When product design engineers select a steel material for their metal parts, they need to weigh performance, weight, actual manufacturing costs, and other factors. While standard carbon steels(such as 1045 steel) are cost-effective, they often fall short when components face high stress, impact loads, or extreme wear.

This is where High-Strength Low-Alloy(HSLA) steels come in. Choosing the correct alloy steel isn’t just about picking the material with the highest yield strength number on a datasheet. It requires understanding how the material behaves on the CNC machine, how it reacts to heat treatment, and how much it will drive up your final part cost.

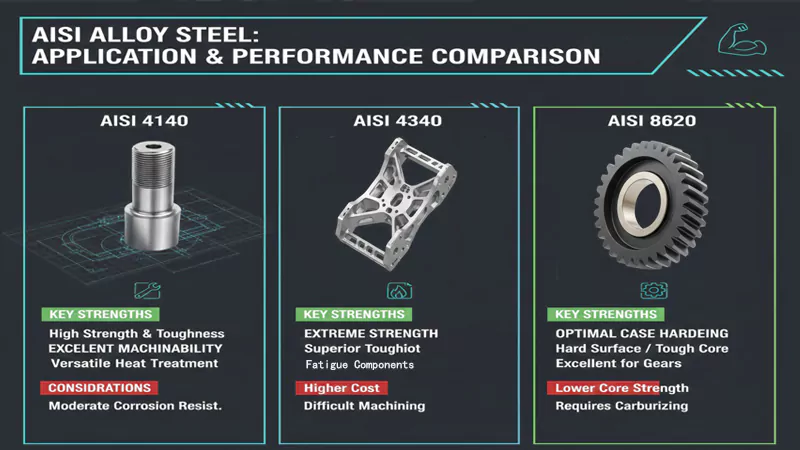

This article will detail the factors to consider when selecting alloy steels – AISI4140, 4340, and 8620 – the three most commonly used alloy steels in CNC machining, to help you select the right “heart” for your precision parts.

Table of Contents

Understand Alloy Steel Properties

When you pick alloy steel for strong metal products, you need to know what makes it work well. These things decide how long your product lasts and how easy it is to make. Each thing helps your product act a certain way when used. Let’s look at the most important ones.

Key Mechanical Properties

Yield Strength

This is often more critical than Ultimate Tensile Strength(UTS). It marks the limit of elastic behavior – the point at which your part will permanently deform. For structural components, high yield strength is non-negotiable

Toughness(Impact Resistance)

A material can be strong but brittle. Toughness measures a material’s ability to absorb energy and deform plastically before fracturing. This is vital for parts subjected to sudden shock loads, like landing gear or hydraulic pistons.

Hardenability

This is frequently misunderstood. It doesn’t just refer to how hard the surface can get; it refers to the depth to which the steel can be hardened. If you are designing a large-diameter shaft(e.g.,>4 inches), you need a steel with high hardenability.

Hardness and Wear Resistance

Hardness tells you how well alloy steel fights scratches and dents. Wear resistance is important for parts that move or rub together. If you want your part to last a long time, pick a steel grade with the right hardness.

Here are normal hardness values for common alloy steel grades:

| Steel Grade | Hardness (HRC) |

|---|---|

| 40Cr | 25-32 |

| 35CrMo | 25-32 |

| 42CrMo | 28-35 |

| 40CrNiMo | 25-32 |

| 38CrMoAl | 25-32 (≥65 after nitriding) |

A higher HRC number means better wear resistance. For gears, shafts, and tools, you want alloy steel with high hardness so your part works longer.

Corrosion and Heat Resistance

Corrosion resistance is very important for alloy steel in tough places. If your part will be near water, chemicals, or salt, you need steel that fights rust. Corrosion resistance keeps your part strong and safe for a long time.

Here is a table that compares how materials do in tough places:

| Material | Corrosion Resistance | High-Temperature Performance |

|---|---|---|

| Alloy Steel | Can rust unless mixed with the right elements | Works well if heat-treated, but may need coatings in bad places |

| Stainless Steel | Very good because of chromium, which makes a shield | Stays strong at high heat |

You can make alloy steel fight rust better by picking grades with chromium, nickel, or molybdenum. These elements make a shield on the steel to stop rust and damage. If your part faces both heat and bad weather, you may need coatings or a special alloy steel grade.

Tip: Always check the corrosion resistance rating for your alloy steel, especially for outdoor, sea, or chemical use. This helps you avoid repairs and keeps your product working well.

Fabrication Properties

Weldability and Machinability

How you make your part depends on how easy it is to cut, shape, and join alloy steel. Machinability means how well you can drill, mill, or turn the steel. Weldability shows how easy it is to join pieces without losing strength or corrosion resistance.

Here is a table with machinability ratings for a popular alloy steel grade:

| Steel Grade | Condition | Machinability Rating (%) |

|---|---|---|

| 4140 Annealed | ~20 – 25% | Good for cutting and shaping |

| 4140 Quenched & Tempered | ~50 – 60% | Tougher, needs special tools |

| 4140 Pre-Hardened (28-32 HRC) | ~55% | Okay to machine with the right tools |

If you need to make parts with tight sizes, pick an alloy steel grade that is easy to machine. This saves time and money. For welding, make sure the steel does not lose corrosion resistance or get brittle after joining. Some alloy steels need special welding methods or filler to keep their good traits.

Note: Always plan for cutting and welding early. The right alloy steel grade makes it easier to make good parts and lowers the chance of problems.

Why These Properties Matter

- Strength and toughness keep your part safe under heavy loads and hits.

- Hardness and wear resistance help your part last longer, especially if it moves.

- Corrosion resistance stops rust and damage, saving you money.

- Good machinability and weldability make it easier and cheaper to make your part.

By knowing these things, you can pick the best alloy steel for your strong metal products. This makes sure your part works well, lasts longer, and does what you need.

Compare Alloy Steel Grades

Picking the right alloy steel grade is very important. You need to look at the most used grades. You should know what each one does well and where it does not. Then you can match the grade to your project. This part will show you how different alloy steel grades work and where they are best.

Popular Alloy Steel Options

AISI 4140 (Chromium-Molybdenum Steel)

Often called”Chromoly”, 4140 is the workhorse of the alloy steel world. It offers a fantastic

- Best For: Axles, conveyor parts, high-stress bolts, and connecting rods.

- The Manufacturing Reality: 4140 is generally available in two states: “Annealed” or “Pre-Hardened”(PH).

AISI 4340 (Nickel-Chromium-Molybdenum Steel)

When 4140 is not enough, engineers upgrade to 4340. The primary difference is the addition of Nickel, which grants this alloy superior toughness and deep hardenability.

- Best For: Aircraft landing gear, heavy truck power transmission, and severe-service shafts where failure is not an option.

- The Trade-off: 4340 is significantly more expensive than 4140, both in raw material cost and machining difficulty. It should be reserved for critical applications where impact resistance is paramount.

AISI 8620 (Nickel-Chromium-Molybdenum Case-hardening Steel)

8620 is unique among this trio. It is a low-carbon alloy designed specifically for case hardening. This allows the part to have an incredibly hard, wear-resistant outer skin(case) while maintaining a soft, ductile core.

- Best For: Gears, camshafts, and pins where surface wear is the main enemy, but the part must still absorb shock without snapping.

- Machinist’s Note: In its annealed state, 8620 can be somewhat “gummy” to machine. It requires specific chip-breaking strategies to prevent long, stringy chips from wrapping around the tool.

Here is a table that shows how these grades are different:

| Property | 4140 Steel | 4340 Steel | 8620 Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 850 – 1000 | 930 – 1080 | 620 – 850 |

| Yield Strength (MPa) | 655 – 830 | 745 – 980 | ~380 (core) |

| Rockwell Hardness (HRC) | 28 – 32 | 30 – 36 | 55 – 62 (surface) |

| Elongation at Break (%) | 20 – 25 | 18 – 22 | ~15 |

| Impact Toughness | Good | Excellent | Good (core) |

You can see that 4340 is the strongest and toughest. 4140 is good if you want strength and easy cutting. 8620 is best if you need a hard outside and a tough inside.

Pros and Cons by Grade

Application Suitability

You should look at the good and bad sides of each alloy steel grade before you pick one.

4140 Alloy Steel

- Advantages:

- High strength and good toughness

- Easy to cut for its strength

- Many ways to heat treat it

- Wears well because of chromium and molybdenum

- Disadvantages:

- Only okay at fighting rust

- Only okay for welding (needs preheating and slow cooling)

- Costs more than plain carbon steel

- It can be tricky with heat treatment

4340 Alloy Steel

- Advantages:

- Very strong and tough, even when cold

- Fights repeated stress well

- Good for important, high-stress parts

- Disadvantages:

- Costs more than 4140

- Needs careful heat treatment

- Not as easy to cut

8620 Alloy Steel

- Advantages:

- Great for case hardening

- Tough inside with a hard outside

- Good for gears and parts that need both

- Disadvantages:

- Not as strong inside as 4140 or 4340

- Needs carburizing to work best

- Not good for parts that need to be strong all the way through

Note: Always pick the alloy steel grade that fits your product’s needs. For example, use 4140 for shafts that need to be strong and easy to cut, 4340 for plane parts that face a lot of stress, and 8620 for gears that need a hard outside.

Overview Table of Grades

You can use this table to quickly see the most common alloy steel grades, what they are like, and what they are used for:

| Alloy Steel Grade | Carbon Content | Key Characteristics | Typical Applications |

|---|---|---|---|

| 4140 | 0.38–0.43% | High strength, good toughness, versatile | Shafts, gears, bolts, connecting rods |

| 4340 | 0.38–0.43% | Very high strength, excellent toughness | Aircraft landing gear, crankshafts |

| 8620 | 0.18–0.23% | Case hardening, tough core, hard surface | Gears, camshafts, bushings |

| 17-4 PH | 0.07% max | High strength, corrosion resistance | Aerospace, chemical processing |

| Maraging 250 | <0.03% | Ultra-high strength, good machinability | Aerospace, tooling, high-stress parts |

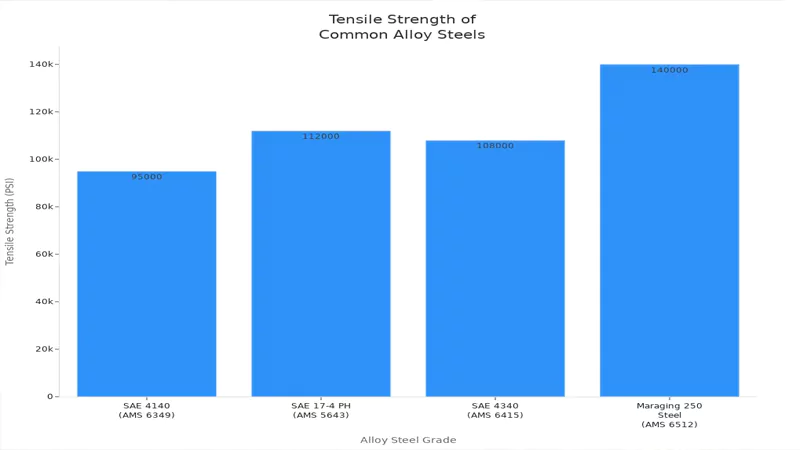

You can also see how strong each one is in this chart:

Tip: Alloy steel is stronger, tougher, and wears better than carbon steel. It costs more, but it is the best for tough jobs and high performance.

When you compare alloy steel grades, always check the mechanical properties, price, and how well the grade fits your job. This helps you pick the right alloy steel for your strong metal products.

Heat Treatment: the Critical ” Second Step”

Alloy steels rarely leave the machine shop in their raw state. To unlock their potential, they undergo heat treatment. Heat treatment changes how strong, tough, and hard to wear out your alloy steels. The right heat treatment helps your product last longer and work better.

Through hardening (Quench & Temper)

Used for 4140 and 4340. This process heats the entire part and quenches it to achieve uniform hardness and strength from the surface to the core.

Carburizing (Case Hardening)

Used for 8620. The part is heated in a carbon-rich atmosphere. Carbon diffuses into the surface, creating a hard “case”(often 60+ HRC) while the low-carbon core remains tough.

| Alloy Element | Effect on Properties | Application Impact |

|---|---|---|

| Chromium | Makes steel harder and fights wear | Helps in tough jobs with lots of stress |

| Nickel | Makes steel tougher | Good for parts that move a lot |

| Molybdenum | Keeps steel strong when hot | Great for things that get very hot |

| Vanadium | Makes steel stronger and harder | Good for parts that hold heavy loads |

| Manganese | Makes steel harder and fights wear | Best for things that rub or wear out fast |

| Silicon | Makes steel stronger and fights rust from heat | Good for things used in hot places |

Match Alloy Steel to Application

Industry-Specific Examples

Automotive, Aerospace, and Heavy Machinery

You must pick the right alloy steel for your industry. In cars, high strength is very important for safety and how well things work. For example, people use alloy steel 4140 and 4340 in many car parts. These types have high tensile strength and great fatigue resistance. This makes them good for suspension parts, crankshafts, and gear shafts. The table below shows how these steels are used in cars:

| Alloy Steel Grade | Key Properties | Common Automotive Applications |

|---|---|---|

| Alloy Steel 4140 | High tensile strength, excellent fatigue resistance, superior wear resistance | Suspension components, crankshafts, gear shafts, high-performance engine components |

| Alloy Steel 4340 | Exceptional toughness, impact resistance | Transmission components, chassis, suspension parts |

In planes, you need materials that are strong but not heavy. Alloy steel 4340 is used for landing gear and main parts. It can take hard hits and stays tough even when it is cold. Big machines need strong alloy steel for gears, shafts, and frames. These parts must hold heavy loads and withstand stress again and again.

Tip: Always check what your industry needs. High strength alloy steels help you reach safety, last longer, and work better.

Decision Matrix and Checklist

You can use a simple chart to help pick the best alloy steel for your job. Think about these things:

| Requirement | 4140 | 4340 | 8620 |

|---|---|---|---|

| High Strength | ✔️ | ✔️✔️ | ✔️ |

| Fatigue Resistance | ✔️ | ✔️✔️ | ✔️ |

| Wear Resistance | ✔️✔️ | ✔️ | ✔️ |

| Toughness | ✔️ | ✔️✔️ | ✔️ |

| Case Hardening | ✔️✔️ | ||

| Machinability | ✔️✔️ | ✔️ | ✔️ |

| Weldability | ✔️ | ✔️ |

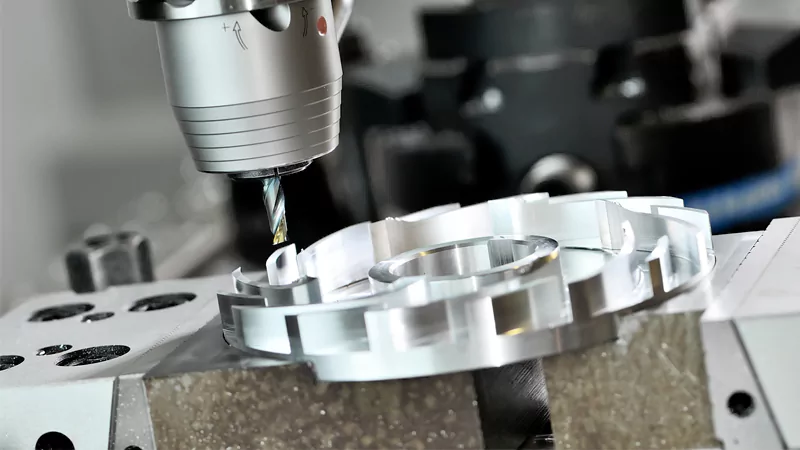

Role of Machining in Application Fit

Machining is very important for how well your alloy steel part works. CNC machining uses careful engineering and strong steel. You get parts that are very exact and last a long time. This is needed for strong parts in cars, planes, and big machines.

CNC machining makes tight fits and tricky shapes. This means your alloy steel parts will fit right and work well. When you pick a strong alloy steel, you should also think about how easy it is to cut and shape. Some types are easier to machine, which saves time and money.

Experts in alloy steel CNC machining make sure your designs become real parts fast and just right. Good machining helps your strong parts work their best.

Note: Always plan for machining early. The right alloy steel and machining steps together give you the best strong metal products.

Common Mistakes and Best Practices

Picking the right alloy steel for strong metal products is not easy. Many engineers and designers make the same mistakes when choosing. If you know these mistakes, you can stop problems and make sure your products work well.

Overlooking Application Needs

You might think one material works for everything, but each job is different. If you do not check where and how your product will be used, you might pick the wrong alloy steel. Here are some mistakes people make:

- Not looking at corrosion data before picking a material. This can cause big failures, like in some famous projects.

- Thinking stainless steel or other alloys always fight all corrosion. Some places, like those with hydrochloric acid, can hurt even the best steels.

- Not seeing corrosion risks in places that look safe. High-strength steels can crack from stress even in air or clean water.

- Not thinking about how your design can cause rust. Small spaces or tight corners can hold water and make rust happen faster.

- Forgetting about galvanic corrosion. When two different metals touch, rust can get worse.

- Not remembering that making parts, like welding or bending, can leave stresses. These stresses can make cracks or rust more likely.

Tip: Always pick alloy steel that fits where and how your product will be used. Look at corrosion data and think about how design and making steps change how your product works.

Ignoring Machining Constraints

You may care most about strength and fighting rust, but how easy it is to cut and shape is also important. If you forget this, you can have trouble making your product:

- You might pay more and wait longer if you pick steel that is hard to cut.

- Your parts might not be good if you do not know how your alloy steel acts when machined.

- You might forget you need the right feed and sharp tools to keep parts good.

Steel that is hard to cut or shape can slow your work and cost more. Always check how easy it is to machine and plan for the right tools and steps.

Note: Think about machining early. The best alloy steel should be strong, fight rust, and be easy to make.

Summary

This article discusses the mechanical and chemical properties of alloy steels and compares the characteristics and applications of three commonly used alloy steels: 4140, 4340, and 8620. The aim is to provide mechanical engineers and product design engineers with a comprehensive understanding of alloy steels, enabling them to select more suitable alloy steel components for their products.

FAQ

Alloy steel is stronger and tougher than regular steel. It also fights wear better. You can make parts that are lighter but still last a long time. These parts work well even in hard places.

Pick a grade that fits your product’s load and where it will be used. Think about how you will make the part. Always check how strong it is, if it fights rust, and if it is easy to shape before you decide.

No, not all alloy steels are easy to weld. Some need special ways or heating first. Always check if your grade is good for welding. Ask your supplier for the best way to weld it.

Alloy steel fights rust better than carbon steel. But it does not fight rust as well as stainless steel. For tough places, pick grades with chromium, nickel, or molybdenum added.

If alloy steel is easy to machine, you save time and money. You can also make parts that fit just right and look good.

Check ASTM, SAE, AISI, or ISO standards. These rules make sure your alloy steel has the right mix and strength for your job.