You have a critical engineering decision to make in thread manufacturing for hardened materials. In the context of hard alloys (typically >45 HRC), the choice between rigid tapping and helical thread milling is not merely a preference—it dictates process stability. Your choice directly impacts cycle time, tool life cost-per-part, and the resultant thread quality class (e.g., 6H vs. 4H).

It also fundamentally changes the mechanics of how material is removed. Engineering studies indicate that thread milling generates tangential cutting forces, whereas tapping generates significant axial torque and friction. This distinction is vital for tool longevity. Tapping is traditionally superior for small diameter threads (e.g., <M5) in high-volume softer steels. However, as material hardness increases and diameter scales up, the torque requirements for tapping become exponential, often exceeding machine spindle limits.

Look at the comparative engineering analysis below to see how each method functions in a production environment:

| Threading Method | Process Mechanics & Advantages | Limitations & Risks |

| Thread Milling | Interrupted cut produces manageable chips; Low cutting forces allow threading thin walls; Adjustable pitch diameter for wear compensation. | Requires 3-axis simultaneous interpolation capability; Cycle time is generally longer for small holes (<M8) compared to tapping. |

| Tapping | Continuous contact provides fastest cycle time for standard holes; Fixed geometry ensures thread profile consistency (if the tap is new). | High torque risk in hard alloys; Catastrophic failure mode (tap breakage scraps the part); Non-adjustable pitch diameter. |

| Single Point Turning | Excellent for concentricity on lathe parts; precise control. | Limited to lathe operations; difficult for small internal diameters due to bar deflection; slow material removal. |

Think about the specific physics of your job before you start.

Check the exact Rockwell Hardness (HRC) and the work hardening coefficient of your alloy.

Key Takeaways

- Hardness Thresholds: For materials over 50 HRC, thread milling is statistically safer. It utilizes high-speed machining strategies (low radial depth of cut) to extend tool life.

- Volume vs. Risk: Use tapping for threads smaller than M6 in high-volume runs (<45 HRC), provided you use synchronous rigid tapping. Tapping is faster, but high-risk in large diameters.

- Precision Control: Thread milling allows CNC compensation of the thread diameter to maintain tolerance as the tool wears. You can use one pitch-insert to cut multiple diameters (e.g., M20x1.5 and M40x1.5).

- Ductility Requirement: Thread forming (Cold Rolling) is restricted to ductile materials (typically >10% elongation). It creates work-hardened threads with superior fatigue strength, but cannot be used in brittle hardened alloys.

- Material Verification: Always correlate the specific alloy grade (e.g., Inconel 718, H13 Tool Steel) with the threading method, not just the hardness value.

Table of Contents

This strategic selection stops catastrophic tool failures inside expensive workpieces. This keeps process capability high and lowers scrap rates. Good planning helps things go faster and stops tools from breaking. Take care of machines and tools often. This keeps work smooth and helps tools last longer.

Thread Manufacturing Methods Overview

When you work with hard alloys, you need to choose the right thread manufacturing method based on specific cutting mechanics. Each method has its own strengths defined by chip formation and heat dissipation. You want to get strong threads, predictable tool life, and smooth production. Let’s look at the main ways you can make threads in hard alloys from a manufacturing engineering perspective.

Tapping Basics

Tapping is a continuous cutting process where the tool’s teeth engage the material simultaneously. The tap cuts the thread shape as it moves into the material, synchronized with the spindle rotation.

Tapping works well for small holes and high-volume production because the cycle time is simply Depth / (RPM \times Pitch). You often see tapping in shops that need many parts fast. However, tapping can be treacherous in hard alloys. The tool faces high torsional stress because the cutting edges are in constant contact, generating immense heat.

This can cause “chip welding” or immediate breakage if the torque exceeds the tap’s structural limit. You need to use specific Powdered Metal (PM) or Solid Carbide taps with advanced coatings (like TiAlN). Tapping is not the best choice for very hard materials (>50 HRC) or blind holes with poor chip clearance.

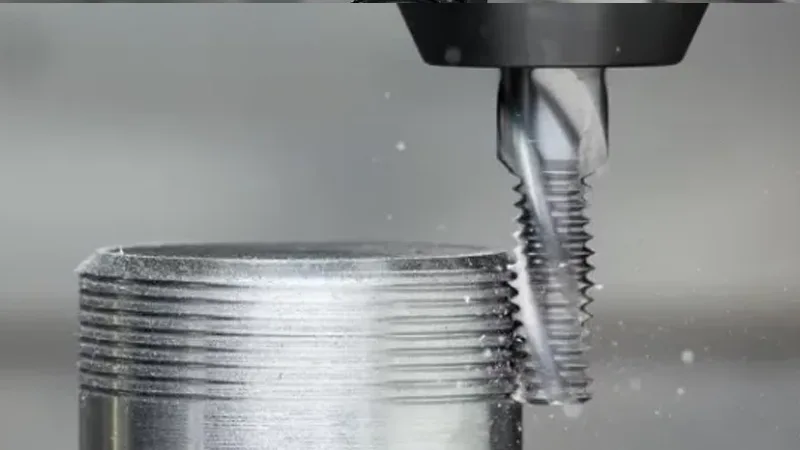

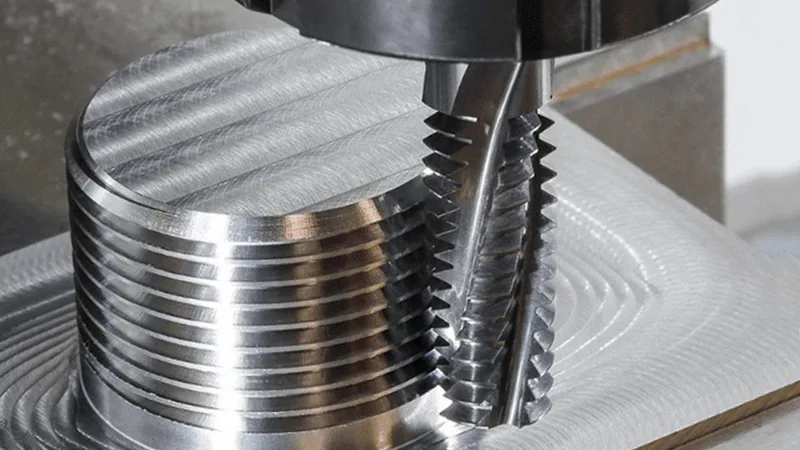

Thread Milling Basics

Thread milling uses a rotating tool with a smaller diameter than the thread to interpolate the thread profile. You use a 3-axis CNC milling machine capable of helical interpolation for this process.

The thread mill moves in a spiral path (G02/G03 helical move) to create the thread, typically performing a “climb milling” action. Thread milling gives you absolute control over the thread size (Pitch Diameter). You can use one tool for different thread sizes of the same pitch. This method works exceptionally well for hard alloys.

The cutting forces stay low because the arc of engagement is small. This allows for better heat dissipation into the chip rather than the workpiece. Thread milling is critical for thin-walled parts because the low lateral forces prevent wall deformation, whereas a tap acts like a wedge.

Contrary to older beliefs, modern micro-thread mills can process threads as small as M1.6, and handle materials up to 65 HRC. Many aerospace and automotive shops use thread milling for tough jobs like Titanium Grade 5. You get precise threads and longer tool life. CNC milling makes this process possible and efficient.

Tip: Thread milling is ideal for hard alloys and deep threads (where chip evacuation is hard for taps). You avoid the risk of a tap breaking inside a nearly finished part.

Thread Forming Overview

Thread forming is a chipless displacement process. You do not cut the material. Instead, you use a polygon-shaped tool to press and plastically deform the substrate.

This thread forming process works by cold-forming the grain flow. You get strong, smooth threads with no chips to clean up, which eliminates the risk of re-cutting chips. Thread forming is popular in the aerospace and automotive industries for fatigue-critical fasteners.

It gives you uniform threads and high tensile strength. However, you need ductile materials for thread forming. Hard alloys that are too brittle (typically >45 HRC or cast materials) will crack or shatter under the forming pressure. The process uses pressure, resulting in compressive residual stress at the thread root. Thread forming is a good choice when you want strong threads, but only if the material’s elasticity allows it.

Main thread manufacturing methods for hard alloys:

- Tapping: Efficient for small holes (<M6) in moderately hard materials (<45 HRC).

- Thread Milling: Best for high hardness (>50 HRC), large diameters, and expensive components where process security is paramount.

- Thread Forming: Chip-free, high-strength threads, but strictly limited to ductile materials; generally unsuitable for hardened tool steels.

When you pick a method, think about your material hardness, thread size, and risk tolerance. CNC milling lets you use advanced methods like thread milling and thread forming. You can get better threads and longer tool life with the right choice.

Tapping vs. Thread Milling: Quick Comparison

When you work with hard alloys, you want to choose the best thread manufacturing method based on Process Reliability. You need to look at how tapping and thread milling perform under thermal and mechanical stress. Each method gives you different results for thread quality, speed, and efficiency. Let’s break down the main differences so you can pick the right process for your threads.

Performance in Hard Alloys

You face tough challenges when you cut threads in hard alloys. Tapping often struggles because the cutting speed ($V_c$) must be drastically reduced to manage heat. The tap can wear out fast or even break due to excessive torque at the reversal point.

Thread milling works better for hard alloys. The thread mill uses interrupted cutting, allowing the cutting edge to cool down during rotation. You get smoother threads and longer tool life. Thread forming is generally disqualified for hardened alloys due to a lack of ductility. If the alloy is brittle, thread forming will cause cracks.

You should use thread milling for alloys above 50 HRC (like hardened D2 or H13). Tapping these materials requires expensive CBN or specific carbide taps and carries high risk. Note: Thread milling gives you more control and significantly less risk of tool breakage in hard alloys. Tapping works best for softer materials or small threads where the milling cycle time is too long.

Speed and Efficiency

You want to finish your threads quickly, but “speed” can be misleading.

- Tapping is faster for cycle time per hole on small diameters. For example, tapping an M6 hole takes seconds.

- However, when you work with large threads (e.g., M24) or hard alloys, tapping requires massive machine horsepower and slow speeds. You need to reverse the tap and clear chips. This takes extra time and risks chip jamming.

- Thread Milling is slower for small threads (due to the helical path length), but it shines with large diameters. You use one thread mill for many sizes (e.g., M30, M42, M60), reducing tool inventory setup time.

- Thread forming is efficient for high volume but irrelevant for hard alloys.

If you want high-volume production, tapping works well for small threads. For hard alloys and big threads, thread milling is the better choice because it eliminates secondary operations (like removing broken taps via EDM).

- Tapping: Lowest cycle time for <M10 holes.

- Thread Milling: Highest efficiency for >M12 holes and hard alloys (>50 HRC).

Precision and Thread Quality

You need high thread quality for strong parts. Precision in threading is defined by the Thread Class (e.g., 6H, 4H).

- Thread Milling allows you to achieve tight tolerances (e.g., 4H) easily. You can adjust the cutter radius compensation in the CNC control to shave microns off the thread flank.

- Tapping relies entirely on the tap’s physical size. If the tap wears by 0.02mm, your thread changes by 0.02mm. You cannot adjust it. You may see more variation in thread quality, especially in hard alloys where taps wear rapidly.

Thread forming creates strong threads, but is not for hard alloys.

Look at the table below to see the difference in process capability:

| Machining Method | Precision Control Mechanism | Tolerance Capability |

|---|---|---|

| Thread Milling | CNC Radial Compensation (Wear offsets) | Adjustable to ±0.01mm or better (Class 4H) |

| Tapping | Fixed Tool Geometry | Fixed to Tap Class (typically ±0.05mm / Class 6H) |

You see that thread milling gives you better precision because it is adjustable. You get higher thread quality and fewer defects. If you need perfect threads in hard alloys, thread milling is your best option. Tapping works for general commercial tolerances. Thread forming is great for ductile alloys.

Tip: Choose thread milling for the best thread quality and precision in hard alloys. Use tapping for quick jobs with small threads. Try thread forming for chip-free, strong threads in ductile materials.

Tapping in Hard Alloys

Advantages

Tapping helps you make threads at high speed in specific contexts. The pitch, depth, and diameter are fixed by the tool, ensuring consistency if the process is stable. Machines can tap many threads with the same quality. This makes tapping good for big jobs in moderately hard steels (<40 HRC).

You can use tapping with lots of materials, but rigid setups are required. You do not need to move the workpiece. Fast spindle speeds (in soft materials) let you finish threads quickly. This saves time and lowers labor costs. Automatic tool changers keep your work moving.

Rigid tapping cycles (G84) synchronize spindle and feed, improving accuracy. You can use tapping for small batches or big production runs.

| Advantage | Description |

| Cycle Speed | Fastest method for small holes (e.g., <M10). |

| Simplicity | Standard G-code cycles (G84) are easy to program. |

| Deep Holes | Special long-shank taps can reach areas thread mills cannot. |

| Versatility | Works with many materials and thread types. |

Limitations

Tapping has severe problems with hard alloys.

- Hardness Limit: It becomes exponentially difficult above 45-50 HRC. The tap cutting edges chip instantly.

- Chip Evacuation: In blind holes, chips can pack at the bottom, causing the tap to explode upon reaching depth.

- Reversal Torque: You must reverse the tap to exit. This moment of zero-velocity is where most chipping occurs in hard materials.

- Rigidity: You need high-end “Synchro-Chucks” to prevent pitch error. Floating holders are often too unstable for hard alloys.

- Coolant: You need specific oil-based or high-concentration (10-15%) emulsion. Standard coolant may lead to tap seizure.

If you do not line up the tap (runout > 0.02mm), the threads can get oversized. You must watch tool wear and change your process often.

Best Applications

Use tapping when you need lots of threads fast in softer hard alloys (e.g., <40 HRC pre-hardened steels). Tapping works best for small threads (M2-M8) and through-holes (where chips fall out). Tapping is great for making screw threads in parts that do not need super tight positional tolerance. You can use tapping for car parts, electronics, and general manufacturing.

If you need stronger threads or work with alloys above 50 HRC, try thread milling. Tapping gives steady results for regular threads in easier jobs. Use tapping for prototypes, small batches, or big runs if the material is right. Always check how hard your alloy is and what kind of thread you need before you pick tapping.

Common Issues

When you use tapping in hard alloys, you may run into several problems. These issues can affect your thread quality, tool life, and even your machine. Knowing what to watch for helps you avoid costly mistakes.

1. Tool Breakage

Hard alloys put a lot of torque on your tap. The tool can snap if you use the wrong speed or feed. You might also see breakage if you use a dull tap or a standard HSS tap instead of a Carbide/PM tap. Always check your tap before you start. Use sharp, high-quality taps made for hard alloys.

2. Poor Chip Evacuation

Chips can get stuck in the hole during tapping. This problem gets worse with deep holes or blind holes. If chips do not clear, they can jam the tap and break it. You should use proper cutting fluid and consider spiral-flute taps for pulling chips out of blind holes. Clean the hole before you start tapping.

3. Thread Quality Issues

You want strong, clean threads. In hard alloys, you may see rough or torn threads (galling). This can happen if the tap wears out (cold welding) or if you use the wrong tap geometry. Always inspect your threads after tapping. Replace worn taps right away.

4. Alignment Problems

If you do not align the tap with the hole, you can damage both the tap and the part. Misalignment leads to crooked threads. Use rigid tapping holders (hydraulic or shrink-fit) to keep the tap straight. Double-check your setup before you begin.

5. Excessive Heat

Tapping in hard alloys creates a lot of heat. Too much heat can anneal the tap cutting edge. Use internal coolant (Through-Spindle Coolant) if possible.

Here is a quick table to help you spot and solve common tapping issues:

| Issue | Cause | Solution |

|---|---|---|

| Tool Breakage | Excessive Torque / Wrong Material | Use Carbide/PM taps; Reduce speed |

| Chip Jamming | Blind hole packing | Use Spiral Flute taps; Check drill depth clearance |

| Rough Threads | Galling / Cold Welding | Increase Coolant concentration; Check coating (TiAlN) |

| Misalignment | Runout | UUse Synchro/Hydraulic chucks |

| Overheating | Friction | Use Through-Coolant taps; Reduce RPM |

Tip: Always monitor your spindle load meter. Stop and check your work often. This helps you catch problems early and save time. Good habits and regular checks make a big difference in your thread quality and tool life.

Thread Milling for Hard Alloys

Advantages

You get many benefits when you use thread milling for hard alloys. This method gives you high precision and process security. You can use a thread mill to cut threads in tough materials like Inconel 718, Titanium 6Al-4V, and Hardened Tool Steels (H13, D2).

Thread milling works well for large diameters and deep holes. You can use one tool for different thread sizes (e.g., same pitch 1.5mm), which saves you time and money on inventory. The process creates lower radial cutting forces, minimizing tool deflection. You also get better control over the thread size and shape via CNC cutter compensation.

Thread milling helps you avoid tool breakage, especially in hard alloys above 50 HRC. Even if a tool breaks, it is loose in the hole and easy to remove—unlike a jammed tap. You can use thread mills to make threads with tight tolerances (4H/5H). This method gives you smooth threads and reduces the risk of defects.

Limitations

Thread milling does have some limits.

- Machine Requirements: You need 3-axis simultaneous CNC capability (helical interpolation).

- Min Diameter: While modern tools go down to M1.6, for general job shops, stable thread milling is most cost-effective above M4 or M6. Below this, tools are fragile and expensive.

- Depth Limit: Thread mills typically have a length-to-diameter ratio (L:D) limit of 2.5x or 3x. Deeper than that, deflection causes tapered threads.

- Cost: Solid carbide thread mills are more expensive upfront than taps.

You must use the right feeds and speeds to avoid tool wear. Thread forming taps may not work well in very small holes or with brittle materials.

Here are some key points to remember:

- You need advanced machinery for thread milling in hard alloys.

- Cost-effectiveness is best for holes >M6 or hard materials.

- Solid carbide thread mills are best for stainless steel, titanium, and hardened alloys.

Ideal Scenarios

Thread milling shines in certain jobs. You should use this method when you need precise threads in hard alloys. It works best for large diameter threads and expensive parts where scrap is not an option. You can also use it for deep cavity structures where tapping is hard.

The process gives you high accuracy. Look at the table below to see when thread milling is the best choice:

| Advantages | Applicable Scenarios |

|---|---|

| Process Security (No broken taps) | High-value Aerospace/Medical parts |

| Precision(±0.01mm adjustable) | Bearing fits / Gauge threads |

| Versatility | One tool for M20, M30, M50 (same pitch) |

| Hard Machining | Materials 50-65 HRC |

You get the best results when you use sharp tools and follow the right feeds and speeds. Thread milling is your go-to method for hard alloys, large threads, and deep holes. Always check your machine and tool setup before you start.

Pitfalls to Avoid

When you use thread milling for hard alloys, you can get great results. Still, you need to watch out for some common mistakes. If you avoid these pitfalls, you will get better threads and longer tool life

1. Using the Wrong Tool Material

You need to pick the right tool for thread milling. If you use a tool that is not made for hard alloys, it will wear out fast. Solid carbide tools with AlTiN or TiSiN coatings work best for tough materials. Always check the tool specs before you start.

2. Incorrect Machine Settings

Thread milling needs calculated speeds and feeds. Feed rate at the cutting edge is different from the center of the tool (Internal interpolation error). If you don’t adjust for “Centerline Feed,” you will move too fast and break the tool. If you go too slow, you may get rubbing/work hardening. Test on a scrap piece if you are not sure.

3. Poor Chip Evacuation

Chips can build up in the hole during thread milling. This can cause the tool to recut chips. Use Air Blast or high-pressure coolant to clear chips. You can also use air blasts to keep the hole clean. Always check for chip buildup during the process.

4. Not Checking Thread Depth

You must set the correct thread depth in your CNC program. If you go too deep, you can hit the bottom and snap the tool. If you do not go deep enough, the thread will not hold. Double-check your program before you start thread milling.

5. Skipping Tool Inspection

A worn or damaged tool will not cut clean threads. Inspect your thread milling tool before each job. Look for chips, cracks, or dull edges. Replace the tool if you see any damage.

Tip: Always keep your tools sharp and your machine clean. This helps you avoid most problems with thread milling.

| Pitfall | How to Avoid It |

|---|---|

| Wrong tool material | Use Solid Carbide + TiAlN/TiSiN coating |

| Feed Rate Error | Calculate Feed at Periphery vs Centerline |

| Recutting Chips | Use Air Blast or Through-Coolant |

| Tapered Threads | Use “Spring Pass” (zero cut pass) to fix deflection |

| Worn tools | Inspect and replace as needed |

If you pay attention to these details, you will get strong, precise threads in hard alloys. Thread milling gives you control and quality, but only if you avoid these common mistakes.

Choosing the Right Threading Method

Material Hardness

You need to look at how hard your material is before you pick a threading method.

- < 45 HRC: Tapping is viable and efficient. Use TiCN coated taps.

- 45 – 50 HRC: The “Danger Zone”. Tapping requires specialized Carbide taps. Thread milling becomes cost-competitive due to tap breakage risks.

- > 50 HRC: Thread Milling is the standard. Tapping is extremely risky and requires expensive tools.

Thread milling works better for hard alloys because it uses lower cutting forces. Thread forming can also work, but only if your material is ductile (e.g., Soft Stainless, Aluminum). It fails in Hard Alloys.

The tap material you choose changes how fast you can work. Thread forming needs ductile materials. If your alloy is too hard or brittle, thread forming will not work well. Thread milling is best for alloys above 50 HRC. Tapping is good for softer hard alloys and small threads. You should always check material compatibility before you start. This helps you avoid tool failure and wasted time.

Thread Size and Depth

Thread size and depth play a big role in your decision.

- Small / Shallow (e.g., M4 x 8mm): Tapping is unbeatable for speed.

- Large / Deep (e.g., M20 x 40mm): Thread milling gives better results. Tapping large holes requires immense torque.

- Deep Blind Holes: Taps pack chips at the bottom. Thread mills allow chips to fall to the bottom while the tool lifts out, making them safer.

You can use one tool for many thread sizes, which saves you time and money. Thread forming works best for medium threads in ductile materials. If you try thread forming in a small or brittle hole, you may damage your part. Always match your method to the thread size and depth you need.

Tip: For deep or large threads in hard alloys, choose thread milling. For small, shallow threads, tapping or thread forming may be faster.

Production Volume

Production volume affects your choice of threading method.

- High Volume (>1000 parts): Tapping is preferred for cycle time. Invest in process development to make tapping stable (custom taps, high-quality holders).

- Low/Medium Volume: Thread milling is better. It requires less setup time (one tool for multiple pitches) and offers zero scrap risk.

Tapping works well for high-volume production with small threads. Thread milling is slower for small threads but shines in large or deep threads. You can use one thread mill for different sizes. Thread forming is great for high-volume production in ductile materials.

Quick Checklist:

- High-volume, small threads: Use Tapping.

- Large or deep threads: Use Thread Milling.

- Ductile materials: Thread Forming is a good choice.

- Hard alloys above 50 HRC: Thread Milling works best.

| Method | Best For | Not Ideal For |

| Tapping | Small (<M10), Shallow, High-Volume | Hard (>50HRC), Brittle, Deep threads |

| Thread Milling | Large, Deep, Hard Alloys, High Value Parts | Very small holes (<M3), High volume low cost |

| Thread Forming | Very small holes (<M3), High volume, low cost | Hardened Alloys, Brittle Cast Iron |

You can see that each method fits a different job. Match your threading method to your material, thread size, and production needs for the best results.

Tooling and Machine Capability

You need the right tools and machines for good thread manufacturing.

- Tapping: Requires a machine with a Rigid Tapping Cycle (Synchronized Spindle). Older machines with “Floating Tapping Heads” will struggle with hard alloys.

- Thread Milling: Needs a CNC machine with 3-Axis Helical Interpolation. Machines must be rigid to prevent vibration (chatter).

- Thread Forming: Needs high spindle torque and a rigid machine structure to withstand the forming pressure.

You also need special thread forming tools. These tools look different from cutting taps or thread mills. You must check your machine’s power and rigidity. Weak machines can break tools or make bad threads.

| Method | Machine Needed | Tool Needed | Special Needs |

|---|---|---|---|

| Tapping | CNC w/ Rigid Tapping | Carbide/PM Tap | Synchro-Chuck, Oil/High% Coolant |

| Thread Milling | 3-Axis CNC Mill | Solid Carbide Mill | Helical capability, Air Blast |

| Thread forming | High Torque CNC | TForming Tap | HHigh Lubricity Coolant |

Tip: Always check your machine’s specs before you start. Make sure your tools match your machine’s power and speed.

Thread Quality Requirements

You must think about the quality you need for your threads.

- Aerospace/Medical: Often requires Thread Milling for 4H/5H tolerance and surface finish control. Tapping can leave “torn” grain structures.

- General Engineering: Tapping (6H) is sufficient.

- Fatigue Critical: Thread Forming creates compressed surfaces, excellent for fatigue resistance, if the material allows.

If you need perfect threads, use thread milling. If you want strong threads with no chips, use thread forming. Tapping works for general jobs where you do not need perfect threads.

Checklist:

- Do you need very precise threads (micron adjustment)? -> Thread Milling.

- Do you want strong, chip-free threads in soft metal? -> Thread Forming.

- Do you need fast, basic threads? -> Tapping.

Note: Always inspect your threads after machining. Use thread gauges (Go/No-Go) to check size.

Optimization and Troubleshooting Tips

Maximizing Tool Life

You want your tools to last as long as possible in thread manufacturing. Hard alloys can wear out tools quickly, but you can take steps to extend tool life.

- Coatings: Use TiAlN, AlTiN, or TiSiN coatings. These are heat-resistant and perfect for hard milling.

- Geometry: Use tools with variable helix angles to reduce vibration.

- Strategy: In thread milling, use Climb Milling (generating thin-to-thick chips) for better surface finish.

- Multi-Pass: For hard alloys (>50 HRC), do not cut the thread in one pass. Use 2-3 radial passes (e.g., 60% – 30% – 10% material removal). This reduces tool deflection.

| Strategy | Description |

|---|---|

| Advanced Coatings | Use TiAlN/TiSiN for heat resistance. |

| Climb Milling | Ensures heat goes into the chip, not the tool. |

| Multi-Pass | Take 2-3 radial passes to reduce tool load in hard alloys. |

| Wet vs Dry | Thread Milling: Often dry + air blast (to avoid thermal shock). Tapping: Always heavy oil/coolant. |

Tip: Always inspect your tools before and after each job. Replace worn tools to keep your threads sharp and your production running smoothly.

Preventing Thread Defects

You want every thread to be strong and clean.

- Tapping Defects: Oversized threads are usually caused by runout in the holder or “axial lag” in older machines. Use a floating holder (tension/compression) only if the machine lacks rigid tapping.

- Milling Defects: Tapered threads (conical shape) happen due to tool deflection. Use a “spring pass” (repeat the final cut with zero offset) to correct this.

Always use enough cutting fluid. Lubrication reduces friction and stops galling during threading. Maintain sharp tools for clean threads. Check tool alignment with the workpiece. Use tools harder than the alloy. Apply enough cutting fluid for smooth operation.

Boosting Efficiency

To boost efficiency in threading hard alloys:

- Thread Milling: Increase cutting speed ($V_c$) but keep chip load ($f_z$) moderate. Use high-feed entry methods.

- Tapping: Optimization is limited by the machine’s reversal speed. Optimize the Retract Plane (R-plane) to be as close to the part as safe (e.g., 2mm) to save air-cutting time.

Plan your toolpaths carefully. Good planning prevents collisions and cuts down on wasted movements. Pick the right cutting speeds and feed rates for your material. Use effective chip control methods

Tip: Review your process after each batch. Small changes can make your thread manufacturing faster and more reliable.

Maintenance Best Practices

You need good habits to keep your threading tools working well. Hard alloys make your tools work harder.

- Monthly: Inspect tool holders (Collets/Hydraulic chucks) for damage/dirt. A dirty collet causes runout.

- Daily: Check coolant concentration (Refractometer). Low concentration leads to tap breakage.

- Weekly: Check Spindle Runout. Runout kills carbide tools instantly.

Tip: Set reminders for each maintenance task. Regular care keeps your shop running well and threads strong.

FAQ

Standard taps will fail. Thread milling uses interrupted cuts and allows for multi-pass strategies to safely machine hard materials.

Yes, with Thread Milling. A single tool with a pitch of 1.5mm can cut M12x1.5, M20x1.5, and any other diameter >M12 with that pitch. Tapping requires a specific tool for every single diameter.

Use specific Hard-Material Taps (Solid Carbide or PM-HSS-E). Use a Rigid Tapping cycle. Ensure the coolant concentration is >10%. Reduce cutting speed.

Yes, modern tools allow thread milling down to M1.6, but it is generally most cost-effective for holes >M5/M6. Below M4, taps are usually preferred unless the material is too hard (>50 HRC).

It produces the strongest threads due to grain flow and cold working. It is chip-free. However, it cannot be used in hard alloys (typically limited to <35-40 HRC materials).

Check your material hardness and thread diameter.

- Soft + Small (<M10): Tap.

- Hard (>45 HRC) OR Large (>M12): Thread Mill.

For Tapping: Check for “cold welding” (need more oil/coolant) or a dull tap. For Milling: Check for vibration (chatter) or deflection. Add a spring pass.