You can bend brass without breaking it if you first anneal the metal, use gradual force, and choose the right tools. This approach helps you avoid cracks that often develop from local brittleness or stress. Recent studies show that brass cracks during bending because of changes in chemical composition or microhardness near the bend. When you follow the right steps for how to bend brass without breaking, you reduce the risk of defects and keep your work safe and smooth.

Key Takeaways

- Always anneal brass before you bend it. This step makes the metal softer. Softer metal is less likely to crack.

- Use the correct tools for bending brass. Manual benders, roll benders, and hydraulic presses work best. These tools give you more control and better accuracy.

- Get your brass ready by marking and measuring it well. Clear marks help you get the right angle and shape.

- Hold the brass tightly while you bend it. Use a vise or wooden boards to keep it steady. This helps stop damage.

- Keep your workspace clean and neat. A tidy area lowers the chance of accidents. It also helps you focus on your work.

- Bend the brass slowly and gently. Do not rush or push too hard. Moving slowly helps stop cracks and gives smoother bends.

- Check the brass for cracks as you bend and after. Finding cracks early stops more damage and keeps you safe.

- Always wear personal protective equipment. Gloves, goggles, and boots keep you safe from injuries when working with brass.

Table of Contents

What You Need to Bend Brass

Before you start bending brass, you need to gather the right tools and safety equipment. Using the correct setup helps you work safely and get the best results. You also reduce the risk of damaging the brass or hurting yourself.

Essential Tools and Machining Equipment

To bend brass without breaking it, you need tools that give you control and accuracy. Here are some of the most important tools you should have:

- Manual benders help you shape brass rods or sheets by hand. These tools use dies and handles to guide the bend.

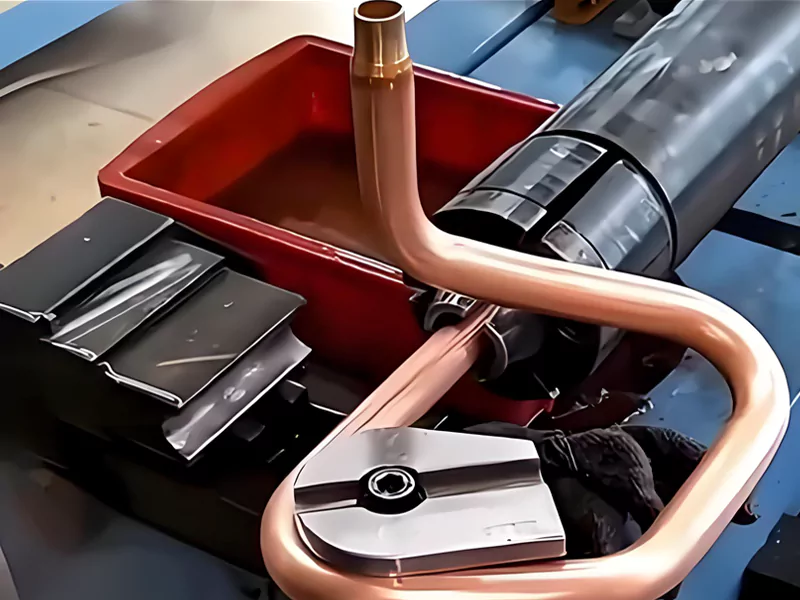

- Roll benders use rotating rolls to slowly curve brass into smooth shapes. You can use them for sheets, rods, or pipes.

- Hydraulic press brakes use hydraulic pressure to bend thick brass sheets or plates. They give you precise control over the angle and shape.

- Tube and pipe benders are made for bending brass tubes or pipes. You can find manual, hydraulic, or electric versions.

- Heat sources, such as a torch, are important for annealing brass before bending. Heating softens the metal and makes it less likely to crack.

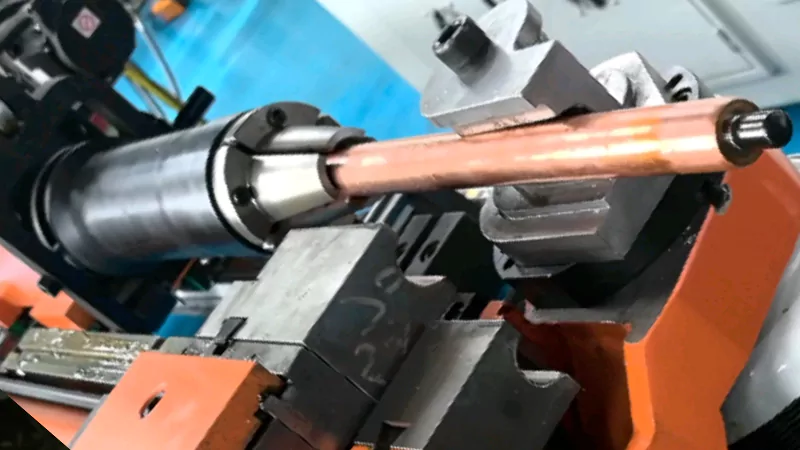

- Machining equipment, like a CNC machine, offers a versatile solution for high-precision brass bending. Machining lets you create complex bends and repeat the same shape many times with great accuracy.

Tip: Always check that your tools are clean and in good condition before you start. Well-maintained equipment helps you avoid mistakes and keeps your brass looking smooth.

Materials and Safety Gear

You also need to prepare the right materials and wear safety gear to protect yourself. Here is what you should have ready:

- Brass stock in the size and shape you want to bend. Make sure the brass is clean and free from dirt or oil.

- Safety gloves protect your hands from sharp edges and hot surfaces.

- Safety goggles shield your eyes from flying particles or sparks.

- Work boots keep your feet safe from falling objects or sharp pieces of brass.

- Personal protective equipment (PPE) is always important when working with metal. This includes gloves, goggles, and boots.

Note: Never skip safety gear. Even a small piece of brass can cause injury if you are not careful.

Having the right tools, materials, and safety gear sets you up for success. When you use proper machining methods, you can bend brass with confidence and achieve professional results.

Preparing Brass for Bending

Getting ready to bend brass is just as important as the bending itself. Careful preparation helps you avoid mistakes and keeps your project safe and accurate. You want to make sure every step is clear before you start.

Marking and Measuring

Start by measuring the brass piece you plan to bend. Use a ruler or measuring tape to find the exact spot where you want the bend. Mark this spot with a fine-tip marker or a scribe. Double-check your measurements to avoid errors. If you need to make more than one bend, mark each location clearly. Accurate marking helps you get the right angle and shape.

Tip: Use a square or angle finder to make sure your marks are straight and even. This helps you keep your bends consistent.

Securing the Brass

You need to hold the brass steady while you bend it. If you are working with a brass bar, score a groove along the inside of the bend. This groove lets the metal fold more easily and gives you a cleaner bend. Place the scored bar in a vise to keep it from moving. Tighten the vise just enough to hold the brass without crushing it.

For brass sheets, put the metal between two wooden boards in the vise. The boards support the brass and stop it from getting scratched or bent out of shape. Press down with a third piece of wood to help guide the bend. This method gives you more control and keeps the brass looking smooth.

- Use a vise for bars and rods.

- Sandwich sheets between boards for extra support.

- Score the inside of the bend for easier folding.

Cleaning the Work Area

A clean work area makes a big difference in the quality of your brass bending. Wipe down your tools and the brass to remove any dirt, grease, or dust. These small particles can cause problems during bending. Clean surfaces help the brass bend at the right angle and reduce the risk of cracks or defects.

Keeping your workspace tidy also helps you stay safe. You are less likely to trip or drop tools when everything is in its place.

Take a few minutes to organize your tools and clear away clutter before you begin. This simple step can improve your results and make the whole process smoother.

When you take time to mark, secure, and clean before bending, you set yourself up for success. Each step helps you work with brass more safely and with better results.

How to Bend Brass Without Breaking

Annealing Brass for Safe Bending

Annealing is the most important step if you want to learn how to bend brass without breaking it. When you anneal brass, you make it softer and much easier to bend. This process changes the metal’s microstructure, making it more ductile and less likely to crack.

Heating Techniques

To anneal brass, you need to apply heat in a controlled way. Place your brass piece on a fireproof surface. Use a torch to heat the area you want to bend. Move the flame back and forth so the heat spreads evenly. You want the brass to reach the right temperature for safe bending.

Here is a table that shows the best temperature ranges for annealing brass and how they affect cracking:

| Temperature Range (°C) | Effect on Cracking Potential |

|---|---|

| 350° – 450° | Reduction in cracking potential, but risk remains |

| 500° or higher | Instances of cracking drop to zero |

| 500° – 550° | Complete mitigation of cracking without affecting microstructure |

When you heat brass to 500°–550°C, you almost completely remove the risk of cracking. You do not need to guess the temperature. Watch for a dull red glow on the brass, which means it is hot enough.

As you heat the brass, several changes happen inside the metal:

- New, strain-free grains start to form and grow.

- The cold-worked structure breaks down, so the brass becomes less hard.

- Ductility increases, which means the brass can bend more without snapping.

- The grain size stays about the same at first, but the metal gets much easier to shape.

Tip: Do not overheat the brass. Too much heat can cause the metal to melt or lose its shape. Always keep an eye on the color and remove the heat as soon as you see a dull red glow.

Cooling and Handling

After you finish heating, let the brass cool down. You can let it cool in the air or dip it in water. Both methods work, but air cooling is gentler and helps keep the brass from warping. Once the brass is cool, handle it carefully. The metal will be softer and easier to bend, but it can still get scratched or dented.

You can now bend the brass using your chosen method. Because you annealed it, the brass will bend smoothly and will not crack as easily. This step is key for anyone who wants to master how to bend brass without breaking.

Using Machining for Precision Bends

If you need very accurate bends or want to make the same shape many times, machining is the best choice. Machining uses advanced equipment, like CNC machines, to bend brass with high precision. This method is perfect for projects where you cannot risk mistakes.

Machining offers several advantages over manual bending:

- CNC machines work faster and more reliably than hand tools.

- Automation reduces labor costs and cuts down on human error.

- You get fewer defects, which saves time and money.

- CNC machines can handle large batches in one go, making them great for big projects.

- You can set up the machine quickly and switch between different bends without much delay.

- Operators can manage several machines at once, which keeps the workspace safer.

When you use machining, you can achieve complex bends that are hard to do by hand. This method is a top solution for how to bend brass without breaking, especially if you want every piece to look the same.

Note: Machining is not just for factories. Many small workshops now use CNC machines for custom brass work. This makes high-precision bending available to more people.

Gradual Bending Methods

You can also bend brass by hand or with simple tools, but you need to use gradual force. Rushing the process or using too much force at once can cause the brass to snap. Here are some of the most effective gradual bending methods:

- Metal Coil Spring: Place a coil spring inside a brass tube before bending. The spring supports the wall and stops it from collapsing. This method works well for gentle bends.

- Tube Bender Machines: Use a tube bender for high-precision bends. These machines guide the brass smoothly and prevent kinks.

- Cold Bending: Bend brass at room temperature using slow, steady pressure. This method is good for simple shapes.

- Heat Induction Bending: Apply localized heat to soften the brass for more complex bends.

- Annealing: Always anneal the brass before bending to reduce hardness and improve ductility.

- Grain Direction: Bend the brass perpendicular to the grain. This spreads out the stress and lowers the chance of cracks.

- Gradual Forming: Shape the brass a little at a time. Small, progressive bends are less likely to cause damage.

Tube Bender Use

A tube bender is a great tool for learning how to bend brass without breaking. Place the brass tube in the bender, line up the mark where you want the bend, and pull the handle slowly. The bender supports the tube and makes a smooth, even curve. Always use steady pressure and avoid jerky movements.

Hand Bending with Support

If you do not have a tube bender, you can bend brass by hand. Secure the brass in a vise, and use a wooden block to press against the area you want to bend. Move the block slowly to shape the brass. For extra support, use a metal coil spring or fill the tube with sand to keep it from collapsing.

Tip: Take your time. Gradual bending is the best way to avoid cracks and get a clean result.

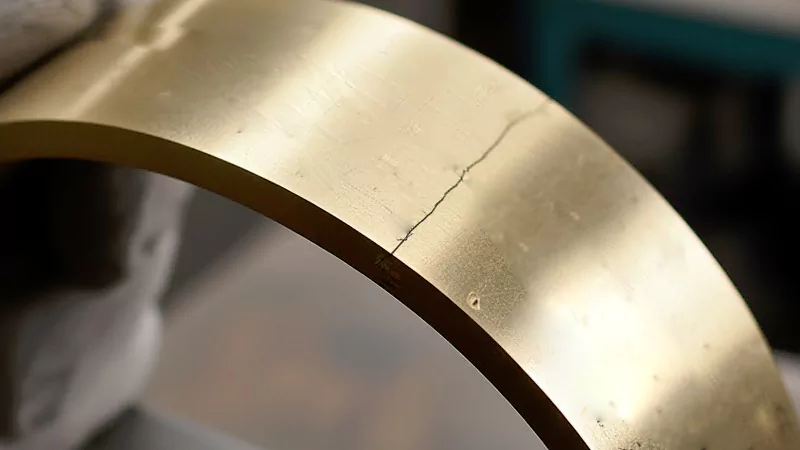

Checking for Cracks or Stress

You need to check your brass carefully during and after bending. This step helps you catch problems early and avoid bigger issues later. Cracks or stress in brass can lead to failure, so you want to spot them before they get worse.

Start by looking closely at the area you bent. Use a bright light and a magnifying glass if you have one. Move the brass around so you can see all sides. Pay special attention to the inside and outside of the bend.

Here are some signs that show stress or cracks in brass:

- Small lines or splits appear on the surface, especially near the bend.

- Cracks often run across the bend, perpendicular to the direction you applied force.

- You may see black stains if the brass was exposed to ammonia or chemicals.

- The surface might look brighter or stained where a crack is starting.

- Long cracks can form along the length of a brass tube, especially if it was bent without proper annealing.

- Cold bent pipes sometimes show cracks along the neutral axis, which is the center line of the bend.

- If you see any of these signs, stop and do not keep bending. Bending further can make the cracks worse.

Tip: Run your finger gently over the bend. If you feel a sharp edge or a change in texture, check that spot more closely. Sometimes you can feel a crack before you see it.

You can also test for hidden stress by gently flexing the brass back and forth. Listen for any snapping or popping sounds. These noises can mean a crack is forming inside the metal.

If you find a crack, you should not try to fix it by bending the brass back. Cracked brass is weak and may break completely if you keep working it. Instead, cut out the damaged section or start with a new piece.

Checking for cracks or stress is a key part of learning how to bend brass without breaking. Careful inspection keeps your project safe and helps you get the best results every time.

Common Mistakes to Avoid

Bending Too Quickly

Rushing the bending process is a common mistake many people make. When you bend brass too fast, you put a lot of stress on the metal in a short time. This sudden force can cause the brass to crack or snap. You might think that bending quickly will save time, but it often leads to more problems. Cracks can form along the bend, and the metal may lose its smooth shape. If you want a clean, strong bend, always use slow and steady pressure. Take your time and let the metal move at its own pace. This approach helps you avoid damage and keeps your project on track.

Tip: Slow, even pressure gives you more control and helps you spot any issues before they become serious.

Skipping Annealing

Some people skip the annealing step because they want to finish faster or think it is not necessary. This is a big mistake when working with brass. Annealing makes the metal softer and easier to bend. If you skip this step, you face several problems:

- The brass becomes much harder, making it difficult to shape.

- You may notice that the metal resists bending and feels stiff.

- Residual stresses build up inside the brass, which can cause it to deform after you finish bending.

These issues can ruin your work and waste your materials. Always take the time to anneal the brass before you start bending. This simple step can save you from headaches later.

Note: Annealing is not just for experts. Anyone can do it with the right tools and a little practice.

Using the Wrong Tools

Choosing the wrong tools for the job is another mistake that can lead to poor results. If you use tools that are not designed for brass, you risk damaging the metal. For example, using a steel pipe bender on a thin brass tube can crush or kink the tube. Tools that are too large or too small may not give you the control you need. You might also end up with uneven bends or scratches on the surface.

To avoid these problems, always select tools that match the size and type of brass you are working with. Manual benders, tube benders, and proper vises help you get smooth, accurate bends. If you need high precision, consider using machining equipment. The right tools make the job easier and help you achieve professional results.

Using the correct tool not only protects the brass but also keeps you safe during the process.

Avoiding these common mistakes will help you bend brass more successfully. Take your time, follow each step, and use the right equipment for the best outcome.

Ignoring Safety Precautions

Many people overlook safety when bending brass. You might think you can skip a few steps, but ignoring safety can lead to serious injuries. Always make safety your top priority. When you work with metal, you face risks from sharp edges, hot surfaces, and heavy tools. If you do not follow safety rules, you put yourself and others in danger.

Here are some of the most frequently ignored safety precautions and the risks they pose:

- Wearing Protective Equipment: You need to wear gloves, goggles, and work boots every time you bend brass. Gloves protect your hands from cuts and burns. Goggles shield your eyes from flying debris or sparks. Work boots keep your feet safe if you drop a heavy piece of brass.

- Following Machine Safety Guidelines: Always read and understand the safety instructions for your tools and machines. Each machine has limits and special safety features. If you ignore these, you could get hurt or damage your equipment.

- Using Proper Lifting Techniques: Brass sheets and rods can be heavy. If you lift them the wrong way, you can hurt your back. Bend your knees and keep your back straight when you pick up heavy items. Ask for help if something feels too heavy.

- Maintaining a Clean Work Area: Keep your workspace tidy. Clutter on the floor or workbench can cause you to trip or drop tools. A clean area helps you move safely and find your tools quickly.

- Never Working Alone: Try not to work alone, especially when using heavy tools or machines. If an accident happens, you need someone nearby to help or call for assistance.

Tip: Make a habit of checking your safety gear and workspace before you start. This simple step can prevent many accidents.

Ignoring safety precautions does not just risk injury. It can also ruin your project. For example, if you do not wear gloves, you might drop a hot piece of brass and damage it. If you do not use goggles, a small chip could hit your eye and send you to the hospital. When you skip safety steps, you lose time and may have to start over.

You can avoid these problems by making safety a routine. Put on your protective gear, check your tools, and keep your area clean. Ask for help when you need it. These habits keep you safe and help you finish your brass bending projects without trouble.

Safety Tips for Bending Brass

When you bend brass, you must always put safety first. Working with metal and heat can be risky if you do not follow the right steps. These tips will help you stay safe and avoid injuries while getting the best results.

Personal Protective Equipment

You need to wear the right personal protective equipment every time you work with brass. This gear keeps you safe from sharp edges, hot surfaces, and flying debris. Here is what you should use:

- Gloves protect your hands from cuts, burns, and heat.

- Eye protection shields your eyes from sparks and small pieces of metal.

- Steel-toed boots keep your feet safe from heavy or sharp objects.

Always check your personal protective equipment before you start. Make sure everything fits well and is in good condition. Wearing the right gear is one of the best ways to prevent accidents.

Safe Work Environment

A safe work environment helps you avoid accidents and makes bending brass easier. You should keep your workspace clean and organized. When you remove clutter, you lower the risk of tripping or dropping tools. Kaizen events show that small changes, like moving a parts bin closer, can reduce awkward posture and make your work safer.

- Implement safety and wellness programs to find and fix risks in your workspace.

- Get proper training so you know how to use tools and handle brass safely.

- Ask for ergonomic assessments to make sure your work area fits your needs.

Watch out for these common risks:

- Awkward posture

- Improper bending or lifting

- Forceful exertions

- Repetitive motions

- Static or strained postures

A tidy workspace helps you move safely and find your tools quickly. Good organization also helps you focus on your work and spot problems before they cause harm.

Handling Hot Brass

When you use heat to bend brass, you must handle hot metal with care. Hot brass can cause serious burns if you touch it without protection. Always use the right tools and follow these best practices:

- Avoid touching or mishandling hot or molten metal to prevent burns.

- Use tongs or other handling equipment to move hot brass and keep your hands away from the heat.

- Check your tools and equipment often to make sure they are safe to use.

- Wear gloves and helmets when handling scrap or hot metal.

- Choose long sleeves and thick materials to protect your skin from heat and sharp edges.

- Use eye protection and a mask to guard against metal dust and fumes.

- Support your body with sturdy boots to prevent falls or sprains.

Never rush when working with heat. Take your time and let the brass cool before you touch it. If you are not sure if the metal is still hot, test it with a tool instead of your hand.

By following these safety tips, you can bend brass with confidence. You will protect yourself from burns, cuts, and other injuries. Remember, safety is always the most important part of any project.

Troubleshooting Brass Bending

What to Do If Brass Starts to Crack

If you notice a crack forming while bending brass, stop right away. Continuing to bend can make the crack worse. First, check the size and location of the crack. Small surface cracks may not affect the strength, but deeper cracks can cause the brass to break. You should never try to force a cracked piece back into shape. Instead, set the brass aside and decide if you can repair it or if you need to start over.

Tip: Always inspect the bend area with a bright light. Look for tiny lines or splits. If you see any, do not keep bending.

If the crack is small and not in a critical spot, you might be able to file it smooth. For larger cracks, it is safer to cut out the damaged section and use a new piece of brass. Remember, safety comes first. Cracked brass can snap without warning.

How to Straighten a Bad Bend

Sometimes, you may bend brass in the wrong spot or at the wrong angle. You can fix a bad bend, but you need to be careful. Here are some steps you can follow:

- Support the brass so it bends at the same location as the original bend. This area is already work-hardened and will need more force to move.

- Use a high heat gun to warm the brass. Heating helps soften the metal and lowers the risk of cracking, especially if the bend is only a little off.

- Start without heat if you are not sure the material is brass. Some metals look similar but react differently to stress.

- Move slowly and check your progress often. Do not rush the process.

If you try to straighten brass without support, you may cause new bends or even break the piece. Always use steady, gentle pressure.

If the brass does not move easily, stop and try heating it again. For mild bends, you can sometimes use your hands or a wooden block. For tougher bends, a vise and hammer may help, but always protect the surface with a soft cloth.

When to Start Over

Sometimes, fixing a bad bend is not the best choice. If the brass is too damaged, starting over saves time and gives you a better result. Use this table to help you decide:

| Condition | Repair Method |

|---|---|

| Mildly Bent Screws | It can be straightened using a hammer and vise. |

| Severely Bent Screws | Requires heating with a propane torch and careful bending to restore shape. |

If you see deep cracks, severe kinks, or the brass feels weak after bending, it is best to start with a new piece. Trying to fix badly bent brass can lead to more problems later. New brass stock bends more easily and gives you a cleaner finish.

Note: Learning when to start over is a skill. It helps you save time and materials in the long run.

By following these troubleshooting tips, you can handle most problems that come up when bending brass. Careful inspection, the right tools, and knowing when to start fresh will help you get the best results every time.

You can bend brass without breaking it if you do a few things. Start by marking where you want to bend and putting on your safety gear. Hold the brass tightly so it does not move. Use slow, steady pressure with the right tools, like tube benders or CNC machines. Annealing makes brass softer and easier to bend. Machining helps you make exact shapes again and again. Always look for cracks and be careful as you work. If you practice and pay attention, your bends will be smooth and strong every time.

FAQ

You can check by trying to bend a small section. If the brass feels stiff or cracks, you need to anneal it. Soft brass bends easily and does not resist your pressure.

Yes, you can bend thin brass by hand or with a vise and wooden blocks. For thicker pieces, you need tools like tube benders or a torch for heating.

Always anneal the brass before bending. Use slow, steady pressure. Support the brass with a spring or sand if it is a tube. Check for cracks as you work.

Machining gives you more precision and repeatability. You should use machining for complex shapes or large batches. Hand bending works well for simple, small projects.

Stop bending right away. Inspect the crack. If it is small and not deep, you can file it smooth. For larger cracks, replace the brass piece.

You can reuse broken brass by cutting away the damaged section. Use the rest for smaller parts or new bends. Always check for hidden cracks before reusing.

Brass can break if you bend it too quickly, use the wrong tools, or if the brass has impurities. Always use gradual force and inspect your tools before starting.