stores and restaurants. The shiny look is nice and easy to clean. When you pick brass fittings, check for safety labels.

NSF/ANSI/CAN Standard 61 now says six brass rod alloys are okay for drinking water parts. This means they meet rules for less lead.

| Certification | Description |

|---|---|

| NSF 61 | Makes sure drinking water parts are safe to use. |

| NSF 372 | Checks the lead in drinking water parts. It makes sure they meet lead rules. |

You should buy lead-free brass and look for NSF61 labels. This guide will help you choose the right chrome fittings.

Key Takeaways

- Chrome plated brass fittings are tough and shiny. They work well for plumbing in kitchens and bathrooms.

- Check for NSF/ANSI 61 labels. This shows the fittings are safe for drinking water. It also means they do not have lead.

- The chrome layer keeps brass from rusting or getting dull. This helps the fittings last longer.

- Pick the right size and thread type for your pipes. This stops leaks and makes sure the fit is tight.

- Clean chrome fittings often with a soft cloth. This keeps them looking new and stops stains.

- Chrome plated brass fittings can be used in many ways. They work for plumbing and for decoration.

- Always buy from trusted suppliers. This makes sure you get good quality and safe products.

- Check your fittings often for damage. Replace them if you see scratches or rust to keep things safe.

Table of Contents

Chrome Plated Brass Overview

What Are Chrome Plated Brass Fittings

You will find that chrome plated brass fittings combine two strong materials. The base is brass, which is a mix of copper and zinc. On top of this, a thin layer of chrome covers the surface. This layer gives the fittings a shiny look and helps them last longer. The chrome finish also protects the brass from rust and tarnish. You can see the difference between chrome plated brass and unplated brass in the table below:

| Feature | Chrome Plated Brass Fittings | Unplated Brass Fittings |

|---|---|---|

| Base Material | Brass (Copper and Zinc alloy) | Brass (Copper and Zinc alloy) |

| Additional Coating | Layer of Chromium for enhanced aesthetics and corrosion resistance | No additional coating |

| Corrosion Resistance | Higher due to chrome plating | Lower, more susceptible to tarnishing |

You get a fitting that looks good and works well in many places.

Chrome Plating Process

The chrome plating process uses several careful steps to make sure each fitting meets high standards. You can follow these steps to understand how manufacturers create the shiny and tough surface:

- Buff and polish the brass fittings.

- Clean the surface to remove any dirt or oil.

- Dip the fittings in acid to prepare the surface.

- Add zinc and copper plating layers.

- For show chrome, re-buff and clean again.

- Re-dip and apply two to three types of nickel plating.

- Apply the chrome plating and rinse between each step.

Tip: Manufacturers check each fitting for a smooth finish and strong bond. They measure the thickness of the chrome and test how well it sticks to the brass.

This process uses electroplating. The chrome bonds tightly to the brass, making the fittings strong and shiny. You get a product that resists scratches and keeps its bright look for a long time.

Common Uses

You can use chrome-plated brass fittings in many industries. These fittings work well because they look good and last a long time. Here are some common places where you will find them:

| Industry | Application Examples |

|---|---|

| Decorative Arts | Cabinet pulls, sink faucets |

| Plumbing | Pipes, faucets, shower heads, and other fittings |

| Musical Instruments | Saxophones, trumpets |

| Automotive | Door handles, emblems, trims |

You often see chrome in kitchens and bathrooms because it matches other shiny fixtures. In plumbing, chrome plated brass fittings resist water and do not rust easily. You also find them in cars and musical instruments because they keep their shine and do not wear out quickly.

Benefits of Chrome Plated Brass

Corrosion Resistance

You want fittings that last a long time. Chrome plated brass stops rust and damage. The chrome layer works like a shield. Water, air, and cleaners cannot hurt the surface much. Brass alone fights rust, but chrome makes it stronger. You can use these in kitchens and bathrooms. They work well in other wet places too. Chrome finish stays shiny and does not wear out fast. Chrome finish faucets keep their bright look for many years. Chrome bathroom faucets do not stain or tarnish easily. If you need plumbing fittings, chrome plated brass is a smart pick. You will not worry about rust or stains. Corrosion resistance means you fix or replace them less.

Tip: Pick chrome finish fixtures for wet areas. You will see less rust and more shine.

Durability

You need fittings that last through daily use. Chrome plated brass is very strong. The brass base gives it power. The chrome finish adds a hard layer. You can put these in busy kitchens or bathrooms. Chrome finish fixtures do not chip or crack easily. You can clean them often without harm. Chrome finish faucets work well even after lots of use. Chrome kitchen faucets and bathroom faucets last for years. Chrome plated brass fittings last longer than plastic or plain brass. You save money because you do not replace them often.

- Chrome finish fixtures do not scratch easily.

- Chrome plated brass fittings stay strong under pressure.

- Chrome finish faucets stay shiny after many cleanings.

Chrome Finish Appeal

You want your rooms to look nice. Chrome finish gives a bright, shiny look. Chrome finish fixtures add style to kitchens and bathrooms. You see chrome finish faucets in new homes and restaurants. Chrome kitchen faucets and bathroom faucets look modern and sleek. Many people pick chrome because it matches other shiny things. Chrome finish makes fittings stand out. You get a fancy and classy look.

Here is what people say about chrome finish appeal:

| Application | Visual Appeal Description |

|---|---|

| Decorative chrome plating | Shiny, mirror-like surface adds style and class |

| Chrome finish faucets | Polished, shiny look feels fancy and modern |

| Chrome finish fixtures | Bright, shiny, and reflective finish looks great |

Chrome finish fits many styles. You can use it in modern or classic rooms. Chrome finish fixtures catch light and make rooms look clean. Chrome plated brass fittings look new for a long time. Chrome finish does not fade or get dull fast. If you want good-looking and strong fittings, chrome plated brass is a great choice.

Versatility

You want plumbing parts that work in many places. Chrome plated brass gives you this flexibility. You can use these fittings in homes, restaurants, and stores. Chrome makes the fittings strong and shiny. You can trust them in kitchens, bathrooms, and even outdoor spaces.

Chrome finish helps fittings handle tough jobs. You can use them with hot or cold water. Chrome does not peel or fade when you clean it often. You can match chrome with many styles. Modern, classic, or industrial rooms all look good with chrome. You can use chrome in wet or dry areas. Chrome finish does not stain or rust easily.

You can use chrome plated brass fittings in many systems. These include water, air, and even some gas lines. Chrome finish protects the brass inside. You get a fitting that works well and looks great. You can use these fittings in both high and low temperatures. Chrome finish keeps the fittings safe from damage.

Here is a table that shows how chrome plated brass fittings compare to other types. You can see the temperature and pressure ranges for each type:

| Fitting Type | Temperature Range | Pressure Rating |

|---|---|---|

| Chrome Plated Brass | -20°F to 350°F | Up to 125 psi |

| Brass Fittings | -650°F to +2500°F | Up to 1200 psi |

| Brass Hose Barb Fittings | -400°F to +1600°F | 150 PSI maximum |

You can see that chrome plated brass fittings work in a wide range of temperatures. You can use them in cold or hot water lines. Chrome finish helps the fittings last longer, even when you use them every day. You can trust chrome in places where you need both strength and style.

You can also use chrome plated brass fittings with many types of pipes. These include copper, plastic, and steel pipes. Chrome finish makes it easy to clean the fittings. You can wipe them with a soft cloth. Chrome does not need special cleaners. You can keep your fittings looking new with little effort.

Note: You can use chrome plated brass fittings in many projects. You get a strong, shiny, and easy-to-clean part. Chrome finish helps you save time and money because you do not need to replace the fittings often.

You can choose chrome for many reasons. Chrome finish gives you a bright look. Chrome protects the brass inside. Chrome makes fittings last longer. You can use chrome in many places and for many jobs. Chrome finish helps you get the best value for your money.

Types of Brass Fittings

When you look for brass fittings, you will find many types. This guide to fitting types helps you pick the right one for your project. Chrome plated brass fittings give you strong connections and a shiny finish. You can use these fittings in water, air, and gas systems. Let’s explore the main types of brass fittings you will see.

Compression

Compression fittings help you make a tight connection without soldering. You use a nut and a ring (called a ferrule) to seal the joint. You can install these fittings with simple tools. Compression fittings work well for water lines and gas pipes. You often see them under sinks or behind toilets. Chrome finish makes these fittings easy to clean and keeps them looking new.

- You use compression fittings for copper, plastic, or brass pipe fittings.

- These fittings stop leaks and hold strong under pressure.

- Chrome plated brass compression fittings resist rust and stains.

Tip: Always check that the ferrule fits snugly on the pipe. This helps you get a leak-free connection.

Flare

Flare fittings give you a safe and strong connection for high-pressure jobs. You use a special tool to flare the end of the pipe. The fitting then screws onto the flared end. You see flare fittings in gas lines and refrigeration systems. Chrome finish protects the fitting from damage and makes it easy to spot leaks.

- Flare fittings work with brass pipe fittings and copper pipes.

- You use flare fittings for gas, oil, and air connections.

- Chrome plated brass flare fittings last longer in tough jobs.

You can trust flare fittings for gas appliances. The chrome finish helps you see if the fitting is clean and tight.

Pipe

Pipe fittings connect straight pipes or change the direction of flow. You use these fittings in plumbing, heating, and gas systems. Brass pipe fittings come in many shapes. Chrome finish makes them look good and stops rust.

Elbow

Elbow fittings let you turn the pipe at an angle. You use elbows to fit pipes around corners. Chrome plated brass elbows work in tight spaces and keep the connection strong.

- Elbow fittings come in 45° and 90° angles.

- You use elbows in water, air, and gas lines.

Tee

Tee fittings help you split the flow into two directions. You use tees to branch off a main line. Chrome finish makes tees easy to clean and keeps them shiny.

- Tee fittings work in plumbing and gas systems.

- You use tees to connect three pipes together.

Coupling

Coupling fittings join two pipes in a straight line. You use couplings to extend the length of a pipe. Chrome plated brass couplings give you a strong and leak-free connection.

- Coupling fittings work with brass connectors and brass pipe fittings.

- You use couplings in water, air, and gas lines.

Note: Many types of brass pipe fittings are available with chrome plating. You get a fitting that looks good and lasts longer.

You can use chrome plated brass fittings for many jobs. These fittings work in homes, restaurants, and shops. You get strong connections and a bright finish. Chrome makes your fittings easy to clean and keeps them looking new.

Hose Barb

You will often see hose barb fittings when you need to connect flexible hoses to pipes or other plumbing parts. These fittings have a ridged or barbed end that grips the inside of a hose. You push the hose onto the barb, and the ridges hold it tight. Sometimes, you add a clamp for extra security. Hose barb fittings work well in water, air, and low-pressure gas systems.

You can use brass hose barb fittings in many places. They resist rust and last a long time. Chrome plated brass hose barb fittings look shiny and clean. You can use them in kitchens, bathrooms, and outdoor spaces. The chrome finish makes cleaning easy. You can wipe the surface with a cloth, and it stays bright.

Here are some common uses for hose barb fittings:

- Connecting water supply lines to appliances

- Joining hoses in garden irrigation systems

- Attaching air hoses in workshops

- Linking tubing in beverage machines

Tip: Always check that the hose fits snugly over the barb. Use a clamp if you need a stronger hold.

You can find hose barb fittings in many sizes. You can match them to different hose diameters. Chrome plated brass hose barb fittings give you a strong and leak-free connection. You can trust them in places where you need both strength and style.

| Feature | Hose Barb Fittings | Chrome Plated Brass Hose Barb |

|---|---|---|

| Material | Brass | Brass with chrome finish |

| Rust Resistance | Good | Excellent |

| Appearance | Plain | Shiny and clean |

| Common Use | Water, air, gas | Water, air, beverage systems |

You can use hose barb fittings for many jobs. You get a part that works well and looks good.

Caps and Adapters

Caps and adapters help you finish or change your plumbing system. You use caps to close the end of a pipe or fitting. This stops water, air, or gas from leaking out. You use adapters to connect two different types or sizes of fittings. Adapters help you join pipes with different threads or diameters.

Brass caps and adapters give you strong and safe connections. Chrome plated brass caps look shiny and resist rust. You can use them in kitchens, bathrooms, and commercial spaces. The chrome finish matches other fixtures and makes cleaning easy.

Here are some ways you can use caps and adapters:

- Sealing unused pipe ends

- Connecting pipes with different threads

- Joining pipes of different sizes

- Adapting fittings for special equipment

Note: Always pick caps and adapters that match your pipe size and thread type. This helps you avoid leaks.

You can find brass caps and adapters in many shapes. Chrome plated brass caps and adapters work well in wet areas. You can trust them to last a long time. The chrome finish keeps them looking new.

| Type | Use Case | Chrome Plated Brass Option |

|---|---|---|

| Cap | Seal pipe ends | Yes |

| Adapter | Join different fittings | Yes |

You can use caps and adapters to make your plumbing system safe and flexible. Chrome plated brass fittings give you both strength and style.

Guide to Selecting Brass Fittings

Size

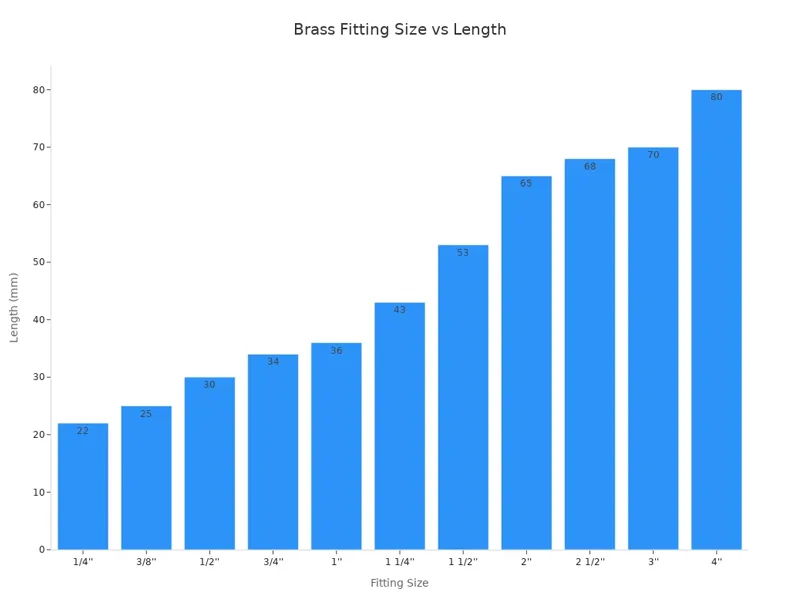

You need to pick the right size when choosing chrome plated brass fittings. The size affects how well the fitting connects to your pipes. If you choose the wrong size, you may get leaks or weak joints. Most brass fittings come in standard sizes for both residential and commercial plumbing. You will see sizes measured in inches, such as 1/4″, 3/8″, 1/2″, and up to 4″. Each size fits a specific pipe diameter.

Here is a table that shows common sizes and their lengths:

| Size | G | L |

|---|---|---|

| 1/4” | 1/4” | 22 |

| 3/8” | 3/8″ | 25 |

| 1/2” | 1/2″ | 30 |

| 3/4” | 3/4″ | 34 |

| 1” | 1″ | 36 |

| 1 1/4” | 1 1/4″ | 43 |

| 1 1/2” | 1 1/2″ | 53 |

| 2” | 2” | 65 |

| 2 1/2” | 2 1/2″ | 68 |

| 3” | 3″ | 70 |

| 4” | 4″ | 80 |

You can also see the size range in this chart:

You should always measure your pipe before buying. This helps you get the right size and avoid problems during installation. If you use the correct size, your chrome finish fittings will seal tightly and last longer. You will also get the best performance from your plumbing system.

Tip: Double-check the size on both the fitting and the pipe. This simple step can save you time and money.

Thread Type

You must also pay attention to the thread type. Threads help connect fittings to pipes and keep them leak-free. The two most common thread types are NPT (National Pipe Thread) and BSP (British Standard Pipe). These threads look similar, but they do not fit together. If you mix them, you may get leaks or damage your fittings.

Here is a table that compares NPT and BSP threads:

| Thread Type | Compatibility | Sealing Method |

|---|---|---|

| NPT | Not directly compatible with BSP | Interference fit with sealants like PTFE tape |

| BSP | Not directly compatible with NPT | Can use sealing washers or O-rings |

- NPT threads need Teflon tape or a sealing compound for a leak-proof seal.

- BSP threads can use sealing washers or O-rings, which makes installation easier.

NPT threads have a tapered shape. You need to wrap the threads with Teflon tape to stop leaks. BSP threads can be parallel or tapered. If you use parallel BSP threads, you can add a washer or O-ring for a better seal. Always match the thread type on your fitting to the pipe. This helps you avoid leaks and makes your chrome finish fittings last longer.

Note: If you are not sure about the thread type, check the markings on the fitting or ask your supplier.

Application

You need to think about your application requirements before you choose brass fittings. The right fitting depends on where and how you plan to use it. Chrome plated brass works well in many places, but you should match the fitting to your needs.

Here are some key points to consider:

- Resistance to corrosion: Chrome finish protects the brass and keeps it clean. This is important for drinking water and food service.

- Durability: Brass fittings can handle high pressure and last a long time. You can use them in both home and industrial settings.

- Easy installation: Chrome finish fittings are simple to install. You do not need special tools.

- Variety of sizes and shapes: You can find fittings for almost any job. This helps you meet your application requirements.

- Recyclable: Brass is good for the environment because you can recycle it.

- Aesthetically pleasing: Chrome finish looks shiny and matches modern fixtures.

- Cost-effective: Brass fittings cost less than stainless steel but still offer high quality.

You should also check the pressure rating & temperature range for your system. Chrome finish fittings work well in most home plumbing, but you need to make sure they fit your operating pressure & temperature. Always choose high-quality fittings that meet safety standards, especially for potable water.

Tip: For drinking water, look for fittings marked as lead-free and NSF61 certified. This keeps your water safe and clean.

Material Grade

You need to pay close attention to the material grade when you choose brass fittings. The grade tells you how strong and safe the brass is. Different grades of brass have different amounts of copper and zinc. Some grades also include small amounts of other metals to improve strength or resistance to corrosion.

You will often see grades like CW614N, CW617N, and DZR (dezincification resistant) brass. DZR brass is a smart choice for water systems because it resists damage from water and chemicals. If you use regular brass in places with hard water, you might see the fittings weaken over time. DZR brass fittings last longer and keep your water safe.

| Brass Grade | Main Feature | Common Use |

|---|---|---|

| CW614N | Easy to machine | General plumbing |

| CW617N | Good for forging | Valves and pipe fittings |

| DZR Brass | Resists corrosion and wear | Drinking water systems |

You should always check if the fittings are lead-free. Lead-free brass keeps your water safe for drinking. Look for NSF61 certification on the fittings. This label means the brass meets strict safety rules. You can trust these fittings in your kitchen or bathroom.

Tip: Pick DZR brass for areas with hard water or high pressure. You will see fewer problems and get longer life from your fittings.

Chrome Finish Options

You have several chrome finish options when you select brass fittings. The chrome finish does more than make the fittings look shiny. It adds a strong layer that protects the brass from rust and scratches. You can use chrome finish fittings in wet places like kitchens and bathrooms. The chrome finish keeps the fittings looking new, even after many cleanings.

Manufacturers use different chrome finish styles. You might see polished chrome, satin chrome, or brushed chrome. Polished chrome finish gives you a mirror-like shine. Satin chrome finish looks softer and hides fingerprints. Brushed chrome finish has fine lines and a modern look. Each style matches different room designs and fixtures.

Chrome finish improves both durability and appearance. The chrome finish acts as a shield against water and air. You can use these fittings in places with harsh conditions. The chrome finish prevents rust and keeps the fittings strong. You will notice that the chrome finish stays bright and does not fade, even with daily use.

| Chrome Finish Type | Appearance | Best Use Area |

|---|---|---|

| Polished Chrome | Mirror-like shine | Kitchens, bathrooms |

| Satin Chrome | Soft, matte look | Modern spaces |

| Brushed Chrome | Textured surface | Industrial settings |

You should match the chrome finish to your other fixtures. If your faucet has a polished chrome finish, pick fittings with the same shine. This gives your room a clean and unified look. Chrome finish fittings are easy to clean. You can wipe them with a soft cloth. You do not need special cleaners.

Note: Chrome finish not only makes brass fittings look good but also helps them last longer. You get both style and strength in one product.

Comparing Chrome Plated Brass

Stainless Steel

You may wonder how chrome plated brass compares to stainless steel. Both materials look shiny and resist rust, but they have important differences. Stainless steel has a higher tensile strength. This means it can handle more pressure and force. You will find stainless steel fittings in places that need extra strength, such as industrial kitchens or hospitals.

Chrome plated brass fittings offer good corrosion resistance, but stainless steel resists rust even better. The chromium layer in stainless steel protects it from water and air. Chrome plated brass can oxidize over time, especially if the chrome layer wears down. Stainless steel does not need extra plating to stay strong.

Cost is another key difference. Chrome plated brass is easier to machine and costs less. Stainless steel fittings are usually more expensive. If you want a strong fitting for a tough job, stainless steel works well. If you want a shiny look and good value, chrome plated brass is a smart choice.

Here is a table that shows the main differences:

| Property | Chrome Plated Brass | Stainless Steel |

|---|---|---|

| Strength | Tensile Strength: 338 – 469 MPa | Tensile Strength: 621 MPa |

| Corrosion Resistance | Lower than stainless steel; oxidizes | High resistance due to chromium layer |

| Cost | More cost-effective to machine | Generally more expensive |

Tip: Choose stainless steel for high-pressure jobs. Pick chrome plated brass for style and savings.

Plain Brass

You may see plain brass fittings in many plumbing systems. Plain brass does not have a chrome layer. It looks duller but lasts a long time. Chrome plated brass fittings give you a shiny finish and lower maintenance at first. You do not need to polish them often. Over time, the chrome layer may wear off. You might need to reapply the plating, which can cost more.

Plain brass fittings resist corrosion better than chrome plated brass. They work well in places with lots of moisture. You may need to polish plain brass to keep it looking good, but it will last longer. Brass fittings handle stress and humidity better. You can trust them in tough plumbing jobs.

- Chrome plated brass fittings look shiny and need less cleaning at first.

- Plain brass fittings last longer and resist rust better.

- Brass fittings work well in wet places and high-stress jobs.

- Chrome may need reapplication, which adds to long-term costs.

- Plain brass needs regular polishing but saves money over time.

Note: Use plain brass for long-lasting jobs. Choose chrome plated brass for easy cleaning and style.

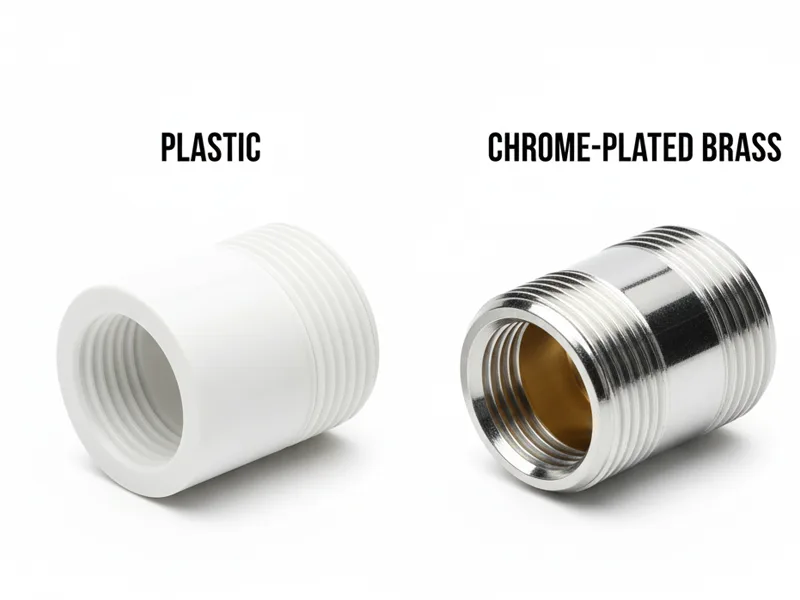

Plastic

Plastic fittings are common in home plumbing. You may like them because they cost less and weigh less. Plastic fittings are easy to install. You do not need special tools. Many people use plastic for DIY projects.

Plastic fittings have some drawbacks. They do not last as long as chrome plated brass. You may need to replace them more often. Plastic can break under high pressure. Some plastic fittings may leach chemicals into water, which is not safe for drinking. Recycling plastic fittings is hard, which can harm the environment.

Brass fittings are strong and resist corrosion. Chrome plated brass fittings look shiny and last longer than plastic. You may pay more for brass, but you save money because you do not replace them as often.

- Plastic fittings cost less and are easy to handle.

- Plastic fittings need less energy to make.

- Plastic fittings are light and simple to install.

- Plastic fittings break more easily and may not be safe for drinking water.

- Brass fittings are strong and resist rust.

- Chrome plated brass fittings last longer and look better.

- Brass fittings save money over time because you replace them less.

Tip: Use plastic fittings for quick, low-cost jobs. Pick chrome plated brass for strength, safety, and style.

Price Range

When you shop for plumbing fittings, price often guides your decision. Chrome plated brass fittings usually cost more than plastic fittings but less than stainless steel. You get a balance between quality and value with brass. The chrome finish adds a small extra cost, but you gain a shiny look and better protection against rust.

You might see price differences based on the type of fitting. Elbows, tees, and couplings made from brass with a chrome finish often cost more than plain brass fittings. The extra step of chrome plating increases the price. Stainless steel fittings cost the most because they use expensive materials and require more work to produce. Plastic fittings cost the least, but you trade strength and durability for savings.

Here is a simple table to help you compare average prices:

| Fitting Material | Average Price (per piece) | Durability Level | Appearance |

|---|---|---|---|

| Chrome Plated Brass | $3 – $8 | High | Shiny, modern |

| Plain Brass | $2 – $6 | High | Dull, classic |

| Stainless Steel | $5 – $12 | Very High | Shiny, premium |

| Plastic | $0.50 – $2 | Low | Basic, matte |

You should think about your budget and the job before you buy fittings. If you want a strong fitting that looks good, chrome plated brass gives you good value. You pay a little more than for plastic, but you get a fitting that lasts longer and resists rust. Stainless steel works best for places with high pressure or where you need extra strength. You pay more up front, but you may not need to replace the fitting for many years.

Plastic fittings help you save money on simple jobs. You can use them for temporary fixes or low-pressure lines. If you need fittings for drinking water or places that get wet often, brass is a safer choice. Chrome plated brass fittings meet safety standards and look clean in kitchens and bathrooms.

Tip: Always check if the fittings are lead-free and certified for drinking water. You protect your health and get better quality.

You may notice that some suppliers offer discounts for buying fittings in bulk. You can save money if you plan a big project. Brass fittings with a chrome finish often come in sets for kitchens or bathrooms. These sets help you match the look of all your fixtures and save on the total price.

When you compare price ranges, remember to look at long-term costs. Chrome plated brass fittings last longer than plastic, so you replace them less often. You spend a little more now, but you save money over time. Stainless steel costs the most, but you get the highest durability. Plain brass fittings cost less than chrome plated brass, but you may need to polish them to keep them looking good.

Choose fittings that fit your budget and your needs. Chrome plated brass gives you a strong, safe, and stylish option for most jobs.

Quality and Safety Standards

Certifications

You should always check for certifications when you buy chrome plated brass fittings. Certifications show that the fittings meet strict safety and quality rules. The most important ones for drinking water are NSF/ANSI 61 and NSF/ANSI 372. These standards make sure that the chrome finish and the brass inside do not add unsafe chemicals to your water. You can trust fittings with these marks for home and business use.

Here is a quick look at key certifications:

| Certification | What It Means |

|---|---|

| NSF/ANSI 61 | Safe for drinking water; limits harmful chemicals |

| NSF/ANSI 372 | Checks lead content; must be very low |

| ISO, ASTM, EN | Show global quality and safety standards |

Tip: Always look for these marks on the packaging or ask your supplier for proof. Certified chrome fittings give you peace of mind.

Lead-Free

Lead-free rules protect your health. You want to keep your water safe, so you need to know about lead limits in brass. The U.S. Safe Drinking Water Act says that brass fittings for drinking water must have no more than 0.25% lead by weight. This rule follows NSF/ANSI 61 and 372. Europe and China also have strict rules for lead in chrome and brass products.

- U.S. law: 0.25% lead limit for brass fittings (NSF/ANSI 61 & 372)

- Europe: EN 15664 and 50930-6 set low lead and migration limits

- China: GB/T 17219 checks for low lead and safe use

You should always check the lead rating before you buy. Look for “lead-free” or NSF/ANSI 61 and 372 on the label. These marks mean the chrome finish and the brass inside are safe for drinking water. If you use fittings without these marks, you risk lead getting into your water.

Note: Lead-free chrome plated brass fittings keep your family and customers safe.

Supplier Reputation

You want to buy from a supplier you can trust. A good supplier gives you safe, high-quality chrome fittings every time. You should check a few things before you buy:

- Read customer reviews to see if the supplier is reliable.

- Make sure the supplier has certificates like ISO or ASTM.

- Check if they offer a wide range of chrome and brass products.

- Look for fair pricing and good value, not just the lowest price.

- Ask about customer support and after-sales help.

- Find out if they deliver on time and keep their promises.

- Make sure they follow industry standards like IS, BS, or EN.

- Ask about their testing and quality checks.

A trusted supplier will show you their certificates and answer your questions. They will have a good rating from other buyers. You can count on them for safe chrome plated brass fittings that last.

Tip: Take your time to research suppliers. Good chrome fittings start with a good supplier.

Installation Guide

Tools

You need the right tools to put in chrome plated brass fittings. The right tools keep the chrome finish safe and make sure the fitting is tight. Some tools can scratch the shiny chrome, so pick your tools with care.

- Strap tool: This tool tightens chrome fittings without scratching them.

- Open end wrench: Use one with flat jaws so you do not mark the chrome.

- Adjustable wrench: Make sure the jaws are smooth and clean before using.

- Teflon tape: Wrap this around threads to stop leaks.

- Pipe thread sealant: Use this for extra sealing on the threads.

- Clean cloth: Wipe the chrome before and after you install it to keep it shiny.

Tip: Be gentle with chrome fittings. Scratches make them look bad and harder to clean.

Steps

Follow these steps to put in chrome plated brass fittings. You will get a tight fit and no leaks.

- Look at the chrome fittings for any problems. Check that the threads are clean and have no dirt.

- Wrap Teflon tape or put sealant on the threads. This stops leaks and keeps the brass safe.

- For flare or compression fittings, follow the directions for each kind. Make sure the fitting is tight and the chrome does not get scratched.

- If you connect chrome to other metals, use dielectric unions or corrosion blockers. This stops rust and keeps the brass strong.

- Tighten the fittings with a strap tool or a wrench with flat jaws. Do not make them too tight or you could hurt the chrome or brass.

- Test the pressure after you finish. Look for leaks and check if the chrome has any scratches.

Note: Always read the maker’s instructions for how tight to make the fittings. This keeps the chrome and brass safe.

Mistakes to Avoid

You can stop common mistakes by following these tips. Mistakes can cause leaks, damage, or even trouble with the law.

- Making chrome fittings too tight or too loose can cause leaks or break the brass. Always use the right amount of force.

- Not checking temperature and pressure ratings can make fittings break. Pick fittings that work for your system.

- Not cleaning and checking fittings can make them wear out faster. Clean the chrome often and look for damage.

- Using cheap or non-certified brass fittings can make them fail. Always buy certified chrome fittings from good sellers.

- Not following building rules can cause legal trouble. Learn the rules before you start your work.

| Mistake | How to Avoid |

|---|---|

| Over-tightening | Use the right force and the right tools |

| Ignoring ratings | Check temperature and pressure before buying |

| Poor cleaning | Clean chrome often and check for damage |

| Low-quality fittings | Buy only certified chrome plated brass |

| Not following codes | Learn and follow local plumbing rules |

Alert: Check your fittings often and install them the right way. This helps your chrome plated brass fittings last longer and stay safe.

Maintenance of Chrome Finish

Cleaning

You want your chrome to look bright and new. Clean chrome plated brass fittings often to keep them shiny. Use a soft, damp cloth to wipe away dust and water spots. Dry the surface with a clean towel. Avoid harsh cleaners or rough sponges. These can scratch the chrome and make it dull. For tough spots, use a mild soap mixed with water. Rinse well and dry right away. If you see fingerprints, polish the chrome with a non-abrasive cloth. This keeps the shine and protects the finish.

Tip: Clean chrome after each use in kitchens or bathrooms. This stops water stains and keeps the chrome looking fresh.

Preventing Damage

You can keep chrome plated brass fittings in top shape with a few simple steps. Prevent scratches and tarnish by following these tips:

- Clean brass surfaces after use. Wearing gloves helps you avoid leaving oils on the chrome.

- Polish the chrome once a month with a soft, non-abrasive cloth. This removes tarnish and keeps the shine.

- Apply a protective coating, such as lacquer or wax, to create a barrier against air and moisture.

- Store brass items in a dry, temperature-controlled place. Wrap them in a soft cloth to protect the chrome.

- Use anti-tarnish cloths or papers in storage areas. These absorb moisture and help prevent tarnishing.

You should never use steel wool or abrasive pads on chrome. These tools scratch the surface and ruin the shine. Always handle chrome plated brass fittings with care. If you move or install them, use tools with smooth jaws or a strap wrench. This protects the chrome from marks.

Note: Regular care keeps chrome looking new and helps your fittings last longer.

Replacement

Sometimes, you need to replace chrome plated brass fittings. Look for signs like deep scratches, peeling chrome, or rust spots. If the chrome finish starts to flake, water can reach the brass underneath. This may cause corrosion or leaks. Replace fittings if you see cracks or if the chrome no longer protects the brass.

Check your fittings every few months. If you notice damage, act quickly. New chrome plated brass fittings keep your plumbing safe and your fixtures looking great. Always choose fittings that match your system and meet safety standards.

Alert: Replace damaged chrome fittings right away. This prevents leaks and keeps your water clean.

You want to make smart choices when buying chrome plated brass fittings. Start by measuring your pipes and checking which brass fittings match your needs. Look at the environment where you will use the fittings. Pick brass that resists corrosion and fits your system. Always check for certifications to make sure the fittings meet safety standards. Compare options from different suppliers to find the best value. Use this checklist before you buy:

- Check if the fittings work with your piping materials.

- Choose brass that resists corrosion in your environment.

- Look for quality and certification marks.

- Make sure the fittings match your installation tools.

- Pick brass fittings that need less maintenance.

- Balance cost with performance.

- Buy from trusted suppliers.

Tip: Measure, select, and verify each fitting before you install. This helps you get safe and long-lasting brass fittings.

FAQ

You get extra protection from rust and scratches with chrome plated brass. The chrome layer keeps the fitting shiny and easy to clean. You also enjoy a modern look that matches most fixtures.

Yes, you can use them for drinking water. Always check for NSF/ANSI 61 or 372 certification. These marks show the fittings are safe and lead-free.

Wipe the fittings with a soft, damp cloth. Use mild soap for tough spots. Avoid harsh cleaners or rough sponges. Dry the surface after cleaning to keep the shine.

The chrome layer protects the brass from rust. If the chrome gets scratched or peels, the brass underneath may corrode. Check your fittings often and replace damaged ones.

You can use them outdoors. The chrome finish resists weather and moisture. For harsh conditions, check the fitting’s rating and inspect it regularly.

You will find NPT (National Pipe Thread) and BSP (British Standard Pipe) threads. Always match the thread type to your pipe for a leak-free fit.

With proper care, these fittings last many years. The chrome finish protects against wear and corrosion. Clean and inspect them often to extend their life.

Yes, you can recycle them. Remove any plastic or rubber parts first. Take the fittings to a metal recycling center.