In the realm of high-precision CNC machining and custom metal fabrication, the structural integrity of a component is as critical as its dimensional accuracy. Non-Destructive Testing (NDT) is not merely a procedural checkpoint; it is a rigorous engineering discipline governed by international standards such as ASME, ASTM, and ISO.

At AFI Parts, we understand that for critical applications in aerospace, automotive, and heavy industry, a “visual check” is insufficient. This guide provides a technical deep-dive into how NDT methods validate the quality of Custom Metal Components, strictly adhering to engineering specifications. By identifying discontinuities—such as micro-cracks, inclusions, and porosity—without compromising the component’s utility, we ensure strict adherence to the Zero Defect philosophy.

Table of Contents

What Is Non-Destructive Testing?

NDT Principles and Physics

Non-destructive testing (NDT) is the application of interdisciplinary engineering principles—physics, metallurgy, and electronics—to evaluate the properties of a material, component, or system without causing damage. Unlike destructive testing, which renders the specimen unusable, NDT employs physical phenomena such as acoustic impedance, electromagnetic induction, ionizing radiation attenuation, and capillary action to inspect custom metal components.

The core objective is to identify discontinuities before they propagate into defects that lead to catastrophic failure. Modern NDT techniques utilize high-frequency sound waves (Ultrasonics), magnetic flux leakage (Magnetic Particle), and penetrating radiation (Radiography) to visualize internal and surface-breaking anomalies.

For mechanical engineers designing complex geometries, understanding these principles is vital for specifying the correct inspection protocols on engineering drawings.

NDT vs Destructive Testing: A Comparative Analysis

While NDT is the cornerstone of in-process and final quality control (QC), Destructive Testing (DT) remains essential for material characterization (e.g., Tensile Strength per ASTM E8, Charpy Impact per ASTM E23). However, for finished machined parts, NDT is the only viable solution for 100% inspection.

The following table contrasts these methodologies within the context of ISO 9001:2015 manufacturing environments :

| Aspect | Non-Destructive Testing (NDT) | Destructive Testing (DT) |

|---|---|---|

| Primary Objective | Detection of volumetric and surface discontinuities (flaws). | Determination of mechanical properties (Yield Strength, UTS, Elongation). |

| Standard References | ASME BPVC Section V, ASTM E1444, ASTM E165. | ASTM E8 (Tensile), ASTM E23 (Impact), ASTM E3 (Metallography). |

| Component Impact | Component Integrity Maintained . Zero distinct physical alteration. | Specimen is destroyed or permanently deformed. |

| Cost Implications | Lower Total Cost of Quality (COQ). No material loss; allows for rework if defects are repairable. | Higher cost due to scrapped parts and machining of test coupons. |

| Sampling Rate | 100% inspection capability for critical lots. | Statistical sampling (e.g., 1 in 1000) based on AQL (Acceptable Quality Limit). |

| Data Output | Qualitative and Quantitative (e.g., crack length, void diameter). | Absolute quantitative data on material failure limits. |

NDT is the standard for assuring the reliability of every single shipped unit, whereas DT validates the raw material heat lot.

Benefits for Metal Components

The integration of NDT into the manufacturing workflow of custom metal components offers significant engineering and economic advantages:

- Verification of Material Integrity: NDT verifies that the raw material (billet, casting, or forging) is free from pre-existing conditions like segregation or hydrogen embrittlement before value-added machining occurs.

- Cost-Effectiveness via Early Detection: Identifying a subsurface casting void via Ultrasonic Testing (UT) before expensive 5-axis CNC machining prevents wasted machine time and tool wear.

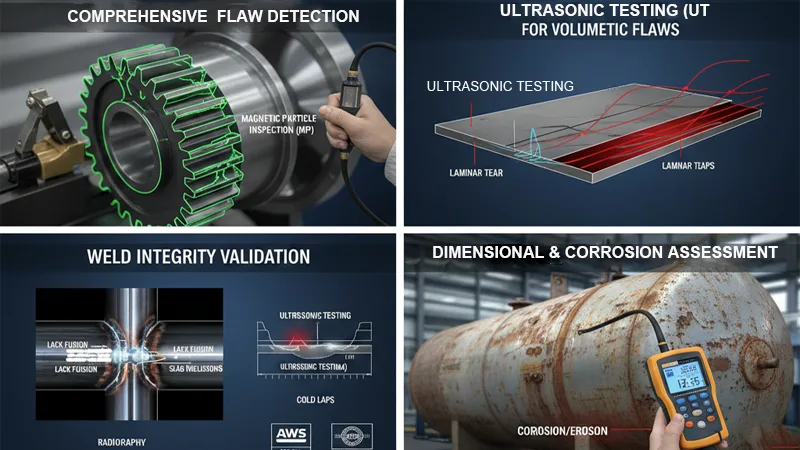

- Comprehensive Flaw Detection: Different methods target specific defect morphologies. For instance, Magnetic Particle Inspection (MPI) is superior for detecting fine surface fatigue cracks in ferromagnetic gears, while Ultrasonic Testing (UT) is critical for identifying volumetric laminar tears in plates.

- Weld Integrity Validation: For welded assemblies, NDT (specifically Radiography and UT) is mandatory to meet codes like AWS D1.1 (Structural Welding) or ASME Section IX. It detects lack of fusion, slag inclusions, and cold laps.

- Dimensional & Corrosion Assessment: Techniques like Ultrasonic Thickness Gauging (UTG) measure wall thickness reduction due to erosion/corrosion in service, essential for pressure vessel maintenance under API 510.

Why NDT Matters for Custom Metal Components

Critical Applications and Industry Standards

In sectors where failure involves high liability or risk to life, NDT is not optional—it is a regulatory mandate.

- Aerospace (AS9100 Rev D): Turbine blades and landing gear components undergo Fluorescent Penetrant Inspection (FPI) per ASTM E1417 to detect micro-cracks caused by machining stress.

- Automotive (IATF 16949): Steering knuckles and brake calipers are inspected for porosity and shrinkage using Automated X-ray Inspection (AXI).

- Oil & Gas (API 6A / API 17D): High-pressure valves and manifolds require Ultrasonic Testing per ASME Section V Article 4 to ensure they can withstand subsea pressures.

- Power Generation: Turbine rotors and steam piping are inspected using Eddy Current and Phased Array Ultrasonics to detect creep damage and thermal fatigue.

Risks and Assurance: The Cost of Failure

Latent defects in custom metal parts represent a significant liability. A “clean” surface finish (Ra 0.8µm) can hide internal stress cracks or inclusions that act as stress risers, leading to sudden fatigue failure under cyclic loading.

- Poor Material Selection & Processing: Using 304 Stainless Steel where 316L is required, or improper heat treatment (e.g., failed quenching), can result in microstructure anomalies detectable by NDT.

- Inadequate Quality Control: Relying solely on dimensional inspection (CMM) leaves the internal structure unverified.

NDT assures that the component meets the calculated Factor of Safety (FoS).

Compliance Standards and Certification

AFI Parts operates in strict accordance with global standards to ensure universal acceptance of our testing reports.

| NDT Method | Relevant Standards | Compliance Objective |

| Ultrasonic (UT) | ASTM E114, ASME Sec V Art 4, ISO 16810 | Volumetric verification of forgings and billets. |

| Penetrant (PT) | ASTM E1417, ASTM E165, ISO 3452 | Detection of surface-breaking discontinuities in non-ferrous metals. |

| Magnetic Particle (MT) | ASTM E1444, ASTM E709, ISO 9934 | Detection of surface/near-surface defects in ferromagnetic materials. |

| Radiography (RT) | ASTM E1742, ASTM E94, ASME Sec V Art 2 | Internal imaging for weldments and complex castings. |

NDT Methods for Custom Metal Components

Selecting the correct NDT method requires an understanding of the material’s magnetic properties, electrical conductivity, and the geometry of the part.

Visual Testing (VT)

Standard: ASME Section V, Article 9

Visual Testing (VT) is the most fundamental yet often underestimated method. It is not merely “looking” at a part; it is a quantified inspection process.

- Methodology: Inspectors utilize direct visual lines of sight and remote visual aids (borescopes, videoscopes) to inspect internal channels of machined manifolds.

- Requirements: Lighting intensity must be a minimum of 1000 Lux (100 fc) at the surface, and the eye-to-surface angle must not be less than 30 degrees.

- Application: Detection of gross surface defects such as undercut, surface porosity, tooling marks, and burrs.

- Advanced VT: We utilize automated optical inspection (AOI) with smart image stitching algorithms to scan large surface areas, ensuring no localized pitting or corrosion is missed.

Ultrasonic Testing (UT)

Standard: ASTM E114 (Contact Pulse-Echo), ASTM E2375 (Wrought Products)

Ultrasonic testing employs high-frequency sound waves (typically 0.5 MHz to 20 MHz) transmitted into the material via a piezoelectric transducer.

- Physics: When the sound wave encounters a boundary with different acoustic impedance (such as air in a crack or slag in a weld), a portion of the sound energy is reflected to the probe.

- Deep Flaw Detection: UT is the premier method for inspecting thick-section parts (e.g., heavy shafts, mold blocks) where X-rays are impractical. It can detect delaminations and mid-wall inclusions.

- Phased Array UT (PAUT): We utilize advanced PAUT equipment, which uses multiple elements to steer the beam electronically, creating a cross-sectional image (B-scan) of the part. This allows for precise sizing and location of defects.

Radiographic Testing (RT)

Standard: ASTM E1742, ASME Section V Article 2

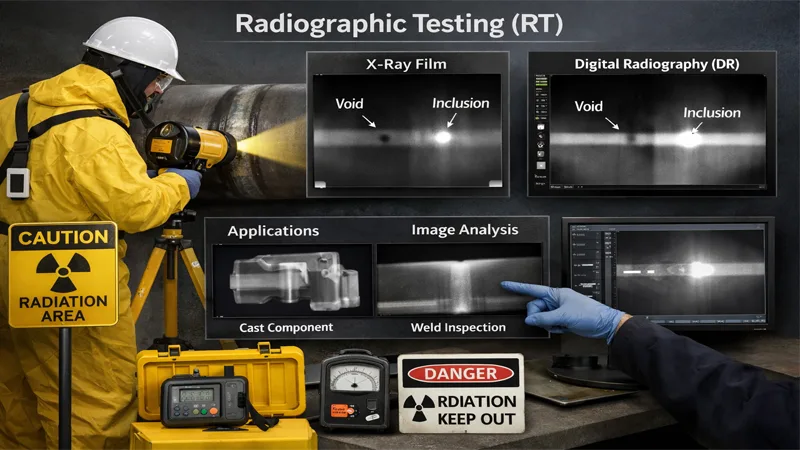

Radiographic testing utilizes ionizing radiation (X-rays or Gamma rays from isotopes like Iridium-192) to penetrate the component and expose a film or digital detector .

- Principle: Variations in material density or thickness result in different levels of radiation absorption. A void (air pocket) absorbs less radiation, appearing darker on the radiograph. An inclusion (like Tungsten) absorbs more, appearing lighter.

- Application: Essential for complex cast parts with internal coring, and for certifying critical full-penetration butt welds.

- Digital Radiography (DR): Modern DR systems provide immediate digital images with higher dynamic range, allowing for advanced image processing and easier archiving for compliance audits.

- Safety: Strict adherence to radiation safety protocols is mandatory due to the hazards involved.

Magnetic Particle Inspection (MPI)

Standard: ASTM E1444, ASTM E709

MPI is a sensitive method for detecting surface and slightly subsurface discontinuities in ferromagnetic materials (e.g., Carbon Steel, Cast Iron, 400-series Stainless) .

- Physics: The part is magnetized using a yoke or a bench unit (Head Shot/Coil Shot). If a crack is present, it disrupts the magnetic field lines, creating magnetic flux leakage. Ferromagnetic particles (often suspended in a fluid) are applied and trapped by this leakage field, forming a visible indication.

- Types:

- Wet Fluorescent MT (WFMT): Uses UV light and fluorescent particles for maximum sensitivity. Standard for aerospace components.

- Dry Powder MT: Used for rough surfaces or field welds.

- Limitations: It cannot be used on non-ferromagnetic materials like Aluminum, Copper, or 300-series Stainless Steel.

Dye Penetrant Testing (PT)

Standard: ASTM E1417, ASTM E165

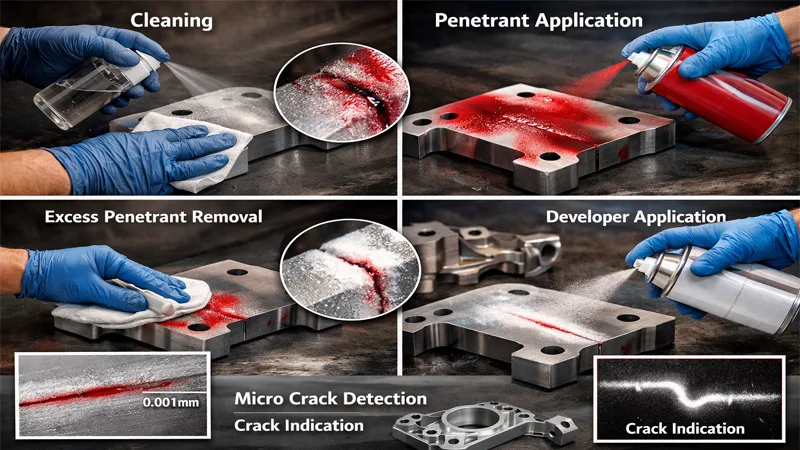

Liquid Penetrant Testing is a versatile method for detecting surface-breaking defects in non-porous materials (metals, plastics, ceramics) .

- Process:

- Cleaning: Surface must be free of oil/grease (solvent cleaning).

- Application: Penetrant is applied and allowed to dwell (5–30 minutes) to seep into cracks via capillary action.

- Removal: Excess surface penetrant is removed.

- Development: A developer is applied, drawing the penetrant out of the crack (“bleed out”) to form a visible indication.

- Sensitivity: Capable of detecting fatigue cracks as narrow as 1 micron.

- Application: Ideal for Aluminum CNC parts, Titanium aerospace fittings, and checking for leaks in thin-walled housings.

Eddy Current Testing (ET)

Standard: ASTM E1004 (Conductivity), ASTM E309 (Tubular Products)

Eddy Current Testing utilizes electromagnetic induction to detect surface and near-surface flaws in conductive materials.

- Physics: An alternating current in a coil creates a magnetic field, which induces eddy currents in the test part. Defects disrupt these currents, changing the coil’s impedance.

- Material Sorting: ET is highly effective for sorting mixed batches of materials based on conductivity (e.g., distinguishing 6061-T6 from 6061-T4 aluminum) or measuring coating thickness (e.g., anodizing thickness).

- Applications: Detecting heat treat cracks, measuring conductivity (IACS), and inspecting heat exchanger tubing.

Non-Destructive Testing Process

Method Selection: Engineering the Inspection

The choice of NDT method is dictated by the Material Specification, Part Geometry, and the Type of Defect anticipated.

- Surface Cracks in Steel: Choose Magnetic Particle (MPI).

- Internal Voids in Aluminum Castings: Choose Radiography (RT).

- Laminations in Steel Plates: Choose Ultrasonic (UT).

- Surface Cracks in Stainless Steel (Non-Magnetic): Choose Dye Penetrant (PT).

Preparation Steps: Surface Condition

NDT reliability relies heavily on surface preparation.

- Cleaning: Parts must be cleaned in accordance with ASTM E165 or SSPC-SP standards. Scale, rust, paint, and machining coolant must be removed.

- Machining Finish: A rough surface (e.g., Ra > 6.3µm) can cause false indications in PT and UT. Polishing or grinding may be required.

Test Execution and Calibration

Technicians must perform system calibration using standard reference blocks (e.g., IIW blocks for UT, ASTM penetrant sensitivity panels) before testing begins. This ensures the equipment is sensitive enough to detect the Critical Flaw Size defined by the design engineer.

Analysis and Reporting

Data analysis is performed against specific Acceptance Criteria (e.g., AWS D1.1 Table 6.1).

- Indication vs. Defect: Not all indications are defects. A tool mark is an indication; a crack is a defect. The technician must interpret the signal.

- Reporting: Reports must include the procedure used, acceptance standard, equipment calibration data, and a map of any findings. At AFI Parts, we utilize centralized data management to ensure full traceability for 10+ years.

Choosing an NDT Provider

Qualifications and Certifications

The competence of the NDT technician is paramount. We adhere to the ASNT SNT-TC-1A and NAS 410 (National Aerospace Standard) certification schemes.

- Level I: Qualified to perform specific calibrations and tests.

- Level II: Qualified to set up equipment, interpret results, and sign off on reports.

- Level III: Qualified to develop procedures and train personnel.

Ensure your provider holds relevant company certifications such as ISO 9001:2015, AS9100 (Aerospace), or NADCAP accreditation for special processes.

Experience with Custom Metal Components

Testing a standard pipe is different from testing a complex 5-axis machined aerospace manifold. Experience in GD&T and complex geometries is essential to distinguish between geometry signals and actual defects.

Technology and Equipment

AFI Parts invests in cutting-edge technology:

- PAUT (Phased Array): For mapping corrosion profiles.

- Digital Detectors (DDA): For high-resolution X-ray without chemical processing.

Quality Assurance

Quality Assurance (QA) in NDT involves rigorous Performance Demonstration and Process Control.

- Process Control Checks: Daily checks of magnetic particle bath concentration (settling test), penetrant sensitivity, and UV light intensity.

- Audit Trails: Every inspection is linked to the specific machine, operator, and date/time stamp, ensuring full accountability.

Ongoing NDT Testing and Reliability

Regular Inspections and Predictive Maintenance

For components in service (e.g., pumps, valves), “cradle-to-grave” traceability is vital. Periodic NDT (e.g., annual UT thickness checks) monitors degradation mechanisms like erosion or stress corrosion cracking.

Maintenance Integration

Integrating NDT data into Computerized Maintenance Management Systems (CMMS) allows for predictive rather than reactive maintenance, significantly reducing downtime.

FAQ

An indication is any signal observed during testing (e.g., a blip on a UT screen). A discontinuity is an interruption in the physical structure. A defect is a discontinuity that exceeds the rejection limit specified by the governing standard (e.g., ASME or AWS) and renders the part unusable.

NDT methods like Magnetic Particle or Penetrant testing can detect the cracks resulting from hydrogen embrittlement, but they do not detect the embrittlement itself. Process control (baking after plating) is the primary prevention, verified by destructive testing of sample coupons.

Yes, our Level II and III technicians are familiar with both ASME/ASTM (US) and ISO/EN (European) standards, ensuring your documentation meets global import requirements.

For non-conductive materials like ceramics or composites used in metal assemblies, we utilize Ultrasonic Testing (UT) or Radiography (RT), as Magnetic Particle and Eddy Current methods are ineffective.

Common ways include visual testing, ultrasonic testing, radiographic testing, magnetic particle inspection, dye penetrant testing, and eddy current testing. Each way finds different problems in metal parts.

NDT can find many internal and surface problems. Some ways work better for certain flaws. Picking the right way helps get the best results for each part.

No, NDT does not hurt the part. The part is still safe to use after testing. This makes NDT great for important custom metal parts.