When you perform steel casting welding, whether on cast steel or cast iron, you must use different methods.

Each material behaves uniquely when heated. For cast iron, you often need special electrodes. Additionally, it is essential to heat it up slowly before welding and allow it to cool down gradually afterward to prevent cracks from forming. Cast steel is generally easier to work with, allowing the use of mild steel electrodes.

Understanding these differences is crucial to avoid issues like cracks or brittleness. The table below outlines the main differences in welding techniques for each material:

| Aspect | Cast Iron | Cast Steel |

|---|---|---|

| Electrode Types | Cast iron covered, copper base, nickel base, mild steel | Typically mild steel electrodes are used. |

| Preheating Requirements | Preheating to 120-425°C is necessary depending on size and complexity | Preheating is generally less critical. |

| Ductility and Machinability | Nickel and nickel-iron deposits are ductile; mild steel deposits can become brittle | Mild steel deposits are more ductile and machinable. |

| Recommended Techniques | Medium arc length, flat position, small electrodes at low current | Various techniques depending on the specific steel type. |

To achieve a strong weld, it is vital to know the characteristics of your material. Welding steel castings often requires careful machining to ensure a quality finish and optimal results.

Key Takeaways

- Know that cast steel and cast iron are different. Cast steel has less carbon. This makes it easier to weld. It also cracks less often.

- Always heat up cast iron before welding. This step helps stop cracks. It also makes the weld stronger.

- Pick the right electrodes for each metal. Nickel-based electrodes are best for cast iron. Mild steel electrodes work well for cast steel.

- Control how the metal cools after welding. Let cast iron cool slowly. This helps stop cracks and keeps it from getting brittle.

- Use the right welding method for each metal. Cast steel is more flexible. Cast iron needs careful handling.

- Machining is often needed after welding. This gives a smooth finish and exact size. It is important for cast steel.

- Watch the heat-affected zone during welding. Too much heat on cast iron can make it hard and brittle.

- Always check welds for problems. Fix any defects right away. This keeps the welded parts strong.

Table of Contents

Key Differences

Cast Steel vs Cast Iron

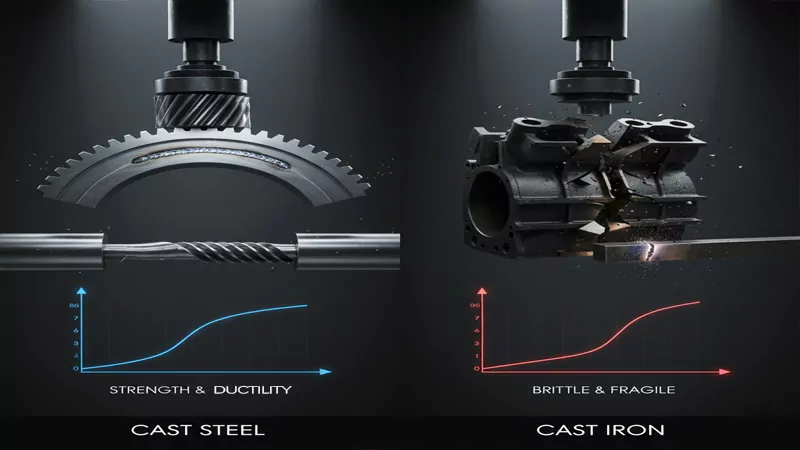

Cast steel and cast iron are not the same. They have important differences that change how you weld them. The biggest difference is the amount of carbon in each metal. Cast steel has less carbon. This makes it easier to weld. It also means it does not crack as much. Cast iron has more carbon. This makes it hard and easy to break. It can crack when you weld it. You need to remember these things when you pick how to cast your metal.

Here is a table that shows the main differences between cast steel and cast iron:

| Aspect | Cast Steel | Cast Iron |

|---|---|---|

| Weldability | Easier to weld because it has less carbon, so it cracks less. | Cracks more during welding because it has more carbon. |

| Cracking Risk | Not as likely to crack. | Cracks more easily, so you must heat and cool it slowly. |

| Application Scope | Used for things like building machines and mining tools because it is strong. | Used for engine blocks and machine bases. |

You will use different ways to cast the metal depending on what it is. For cast steel, you might use sand casting or investment casting. For cast iron, you might use gray iron casting or ductile iron casting. These ways of casting change how the metal acts and how you should weld it.

- Cast steel has less carbon, so it is easier to weld and does not crack as much.

- Cast iron has more carbon, so it is hard and cracks more when you weld it.

- You need to pick the right way to cast the metal for what you want to make.

Welding Challenges

Welding cast iron is hard. It has a lot of carbon, so it breaks easily. If you heat or cool it too fast, it can crack. You need to use special ways to cast it and watch the temperature closely. Heating the metal before welding helps stop cracks. Letting it cool slowly after welding is also important.

Cast steel is easier to work with. You can use more ways to cast and weld it. You do not always have to heat it first, but you still need to be careful. You must control how you weld so you do not make mistakes.

Knowing these differences helps you pick the best way to weld. If you use it the wrong way or forget what cast iron needs, your welds can be weak and break. Always match your welding to the metal and how it was cast. This helps you make strong welds that last.

Tip: Picking the right way to weld is very important if you want strong welds. Heating the metal first is very important for cast iron. This helps stop cracks from forming.

Composition & Structure

Cast Steel Properties

Cast steel is special because of what it is made of and how it is built inside. It has less carbon than cast iron, usually under 2.11%. This makes cast steel tough and easy to bend. You can shape it without breaking it. The grains inside are even, so it does not crack easily. Cast steel can handle heat and stress well when you weld it. You can use many welding methods on cast steel. It works well in tough jobs like building or mining. Because it has less carbon, the weld stays strong and flexible.

Cast Iron Properties

Cast iron is not the same as cast steel. It has more carbon, from 2% to 4%. This makes it hard and easy to break. Cast iron does not bend much. It can crack if you put stress on it. Inside, cast iron has graphite. The shape of the graphite changes how it acts. The table below shows how graphite affects cast iron:

| Type of Cast Iron | Graphite Structure | Ductility Level | Weldability Impact |

|---|---|---|---|

| Grey Cast Iron | Coarse graphite flakes | Low | Difficult to weld due to brittleness |

| Nodular Cast Iron | Spheroidal graphite | High | Improved weldability due to higher ductility |

| Malleable Iron | Carbon aggregates | High | Better weldability compared to grey iron |

Grey cast iron is the hardest to weld and breaks the easiest. Nodular and malleable iron bends more, so they are easier to weld. But all cast iron types need careful welding because they can crack.

Impact on Weldability

The way cast steel and cast iron are made changes how you weld them. Here are the main things to remember:

- Cast iron has more carbon, so it cracks more when you weld it.

- The carbon in cast iron moves into the weld and makes it brittle.

- Cast steel has less carbon, so it is tougher and easier to weld.

- Cast steel can take more heat and stress during welding.

- Cast iron is hard and brittle, so welding it is harder.

Note: Always use the right welding method for the metal. Cast steel lets you use more ways to weld. Cast iron needs extra care so it does not crack.

If you know these facts, you can pick the best way to weld. This helps you make welds that last longer and are stronger.

Mechanical Properties

Strength & Ductility

When you work with cast steel, you notice its strength and ductility right away. Cast steel can handle heavy loads and bends without breaking. This makes it a top choice for parts that need to be tough, like gears or machine frames. You can weld cast steel with confidence because it stays strong after welding. The metal stretches a bit before it breaks, so it does not snap suddenly.

Cast iron acts differently. It is strong when you press on it, but it does not bend much. If you try to stretch or bend cast iron, it can break quickly. You must be careful when welding cast iron because it does not handle stress well. If you do not control the heat, cast iron can crack. You need to use special techniques to keep the weld strong.

Tip: Always check if your part needs to bend or stretch. If it does, cast steel is usually the better choice for welding.

Brittleness & Hardness

You will see big differences in brittleness and hardness between cast steel and cast iron. Cast steel is less brittle, so it can take hits and shocks without breaking. Cast iron is more brittle, especially gray and white types. If you drop a cast iron part, it might crack or shatter.

The table below shows how different types of cast iron compare in brittleness and hardness, and what this means for welding:

| Type of Cast Iron | Brittleness | Hardness | Implications for Welding |

|---|---|---|---|

| Gray Cast Iron | Moderate brittleness | Lower than steel | Less impact resistance, requires careful welding techniques. |

| White Cast Iron | High brittleness | High | Prone to cracking during welding due to high carbon content. |

| Ductile Cast Iron | Lower brittleness | Moderate | More forgiving in welding, but still requires skill. |

| Malleable Cast Iron | Low brittleness | Variable | Easier to weld, can be manipulated post-weld. |

Cast steel is usually softer than white cast iron but harder than gray cast iron. You can machine cast steel after welding, which helps you get a smooth finish. Cast iron, especially white cast iron, is hard to machine. You need special tools and extra care.

Note: If you want a weld that will not crack, pick cast steel or a ductile type of cast iron. Avoid white cast iron for welding if possible.

Heat-Affected Zone

The heat-affected zone (HAZ) is the area next to the weld that gets hot but does not melt. In cast steel, the HAZ stays tough and does not change much. You can weld cast steel without worrying too much about the HAZ. The metal keeps its strength and does not get brittle.

Cast iron is different. The HAZ in cast iron can become very hard and brittle. If you heat cast iron too much, the carbon moves and forms hard spots. These spots can crack when the part cools down. You must control the heat and let the cast iron cool slowly. If you rush, the HAZ will crack and ruin your weld.

- For cast steel, you can use normal welding speeds and let it cool in the air.

- For cast iron, you must heat it up before welding and let it cool down slowly, sometimes in sand or a furnace.

Remember: The way you handle the HAZ can make or break your weld. Always match your welding speed and cooling method to the type of metal.

Machinability & Weldability

Machining Cast Steel

Machining cast steel is easy for many jobs. You can cut and shape it in lots of ways. Cast steel lets you make parts that fit very well. The surface looks smooth when you finish. You can make parts that are the same size every time. This is important for cars and buildings. Machining cast steel helps you make shapes with lots of details. You can meet strict rules for size and how things look.

- Cast steel lets you make parts that fit perfectly and look smooth.

- You can make the same part over and over again.

- The size of each part is always right for tough jobs.

After welding, you may need to machine cast steel. This removes extra metal and fixes rough spots. Machining helps the welded area look like the rest of the part. You can trust machining to help you make a good product that meets what people want.

Machining Cast Iron

Machining cast iron is harder than machining cast steel. Cast iron is tough and breaks easily. If you use the wrong tool, it can chip or crack. After welding, cast iron makes sharp chips and fine dust. These chips can wear out your tools fast. The dust can make your work area dirty.

- Cast iron is hard and breaks easily, so it is hard to machine.

- Sharp chips and dust can hurt your tools.

- You need strong tungsten carbide tools to cut cast iron.

- Change your cutting speed and use dust collectors to keep things safe and clean.

You can fix these problems by picking the right tools and ways to work. Always check your tools and change how you work to match cast iron. This helps you get a smooth finish and keeps your tools working well.

Weldability Ratings

It is important to know how well cast steel and cast iron can be welded. Cast steel is easy to weld. You can use many ways to weld it. It does not crack or get weak after welding. This is why people use cast steel for strong parts that need fixing sometimes.

Cast iron is harder to weld. It can crack or get weak if you do not use special steps. You must heat cast iron before welding and let it cool slowly. You also need special electrodes and careful ways to weld.

| Material | Weldability Rating | Notes |

|---|---|---|

| Cast Steel | High | Welds easily, stays strong after welding |

| Cast Iron | Low to Moderate | Needs preheating, slow cooling, special care |

Tip: Always pick the right way to machine and weld for the metal you use. This helps you get good results and saves you from making mistakes.

Pre- and Post-Weld Treatments

When you weld cast steel or cast iron, you must pay close attention to how you heat and cool the metal. These steps—called pre-weld and post-weld treatments—help you avoid cracks, control stress, and make your welds last longer.

Pre-Weld Treatments

Before you start welding, you need to preheat the workpiece. Preheating slows down the cooling rate and keeps the metal from cracking. The right temperature depends on the type of metal and its carbon content.

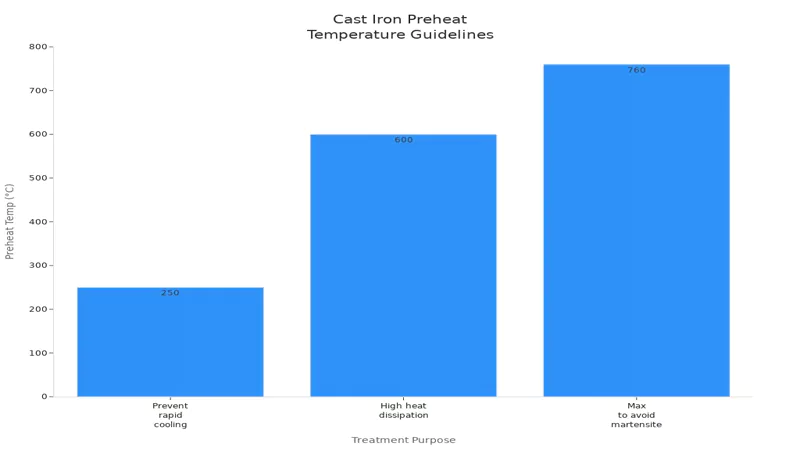

Here is a table that shows common preheat temperatures and their purposes:

| Material Type | Preheat Temperature (°C) | Purpose |

|---|---|---|

| Mild Steels | 100–150 | Minimize thermal stresses and reduce cracking risk |

| High-Carbon Steels | 200–300 or higher | Lower the chance of hydrogen-induced or cold cracking |

| Cast Irons | 250–400 | Prevent rapid cooling and cracking, especially with high carbon |

| 600–650 | For parts with high heat dissipation | |

| 760 | Maximum to avoid martensite formation |

Note: For cast iron, you often need to preheat to at least 250 °C. If the carbon content is high (C ≥ 3%), you may need to go up to 400 °C or more. For very large or thick parts, you can preheat up to 760 °C, but do not exceed this limit.

You can see how the recommended preheat temperatures compare in this chart:

Why Preheating Matters:

- Reduces the risk of sudden temperature changes that cause cracks.

- Helps carbon in cast iron stay stable, so the weld does not become brittle.

- Makes the weld area easier to machine after welding.

Post-Weld Treatments

After welding, you need to control how the metal cools. If you let it cool too fast, cracks can form. Post weld heat treatment (PWHT) helps you manage this process.

- PWHT means heating the welded part to a set temperature (usually between 450 °C and 700 °C).

- You hold this temperature for 6 to 8 hours.

- Then, you let the part cool down slowly, often in a furnace or under insulation.

Benefits of PWHT:

- Reduces internal stresses in the weld and the heat-affected zone (HAZ).

- Makes the weld joint more ductile and less likely to crack.

- Improves machinability, so you can finish the part to a high standard.

Tip: Always match your pre- and post-weld treatments to the type of metal and the size of your workpiece. Careful temperature control gives you stronger, longer-lasting welds.

Summary Checklist for Success:

- Preheat cast iron and cast steel to the right temperature before welding.

- Use slow, even heating and cooling to avoid stress and cracks.

- Apply PWHT after welding, especially for thick or high-carbon parts.

- Always monitor temperatures with reliable tools.

By following these steps, you ensure your welded parts stay strong, safe, and easy to machine.

Steel Casting Welding Techniques

Welding Processes

When you weld cast steel, you have several welding processes to choose from. Each process offers unique benefits, and your choice depends on the thickness of the steel, the working environment, and the quality you want to achieve. You can use these welding methods for steel casting welding:

- The hybrid laser–electric arc process works well for thick cast steel plates, such as those 20 or 25 mm thick. This process combines the deep penetration of laser beam welding with the flexibility of arc welding. You get strong, stable welds, especially for large or critical parts.

- Laser beam welding gives you excellent stability and high power density. You can use this method for underwater welding or when you need a very precise weld. It is fast and produces minimal distortion.

- For most jobs, you can use common arc welding methods. These include Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Submerged Arc Welding (SAW), and Shielded Metal Arc Welding (SMAW). You usually perform these with multi-pass procedures, especially when working with thick or complex cast steel parts.

You should always match the welding process to the job. For example, if you need to weld a thick cast steel plate, the hybrid laser–arc process or SAW will give you the best results. For smaller repairs or detailed work, GTAW or GMAW may be better choices.

Tip: Always check the thickness and type of cast steel before you choose your welding process. The right process helps you avoid defects and ensures a strong, lasting weld.

Material Selection

Material selection plays a key role in the outcome of your weld. You must decide if your project needs casting or welding, and you must know the properties of the materials you use. Each type of cast steel has unique characteristics that affect how it responds to heat and welding.

- Low-carbon cast steel is easier to weld. It resists cracking and gives you a ductile, strong weld.

- Medium-carbon and high-carbon cast steel need more care. They can crack if you do not preheat them or control the cooling rate.

- Alloyed cast steel may contain elements like manganese, chromium, or nickel. These elements improve strength but can make welding more challenging.

You should always match your filler material to the base metal. If you use the wrong filler, your weld may become brittle or weak. For most cast steel, mild steel electrodes work well. For alloyed cast steel, you may need special electrodes that match the alloy content.

Note: The right material selection ensures your weld is as strong as the original cast steel. Always check the specifications before you start.

Defect Repair

Defects can occur during steel casting and welding, but you can repair most of them if you use the right methods. Here are the most common types of defects you might find in cast steel welds and how you can repair them:

| Defect Type | Repair Method |

|---|---|

| Penetrating cracks | Remove the defect, preheat the area, and use specific welding techniques. |

| Honeycomb pores | Use carbon arc air gouging, then grind the area until you see a metallic shine. |

| Shrinkage defects | Clean the defect, grind it to a U-shape, and use <4mm-J422 rods at 160~180A. |

| Sand and slag inclusions | Remove all inclusions before welding. Some defects cannot be repaired. |

| Large shrinkage areas | Judge before repair. Some large areas may not be allowed to be repaired. |

You can use these steps to repair most defects:

- Use carbon arc air gouging to remove cracks or pores.

- Grind the area with a handheld angle grinder until you see a bright, metallic surface.

- Preheat the area before welding to prevent new cracks from forming.

- Remove slag immediately after welding to keep the weld clean and strong.

Tip: Always inspect your welds carefully. If you find a defect, repair it right away using the correct method. This keeps your cast steel parts safe and reliable.

By following these techniques, you can handle most challenges in steel casting and welding. You will produce strong, durable welds and extend the life of your cast steel components.

Quality Control

You need to watch quality control closely when welding cast steel. Quality control helps make sure each weld is strong and safe. It also helps you find hidden problems before they cause trouble. If you skip steps, your welds might be weak or break later. You should follow a list of checks at every step.

Here are the main ways to control quality for cast steel:

| Quality Control Measure | Description |

|---|---|

| Specimen Sectioning | Cut samples that include the whole weld. This lets you see if there are hidden problems inside. |

| Surface Conditioning | Grind or polish the surface first. This makes it easier to test for cracks or holes. |

| Process Specifications | Always use the right rules for welding. This helps stop weak welds or bad seams. |

| Quality Assurance Systems | Use a system like ISO 9001 to keep your work the same every time. |

| Documentation | Write down every check and repair. Good notes help you find and fix problems. |

| Training | Make sure everyone learns the newest ways to check welds. Training keeps your work good. |

Start by checking each cast steel part before you weld. Look for cracks, holes, or other problems on the surface. If you find any, fix them first. After you finish welding, check the welds again. Use your eyes and also use special tests, like ultrasonic or X-ray, to find hidden flaws.

Note: Grinding or polishing the surface helps you see small cracks or holes. Always get the surface ready before you test it.

You also need to cut through the weld to look inside. This helps you find problems you cannot see from the outside. If you find a problem, change your process before you weld more parts. This is very important for thick or important cast steel pieces.

Always use the right welding settings, like current and speed. Do not change these unless you have a good reason. If you use the wrong settings, your welds can be weak. Always follow the approved process for each kind of cast steel.

A good quality system helps you stay organized. Systems like ISO 9001 help you plan checks, repairs, and training. They also help you find out where a problem started. Keep good notes about every check, test, and repair. If something goes wrong later, you can look back and see what happened.

Training is also very important. You and your team should learn new ways to check and weld often. New tools and methods come out all the time. Learning them helps you avoid mistakes and keeps your welds strong.

- Check cast steel parts before and after welding.

- Get surfaces ready for testing.

- Cut through welds to look for hidden problems.

- Follow all welding rules.

- Use a quality system and keep good notes.

- Train your team often.

If you do all these things, your welds will be safe and strong. You will do a good job every time, and people will trust your work.

Welding Cast Iron Techniques

Welding Processes

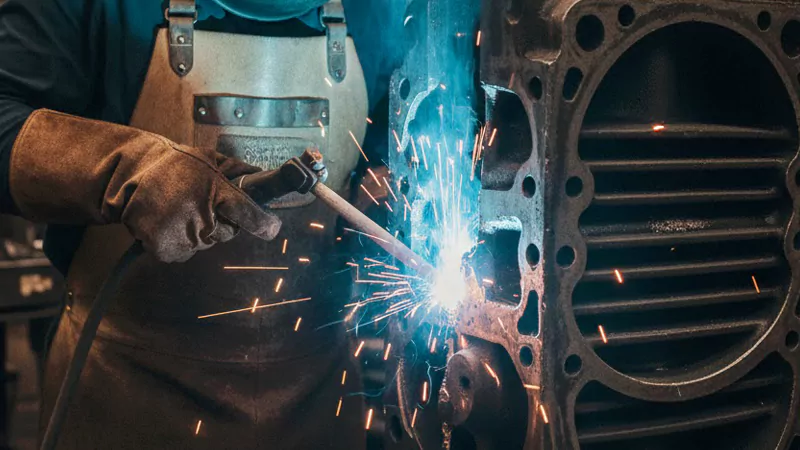

Welding cast iron is tricky because it breaks easily. This happens because it has a lot of carbon. You need to pick the right welding process to stop cracks. Most people use Shielded Metal Arc Welding (SMAW) for cast iron. SMAW lets you control heat and the weld pool well. For careful work, you can use Gas Tungsten Arc Welding (GTAW) or Gas Metal Arc Welding (GMAW). These methods help you control heat and stop cracks.

If you have a small repair, oxy-acetylene welding works well. It lets you control the heat and cool the part slowly. If you must weld outside or when it is windy, flux-cored arc welding helps. It keeps the weld safe from wind and dirt.

Always clean the area before you start welding. Take off oil, paint, and rust. Use a grinder to make the surface smooth. This helps the weld stick and stops problems. Weld in short sections and let each one cool. This keeps the part from getting too hot and cracking.

Tip: Pick your welding process based on the size and shape of the cast iron part. For big or tricky parts, use a method that lets you control heat and cooling.

Preheating & Cooling

Preheating is very important when welding cast iron. You must heat the whole part before you start. This helps stop cracks from sudden temperature changes. Studies show preheating between 300°C and 600°C makes the weld less hard. A preheat of 540°C works well to stop hard spots and cracks.

When you preheat, the whole part gets warm. This stops fast cooling, which can make the weld hard and easy to break. Preheating also slows cooling after welding. This gives carbon time to move back into the metal. It keeps the weld from getting too hard. Preheating also lowers stress inside the part. This helps stop cracks and bending.

Here are the main reasons to preheat and cool slowly:

- Preheating makes the whole part warm, so heat spreads out.

- It stops fast cooling, which can make the weld hard and brittle.

- Preheating slows cooling, so carbon can move back into the metal.

- It lowers stress inside the part and stops cracks.

Follow these steps for preheating and cooling:

- Heat the cast iron part to between 200°C and 400°C.

- For thick parts, use more heat so the middle gets warm.

- If the part has lots of carbon, use a higher preheat.

- After welding, let the part cool very slowly. You can put it in dry sand or use a furnace to slow down cooling.

Note: Do not cool the part too fast. Slow cooling is just as important as preheating for good welds.

Electrode Selection

Picking the right electrode is very important for cast iron. The type of cast iron, where you work, and how you weld all matter. You need to match the electrode to the job for the best weld.

Here is a table that shows what to think about when picking electrodes for cast iron:

| Criteria | Description |

|---|---|

| Type of Cast Iron | Each type of cast iron (grey, white, malleable) welds differently. |

| The Project’s Environment | Things like wind and wetness change how the weld turns out; some electrodes work better outside. |

| Preheating & Post-Heating | Controlling temperature is key to stop cracks; some electrodes are better for hot jobs. |

| Matching Welding Techniques | The electrode must fit the welding method (like TIG for careful work, flux core for outside). |

Most of the time, nickel-based electrodes work best for cast iron. They make a soft weld that is easy to cut and shape. If you want to save money, you can use iron-based or steel electrodes. These can make the weld harder and easier to break. Copper-based electrodes are good for some repairs, especially if you need to cut the weld later.

Always check what kind of cast iron you have before picking an electrode. Grey cast iron needs electrodes that stop carbon from moving and keep the weld soft. Malleable and ductile cast iron allows you to use more kinds of electrodes. For outside jobs, use electrodes that do not mind wind or wetness.

Tip: Always read the instructions that come with your electrodes. Use the right current and method for the best weld on cast iron.

If you follow these tips, you can weld cast iron well. You will have fewer cracks, stronger welds, and repairs that last longer.

Crack Prevention

When you weld cast iron, preventing cracks is your top priority. Cracks can form easily because cast iron is brittle and sensitive to heat changes. If you do not control the process, the weld can fail quickly. You need to follow proven steps to keep your welds strong and reliable.

Here are the most effective ways to prevent cracks when welding cast iron:

- Preheat the workpiece properly. Heating the entire piece before you start welding cast iron helps reduce thermal stress. This step keeps the temperature even and stops cracks from forming.

- Use short weld passes. When you weld cast iron, keep each weld pass short. This limits the amount of heat in one spot and lowers the risk of cracking.

- Peen the weld bead after each pass. Lightly tapping the weld with a hammer while it is still hot relieves stress. This action spreads out the tension and helps prevent cracks.

- Cool the part slowly. After welding cast iron, let the part cool down very slowly. You can use dry sand, a furnace, or special blankets to keep the temperature from dropping too fast.

Tip: Never rush the cooling process. Rapid cooling is one of the main reasons cracks appear in cast iron after welding.

You should also choose the right welding technique for the job. For example, if you use steel casting welding methods on cast iron, you must adjust your approach. Cast iron needs more care than steel. Always clean the area before you start welding cast iron. Remove oil, paint, and rust to help the weld stick and reduce the chance of cracks.

A table can help you remember the main steps for crack prevention:

| Step | Why It Matters |

|---|---|

| Preheat | Reduces thermal stress and prevents cracking |

| Short Weld Passes | Limits heat input and lowers crack risk |

| Peening | Relieves stress in the weld bead |

| Slow Cooling | Prevents rapid temperature changes and cracks |

When you follow these steps, you make welding cast iron safer and more successful. You protect your work from costly repairs and keep your parts strong. Always pay attention to the details. Small changes in your process can make a big difference in the quality of your welds.

If you want your welding cast iron projects to last, focus on crack prevention every time. This approach will help you get the best results, whether you are repairing machinery, restoring old parts, or working on new builds.

Practical Tips & Troubleshooting

Workpiece Preparation

You set the stage for a successful weld by preparing your workpiece the right way. Start by cleaning the weld area with a non-chlorinated degreaser. Remove all oil, grease, and dirt. Use a grinder or a wire brush to expose clean, bright metal. This step helps the weld stick and prevents defects.

Before you begin welding, follow these best practices:

- Preheat the casting to at least 250°F (120°C) for cast iron and 300°F (150°C) for cast steel. This relieves stress in the heat-affected zone.

- Use a propane torch or heat blanket to bring the entire part or weld area to the correct temperature. Make sure the heat spreads evenly.

- Clean the edges to bare metal. This ensures a strong bond.

- For cast steel with more than 0.40% carbon, preheat to prevent hydrogen from causing cracks.

- Maintain a steady preheat of 150–200°C during welding. Allow the part to cool slowly over several hours after welding.

- Run a low-amp test bead to check if the area is clean enough for welding.

Tip: Always bring the whole part or weld area to temperature before you start. This reduces thermal shock and helps prevent cracks.

Distortion Control

Welding can cause parts to bend or twist. You can control distortion by using the right techniques and tools. Here are some proven methods:

- Tack welding: Place small, temporary welds to hold pieces in position. This keeps them from moving as you weld.

- Back-to-back assembly: Weld components in pairs to balance heat and reduce the risk of distortion.

- Stiffening: Add braces or gussets to reinforce areas that might bend.

- Choose precise welding methods like TIG welding. This gives you better heat control and reduces thermal stress.

- Plan your welding sequence. Weld in an order that spreads heat evenly.

- Use fixtures and jigs to keep parts in place during welding and cooling.

- Preset your assembly to allow for expected distortion. This helps you achieve the right shape after welding.

Note: Always use fixtures or jigs when possible. They help you keep everything accurate and reduce distortion.

Repair Methods

When you find a defect in your weld, you have several repair options. The method you choose depends on the type of metal, the defect, and the finish you want.

- Select the right filler material. Match the electrode or rod to the type of cast iron or steel and the finish you need.

- Nickel-arc rods work well for cast iron. They come in different grades based on nickel content.

- For some repairs, you can use brass rods and braze the area. This method needs skill, especially in the field.

- Metal stitching is a strong repair method for cast iron thicker than 1/4 inch. It uses minimal heat and helps avoid cracks.

You can also use these welding techniques for repairs:

- Stick Welding (SMAW): Use electrodes like ENi99 for cast iron. This gives you a strong, machinable weld.

- TIG Welding: Best for thin castings. Use high-quality nickel-based filler for precision.

- Oxy-Acetylene Welding: This lower-temperature method seals cracks and reduces the risk of new cracks.

Tip: Always match your repair method to the defect and the type of metal. This ensures a strong, lasting fix.

By following these steps, you prepare your workpiece, control distortion, and repair defects with confidence. These tips help you achieve high-quality results in steel casting, welding, and cast iron projects.

When to Use Machining

When you work with cast steel or cast iron, you sometimes need to pick between welding and machining. Machining is very important in some situations. Knowing when to use machining helps you get good results and saves money.

Here are times when you should use machining:

- After Welding Repairs:

Welding can leave the surface bumpy or uneven. Machining takes off extra weld metal and brings back the original shape. You get a smooth finish that matches exact sizes. - For Precision Features:

If your part needs holes, slots, or threads that must be exact, machining is the best way. Welding cannot make features as accurate. Machining makes sure everything fits just right. - To Remove Defects:

Welding can leave small cracks, pores, or rough spots. Machining lets you cut away these problems. You can check the area and make sure the part is strong. - When Surface Finish Matters:

If you want a shiny or smooth surface, machining gives you the look you need. Welded surfaces are often rough. Machining makes the part look better and work better. - For Complex Geometries:

If you need special shapes or patterns, machining is the most flexible. You can make parts that welding alone cannot create.

Tip: Plan to use machining if your part needs to meet strict rules or if you want a perfect finish.

Here is a simple table to help you choose:

| Scenario | Should You Use Machining? | Why? |

|---|---|---|

| Welded surface is rough | Yes | Get a smooth finish |

| Tight tolerances are required | Yes | Make sure sizes are correct |

| Small cracks or pores remain | Yes | Remove problems |

| Complex shapes are needed | Yes | Make detailed features |

| Simple, non-critical repair | No | Welding might be enough |

Machining helps your process in many ways:

- You make your parts better and stronger.

- You meet what customers want for looks and size.

- You help your parts last longer by fixing weak spots.

Machining gives you high accuracy, does the same job every time, and makes parts look great. New machining tools like CNC machines let you make lots of parts and change them for any job. When you use both welding and machining, you get strong parts and perfect shapes.

Note: If you do not know what to do, ask a machining expert. They can help you pick the best way for your project.

Applications & Use Cases

Cast Steel Applications

Cast steel is used in many jobs because it is strong and flexible. People pick cast steel for parts that must hold a heavy weight or take a lot of force. If you need something that bends but does not break, cast steel is a good choice.

Car makers use cast steel for engine blocks and crankshafts. In airplanes, cast steel is used for landing gear and engine mounts. Big machines like bulldozers and cranes use cast steel for their frames and arms. Power plants use cast steel for turbine blades and pressure vessels. Ships have cast steel propellers and rudders. Oil and gas workers use cast steel for valves and drill bits.

Cast steel is great when you need a part that lasts a long time and works in tough places.

Cast Iron Applications

Cast iron is good for different reasons. It is used when you want something that does not wear out fast and can withstand vibration.

Cast iron is used for engine blocks, machine bases, and pipes. Builders use cast iron for columns and fancy railings. Manhole covers and street grates are often made from cast iron because it can handle cars and bad weather. In the kitchen, cast iron is used for pans and pots that keep heat well. Cast iron is also found in pumps, valves, and gear housings.

If you need a part that stays the same shape and does not move, cast iron is a smart choice. People pick cast iron because it is hard and can stop noise and shaking.

Industry Examples

You can look at real examples to see how cast steel and cast iron are used. Here is a table that shows where each one is used:

| Industry | Cast Steel Uses | Cast Iron Uses |

|---|---|---|

| Automotive | Engine blocks, crankshafts | Brake drums, cylinder heads |

| Aerospace | Landing gear, turbine housings | Pump housings, brackets |

| Construction | Crane arms, excavator frames | Columns, manhole covers |

| Energy | Turbine blades, pressure vessels | Pipe fittings, valve bodies |

| Marine | Propellers, rudders | Anchor housings, pump bases |

| Oil and Gas | Drill bits, valves | Compressor housings, pipe supports |

Note: Always pick the right material for your job. Cast steel is best for strength and bending. Cast iron is best for staying in place and not wearing out.

Both cast steel and cast iron are important in many jobs today. Use cast steel if you need something tough that can take a lot of stress. Use cast iron if you want a part that does not move and lasts a long time. Knowing these uses helps you make better choices for your work.

Cost & Environmental Factors

Material Costs

When you pick between cast steel and cast iron, you should think about how much each one costs. Cast iron is usually cheaper. This is because it is easier to make and the materials do not cost as much. Cast steel costs more money. It is stronger and lasts longer, so you pay extra for those good qualities.

Here is a table to help you see the differences:

| Aspect | Cast Iron | Cast Steel |

|---|---|---|

| Material Cost | Cheaper because it is easy to cast and uses less expensive materials. | Costs more, but it is stronger and lasts longer. |

| Environmental Impact | Easy to recycle, but making it still needs a lot of energy. | Needs even more energy, but recycling is getting better. |

| Lifecycle Cost | Costs less at first, but you might spend more on fixing or shaping it. | Costs more at first, but you save money later because it lasts longer. |

You might choose cast iron if you want to spend less money at the start. If you want something that will last a long time and not break easily, cast steel is a better pick. Even though cast steel costs more at first, you may save money over time because you do not have to fix or replace it as much.

Consumable Availability

You also need to think about what you use to weld these metals. For cast iron, you often need special rods, like nickel or copper ones. These rods can be hard to find and cost more money. Cast steel uses rods that are easy to get, like mild steel rods. You can buy these almost anywhere, and they do not cost as much.

- Cast iron welding rods are not always easy to find.

- Cast steel rods are common and simple to buy.

- If you work far from a city, it might be hard to get the right rods for cast iron.

Tip: Always check with your local stores before you start. Make sure you can get the right rods for cast steel or cast iron.

Environmental Impact

You should also think about how your choice affects the Earth. Cast iron is easy to recycle. Many places can melt old cast iron and use it again. But making new cast iron still uses a lot of energy. Cast steel needs even more energy to make, but new ways to recycle it are helping the planet.

- Making cast iron uses less energy than making cast steel, but both need a lot of heat.

- Recycling cast iron is common and saves resources.

- Recycling cast steel is getting better with new technology.

If you want to help the earth, recycle both cast steel and cast iron when you can. You can also pick companies that use recycled metal and save energy.

Note: Picking the right metal is not just about saving money. You also help the earth when you recycle and use materials carefully.

Quick Comparison Table

Key Differences

You need to pick cast steel or cast iron for welding. Each one acts differently when you work with it. The table below shows the main differences between them:

| Feature | Cast Steel | Cast Iron |

|---|---|---|

| Carbon Content | Lower (usually <2.11%) | Higher (2%–4%) |

| Weldability | High, easy to weld | Low, needs special care |

| Brittleness | Less brittle, more ductile | Very brittle, cracks easily |

| Preheating Needs | Sometimes needed | Always needed |

| Cooling Requirements | Air cooling often enough | Slow cooling required |

| Machinability | Easy to machine | Hard to machine |

| Application Examples | Gears, frames, turbines | Engine blocks, pipes |

| Cost | Higher | Lower |

| Environmental Impact | High energy to produce | Easier to recycle |

| Consumable Availability | Common electrodes | Special rods often needed |

Note: Always use the right welding method for your metal. Cast steel lets you use more ways to weld. Cast iron needs careful steps every time.

Technique Summary

Welding cast steel is simple. You can use regular welding methods. You do not worry much about cracks. Preheating is not always needed. You can let cast steel cool in the air. Welds stay strong and bend easily. Machining after welding is easy and gives a smooth finish.

Welding cast iron is harder. You must preheat every time before welding. Use special electrodes like nickel rods. Weld in short passes and let it cool slowly. Sometimes you cool it in sand or a furnace. If you skip these steps, cast iron can crack or break. Machining cast iron after welding is tough. You need strong carbide tools.

Here is a checklist to help you remember:

- For cast steel:

- Use regular electrodes.

- Preheat only if the part is thick or has lots of carbon.

- Weld with normal methods.

- Let it cool in the air.

- Machine it easily after welding.

- For cast iron:

- Always preheat before welding.

- Use nickel or copper electrodes.

- Weld in short, careful passes.

- Cool it slowly to stop cracks.

- Use carbide tools for machining.

Tip: If you want your weld to last, always use the right steps for cast steel or cast iron. Your results depend on matching your technique to the metal.

You now understand the key differences between cast steel and cast iron. Cast steel gives you flexibility and strength for many welding jobs. Cast iron needs careful handling to avoid cracks. Always match your welding technique to the material. Use the comparison table to guide your choices. Cast steel works well for parts that need to bend or take heavy loads. Cast iron fits best where vibration and wear matter most. If you face a complex project, seek expert advice. You can achieve strong, lasting welds with the right approach.

FAQ

You must preheat cast iron before welding. This step helps prevent cracks and keeps the weld strong. Always let the part cool slowly after welding.

You can often weld cast steel without preheating, especially if the part is thin or low in carbon. For thick or high-carbon cast steel, preheating helps reduce the risk of cracking.

Nickel-based electrodes work best for most cast iron repairs. You can also use copper-based or mild steel electrodes for some jobs, but these may make the weld harder and less machinable.

- Use tack welds to hold parts in place.

- Weld in a balanced sequence.

- Add stiffeners or use jigs for support.

These steps help keep your workpiece straight and true.

You should machine a welded part when you need a smooth finish, tight tolerances, or to remove defects. Machining after welding ensures your part meets exact size and quality requirements.

Cast steel welds easily and stays ductile. Cast iron needs preheating and slow cooling to avoid cracks. You must use special electrodes for cast iron, while mild steel electrodes work for cast steel.

Yes, you can repair cracks in cast iron with welding. Preheat the part, use short weld passes, and let it cool slowly. For best results, use nickel-based electrodes and peen the weld bead after each pass.