Aluminum, a widely used metal, plays a crucial role in various fields. In this article, we will delve into the knowledge of aluminum, from its basic properties and alloy classification to processing technology and its applications in various industries, to provide a comprehensive introduction to the properties of aluminum materials.

Target readers: beginners, engineers, purchasers, publicists, etc.

Table of Contents

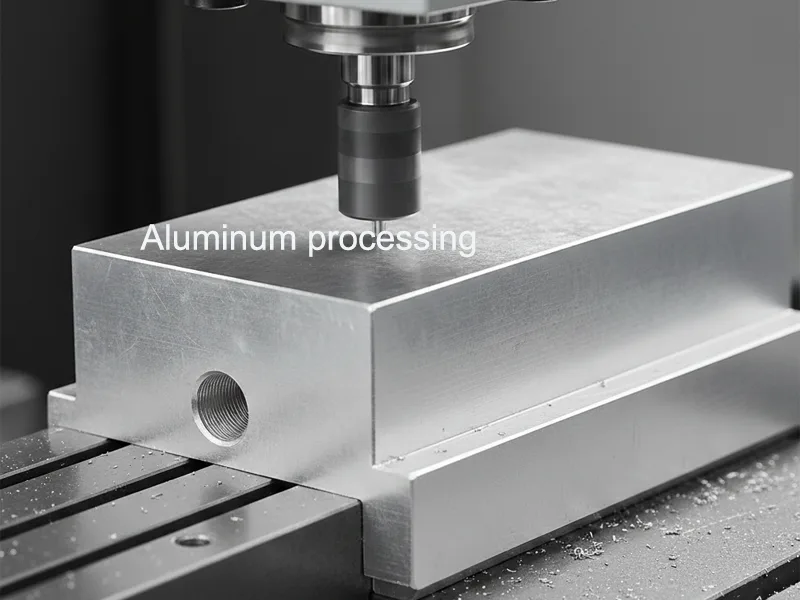

What is aluminum for machining?

Aluminum is a silvery-white light metal with the element symbol Al, abbreviated in practice to AL, and an atomic number of 13. Aluminum’s low density and the fact that products made from it are light, about one-third the weight of steel, make it useful in a wide range of applications.

Properties of Aluminum

Physical Properties

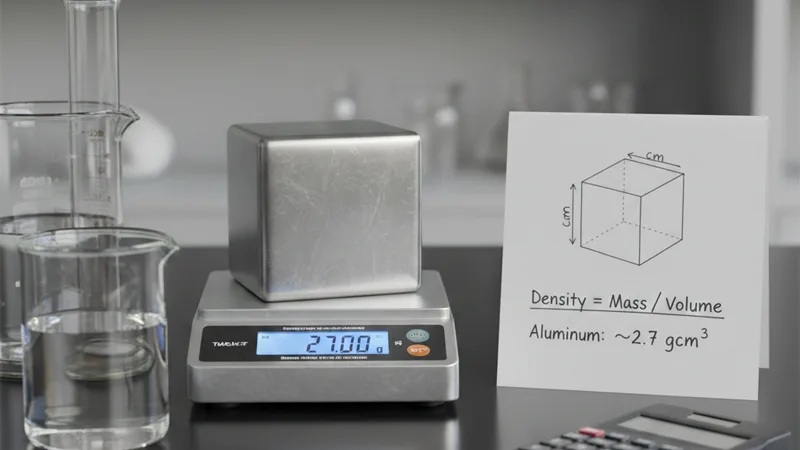

Low density:

Aluminum has a density of about ≈2.7 g/cm3, which is only ≈1/3 the density of iron. This property makes aluminum alloys more suitable for use in hardware that uses aluminum materials because it makes aluminum very light when measured against other materials. High conductivity:

Its electrical conductivity is about 61% of that of copper; aluminum’s conductivity is second only to silver, copper, and gold.

Thermal conductivity:

Aluminum has a relatively high thermal conductivity of about 200-220 watts/(m-km), and heat is conducted through aluminum very quickly and is dissipated quickly.

Thermal Conductivity:

Aluminum foil is used in cooking and food packaging because of its good thermal conductivity.

High Reflectivity:

With a smooth surface, aluminum reflects more than 90% of visible light and even more infrared light. Because it reflects light and heat, it contributes to energy efficiency and thermal insulation.

Chemical Properties

Activity:

Aluminum is a kind of active metal, located in the order of activity of the metal table before hydrogen, and can react with acid to generate hydrogen gas.

Surface Oxidation:

Aluminum can form a dense film of aluminum oxide on its surface after electrolysis in a chemical solution. This film effectively prevents aluminum from rusting further, thus giving it good corrosion resistance. In general atmospheric conditions, aluminum products can maintain a bright appearance for a long time, without the need for additional anti-corrosion treatment.

Recyclability:

Aluminum is a recyclable metal, and the recycling process consumes low energy, only about 5-6% of primary aluminum production. Recycled aluminum can be remelted, processed, and made into a variety of aluminum products with little or no degradation in performance.

Mechanical Properties

Strength and hardness:

Pure aluminum has relatively low strength and hardness, but this property can be greatly enhanced by alloying.

Toughness:

Aluminum and its alloys exhibit good toughness, allowing them to absorb energy without fracturing easily upon impact.

Machinability:

Aluminum can be processed by a variety of processes, including casting, extrusion, rolling, and forging, and has good processability.

Other Characteristics

Other Characteristics

Non-magnetic:

Aluminum is a non-magnetic material and is not attracted to magnetic fields.

Biocompatibility:

Aluminum and its alloys have good biocompatibility and are non-toxic and harmless to the human body. Ensure the safety of use.

Grades

Aluminum grades are differentiated primarily based on their grades and states.

Presentation:

Aluminum Alloy Grades

1000 Series Aluminum Alloy

Acrylic `1) Structure (one-piece structures) Main components: pure aluminum, aluminum content of more than 99%.

Properties: Good thermal and electrical conductivity, but lower strength.

The application: mainly for the production of wires, aluminum foil, and other products.

2000 Series Aluminum Alloy

Predominant materials: aluminum-copper alloy.

Properties: Increased strength and heat resistance.

Application: Applicable for aerospace field parts manufacturing, such as aircraft fuselage and engine components.

3000 Series Aluminum Alloy

Primary materials: Aluminum-manganese alloy.

Properties: Shall resist corrosion and be Welded Well

Application: Often used in the manufacture of air conditioners, refrigerators, and other products that require high corrosion resistance.

5000 Series Aluminum Alloy

Main materials: magnesium-aluminum alloy.

Features: Good tensile strength and corrosion resistance.

Application: for ships, car bodies, and other products requiring strength and corrosion resistance.

6000 Series Aluminum Alloy

Detail: aluminum-magnesium-silicon alloy.

Features: Good strength, plasticity, and corrosion resistance, excellent process performance.

Applications: popularly used for building profiles, automobile parts, electronic equipment, etc.

7000 Series Aluminum Alloy

Key constituents: aluminum-zinc-magnesium-copper alloy.

Features: High strength, good corrosion resistance, and higher cost.

Application: It is used for parts of high-strength structures of aviation and spacecraft, such as airplane wings and fuselage.

Aluminum Alloy State

Fst (free milling state)

Features: No special treatment after machining or casting, only applied to the material that needs further processing.

O state (annealed state)

After the annealing, its hardness and strength are low, but its plasticity and toughness are good, so it is suitable for materials that need to bend and stretch and other processing.

H state (work-hardened state)

Features: The method of cold processing (cold rolling, cold drawing, etc.) makes the material hardened, improves strength and hardness, but reduces plasticity. This makes it suitable for structural parts with high strength requirements.

TA state (heat treatment state)

T4 state (solution treatment + natural ageing)

Casting: Aluminum profiles are extruded from the extruder and then cooled and treated, and do not go into the aging furnace. Low hardness, good deformability, suitable for subsequent bending and other forming machining.

T5 condition (solution treatment + incomplete artificial aging)

Feature: Extrusion post-air cooled quench transfer to aging furnace, heat preservation about 200 degrees for 2-3 hours. More hard, have certain deformability, commonly used in curtain wall, etc.

T6 temper (solution heat-treated + artificially aged)

Features: extrusion is water-cooled quenching, quenching and artificial aging, than more than T5, heat preservation time, so that T5 can reach a higher hardness state, suitable for some places whose demand for material hardness is relatively high.

Density

Aluminum has a density of about 2.7 g/cm3

Melting point

Aluminum has a melting point of 660.32°C (1220.58°F)

Boiling point

Aluminum has a boiling point of 2467°C (4472.6°F)

Conduction coefficient

The thermal conductivity of aluminum is about 237 W/(m-K) at room temperature.

Resistivity

The resistivity of aluminum is about 2.65×10-⁸ to 2.82×10-⁸ Ω-m at room temperature.

yield strength

| Material | Yield Strength (MPa) | Yield Strength (ksi) |

| 1100 Aluminum Alloy Annealed (O Temper) | 34 | 5 |

| Aluminum Alloy 1100 Strain Hardened (H14 Temper) | 117 | 17 |

| 2024 Aluminum Alloy Annealed (O Temper) | 75 | 11 |

| Aluminum Alloy 2024 Heat Treated and Aged (T3 Temper) | 345 | 50 |

| Aluminum Alloy 2024 Heat Treated and Aged (T351 Temper) | 325 | 47 |

| 6061 Aluminum Alloy Annealed (O Temper) | 55 | 8 |

| 6061 Aluminum Alloy Heat Treated and Aged (T6 and T651 Tempers) | 276 | 40 |

| 7075 Aluminum Alloy Annealed (O Temper) | 103 | 15 |

| Aluminum Alloy 7075 Heat Treated and Aged (T6 Temper) | 505 | 73 |

| Aluminum Alloy 356.0 As-cast | 124 | 18 |

| Aluminum Alloy 356.0 Heat Treated and Aged (T6 Temper) | 164 | 24 |

Young’s modulus

6000 Series

Young’s modulus: 103 ksi (approx. 70 GPa)

7000 Series

Young’s modulus: 71.7 GPa

2000 Series

Young’s modulus: 72.4 GPa (at 20°C)

Aluminum Alloy Series

Young’s Modulus: 70 GPa

Metal formula

The main component of aluminum is alumina (Al₂O₃-nH₂O). After refining and processing, pure aluminum can be extracted.

Molecular mass of aluminum

The molecular weight (or atomic weight) of aluminum is 26.9815386. In practice, we use 26.98 as a simplified counting value.

Aluminum Anodizing

Anodizing of aluminum is an electrochemical process in which an electric current and a chemical solution are applied to the surface of aluminum to form a durable oxide layer that enhances its corrosion and wear resistance.

Aluminum vs Stainless Steel

Physical properties

| causality | aluminum | stainless steels |

|---|---|---|

| densities | 2.7 g/cm³ | 7.8 g/cm³ |

| melting point | 660°C | 1400°C – 1530°C |

| thermal conductivity | 237 W/(m·K),high | 15-25 W/(m·K),low |

| conductivity (elec.) | 37.7 million S/m | 1.45 million S/m |

| tensile strength | 70-700 MPa | 515-1275 MPa |

| yield strength | 30-500 MPa | 215-900 MPa |

| durometer | Lower, easy to process | Higher, more difficult to process |

Aluminum vs Titanium

Physical properties

| causality | aluminum | titanium |

|---|---|---|

| densities | 2.7 g/cm³ | 4.5 g/cm³ |

| melting point | 660°C | 1650-1670°C |

| heat conductivity | 210-235 W/m·K | 17-21.9 W/m·K |

| Conductivity (based on copper) | 64% | 3.1% |

| tensile strength | 90-690 MPa | 230-1400 MPa |

| yield strength | 200-600 MPa | 170-480 MPa |

Chemical Properties

Corrosion resistance:

Aluminum: Aluminum forms a dense film of aluminum oxide in air, which provides some corrosion resistance, but is susceptible to corrosion in alkaline environments.

TITANIUM: Titanium has excellent corrosion resistance, especially in marine and acidic environments.

Oxidizability:

Aluminum: Aluminum is prone to forming an oxide layer on its surface, but this oxide layer prevents further corrosion.

Titanium: Titanium has excellent oxidation resistance at high temperatures and is suitable for high-temperature applications

FAQ

The “best” alloy depends entirely on your part’s application. For most custom metal parts, 6061-T6 is the gold standard due to its excellent machinability, weldability, and balanced mechanical properties. However, if your project requires high-strength-to-weight ratios (like aerospace components), 7075-T6 is the preferred choice. For parts requiring high corrosion resistance in marine environments, we often recommend 5052.

It usually comes down to a trade-off between strength and cost.

- 6061 Aluminum: More affordable, easier to weld, and highly versatile. It’s ideal for structural components and general precision machining.

- 7075 Aluminum: Significantly stronger (comparable to some steels) but more expensive and harder to weld. Choose this for high-stress applications where weight savings are critical.

Aluminum is incredibly versatile when it comes to post-processing. As a full-service custom metal parts manufacturer, we offer several options:

- Anodizing (Type II or Type III): Increases corrosion resistance and allows for color coding.

- Bead Blasting: Creates a uniform, matte “satin” finish to remove tool marks.

- Chromate Conversion Coating: Enhances conductivity and corrosion protection.

- Powder Coating: Provides a thick, durable aesthetic layer.

To make your metal part production more cost-effective, consider these SEO-friendly design tips:

- Standardize Radii: Use internal corner radii that match standard end mill sizes.

- Limit Tolerances: Only apply tight tolerances to critical mating surfaces; standard tolerances are much cheaper to produce.

- Simplify Geometry: Avoid deep pockets or thin walls that require specialized tooling and longer cycle times.

For standard CNC aluminum machining, we typically achieve tolerances of ±0.127 mm (0.005”). For high-precision requirements, our advanced equipment can reach ±0.025 mm (0.001”) or even tighter depending on the part geometry. Always specify your critical dimensions during the RFQ (Request for Quote) phase to ensure perfect fitment.

Working with a specialized manufacturer ensures you benefit from Dfm (Design for Manufacturing) feedback. We don’t just “cut metal”; we optimize your designs for better performance and lower costs. Our facility handles everything from material sourcing and precision CNC machining to final quality inspection, ensuring your parts meet ISO-certified standards every time.