When you look at which metals work best for casting engine blocks, you find two main choices: cast iron and aluminum. These metals stand out because they balance cost, strength, and how well they can be shaped. Take a look at this table to see how they compare:

| Property | Cast Aluminum | Cast Iron |

|---|---|---|

| Cost Efficiency | Costs more at first, but recycling can help. Lighter weight lowers shipping costs. | Slightly cheaper, good for making many parts. |

| Strength | Moderate strength, best for lighter engines. | High strength, great for heavy-duty engines. |

| Temperature Tolerance | Melts at lower heat, not for extreme temperatures. | Handles high heat, perfect for engine blocks. |

Key Takeaways

- Cast iron and aluminum are the main metals for engine blocks. Each metal has its own special benefits. Cast iron is very strong and lasts a long time. It works well for engines that do heavy work. But cast iron is heavy and can make cars use more gas. Aluminum is much lighter and helps cars save gas. But aluminum can wear out faster if stressed a lot. There are different types of cast iron, like gray and ductile iron. Each type has special features for different engines. Aluminum alloys like 319, A356, and A357 are also used. These alloys are strong and resist rust, which is good for engine blocks. Sand casting is cheap for making a few engine blocks. Die casting is better for making many blocks quickly and accurately. Think about how much materials cost over time. Aluminum may cost more at first, but it can save money on gas and repairs later. In the future, engine blocks may use lighter and recycled metals. This will help engines work better and be better for the planet.

Table of Contents

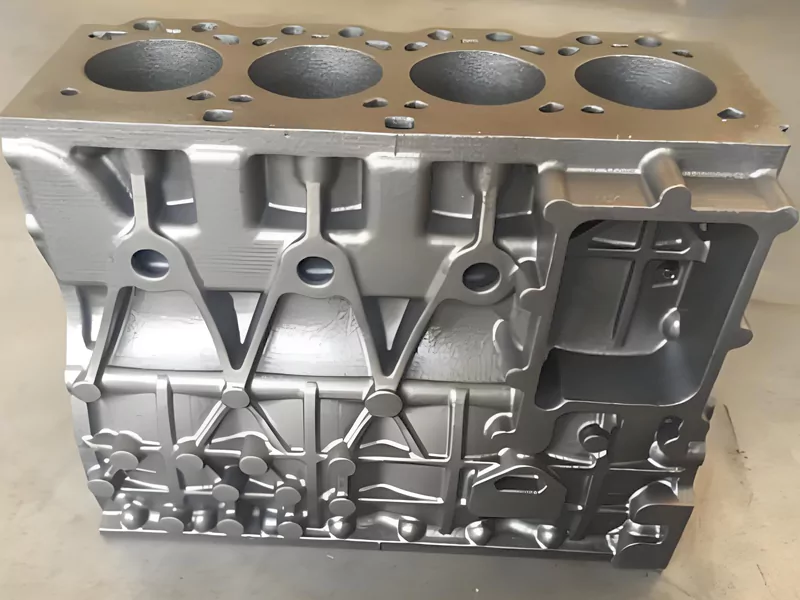

Cast Iron

Types of Cast Iron

When you check the engine block cast materials, you see different types of cast iron. Each type has special features that change how it works in engines. Here is a table that lists the main types and what they are like:

| Type of Cast Iron | Composition | Properties | Applications |

|---|---|---|---|

| Gray Cast Iron | 2-4% C, 1-3% Si | Good machinability, excellent damping | Engine blocks, cylinder heads |

| Ductile Cast Iron | 3-4% C, 2-3% Si, Mg | High strength, good ductility | High-performance engine components |

| Vermicular Graphite Cast Iron | 3-4% C, 2-3% Si | Strength, good castability | Diesel and high-performance engines |

Gray Cast Iron

Gray cast iron is the most common for engine block casting. It has graphite flakes inside. These flakes help soak up vibrations and lower noise. Gray cast iron is easy to shape when making parts. It also stands up well to wear, so it works well for cylinder liners.

Ductile Cast Iron

Ductile cast iron is also called nodular iron. It has round graphite shapes in its structure. This makes it stronger and tougher than gray cast iron. Ductile cast iron is used for high-performance engine block casting. It can take more stress and hits, so engines last longer.

Vermicular Graphite Cast Iron

Vermicular graphite cast iron has worm-shaped graphite. Its properties are between gray and ductile iron. It is stronger, more flexible, and tougher than gray iron. But it still casts well and moves heat easily. Many diesel and high-performance gasoline engines use this type for blocks and cylinder heads.

Properties

Cast iron is known for its strong mechanical and thermal properties. It resists wear, so the engine block cast lasts longer. It also reduces vibrations, making engines smoother and quieter. Gray cast iron moves heat well, which helps control engine temperature. Ductile iron is stronger and more flexible, so it works for engines that need to handle more force. Vermicular graphite iron gives a good mix of strength and heat control.

Here is a quick look at the main properties:

| Type of Cast Iron | Mechanical Properties | Thermal Properties |

|---|---|---|

| Gray Cast Iron | Good wear resistance, vibration damping | Excellent thermal conductivity |

| Ductile Cast Iron | Higher mechanical strength and ductility | Moderate thermal conductivity |

| Vermicular Graphite Iron | High strength, plasticity, toughness | Good heat conductivity |

Advantages

Cast iron has many good points for an engine block. Cast iron blocks are strong and simple to fix. If you need to weld or repair a block, it keeps its strength. This makes cast iron great for rebuilding engines, especially in big vehicles. The graphite inside gives great wear resistance, so cylinder liners and pistons last longer. Cast iron is easy to shape into complex engine block cast designs. It has been used for a long time because it is tough and dependable.

Tip: If you want an engine block cast that lasts and can take hard use, cast iron is a smart pick.

Disadvantages

When you pick cast iron for an engine block, you should know some problems. Here are the main disadvantages:

- Cast iron weighs a lot more than aluminum. This extra weight makes cars heavier and requires more fuel. You might pay more to move heavy vehicles.

- Heavy cast iron can make engines less efficient. A heavier engine means your car needs more fuel to drive.

- Cast iron can break easily. If you put it under a lot of pressure, it might crack instead of bending. This can make your engine less reliable if you use it hard.

- Cast iron does not rust easily, but it is not perfect. In some hot places, metals like aluminum may fight rust better.

Note: If you want a lighter engine or better gas mileage, cast iron may not be the best pick.

Casting Engine Blocks Methods

There are two main ways to make a cast iron engine block: sand casting and die casting. Each way has its own features, costs, and quality.

Sand Casting

Sand casting uses sand molds to shape the engine block. This way works well for tricky shapes and small batches. You can make detailed designs with sand casting. The process is old and is used a lot in factories. Sand casting costs less than other ways, so many engine makers use it.

Die Casting

Die casting, also called metal mold casting, uses strong metal molds instead of sand. This way gives you more exact shapes and smoother surfaces. Die casting works best for making lots of engine blocks because the molds last longer. The first cost is higher, but you save money if you make many blocks. You get better quality and accuracy with die casting.

Here is a table to help you compare the two ways:

| Casting Method | Characteristics | Quality Implications | Cost Implications |

|---|---|---|---|

| Sand Casting | Uses sand molds, good for tricky shapes and small runs | Handles tricky designs, old process | Low cost, used a lot |

| Die Casting | Uses metal molds, best for making many blocks | Exact sizes, smoother surfaces | Higher first cost, saves money later |

Tip: If you need a few engine blocks with tricky shapes, sand casting is a good choice. For many blocks and high accuracy, die casting is better.

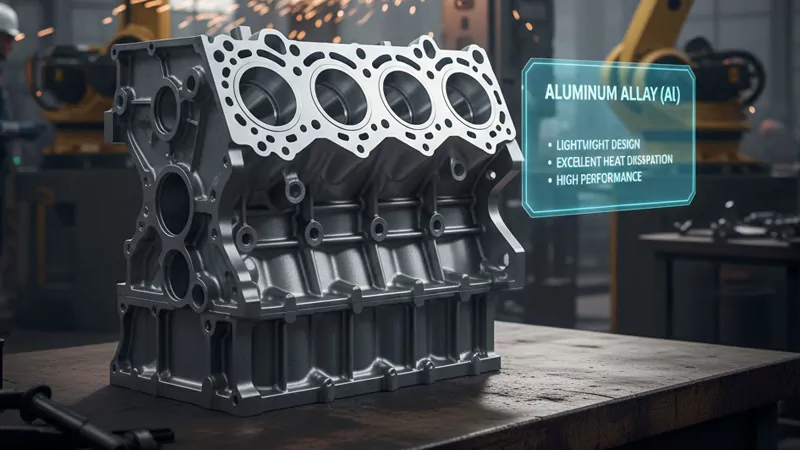

Aluminum

Aluminum Alloys

Aluminum alloys are light and strong. They are used for the engine block casting. There are three main alloys: 319, A356, and A357. Each alloy has a special mix of elements. This mix changes how it works in engines.

319 Alloy

The 319 alloy is commonly used for engine block casting. It gives a good mix of strength and cost. It has aluminum, silicon, and copper. Copper helps it stay strong when hot. This alloy lasts long. But it can have small holes after casting.

A356 Alloy

A356 alloy is also used a lot. It is easy to cast and does not rust easily. It has aluminum, silicon, and magnesium. Magnesium makes it stronger but not heavier. This alloy fights rust and can be shaped into tricky forms.

A357 Alloy

A357 alloy is like A356 but has more magnesium. The extra magnesium makes it stronger and tougher. This alloy is used for engines that need more power. It works well for blocks under more stress.

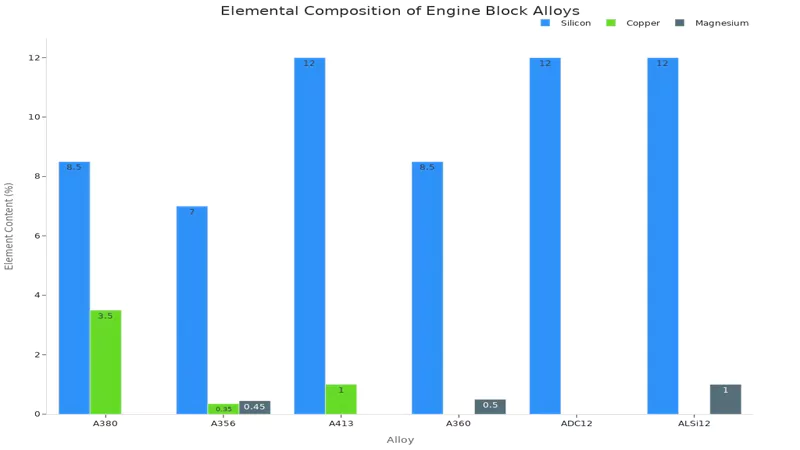

Here is a table with the main aluminum alloys and what them:

| Alloy | Silicon (%) | Copper (%) | Magnesium (%) | Properties |

|---|---|---|---|---|

| 319 | 6.5 | 3.5 | 0.5 | Good strength at medium heat, can get small holes |

| A356 | 7 | 0.35 | 0.45 | Easy to cast, welds well, tight, fights rust |

| A357 | 7 | 0.04 | 0.6 | Stronger and tougher, good for powerful engines |

Silicon and magnesium help these alloys flow well. They also help stop rust.

Properties

Aluminum alloys have many good points for an engine block cast. They make blocks light, so cars use less gas. These alloys are strong but weigh less than cast iron. Aluminum moves heat fast, so engines stay cool. The oxide layer on aluminum stops rust.

Here is a table with the main properties:

| Property | Description |

|---|---|

| Strength | Strong and keeps shape, even though light |

| Thermal Conductivity | Moves heat fast, keeps engine cool |

| Corrosion Resistance | The oxide layer stops rust |

| Lightweight | Makes the engine lighter, saves fuel |

Silicon helps these alloys flow well when casting. This lets you make tricky shapes for the engine block cast. How strong and hard the block is depends on the alloy and how you treat it after casting.

Here is a chart that shows the silicon, copper, and magnesium in the main aluminum alloys for engine blocks:

Advantages

Aluminum has many good points for an engine block cast. Aluminum blocks are much lighter than cast iron ones. You can make the engine 40-50% lighter. This helps cars go faster and use less gas. Aluminum also moves heat away fast, so engines do not get too hot.

Here are the main good points:

- Lighter blocks help save fuel.

- Aluminum moves heat fast, so engines stay cool.

- You can make tricky shapes with aluminum alloys.

- Aluminum does not rust, so engines last longer.

- Cars run better and handle well.

Tip: If you want to save gas and keep your engine cool, aluminum is a good pick.

A study found that using aluminum in cars can cut fuel use by 20%. It can also lower CO2 by 10%. Aluminum also helps make rides smoother and safer because it absorbs shocks.

Disadvantages

Aluminum engine blocks have some problems you should know about. They are lighter, but not as strong as cast iron. They also do not resist wear as well. This means aluminum engine blocks may not last as long if used hard.

Here is a table that compares aluminum and cast iron:

| Material | Strength | Wear Resistance | Weight |

|---|---|---|---|

| Aluminum | Lower strength | Wears out faster | Lighter |

| Cast Iron | Higher strength | Wears out slower | Heavier |

Aluminum blocks can wear down faster in tough engines. The metal is softer, so it can scratch or bend more easily. It also does not protect as well from heat and pressure. If you push the engine hard, aluminum might crack or bend.

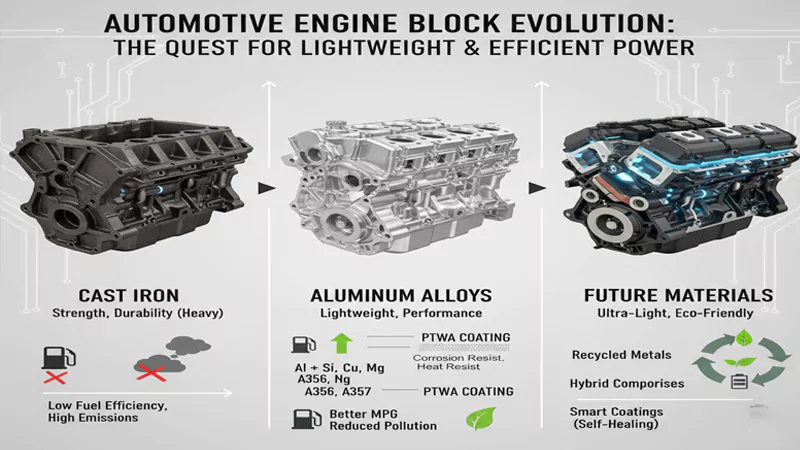

Manufacturers use special ways to fix these issues. Many aluminum blocks have cast iron sleeves inside. These sleeves make the cylinder walls stronger. But they add weight and make the block more complicated. Some companies use plasma transferred wire arc (PTWA) coatings. This coating makes the surface stronger without much extra weight. PTWA helps the engine last longer and stay cooler.

Here is a table with common solutions:

| Technique | Benefits |

|---|---|

| Cast Iron Sleeving | Makes aluminum stronger, but adds weight and complexity. |

| Plasma Transferred Wire Arc (PTWA) | Lowers weight, makes the engine last longer, and helps it stay cool. |

Note: If you want a light engine block, you need to protect it from wear and heat. Ask about sleeves or coatings when you look at engines.

Engine Block Cast Methods

There are different ways to cast aluminum engine blocks. Each way changes how strong, costly, or good the block is. You should know about these ways before picking an engine.

Sand Casting

Sand casting uses sand molds to shape the aluminum. You can make detailed and tricky shapes with this method. It works well for small batches or special designs. Sand casting lets you use many alloys and change the block for special needs. The surface may be rough, but the parts are strong.

Common types of sand casting are:

- Green sand casting

- Precision sand casting

- Lost foam casting

Sand casting gives you more choices, but the finish is not always smooth. It is best for testing parts or making a few blocks.

Die Casting

Die casting uses metal molds and high pressure to shape aluminum. You get smooth surfaces and exact shapes. Die casting is good for making lots of engine blocks fast. High die Casting (HPDC) is popular because it makes strong parts. You need to watch for air bubbles, which can make the block weaker.

Other die casting methods are:

- Vertical Low Pressure Die Casting (LPDC)

- Gravity Permanent Mold (PM)

- Semi-Permanent Mold (SPM)

- Semi Solid or Semi Liquid Casting

Die casting is great for making many engine blocks of high quality. You get better shapes and less waste.

Tip: If you want many strong engine blocks, die casting is a good choice. For special or custom engines, sand casting may be better.

Ready to get started on your next project?

Please contact our team, and our senior engineers will provide you with the best solutions for your project!

Get Your Instant QuoteOther Materials

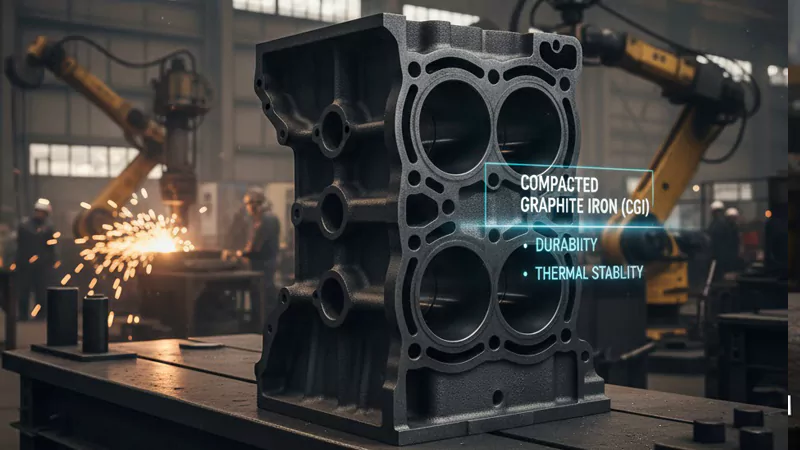

Compacted Graphite Iron

You can find compacted graphite iron (CGI) in many new engine blocks. It is used a lot in diesel engines and fast gasoline engines. CGI is special because it mixes good things from gray iron and ductile iron. The graphite in CGI looks like short worms. This shape makes the engine block strong and tough.

Here is a table that explains why CGI is good for engine blocks:

| Property/Advantage | Description |

|---|---|

| Damping | CGI soaks up vibrations better than ductile iron. Engines run quieter and smoother. |

| Lightweighting | CGI blocks are 10-20% lighter than gray iron blocks. This helps cars use less fuel. |

| Higher Power Density | CGI can handle higher pressure in cylinders. Engines can make more power and torque. |

| Improved NVH | CGI lowers noise, vibration, and harshness. Rides feel more comfortable. |

| Enhanced Durability | CGI is very strong and lasts long, even when used hard. |

| Usage in Automotive | Many top car brands use CGI for diesel and fast gasoline engines. |

You can see CGI used in these places:

- Automotive engine blocks: Diesel trucks and sports cars often use CGI instead of gray iron.

- Heavy-duty diesel engine parts: Big trucks and boat engines use CGI because it is strong and lasts longer.

Tip: If you want an engine that is quiet and lasts long, look for CGI in the engine block.

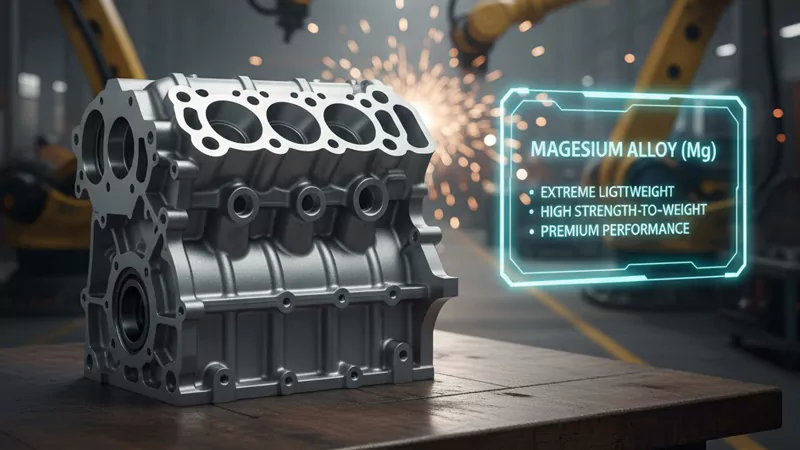

Magnesium Alloys

Magnesium alloys are the lightest choice for engine blocks. Magnesium weighs about half as much as cast iron. It is also 30% lighter than aluminum. This big weight drop helps cars drive better and use less fuel. Magnesium is used in race cars and special light vehicles.

Here is a table that shows the main good and bad points of magnesium alloys:

| Benefits | Challenges |

|---|---|

| About 50% lighter than cast iron blocks | Costs more because it is hard to get |

| 30% lighter than aluminum blocks | Magnesium can rust and catch fire more easily |

| Improved handling and fuel efficiency | Most magnesium comes from a few places, like China |

Magnesium gives you some great benefits:

- Cars feel lighter and are easier to drive.

- You save fuel because the engine is lighter.

- Magnesium helps fast cars go even quicker.

But there are some problems too:

- Magnesium costs more to make.

- It can rust and catch fire if not handled properly.

- Most magnesium comes from only a few countries, so it can be hard to find.

Note: Magnesium alloys are best if you need the lightest engine and can handle the extra cost and safety steps.

Engine Block Cast Comparison

Weight

Weight is very important for engine blocks. The material you pick changes how heavy the engine is. Cast iron blocks are much heavier than aluminum blocks. Magnesium alloys are even lighter than aluminum. You can really feel the difference when you lift them.

A lighter engine block gives you some good things:

- Acceleration: Your car goes faster because the engine is lighter.

- Fuel Efficiency: You use less gas since the engine works less.

- Handling: Your car turns better and feels easier to drive.

If you want a car that saves gas and feels quick, pick an engine with an aluminum or magnesium block. Heavy cast iron blocks are good for trucks and big vehicles. But they make cars slower and use more gas.

Here is a simple comparison:

| Material | Relative Weight | Common Use Cases |

|---|---|---|

| Cast Iron | Heaviest | Trucks, heavy-duty vehicles |

| Aluminum Alloy | Medium | Most modern cars, SUVs |

| Magnesium Alloy | Lightest | Racing, specialty vehicles |

Tip: For better gas mileage and a sporty feel, go with a lighter engine block.

Strength

Strength is also important for engine blocks. Cast iron is very strong. It can take a lot of pressure and heat. That is why trucks and performance engines use cast iron. These engines need to last long and work hard.

Aluminum alloys are strong, but not as strong as cast iron. They are good for most cars and light trucks. Aluminum blocks can handle normal driving and some sporty driving. If you push the engine very hard, the aluminum may wear out faster.

Magnesium alloys are the lightest, but not as strong as cast iron or aluminum. You see magnesium in race cars where weight matters most. These engines need special care.

Here is a table to help you see the difference:

| Material | Strength Level | Best For |

|---|---|---|

| Cast Iron | Very High | Heavy-duty, high-stress engines |

| Aluminum Alloy | Moderate to High | Every day cars, light trucks |

| Magnesium Alloy | Moderate | Racing, lightweight vehicles |

Note: If you want an engine that lasts and can take a lot of stress, cast iron is best. For most people, aluminum gives a good mix of strength and weight.

Heat Dissipation

Heat dissipation means how well the engine block gets rid of heat. This is important because engines get very hot when running. If the block cannot lose heat, the engine can overheat and break.

Aluminum is great at getting rid of heat. It moves heat away from the engine quickly. This keeps your engine cool, even when you drive hard. Cast iron holds heat longer. This helps in cold weather because the engine warms up faster. But in fast engines, cast iron can get too hot and cause trouble.

Look at this table to compare:

| Material | Thermal Conductivity (W/(m·K)) | Heat Dissipation Capability |

|---|---|---|

| Aluminum | 170-200 | Great at losing heat, helps stop overheating. |

| Cast Iron | 40-50 | Holds heat longer, good in cold but can overheat. |

If you want an engine that stays cool and runs well, aluminum is a smart pick. For cold places, cast iron helps the engine warm up faster.

Tip: Always check your car’s cooling system, no matter what engine block you have. Good cooling keeps your engine working well.

Cost

When you choose an engine block material, cost plays a big role. You want to know how much you will spend at first and what you might pay later. Each material—cast iron, aluminum, or magnesium—has its own price story.

Cast Iron

Cast iron engine blocks usually cost less to make at the start. The raw material is cheaper, and the casting process is simple for large shapes. You see cast iron in many older cars and trucks because it keeps the price down. However, you may pay more over time. Cast iron blocks weigh more, so your car uses more fuel. Heavy blocks also put more stress on other parts, which can lead to higher maintenance bills.

Aluminum

Aluminum engine blocks cost more at first. The metal itself is pricier, and the casting process—especially die casting—needs expensive molds and tools. You pay more to get started, but you get some big benefits. Aluminum blocks weigh less, so your car uses less gas. Lighter engines also mean less wear on brakes, tires, and suspension. Over time, you may save money because your car needs fewer repairs and uses less fuel.

Here is a table to help you compare the costs:

| Material | Initial Cost | Long-Term Cost | Notes |

|---|---|---|---|

| Cast Iron | Low | Higher (maintenance, fuel) | Cheaper to make, but heavier and less efficient |

| Aluminum Alloy | High | Lower (fuel, upkeep) | Costs more at first, but saves money later |

| Magnesium Alloy | Very High | Variable | Lightest, but expensive and less common |

Tip: If you want to save money right away, cast iron looks good. If you want to save money over time, aluminum is often the better choice.

You should also think about how the casting method changes the price. Sand casting works well for both iron and aluminum. It costs less for small batches or special shapes. Die casting, used mostly for aluminum, costs more at first because you need special molds. However, if you make many engine blocks, die casting can save money in the long run because it is fast and makes less waste.

Here are some key points to remember:

- Cast aluminum costs more at first, but its lighter weight can lower shipping and fuel costs.

- Cast iron is cheaper to make, but you may pay more for fuel and repairs.

- Aluminum die casting lets you make lots of blocks quickly, but you need to spend more on tools at the start.

- Iron casting is less expensive for big, simple shapes, but gets costly for detailed designs.

You need to balance what you pay now with what you might pay later. If you want a car that costs less to run and fix, aluminum can be a smart pick. If you want the lowest price up front, cast iron is hard to beat. Magnesium gives you the lightest block, but it costs the most and is not common in everyday cars.

Note: Always look at both the first price and the long-term costs when you pick an engine block material. This helps you make the best choice for your needs and budget.

Selection Factors

Performance Needs

When picking a material for an engine block cast, you must think about how the engine will work. Different cars and trucks need different things. Some cars need to be light so they can go fast. Other vehicles need to be strong and last a long time. You want your engine to do its job well.

Here is a table that shows what is important for performance:

| Performance Need | Description |

|---|---|

| Weight Reduction | Lightweight materials help cars use less gas and perform better. |

| Strength | Materials must be strong to handle stress from the engine. |

| Durability | Engine blocks should not wear out or break over time. |

| Cost Efficiency | You need to balance price and how well the material works. |

| Sustainability Goals | Using recycled or green materials helps the environment. |

Look for these things:

- Strong and stiff materials keep the engine block together.

- Materials that resist wear and heat help parts last longer.

- Lighter materials make cars faster and save gas.

If you want a fast sports car, you might choose aluminum because it is light. If you need a tough truck, cast iron is better because it is strong and lasts longer.

Manufacturing

How you make the engine block also matters when choosing a material. Some materials are easy to shape and make in large numbers. Others need special tools or ways to make them.

Check this table to see how making the block changes your choice:

| Material Type | Properties | Manufacturing Process |

|---|---|---|

| High-strength aluminum alloys | Light and good at moving heat away | High-pressure die casting (HPDC) |

| Compacted graphite iron (CGI) | Strong and not too heavy | Good for high-performance engines |

Pick a process that fits your needs:

- High-pressure die casting is fast and works well for aluminum.

- Sand casting is good for small numbers or special shapes.

- Compacted graphite iron is used for strong engines, but it can cost more.

If you want to make lots of engine blocks, pick a way that saves time and money. Die casting is good for making many aluminum blocks. For special engines, sand casting lets you make custom shapes.

Tip: Always ask how the engine block is made. The right way can save money and give you better parts.

Regulations

Rules also affect what material you can use for an engine block cast. Governments make rules to protect the planet and keep people safe. You must follow these rules when you design or buy an engine.

Some rules are about pollution. Lighter materials like aluminum help cars use less gas and produce less pollution. Other rules say you must use recycled metals or avoid some chemicals. That is why more engines use recycled aluminum or iron.

Safety rules are important too. Your engine block must be strong enough to keep you safe in a crash. It should last a long time without breaking.

Remember these things:

- Environmental laws want lighter and cleaner materials.

- Safety rules need strong and safe engine blocks.

- Recycling rules push for using old metals again.

If you want your car to follow all the rules, check what materials and methods the maker uses. This helps you avoid trouble and keeps your car legal.

Note: Rules can change. Make sure your engine block cast meets the newest standards.

Trends

Lightweighting

Today, car makers want lighter engine blocks. They do this to help cars use less fuel and make less pollution. Lightweighting means using metals that are not heavy but still strong. If your engine is lighter, your car uses less gas and goes faster. Many companies now use more aluminum and sometimes magnesium for engine blocks. These metals can make the engine block up to 50% lighter than cast iron.

Here is how lightweighting helps you:

- Better fuel economy: Lighter engines use less gas.

- Improved handling: Your car is easier to steer.

- Lower emissions: Less weight means less pollution.

Tip: If you want to save money on gas, pick a car with an aluminum or magnesium engine block.

Alloy Development

New alloys make engine blocks stronger and last longer. Engineers mix aluminum with silicon, copper, or magnesium to make special alloys. These new mixes help engines stay strong, handle heat, and fight wear. For example, A356 and A357 aluminum alloys help engines last longer and stay cool.

Look at this table to see what new alloys do:

| Alloy Name | Key Elements | What It Improves |

|---|---|---|

| A356 | Al, Si, Mg | Casting, corrosion, strength |

| A357 | Al, Si, Mg (more) | Toughness, heat resistance |

| CGI | Fe, C, Si | Strength, vibration damping |

Car makers also use coatings like plasma transferred wire arc (PTWA). These coatings make aluminum blocks tougher. They help the engine fight wear without making it heavier.

Note: Ask about the alloy and coatings in your engine block. They help your engine last longer.

Future Materials

Engine block materials will keep changing soon. Scientists look for metals and composites that are lighter, stronger, and better for the planet. Some companies test carbon fiber composites and advanced ceramics. These new materials could make engines much lighter and work better.

Here are some trends you might see:

- Recycled metals: More engine blocks use recycled aluminum or iron.

- Hybrid materials: Some blocks mix metals with plastics or fibers.

- Smart coatings: New coatings can fix small cracks or handle heat better.

🚗 The future of engine blocks is exciting. You may drive a car with an engine block that is strong and good for the planet.

You have learned that cast iron and aluminum are the main metals for engine block casting. These metals are popular because they balance price, strength, and how easy they are to cast.

- Cast iron is strong and lasts a long time in big engines.

- Aluminum makes engines lighter and helps cars use less gas.

Knowing about these materials helps you see why engines are built a certain way. Always check what the metal can do when you look at different engines.

FAQ

You get high strength and durability with cast iron. It handles heat well and resists wear. Heavy-duty engines often use cast iron because it lasts a long time.

You get a lighter engine with aluminum. This helps your car use less fuel and improves handling. Aluminum also cools faster, which protects your engine from overheating.

You can repair some cracks in cast iron blocks by welding or using special sealants. Aluminum blocks are harder to fix. Severe damage often means you need a new block.

Aluminum does not rust like iron. It forms a thin oxide layer that protects it from corrosion. You still need to keep your engine clean to prevent other types of damage.

Sand casting works well for small batches or custom shapes. Die casting is better for making many blocks quickly with smooth surfaces. Your choice depends on how many blocks you need and your budget.

You get a very light engine with magnesium, but it can catch fire if not handled right. Car makers use special coatings and designs to make magnesium blocks safer.

Think about your needs. If you want strength and long life, choose cast iron. If you want a lighter car and better fuel economy, pick aluminum. Racing engines sometimes use magnesium for the lowest weight.

Yes, you can recycle both cast iron and aluminum engine blocks. Recycling saves energy and helps the environment. Many car makers use recycled metals in new engines.