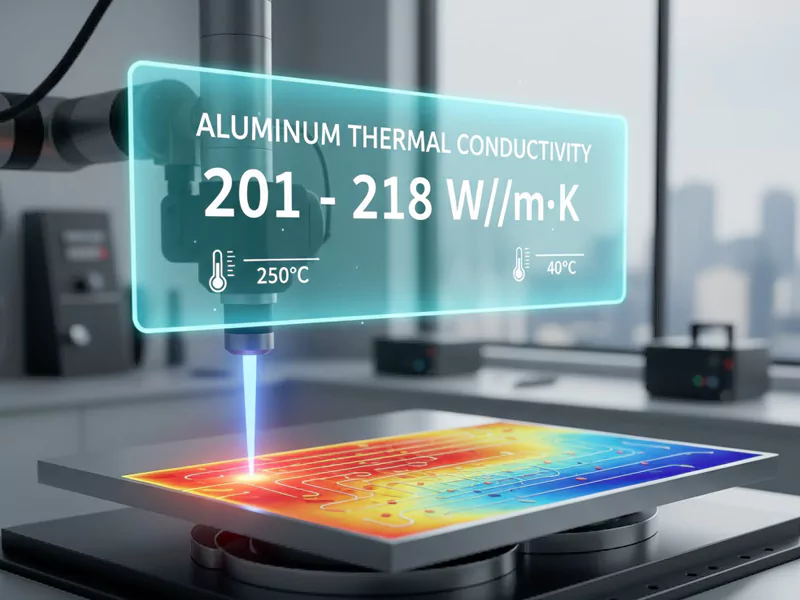

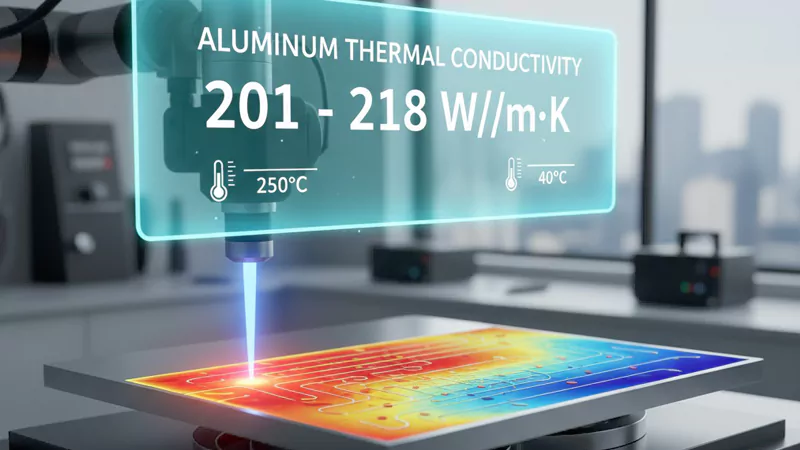

Aluminum 6063 thermal conductivity ranges from 201 to 218 W/(m·K), indicating its excellent ability to transfer heat. You can refer to the table below to see how it compares to other materials:

| Alloy | Thermal Conductivity (W/(m·K)) |

|---|---|

| 6063 | 201-218 |

| Pure Aluminum | 220–237 |

| 6061 | 150–170 |

| 2024 | 140–150 |

| 7075 | 130–150 |

The aluminum 6063 thermal conductivity is crucial for aluminum alloys, as it facilitates rapid heat transfer in applications such as car engines and electronics. This alloy is frequently utilized in building frames and electronic enclosures, where effective temperature management is essential.

Key Takeaways

- Aluminum 6063 has a thermal conductivity between 201 and 218 W/(m·K). This makes it very good at moving heat.

- People often use this alloy in car engines and electronics. It helps control temperature well.

- High thermal conductivity means aluminum 6063 keeps things cool. It stops devices from getting too hot.

- Aluminum 6063 is simple to shape and does not rust. This makes it great for building frames and outdoor furniture.

- When picking materials, think about aluminum 6063 for fast heat transfer and strength.

- The alloy’s thermal conductivity can change with its mix and how it is made.

- Aluminum 6063 can be recycled. This helps the environment and saves energy.

- Always check the temperature for aluminum 6063. This makes sure it stays strong and works well.

Table of Contents

Thermal Conductivity Basics

What Is Thermal Conductivity

People talk about thermal conductivity when they discuss heat and materials. This property shows how well something moves heat from one spot to another. If you put a metal spoon in hot soup, the heat moves fast to your hand. This happens because metals have high thermal conductivity.

Thermal conductivity tells us how easily heat goes through a material. Scientists use the equation q = -k ⋅ (T2 – T1) / L for this. In this formula, “k” means thermal conductivity, “q” is the heat flow, “T2 – T1” is the temperature change, and “L” is the distance heat travels.

Materials with high thermal conductivity, like aluminum, move heat quickly. You see these materials in things that need to cool down fast, like computer parts or car engines. Materials with low thermal conductivity, like wood or plastic, do not let heat move easily. These are good for keeping heat in or out.

Here are some key facts about thermal conductivity:

- It shows how well heat energy moves through something.

- It helps you know if a material is good for insulation or heat transfer.

- It is not the same as other ways heat moves, like convection or radiation.

When you check the thermal conductivity of aluminum alloys, you see why it is used in many industries. Aluminum moves heat faster than most other metals. This makes it great for cooling and heating systems.

Measuring Thermal Conductivity

You can measure thermal conductivity in a lab with special tools. Scientists heat one side of a sample and see how much heat gets to the other side. They write down the temperature difference and how much heat passes through.

Here is a simple table that shows how scientists measure thermal conductivity:

| Step | Description |

|---|---|

| Prepare the sample | Cut the material into a standard shape |

| Apply heat | Heat one side of the sample |

| Measure temperature | Record temperatures on both sides |

| Calculate | Use the equation to find thermal conductivity |

You need to know the sample’s thickness and the temperature difference. The answer tells you how well the material moves heat. If you test aluminum, you will see it has high numbers compared to other materials.

Thermal conductivity helps you pick the right material for your project. If you want to keep something cool or warm, you need to know how heat moves through different things.

Aluminum 6063 Overview

Properties of Aluminum 6063

Aluminum 6063 has special features that make it popular. It is strong enough for many jobs. You can bend and shape it without much trouble. It does not rust easily, so it lasts longer. The surface is smooth, so products look nice and stay good for years.

Here is a table with some important facts about aluminum 6063:

| Property | Value |

|---|---|

| Yield Strength (T6) | 214 MPa (31,000 psi) |

| Ultimate Tensile Strength (T6) | 241 MPa (35,000 psi) |

| Shear Strength (T6) | 152 MPa (22,000 psi) |

| Modulus of Elasticity (T6) | 68.9 GPa (10,000 ksi) |

| Density | 2.70 g/cm³ |

| Thermal Conductivity | 201 W/m·K |

| Electrical Conductivity | 35 % IACS |

| Coefficient of Thermal Expansion | 23.4 × 10⁻⁶ K⁻¹ |

Aluminum 6063 is not the strongest alloy. But it is easy to work with and does not rust much. It also lets heat and electricity move through it well. These things make it useful for many projects.

Tip: Pick aluminum 6063 if you want something that looks good and works well.

Uses of Aluminum 6063

Aluminum 6063 is used in lots of places. Builders use it for buildings and bridges. It is also found in cars, boats, and furniture. You can cut, bend, and shape it into many forms.

Here is a table that shows where aluminum 6063 is used:

| Application Area | Description |

|---|---|

| Extrusions | Used in buildings and bridges for frames and supports. |

| Tubing | Chosen for lightweight and corrosion-resistant tubes. |

| Furniture | Makes strong and attractive chairs, tables, and shelves. |

| Marine | Used in boats and docks because it resists rust from water. |

| Automotive | Found in car parts, especially body panels and trim. |

| Aerospace and Aviation | Used in airplane wings and bodies for low weight and strength against stress. |

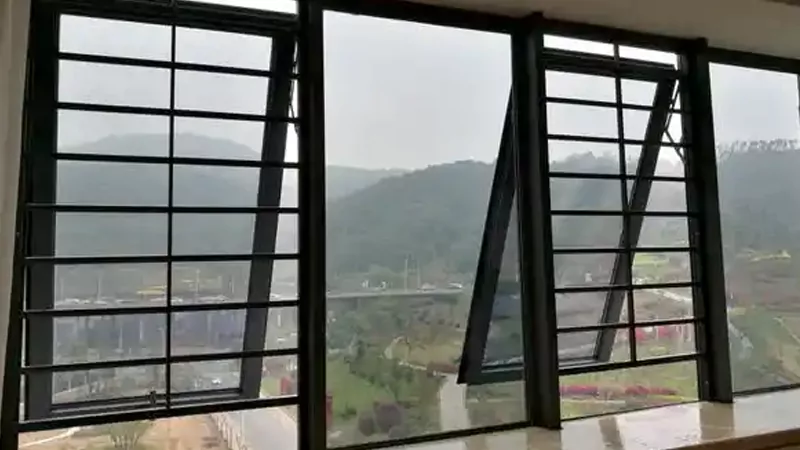

You might see aluminum 6063 in window frames and railings. It keeps its shape and finish for a long time. It is also used in cars and boats because it does not rust easily. If you want something that lasts and looks nice, aluminum 6063 is a good pick.

Aluminum 6063 Thermal Conductivity

Value and Range

Aluminum 6063 thermal conductivity is between 201 and 218 W/(m·K). This number shows how well it moves heat. If you use aluminum 6063, it will transfer heat fast. This is important for things like electronics and building frames. Good thermal conductivity helps keep devices cool. It stops them from getting too hot.

Note: If thermal conductivity is higher, heat moves faster. This helps keep things safe and working well.

Comparison to Pure Aluminum

You might ask how aluminum 6063 compares to pure aluminum. Pure aluminum has even higher thermal conductivity, from 220 to 237 W/(m·K). So, pure aluminum moves heat a little faster. But pure aluminum is soft and not strong enough for many jobs. Aluminum 6063 has other elements mixed in. This makes it stronger and easier to shape. But its thermal conductivity is a bit lower.

Here is a table to show the difference:

| Material | Thermal Conductivity (W/(m·K)) |

|---|---|

| Pure Aluminum | 220–237 |

| Aluminum 6063 | 201–218 |

| Aluminum 6061 | 150–170 |

Aluminum 6063 does not conduct heat as fast as pure aluminum. But it is still better than many other alloys. It is a good pick if you need both strength and good heat movement.

Factors Affecting Thermal Conductivity

Many things can change how aluminum 6063 moves heat. You should know these if you want the best results.

Alloy Composition

The mix of elements in aluminum 6063 changes its thermal conductivity. Magnesium and silicon are the main ones added. These make the alloy strong and easy to shape. They also change how heat moves through the metal.

| Alloying Element | Influence on Thermal Conductivity |

|---|---|

| Magnesium | Affects thermal properties |

| Silicon | Affects thermal properties |

| Thermal Conductivity | 201–218 W/[m·K] |

Changing the amount of magnesium or silicon changes thermal conductivity. Makers control these amounts to get the right mix of strength and heat movement.

Manufacturing Process

How aluminum 6063 is made also matters. The extrusion process pushes metal through a shaped die. Preheating the billets to 700–930°F (370–500°C) is important. This helps the metal flow well and keeps thermal conductivity high.

Makers do several things to keep thermal conductivity steady:

- Preheat billets to the right temperature for easy shaping.

- Use smart die designs for even metal flow.

- Check the product at every step for quality.

Here is a table with key steps:

| Process | Description |

|---|---|

| Quality Control | Careful checks keep size and mix the same. |

| Die Design | Engineers use computers to design dies for smooth flow. |

| Temperature Management | Preheating makes the metal easy to shape. |

These steps help you get aluminum 6063 that moves heat well.

Temperature

The temperature which you use aluminum 6063 also matters. At normal temperatures, its thermal conductivity stays high, around 201 W/(m·K). This helps move heat away from electronics. It keeps devices cool and helps them last longer.

- Aluminum 6063 works well for cooling electronics.

- It helps stop devices from overheating.

- Its light weight and strength are good for cars and portable electronics.

But if you use it in very hot places, its strength can drop. Even if thermal conductivity stays good, the metal might not be strong enough. Do not use it where it gets extremely hot for a long time.

Tip: Always check the temperature before using aluminum 6063. This helps you avoid problems with strength and safety.

Applications

Heat Exchangers

Aluminum 6063 is used a lot in heat exchangers. This alloy moves heat fast from one spot to another. It is great for cooling engines and electronics. You want a material that handles heat well. Aluminum 6063 does this because it has high thermal conductivity. It is also easy to shape into fins and other parts.

- Aluminum 6063 makes heat sinks for computers and electronics.

- You can form it into shapes that help move heat away.

- It is light, so it is easy to carry and put in place.

Tip: Pick aluminum 6063 if you want quick heat transfer and simple making for heat jobs.

Here is a table that shows how aluminum 6063 helps in heat exchangers:

| Feature | Benefit for Heatsinks |

|---|---|

| Thermal conductivity | Moves heat fast from the source to the fins |

| Extrusion design | Makes complex fins in one step |

| Lightweight | Easy to handle and costs less to ship |

| Dimensional repeatability | Works the same every time |

| Recyclability | Good for the environment |

Architectural Uses

Aluminum 6063 is also used in many buildings. It is found in window frames, curtain walls, and channels. Its thermal conductivity helps keep rooms at a steady temperature. Using this alloy helps control heat in and out of buildings. This can save energy and make rooms more comfortable.

- Aluminum 6063 helps keep rooms warm or cool, saving energy.

- It does not rust much, so it lasts a long time.

- Its smooth look and easy shaping make it nice for new designs.

Note: Using aluminum 6063 in buildings helps save energy and is good for the planet.

Electronics

Electronics need good heat control to work properly. Aluminum 6063 is used to make heat sinks for CPUs, GPUs, and LED lights. This alloy moves heat away from important parts. This helps devices last longer and work better.

- In computers, aluminum 6063 heat sinks keep chips cool.

- LED lights use this alloy to stay bright and not get too hot.

- Phones and network gear use aluminum 6063 for steady heat control.

You can count on aluminum 6063 for today’s electronics. Its high thermal conductivity keeps your devices safe from heat.

Choosing Aluminum 6063

When to Select Aluminum 6063

You might ask when aluminum 6063 is the best pick. This alloy is great if you need good heat movement and easy shaping. People use it when heat must move away fast, like in building frames or outdoor furniture. Aluminum 6063 is better than 6061 for moving heat. Pick it if you want your material to stay cool and last longer.

Here are times when aluminum 6063 is a smart choice:

- You want better thermal conductivity than 6061.

- Your project uses heat sinks, building frames, or outdoor furniture.

- You need a material that shapes easily and stays strong.

- You must control heat in electronics or building parts.

Tip: If you want quick heat transfer and a smooth look, aluminum 6063 is a good pick.

Balancing Properties

Picking the right alloy means you must balance different things. Aluminum 6063 has high thermal conductivity, so it helps with heat control. It also has a higher melting point and heat capacity than 6061. These things make it strong and useful for many jobs.

Let’s see how aluminum 6063 compares to other alloys:

| Alloy | Thermal Conductivity (W/(m·K)) |

|---|---|

| 6061 | 151–202 |

| 6063 | 201–218 |

Aluminum 6063 moves heat faster than 6061. This helps keep electronics and building parts cool. It is also easy to shape and does not rust much.

When you pick aluminum 6063, you get these good things:

- High thermal conductivity for better heat control.

- Easy to make into complex shapes.

- Good strength for daily use.

- Resists rust for a longer life.

Think about what is most important for your project. If you need heat movement, strength, and a good price, aluminum 6063 is a smart choice. You can use it for many things, like heat exchangers or window frames.

Note: Always check what your project needs before you choose an alloy. Aluminum 6063 is a good pick if you want good heat control and easy making.

Now you can see why aluminum 6063 is special for heat control. Its thermal conductivity helps products stay cool and last longer. You can also make it into many shapes. This makes it good for both looks and use.

| Property | 6063-T5 Value | Impact on Products |

|---|---|---|

| Thermal Conductivity | ~200 W/(m·K) | Moves heat well |

| Extrudability | Excellent | Easy to make thin fins |

- Check materials closely before you choose.

- Talk to experts about heat control.

- Try out materials in real-life tests.

Always remember, picking the right material helps your products work well and last a long time.

FAQ

You get high thermal conductivity with aluminum 6063. This means it moves heat quickly. You can use it in electronics, building frames, or heat sinks. It helps keep things cool and safe.

Yes, you can. Aluminum 6063 resists rust and weather. You see it in window frames, railings, and outdoor furniture. It lasts a long time outside.

Aluminum 6063 moves heat faster than 6061. You should pick 6063 if you want better heat transfer. 6061 is stronger, but 6063 is better for cooling.

Yes, temperature can change how well it moves heat. At normal room temperature, it works best. If it gets very hot, strength drops, but it still moves heat well.

You can use aluminum 6063 in electronics. It helps keep devices cool. It does not react with most parts. You find it in heat sinks, LED lights, and computer cases.

You can shape aluminum 6063 into many forms. You see it as tubes, bars, channels, and custom profiles. It is easy to bend and cut.

Builders pick aluminum 6063 for windows because it looks smooth, resists rust, and moves heat well. It helps keep rooms comfortable and saves energy.

Yes, you can recycle aluminum 6063. Recycling saves energy and resources. You help the environment by choosing recycled aluminum.