In the manufacturing of custom metal parts, selecting the appropriate surface treatment is as critical as the material selection itself. For mechanical engineers and product designers, this decision often comes down to choosing between Black Oxide Treatment and Nickel Plating. These finishes offer vastly different technical characteristics regarding dimensional stability, corrosion resistance, and wear life.

Technical Comparison: Key Features at a Glance

| Feature | Black Oxide Treatment | Nickel Plating |

|---|---|---|

| Corrosion Resistance | Moderate (strictly requires oil/wax) | Good to Excellent |

| Dimensional Change | Negligible (0.5–2.5 microns) | Adds physical thickness |

| Aesthetics | Professional Matte Black | Versatile (Bright, Satin, Black) |

| Typical Applications | Precision gears, fasteners, tools | Aerospace, medical, electronics |

Table of Contents

Black Oxide Treatment: What You Need to Know

The Technical Process of Black Oxide Application

Black oxide is a chemical conversion coating designed to transform the surface of a metal part into a coherent oxide film. Unlike plating or painting, this process alters the surface chemistry of the substrate to provide a sleek black aesthetic while maintaining absolute dimensional stability. The standard application involves the following rigorous steps:

- Degreasing and Cleaning: A thorough cleaning phase to remove oils, contaminants, and fingerprints, ensuring uniform chemical reactivity across the entire surface.

- Pickling (Acid Treatment): The part is treated with an acid solution to remove scale and light rust, effectively activating the metal surface for the conversion process.

- Neutralizing and Rinsing: Multiple rinsing stages eliminate residual chemicals, preparing the substrate for the blackening chemistry.

- Chemical Blackening Bath: The part is submerged in a controlled alkaline salt solution at specific temperatures. This induces a chemical reaction that grows a layer of magnetite directly on the metal surface.

- Post-Treatment (Sealing): Because the resulting black oxide layer is naturally porous, it is treated with rust-preventative oil or wax. This crucial step provides the necessary corrosion resistance and deepens the matte finish.

Material Compatibility: This process is ideal for carbon steel, alloy steel, cast iron, and specific stainless steel alloys. Depending on your performance requirements and budget, you can specify either Hot Black Oxide or Cold Black Oxide processes.

Key Engineering Features of Black Oxide Coating

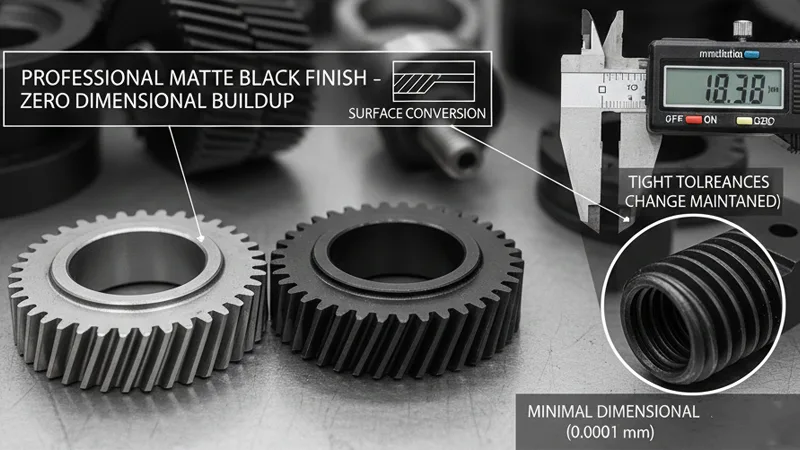

The primary advantage of black oxide treatment is its ability to provide a professional matte black finish with zero dimensional buildup. Since it is a surface conversion rather than an additive coating, the physical dimensions of the part remain unchanged.

Technical Specifications:

| Coating Type | Thickness Range (microns) | Dimensional Change (inches) | Tolerance Impact |

|---|---|---|---|

| Black Oxide | 0.5 – 2.5μm | ~0.000005 | Maintains tight tolerances |

| Hot/Cold Black Oxide | 5 – 10 millionths | Minimal (0.0001 mm) | No effect on precision parts |

Nickel Plating Technology: Engineering Fundamentals

Nickel plating is one of the most versatile surface finishing processes in modern manufacturing. By depositing a nickel alloy onto a metallic substrate, this process significantly enhances oxidation resistance, corrosion protection, and surface hardness. Beyond its functional advantages, nickel plating offers a spectrum of decorative finishes—from matte to high-gloss—making it a critical solution for improving both the service life and maintenance efficiency of precision components.

Categorization of Nickel Plating Processes

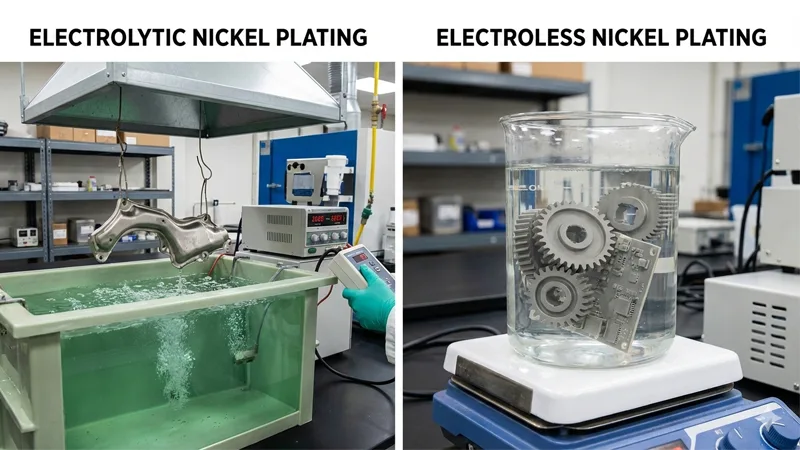

Nickel plating is primarily divided into two systems based on the deposition mechanism: Electrolytic Nickel Plating and Electroless Nickel Plating. Electrolytic plating relies on an external electrical current to drive deposition and offers diverse aesthetic options. In contrast, electroless plating uses an autocatalytic chemical reaction, providing exceptional thickness uniformity on complex geometries.

The table below outlines the technical characteristics and typical applications of various nickel plating types:

| Plating Type | Process Description | Typical Applications |

|---|---|---|

| Electrolytic Nickel | Uses external current; available in bright, satin, or black finishes | Automotive components, hand tools, decorative hardware |

| Electroless Nickel (ENP) | The most significant characteristic of electroless nickel plating is its self-catalytic property | Aerospace parts, precision valves, molds, and electronic assemblies |

| Bright Nickel | Includes organic brighteners for a mirror-like, high-gloss finish | Sanitary fittings, appliance housings, automotive trim |

| Satin Nickel | Produces a semi-gloss or frosted texture; minimizes fingerprints | Furniture handles, architectural hardware, high-end electronics |

| Black Nickel | Provides a dark, decorative, and light-absorbent surface | Optical lens barrels, apparel accessories, circuit shielding |

| Nickel Sulfamate | Autocatalytic deposition achieves superior thickness uniformity | Furniture handles, architectural hardware, and high-end electronics |

Technical Note: Due to its autocatalytic nature, Electroless Nickel Plating (ENP) achieves true “total coverage.” Even for deep bores, blind holes, or intricate thread structures, the thickness deviation remains minimal while providing superior corrosion barriers.

Key Performance Features and Industrial Applications

In industrial environments, nickel plating demonstrates excellent material compatibility, suitable for steel, copper, brass, and even specially pre-treated plastics.

Geometric Adaptability: For parts with complex internal cavities or fine features, Electroless Nickel is the preferred solution. It eliminates the “edge effect” (high current density at corners) common in electroplating, ensuring a perfectly uniform layer across all surfaces—a critical requirement in the aerospace and medical device industries.

Aesthetic Customization: Electrolytic plating offers a wide range of visual possibilities. While Bright Nickel provides high reflectivity, Satin and Black Nickel offer a muted, professional industrial aesthetic.

Corrosion Resistance and Durability: Nickel plating significantly extends the operational lifespan of parts in harsh environments. In Neutral Salt Spray (NSS) testing, electroless nickel coatings typically withstand over 1,000 hours without oxidation, whereas standard electrolytic coatings generally range between 200-500 hours.

Process Stability: The bond between the nickel layer and the substrate is exceptionally strong. Depending on design requirements, parts can undergo moderate mechanical forming or machining after plating without the risk of delamination or brittle fracture.

Engineering Tip: If your components have strict dimensional tolerances or complex internal geometries, always specify Electroless Nickel Plating. For projects where aesthetic appeal, decorative color, or high-volume cost efficiency are the priorities, Electrolytic Nickel Plating is the more cost-effective choice.

Black Oxide Pros and Cons

Advantages of Black Oxide

Precision Tolerance Maintenance: The negligible thickness of the coating makes it the preferred choice for components with micron-level tolerances, such as bearing seats and precision threads.

Anti-Glare Properties: The non-reflective matte finish effectively eliminates glare, which is critical for optical instruments, measuring tools, and firearm components.

Enhanced Aesthetic Appeal: It provides a uniform, high-end industrial appearance while offering moderate resistance to surface abrasions and scratches.

Functional Corrosion Resistance: When integrated with secondary oil or wax sealants, it offers reliable protection against oxidation in indoor environments.

Engineering Tip: If your components require a balance of high-precision fit, professional aesthetics, and cost-effective surface protection, black oxide is the industry-standard solution.

Limitations of Black Oxide

Black oxide has some downsides you should know. The coating needs oil or wax to keep rust away. If you do not add oil often, rust can show up. You must put oil again and again to keep the parts safe. The coating alone will not stop rust for a long time unless you take care of it.

Here is a table that shows the main downsides of black oxide:

| Limitation | Description |

|---|---|

| Supplemental Sealing Required | Needs oil or wax after treatment for full corrosion resistance. |

| Periodic Re-oiling Needed | Requires regular maintenance to prevent rust and maintain protection. |

| Sealing Requirement | Can rust if not properly sealed, limiting corrosion resistance over time. |

| Maintenance Frequency | Protective qualities depend on consistent reapplication of oil or wax. |

You need to plan for regular care to keep parts safe. Black oxide is not the best for places where you cannot do upkeep. The coating’s rust protection depends on how well you keep up with oiling. If you want the most rust protection with little work, you might need a different finish.

Note: Black oxide protects well, but only if you keep up with care. You must reapply oil often for strong rust protection.

Nickel Plating Pros and Cons

Advantages of Nickel Plating

Nickel plating gives your parts many good benefits. This finish is strong and easy to take care of. Nickel plating makes a tough layer on your parts. It keeps out water, chemicals, and rough weather. Your parts stay safe from rust, even in hard places. Nickel plating helps parts last longer. It stops them from wearing down or getting scratched. This means your parts keep working well for a long time.

- Nickel plating protects against rust, so it works in tough jobs.

- The nickel layer is hard, so parts last longer and need fewer replacements.

- Nickel plating makes parts look smooth and nice.

- You can use nickel plating on steel, copper, and brass.

- Nickel plating is good for both looks and how things work.

You can also work on parts after plating. You can cut or grind them to fit just right. This helps when you need parts to be very exact.

Tip: Nickel plating is a good choice if you want your parts to look nice, last long, and be easy to care for.

Limitations of Nickel Plating

Nickel plating has some things you should think about. The coating adds thickness to your parts. This can change how well parts fit together. Even small changes can matter when you need things to be exact.

- Nickel plating costs more than some other finishes, like zinc plating.

- It is important for some jobs, like in planes or medical tools, to have the same thickness everywhere.

- If the coating is not even, parts may not fit or work right.

- The nickel plating process uses expensive materials.

You need to think about these things when you make your parts. If you want a finish that does not change the size much, you may want something else. Nickel plating costs more than zinc plating, but it makes parts last longer.

Nickel plating works well with cutting and shaping. You can make parts the right size after plating. This is helpful when you need parts to be very exact.

Note: Think about what your parts need before you pick nickel plating. Make sure it fits your needs for strength and care.

Black Oxide or Nickel Plating: A Comprehensive Technical Comparison

Corrosion Resistance

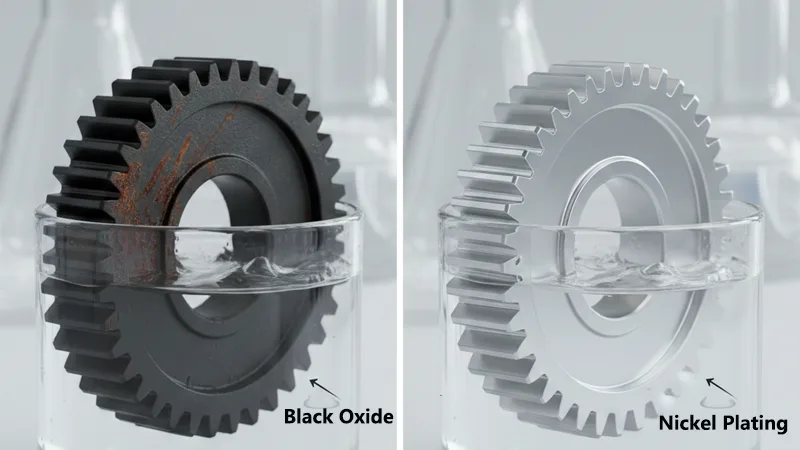

The fundamental difference between black oxide and nickel plating lies in their protective mechanisms. Black oxide is a chemical conversion coating; its corrosion resistance is highly dependent on the integrity of post-treatment sealants, such as rust-preventative oil or wax. Without these, the substrate is prone to rapid oxidation. Nickel plating, conversely, serves as a barrier coating. The deposited nickel layer physically isolates the substrate from moisture and chemical electrolytes, providing superior long-term protection.

Salt Spray Test (NSS) Performance Comparison:

| Coating Type | Corrosion Resistance Characteristics |

|---|---|

| Black Oxide | Provides minimal inherent protection. Requires frequent re-oiling/sealing to prevent oxidation in humid environments. |

| Black Zinc | Reference: Offers significantly better rust resistance through sacrificial anodic protection and chromate sealing. |

Engineering Insight: For high-humidity or chemically aggressive environments, nickel plating (especially electroless nickel) is the preferred choice. Black oxide is best reserved for controlled indoor environments or applications requiring high anti-glare properties.

Wear Resistance and Durability

In applications involving friction or high-frequency contact, each finish offers distinct advantages. Black oxide reduces the coefficient of surface friction, which helps prevent galling (surface seizing) in precision mechanical assemblies during initial break-in periods. Nickel plating—particularly high-phosphorus electroless nickel—possesses high physical hardness, enabling it to withstand severe mechanical abrasion, impact, and wear.

Black Oxide: Ideal for fasteners, hand tools, and transmission gears where maintaining original fit is more critical than extreme hardness.

Nickel Plating: Best for aerospace components, pump valves, and heavy machinery parts intended for extended service life under high-load conditions.

Appearance and Aesthetics

Aesthetic selection is usually dictated by the end-use environment. Black oxide produces a uniform, deep matte black finish that eliminates reflections, giving parts a professional, “industrial-grade” look. Nickel plating offers greater versatility, ranging from high-reflectivity mirror finishes and semi-gloss satin to decorative black nickel.

| Finish Type | Appearance Options | Typical Industries |

|---|---|---|

| Black Oxide | Matte black, non-reflective | Military, precision gauging, machine tool accessories |

| Nickel Plating | Bright, Satin, Black | Automotive, consumer electronics, medical, high-end hardware |

Cost and Economic Value

From a cost-efficiency perspective, black oxide offers high process throughput with relatively simple chemistry, making it ideal for budget-conscious projects. Nickel plating involves higher costs due to multi-stage pre-treatment, precious metal consumption, and longer deposition times. However, given its superior hardness and corrosion life, nickel plating often provides a higher lifecycle value in demanding environments.

Material Compatibility and Dimensional Impact

For precision mechanical design, dimensional buildup is a critical factor:

Black Oxide: As a conversion film, it results in near-zero dimensional change. This makes it the perfect solution for precision-fit components (such as bearing journals and fine threads) where micron-level tolerances must be maintained.

Nickel Plating: This is an additive process that increases part dimensions. Design engineers must account for the coating thickness during the machining stage or provide tolerance compensation.

Impact on Machining and Fit:

| Core Benefit | Technical Description |

|---|---|

| Enhanced Corrosion Resistance | Nickel provides a robust barrier that significantly delays the onset of oxidation. |

| Dimensional Stability | Black oxide does not alter physical dimensions, preserving the original tolerances of precision parts. |

| Reduced Friction Coefficient | The oil-impregnated surface of black oxide reduces contact stress and prevents mechanical seizing. |

Maintenance and Environmental Resilience

Post-installation maintenance is a key consideration. Black-oxided parts require periodic lubrication or re-oiling to maintain their protective qualities, particularly in non-continuous operation. Nickel-plated parts are essentially “maintenance-free,” as the dense metallic layer remains stable in complex environments without additional protection.

Selection Tips:

Choose Black Oxide if your priorities are: Extreme Dimensional Precision > Low Cost > Non-Reflective Appearance.

Choose Nickel Plating if your priorities are: Long-term Corrosion Resistance > Surface Hardness > Decorative Appeal.

Selecting the Optimal Surface Finish for Machined Components

Engineering Decision Matrix

In precision manufacturing, selecting the appropriate surface treatment is critical. This decision dictates more than just the visual quality; it directly impacts the mechanical properties, assembly tolerances, and service life of the component. When evaluating options, prioritize your core design objectives: are you seeking maximum corrosion resistance, increased surface hardness, or specific aesthetic standards?

Refer to the decision matrix below to align your technical requirements with the optimal process:

| Design Objective | Recommended Finishing Method | Common Materials |

|---|---|---|

| Corrosion Resistance | Anodizing, Electroplating (Cr/Ni/Zn), Powder Coating | Aluminum, Carbon Steel, Alloy Steel |

| High Wear Resistance | Hard Anodizing, Hard Chrome Plating, Carburizing | Tool Steel, Aluminum Alloys |

| Industrial Aesthetics | Color Anodizing, Mechanical Polishing, Brushing, Painting | Aluminum, Stainless Steel, Brass |

| Surface Prep / Descaling | Sandblasting, Chemical Cleaning, Shot Peening | PeeningVarious Metals & Engineering Plastics |

| Surface Refinement | Electropolishing, Passivation | Stainless Steel |

| Mechanical Strengthening | Heat Treatment (Quenching & Tempering, Nitriding) | Carbon Steel, Spring Steel, Aluminum |

Engineering Tip: Always define the operational environment (e.g., humidity, temperature, chemical exposure) first. Using this matrix to balance your manufacturing budget with functional performance will ensure a more reliable end product.

Industry Scenarios and Technical Recommendations

Different sectors operate under rigorous standardized requirements. For instance, the Aerospace Industry demands extreme wear resistance for landing gear and hydraulic systems; therefore, electroless nickel or hard chrome plating is often specified to withstand thermal fluctuations and chemical erosion. In the Defense and Tactical sectors, finishes must provide both impact resistance and non-reflective, anti-glare properties.

In Medical and Life Sciences, components must exhibit high cleanliness and biocompatibility. Electropolishing and specific plating grades ensure that implants and surgical instruments remain free of contaminants. Meanwhile, in Electronics and Telecommunications, the focus shifts to electrical conductivity and oxidation resistance for connectors and battery terminals.

Summary and Selection Logic:

As discussed in the previous comparisons, Black Oxide and Nickel Plating each serve distinct strategic purposes. Black Oxide is the gold standard for precision-fit components due to its zero dimensional buildup, whereas Nickel Plating excels as a superior corrosion barrier with high aesthetic versatility.

Before final approval, evaluate these critical factors:

| Critical Factor | Decision Dimension |

| Material Compatibility | Assess substrate hardness, conductivity, and chemical reactivity. |

| Service Environment | Consider exposure to salt spray, chemical solvents, or high-abrasion cycles. |

| Total Cost of Ownership (TCO) | Evaluate process economy for high-volume production vs. functional needs. |

| Regulatory Compliance | Ensure the process meets RoHS, REACH, and other international environmental standards. |

| Geometric Complexity | Evaluate if deep bores or internal cavities require high “throwing power” (uniform thickness). |

FAQ

Nickel plating (especially electroless nickel plating) offers significantly superior corrosion resistance compared to black oxide. While black oxide provides a layer of protection that is primarily effective for indoor use or when combined with oil/wax post-treatments, nickel plating creates a robust chemical barrier. For precision metal parts exposed to harsh chemicals, high humidity, or marine environments, nickel plating is the preferred industrial choice.

This is a critical factor in precision CNC machining.

- Black Oxide: It is a “conversion coating,” meaning it changes the surface of the metal without adding measurable thickness. It is ideal for parts with extremely tight tolerances where even a few microns matter.

- Nickel Plating: This is an “additive process.” It typically adds between 0.0002″ to 0.002″ of thickness per side. Designers must account for this buildup during the initial manufacturing phase to ensure the final custom metal part fits its assembly correctly.

Generally, black oxide is more cost-effective for high-volume production runs. The process is faster and requires fewer expensive chemical materials than nickel plating. If your project requires a uniform aesthetic and basic protection without a high budget, black oxide is the most economical surface finishing service. However, if durability and longevity are required, the higher upfront cost of nickel plating often saves money on replacement parts in the long run.

Black oxide is generally not recommended for outdoor environments unless it is frequently oiled or maintained. It is susceptible to red rust if the oil film breaks down. For outdoor industrial hardware or automotive components exposed to the elements, nickel plating or even zinc plating provides a much more durable shield against oxidation and environmental wear.

Yes. Electroless nickel plating is highly valued in custom metal parts manufacturing for its exceptional hardness and lubricity. It reduces friction and resists galling in moving assemblies. While black oxide provides some lubricity (when oiled), it does not harden the surface of the metal like nickel does. For gears, valves, and sliding components, nickel plating is the superior technical solution.