You use aluminum die casting parts when you want strong and reliable products. These parts are important in making things today because they have special qualities.

- High hardness and heat resistance help stop erosion.

- Strong compressive and fatigue strength make them last longer.

- Great thermal conductivity helps cool things down fast.

- Toughness and ductility stop the parts from cracking.

- Good machinability and polishability give smooth finishes.

- Dimensional stability and corrosion resistance keep parts working well in tough places.

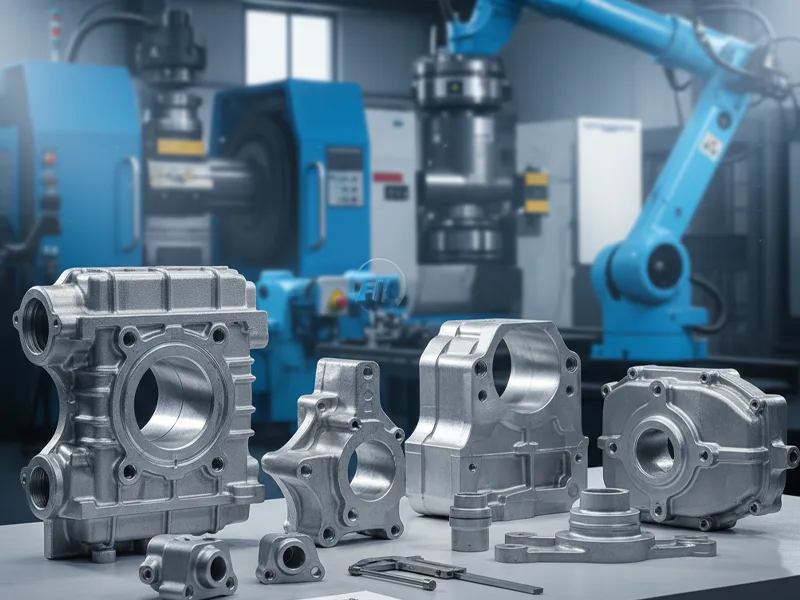

You see aluminum die casting parts in industries that need steady quality and good performance.

Key Takeaways

- Aluminum die casting parts are strong and dependable. They work well in many industries. These parts do not rust easily and resist corrosion. This helps them last a long time.

- The die casting process makes complex shapes fast and at a low cost.

- Aluminum die casting gives great thermal and electrical conductivity. This makes it good for electronics.

- Picking the right aluminum alloy is very important. It helps get the strength and durability you want.

- The process makes parts with high dimensional accuracy. This means less extra machining is needed.

- Aluminum die casting is good for making many parts at once. Costs go down when more parts are made.

- Knowing the limits of aluminum die casting is helpful. It lets you make better design choices.

Table of Contents

What Are Aluminum Die Casting Parts

Aluminum Die Casting Overview

People use aluminum die casting to make detailed shapes. This process is fast and saves money. Molten aluminum gets pushed into a steel mold with high pressure. The mold is very strong and helps make thin and complex parts. You can recycle the leftover aluminum, which is good for the environment.

Aluminum die casting is used a lot in factories. About 30% of all aluminum products are made this way. Car parts and electronics cases are made with this method. Over time, the process has improved. Now, cast aluminum can be almost as strong as wrought aluminum. But there are still some limits.

Key Properties of Aluminum Die Cast Parts

Aluminum die casting parts have special qualities. These qualities make them different from other metal parts. Here is a table that shows the main features you get:

| Characteristic | Description |

|---|---|

| Lightweight | These parts weigh less than other metal parts. |

| High Dimensional Stability | The parts keep their shape and size, even when hot or under pressure. |

| Good Surface Finish | The process gives smooth or bumpy surfaces right from the mold. |

| High Thermal and Electrical Conductivity | Aluminum moves heat and electricity well, so it is good for cooling. |

| Excellent Corrosion Resistance | These parts do not rust easily, so they last longer. |

| Ability to Produce Complex Shapes | You can make tricky and thin parts that are hard to make with other methods. |

| High Precision | The process makes parts with exact sizes and tight fits. |

When you look at these features, you see why these parts work well in tough jobs. Here is a table with important mechanical and physical properties:

| Property | Value Range | Description |

|---|---|---|

| Tensile Strength | 310–325 MPa | These parts can hold heavy loads without breaking. |

| Yield Strength | 150–160 MPa | They do not bend or change shape easily. |

| Elongation | 3–4% | The parts can stretch a little, so they do not break easily. |

| Thermal Conductivity | 90–100 W/m·K | The parts lose heat fast, which helps in engines and electronics. |

| Corrosion Resistance | High | A natural layer on aluminum keeps the parts safe from rust. |

These features make aluminum die casting parts a great pick for jobs that need strong and long-lasting parts.

Common Aluminum Alloys Used

You can pick from many aluminum alloys for your project. The alloy you choose changes how your part will act. It affects strength, ductility, corrosion resistance, and how easy it is to cast. Here are some common alloys used in aluminum die casting:

- AC 46100: This alloy is easy to weld and is strong and hard. It also fights rust and wear.

- AC 46500: This one is strong, flexible, and light for its strength.

- ADC 12: This alloy is easy to weld, resists rust, and melts at a higher temperature.

- ADC 10: This one is tough and can be used for many things.

- A380: This alloy is strong, flexible, and does not rust or wear out fast.

- A360: This one is good for making parts that need to be tight and strong. It also resists rust.

- Al-Si8Cu3: This alloy is strong, resists rust, is light, and does not wear out quickly.

- Al-Si11Cu3: This one has about 90.5% aluminum, 10% silicon, and 3% copper. It has a tensile strength of 310 MPa and melts at 577°C.

ADC12 (A383), A380, and A360 are used a lot in aluminum die casting. These alloys are popular because they are easy to pour, strong, and do not rust. They work for many different uses.

The alloy you pick is important for how your part will work. For example, A360 is very strong and does not rust, even when hot, but it is harder to cast. A380 is easy to pour, light, and easy to machine, so many people use it. A383 is good for small, detailed parts, but it is not as tough as A380.

Tip: Always pick the alloy that fits your needs. The right alloy helps your part do its job, whether you need it to be strong, resist rust, or have a special shape.

Aluminum Die Casting Process

To make accurate and strong parts, you need to know the aluminum die casting process. This process uses high pressure to shape melted aluminum into detailed parts. Each step is important for making sure your parts are of good quality.

Die Casting Steps

The aluminum die casting process has several steps. Here is a table that shows each step and what happens:

| Step | Description |

|---|---|

| Tool creation | First, you design a 3D CAD file. Then, you make the die with CNC machines and hard tool steel. |

| Part production | You close the die halves. Next, you inject melted aluminum at high pressure. This fills the die. |

| Cooling and ejection | The part cools inside the die. Then, you open the die and use pins to push out the part. |

| Cleaning | You clean the die with air and add mold release before making the next part. |

| Trimming | You remove extra material from the part by hand or with machines. |

Mold Preparation

You start by getting the mold ready. The die must be clean and sprayed with a release agent. This keeps the melted aluminum from sticking to the mold. You also check the die for damage or wear. A clean and ready mold helps you get the right shape and finish.

Injection and Solidification

Next, you inject melted aluminum into the die using high pressure. This high pressure helps fill even tiny spaces in the mold. The aluminum fills the mold fast and starts to cool. The pressure keeps the metal thick and stops air bubbles or weak spots. As the metal cools, it takes the shape of the die.

Ejection and Trimming

After the part cools, you open the die. Pins push the part out of the mold. You cut off any extra material, like gates or runners, from the part. Now you have a clean part ready for more work or assembly.

Process Impact on Part Quality

How you control the process changes how good your aluminum die casting parts are. Here are some ways process control helps you get better parts:

- You use good design and quality checks to lower waste and delays.

- You set the right size at the tool release step. This stops mistakes from repeating in every part.

- You watch the temperature closely. This keeps gas out of the metal and stops oxides from forming.

- You use special cooling channels in the die. These channels keep the temperature even and lower stress and bending.

- You use very exact die molds. These molds and cooling channels help you get the right size and finish.

- You use new systems with sensors that watch temperature, pressure, and speed. You can change things right away to keep every part good.

Tip: If you watch every step in the high-pressure aluminum die casting process, you get parts that are the right size and have a smooth finish. This careful control is what makes high-quality parts.

Performance Qualities of Aluminum Die Casting Parts

Strength and Lightweight

Aluminum die casting parts are strong but not heavy. This is called a high strength-to-weight ratio. You can use these parts in cars and planes. These places need parts that are light but strong. The die casting process makes the aluminum alloy even stronger. These parts can hold heavy things without being heavy themselves.

Here is a table that compares the strength-to-weight ratio of different materials:

| Material | Density (g/cm³) | Strength-to-Weight Ratio | Applications |

|---|---|---|---|

| Magnesium Alloys | 1.8 | Superior | Automotive, Aerospace |

| Aluminum Alloys | 2.7 | Balanced | General structural applications |

Many people like aluminum die casting parts because they are light and strong. These parts help make things work better and use less energy. The casting process also lets you make tricky shapes that stay strong and light.

- Aluminum die castings have a great strength-to-weight ratio.

- Many industries want them when the weight needs to be low.

- The die-casting process makes the aluminum alloy even better.

Corrosion Resistance

Aluminum die casting parts do not rust easily. This is because aluminum has little iron in it. These parts last a long time, even outside or in wet places. You can use them where there is water or rain, and they will still work well.

Here is a table that shows how aluminum compares to other metals:

| Metal Type | Corrosion Resistance | Notes |

|---|---|---|

| Aluminum | Exceptional | Rust-proof due to low iron content. |

| Zinc | Moderate | More susceptible to corrosion in marine environments. |

| Magnesium | Varies | Corrosion resistance varies based on environmental factors. |

You can make aluminum die casting parts even better with special finishes. Some finishes, like CastGuard™, help stop rust even more. This means your parts will last longer and you will not need to fix them as much.

- Aluminum die casting can make tricky parts that do not rust.

- Other ways may not make parts this complex or exact.

Dimensional Accuracy

You want parts that fit right every time. Aluminum die casting makes parts with the right size and shape. You do not need to cut or fix them much after. This saves you time and money.

Industry rules like NADCA#207, ISO 8062-3, DIN 1688, and JIS B0405 say how close the size should be. Here is a table that shows the tolerances you can expect:

| Tolerance Type | Tolerance Range |

|---|---|

| Standard | ±0.05 mm to ±0.10 mm |

| Tight | ±0.01 mm |

You can trust aluminum die casting to make parts that meet tough rules. This is important when every millimeter matters. The process lets you make parts with tight fits and tricky shapes. Other casting ways cannot always do this.

Tip: If you need parts that are strong, light, rust-proof, and exact, aluminum die casting is a good pick. You get parts that work well and last a long time.

Heat Dissipation

When you pick aluminum die cast parts, you get more than just strong and light pieces. These parts also help get rid of heat very well. This is really important if you work with electronics or car parts that get hot when used.

Aluminum die casting is special because it moves heat away from hot spots fast. This helps protect important parts and keeps things working right. If you use these parts in electronics, you can stop them from getting too hot. This helps your devices last longer. In cars, good heat dissipation keeps engines and other parts cool, even when working hard.

Here are some main reasons why aluminum die cast parts are good at heat dissipation:

- Aluminum has high thermal conductivity. This means it moves heat faster than many other metals.

- Die cast parts can have thin walls and tricky shapes. These things give more surface area, so heat can leave faster.

- Heat treatment can make aluminum die castings even better at moving heat. Treated parts often move heat better than parts made in other ways.

- Porosity means tiny air pockets inside the metal. These can lower how well heat moves. Careful control during die casting lowers porosity, so your parts work better.

| Feature | Benefit for Heat Dissipation |

|---|---|

| High thermal conductivity | Moves heat away from hot spots quickly |

| Thin wall capability | Increases surface area for faster cooling |

| Complex shapes | Allows for custom cooling designs |

| Low porosity | Maintains high thermal performance |

| Heat treatable | Further improves heat transfer |

Tip: For the best heat dissipation, always pick a supplier who controls porosity and offers heat-treated die cast parts. This helps your parts stay cool and last longer.

You can trust aluminum die cast parts to keep your things safe from heat. If you design power supplies, LED housings, car control units, or engine parts, these parts help you control temperature and make things work better. When you need parts that stay cool under pressure, aluminum die casting is a smart pick.

Machining and Value-Added Processes

Role of Machining in Aluminum Die Casting

You want your aluminum casting parts to fit and work just right. Machining helps make this happen. After casting, you use machines to fix small details. Companies like AFI Industrial Co., Ltd use special machines for this. Machining makes parts more exact than casting alone. You can use machines to make flat spots, drill holes, and add threads. Every size is checked closely.

Here is a table that shows how machining makes aluminum casting parts more exact:

| Parameter | As-Cast Die Casting | After CNC Machining |

|---|---|---|

| Dimensional Tolerance | ±0.2 mm – ±0.5 mm | ±0.005 mm – ±0.02 mm |

| Surface Flatness | Needs secondary grinding | Achieved via face milling |

| Hole Alignment | Variable, needs reaming | Precise, drilled to spec |

| Thread Features | Not suitable | CNC tapping, pitch control |

| Surface Roughness (Ra) | 6.3 – 12.5 µm | ≤ 1.6 µm |

Machining turns a regular aluminum casting into a very exact part. A recent survey says over 67% of people need extra work after casting to get the right size. You count on machining to get the perfect fit and finish you need.

Machining also lets you change things. You can add holes or change shapes without making a new mold. This saves time and money, especially for small jobs or special orders. CNC machines help you make smooth surfaces and tight sizes, even as close as ±0.005 mm. You get the same good results every time.

Surface Finishing and Customization

Surface finishing makes your aluminum casting parts look and work better. You can pick from different finishes to help your parts last longer and look nice. Here is a table that shows some common finishes and what they do:

| Surface Finishing Method | Benefits | Applications |

|---|---|---|

| Anodizing | Makes parts harder and stops rust | Automotive, aviation, marine |

| Coating | Adds color, style, and protection | Consumer electronics, automotive |

| Polishing | Makes parts shiny and smooth | Decorative, high-end products |

These finishes protect your aluminum parts from water, salt, and chemicals. This helps your parts last longer in tough places. You also make the surface harder and stop it from wearing out. The part stays strong even when rubbed or hit. You do not have to fix it as often.

- Surface treatments keep aluminum safe from water, salt, and chemicals.

- These finishes help parts last longer in wet or salty places.

- You make the surface harder and stop it from wearing out.

- You keep the part strong when it gets rubbed or hit.

- You do not have to fix the part as much, so it lasts longer.

Finishes also let you pick how your part looks. You can make it shiny, dull, or glossy. This helps your product look special and match your brand. You get both good looks and strong parts with every aluminum casting.

Tip: When you use both machining and surface finishing, you get the best from aluminum casting. You get parts that are exact, tough, and look just how you want.

Aluminum Die Casting vs. Other Casting Methods

When you pick a casting method, you want it to be fast, good quality, and not too expensive. Let’s look at how aluminum die casting is different from other ways.

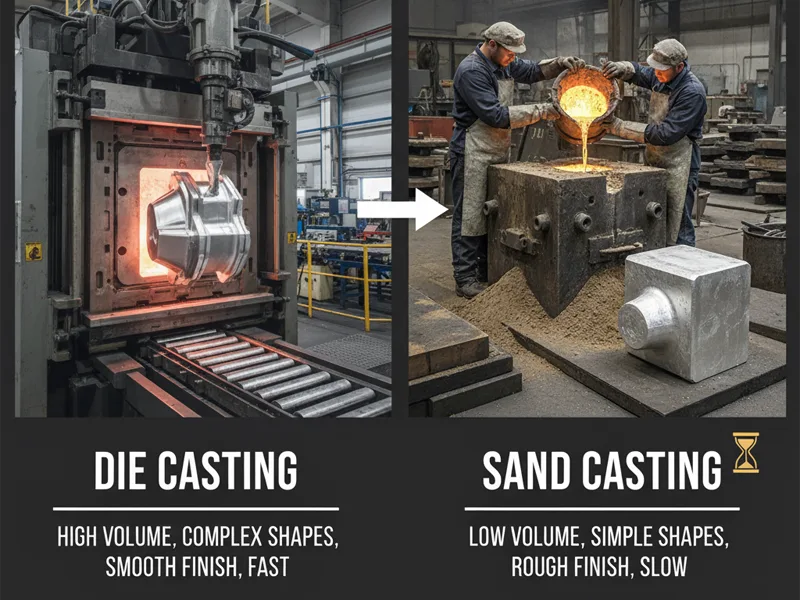

Aluminum Die Casting vs. Sand Casting

Sand casting is used for easy shapes and small batches. Aluminum die casting is better for making lots of parts and for hard shapes. Here is a table to help you see the differences:

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Production Speed | 30 seconds to 1 minute per cycle | Slower, less automated |

| Cost Efficiency | Cost-effective for high-volume runs | More cost-efficient for low to medium-volume runs |

| Surface Finish Quality | Excellent, minimal imperfections | Rougher, requires additional finishing |

| Complexity of Parts | Suited for complex geometries | Better for simpler designs |

Aluminum die casting makes parts faster and smoother. Sand casting takes longer and needs more work after. If you need lots of parts with tough shapes, die casting saves time and money.

Aluminum Die Casting vs. Investment Casting

Investment casting is good for making very detailed parts, but only a few at a time. You see it used for things like airplane parts, dental tools, and jewelry. Aluminum die casting is better when you need strong parts quickly and in large amounts. Here is a table to show the differences:

| Casting Method | Mechanical Properties | Applications |

|---|---|---|

| Die Casting | Denser, stronger components | Load-bearing applications |

| Investment Casting | Ideal for lower-volume complex castings | Aerospace, dental implants, jewelry |

- Investment casting is used for:

- Airplane parts

- Gas turbine pieces

- Fake joints

- Dental tools

- Jewelry

- Knives and forks

- Weapon parts

Aluminum die casting makes parts that are stronger and thicker. Investment casting gives more detail but costs more and takes longer for big jobs.

Unique Benefits of Aluminum Die Casting

Aluminum die casting has special benefits:

- You can make parts with exact sizes and fine shapes. This means you do not need much extra work after.

- The process lets you make thin and tricky parts that other methods cannot do.

- You can design parts with tiny details and special shapes. This gives you more choices for your designs.

- You save time and money when you need lots of parts because the process is quick and repeats easily.

Tip: If you need many parts with hard shapes and exact sizes, aluminum die casting is the best choice. You get strong, detailed parts fast and for less money.

Applications of Aluminum Die Casting Parts

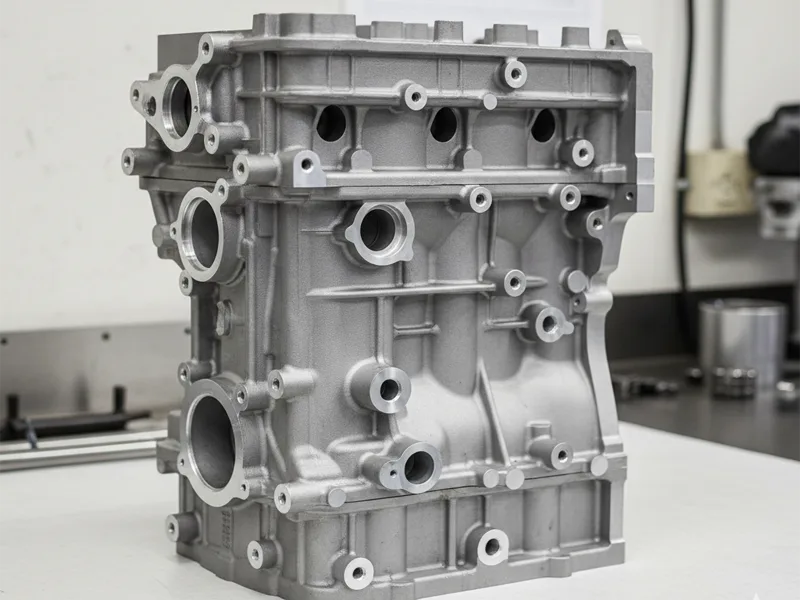

Automotive Industry

Aluminum die casting parts are used a lot in cars. These parts help make cars lighter and stronger. Lighter cars use less gas and pollute less. Aluminum is picked because it is strong but not heavy. Most car castings are made with die casting. Over 70% of the aluminum in cars comes from this process. You can find these parts in engine blocks, wheels, and brackets. They are also in heat exchangers and transmission housings. Aluminum casting lets you make tricky shapes for tight spaces. These parts do not rust easily and last a long time. Even in tough driving, they keep working well. When you use aluminum die casting, cars run better and last longer.

Electronics and Appliances

Aluminum die casting parts are important in electronics and appliances. These parts help move heat away and carry electricity well. They also protect electronics from getting too hot or damaged. Some common uses are bus bars and panel enclosures. You also see them in circuit breakers and junction boxes. Inverter housings and outdoor control units use these parts too.

Transformers and battery packs need aluminum die castings. Heat sinks, motor parts, and connectors use them as well. Terminal blocks and switchgear parts are other examples. Aluminum helps these parts stay cool and not rust. This keeps electronics safe and makes appliances last longer.

The parts are light, so the products are easy to move and install.

Aerospace and Industrial Uses

Aerospace needs parts that are strong and light. Aluminum die casting is perfect for this. You find these parts in airplane bodies and engine housings. Landing gear and turbine blades use them too. These parts must handle lots of stress and heat.

Some alloys like A356 and 356-T6 are used for their strength. A356 is good for casting and welding. 356-T6 is stronger and does not crack easily. Aluminum die casting makes planes lighter, so they use less fuel. This saves money and helps the environment.

The parts are strong for their weight, which is important in planes. In factories, aluminum die casting is used for machine frames and engine blocks. These parts work under heavy loads and in tough places. You trust aluminum die casting for jobs that need strong, exact, and long-lasting parts.

Why Choose Aluminum Casting

When you pick how to make something, you want it to be good, fast, and not cost too much. Aluminum die casting is a top choice for many companies. It gives you many benefits that help your products work better and get to stores faster.

Here are some main reasons to pick aluminum casting:

- Lightweight nature: Aluminum parts are much lighter than steel or iron. This helps make your products weigh less. Lighter parts help cars use less gas and make electronics easier to move.

- High dimensional stability: Aluminum die cast parts keep their shape and size, even when hot or under pressure. This means your parts always fit together just right.

- Excellent corrosion resistance: Aluminum does not rust or corrode easily. You can use these parts in wet or rough places without worrying about them breaking too soon.

- Good mechanical properties: Aluminum die castings are strong and can bend a little without breaking. They can hold heavy things and do not crack easily.

- High thermal and electrical conductivity: Aluminum moves heat and electricity very well. This is good for electronics, lights, and car cooling parts.

- Ability to produce complex part geometries quickly and cost-effectively: You can make tricky shapes and thin parts that other methods cannot do. This lets you make new and special products.

Tip: If you need parts that are light, strong, and exact, aluminum die casting is a smart choice.

The process itself also helps you. Aluminum die casting gives you:

- Fast cycle times: You can make each part in just seconds or minutes. This helps you finish orders fast and keep up with changes.

- Suitability for complex parts: You can make detailed and tricky shapes in one step. This means you do not need to put parts together or do extra work.

- High dimensional accuracy: You get parts that are the right size every time. This means you waste less and do not throw away as many parts.

- Smooth surface finish: The process makes parts with a smooth and clean surface. You do not need to spend much time or money making them look better.

- Repeatable, accurate results: Every part you make is just like the last one. This is important when you need to make a lot of parts and keep them all the same.

When you pick aluminum casting, you get more than just a part. You save time, spend less money, and get parts you can trust. No matter if you work with cars, electronics, planes, or machines, aluminum die casting helps you stay ahead of others.

Advantages and Limitations

Production Efficiency

You want to make things fast and not waste time. Aluminum die casting helps you do this. The process is quick, so you can make lots of parts in a short time. You can make tricky shapes that all look the same. This is good when you need many parts for your business.

- Aluminum die casting works well for making lots of parts.

- Every part comes out the same, so quality stays high.

- You can make parts with small details and special shapes.

- Aluminum die casting is faster and cheaper than squeeze casting when you need many parts.

This process helps you keep up with big orders. It works for cars, electronics, and machines. The speed and repeatability help you finish on time and save money.

Cost and Volume Considerations

When you think about price, aluminum die casting is best for big jobs. The first die costs more than some other ways. But if you make lots of parts, the price for each part goes down. Here is a table to show how the costs work:

| Aspect | Description |

|---|---|

| Initial Die Cost | High at first, but spread out over many parts in large runs. |

| Per-Part Cost | Drops a lot as you make more parts, making it very cost-effective for big orders. |

| Additional Costs | After you pay for the die, there are a few extra costs, so your overall cost per part stays low. |

| Tooling Costs | Higher than some methods, but you get lower per-part costs as production grows. |

| Production Efficiency | You can make complex shapes and tight tolerances in high volumes, which reduces your total costs. |

If you want to make thousands or millions of parts, this is a smart choice. That is why car makers and electronics companies use it a lot.

Note: If you only need a few parts, other ways might be cheaper. But if you need a lot, aluminum die casting saves you the most money.

Design Flexibility

You want to design parts that fit your needs. Aluminum die casting lets you do this. You can make thin walls, tricky shapes, and small details. The process can make walls thinner than 1.5 mm and add cool surface details.

| Feature | Description |

|---|---|

| Design Flexibility | You can make complex shapes and thin walls, even under 1.5 mm thick. |

| Design Freedom | The process allows for fine details and special features not possible with other casting methods. |

This means you can make parts that are lighter and stronger. You can put many functions into one part, so you do not need to put together as many pieces. This saves time and money.

You also get the good things about aluminum, like not rusting, being strong, and looking nice. These help your parts work better in cars, electronics, and machines.

Tip: Use aluminum die casting to make new and better products. You can make shapes and features that others cannot.

Limitations of Aluminum Die Casting

Aluminum die casting offers many advantages, but you should also understand its limitations before choosing it for your project. Knowing these limits helps you make better decisions and avoid problems later.

1. Part Size and Wall Thickness Constraints

You cannot use aluminum die casting for every size or shape. The process works best for small to medium-sized parts. If you need very large parts, you may face challenges with mold size, machine capacity, and cooling. Wall thickness is another key factor. Most aluminum die cast parts have wall thicknesses between 0.5 mm and 5 mm (0.02 to 0.2 inches). You can go up to 25 mm (1 inch) in some cases, but thicker walls increase the risk of defects like porosity or shrinkage. Thin walls below 0.5 mm are hard to fill and may not form correctly.

- Typical wall thickness: 0.5 mm to 5 mm (0.02 to 0.2 inches)

- Minimum wall thickness: about 0.5 mm (0.02 inches)

- Maximum wall thickness: about 25 mm (1 inch)

- Thicker walls: longer cooling times, higher risk of defects

2. Porosity and Surface Defects

You may see tiny holes or bubbles inside aluminum die cast parts. This is called porosity. Porosity can weaken the part and make it harder to finish or machine. It can also cause leaks if you use the part for holding liquids or gases. Careful process control reduces porosity, but it cannot remove it completely.

3. Limited Alloy Choices

You cannot use every aluminum alloy for die casting. Only certain alloys work well with this process. Some high-strength or specialty alloys do not flow or fill the mold properly. If you need a special alloy, you may need to consider other casting methods.

You need a custom steel mold (die) for each part design. Making this die costs a lot at the start. If you only need a small number of parts, the cost per part will be high. Aluminum die casting is best when you need thousands or millions of parts.

5. Design Restrictions

You must follow certain design rules for aluminum die casting. Sharp corners, deep pockets, or undercuts are hard to make. You may need to change your design to fit the process. This can limit your creativity or require extra steps like machining.

Note: Always talk to your casting supplier early in the design stage. They can help you avoid costly mistakes and make sure your part fits the process.

6. Not Ideal for All Applications

Aluminum die cast parts are strong and light, but they may not work for every job. If you need parts that handle very high temperatures, extreme loads, or special chemical resistance, you may need a different material or process.

Summary Table: Key Limitations

| Limitation | Description |

|---|---|

| Part Size | Best for small to medium parts |

| Wall Thickness | 0.5 mm to 5 mm typical, up to 25 mm max |

| Porosity | Possible, affects strength and sealing |

| Alloy Selection | Limited to certain aluminum alloys |

| Tooling Cost | High initial cost, best for large production |

| Design Flexibility | Some shapes and features are restricted |

Understanding these limitations helps you decide if aluminum die casting is the right choice. When you know what to expect, you can plan better and get the best results for your project.

You get lots of good things when you pick aluminum die casting parts. Look at the table to see how these parts work well:

| Performance Quality | Key Benefit |

|---|---|

| Superior Surface Finish | Needs little extra work, so you save time and money |

| High Strength-to-Weight Ratio | Parts are light but strong, which helps things work better |

| Cost-Effective for Mass Production | Making many parts costs less |

| Excellent Corrosion Resistance | Parts last long without needing special coatings |

| Good Thermal and Electrical Conductivity | Great for heat and electricity jobs |

Big companies say you should use light aluminum parts. They also say to use earth-friendly ways and new casting machines. Try aluminum die casting for your next project if you want parts that fit well and work every time.

FAQ

Aluminum die cast parts are used in cars, electronics, planes, and machines. These industries want parts that are strong, light, and exact. Aluminum die casting makes these parts quickly and with steady quality.

You pick the alloy by thinking about how strong your part needs to be. You also look at how well it fights rust and how easy it is to cast. A380 is a common choice because it is strong and easy to use. Always choose the alloy that matches what your part needs to do.

Yes, you can use machines to make these parts more exact. Machining helps you get the right size and smooth surface. You can also add special holes or threads. This step makes sure your parts fit just right.

You can pick finishes like anodizing, powder coating, painting, or polishing. Each finish helps in different ways. Some stop rust, some make the part look better, and some make the surface harder. Choose the finish that works best for your product.

Aluminum die casting makes parts faster and smoother. The parts also fit better. Sand casting is better for small batches or big parts. Die casting is best when you need lots of tricky, high-quality parts.

There are limits to how big or thick the parts can be. You cannot use every alloy. The first mold costs a lot, so it is better for making many parts. Sometimes, tiny holes or design rules can cause problems.

You keep quality high by watching every step. You check the tool, temperature, pressure, and cooling. Sensors and checks help find mistakes early. Careful control makes sure every part is good.