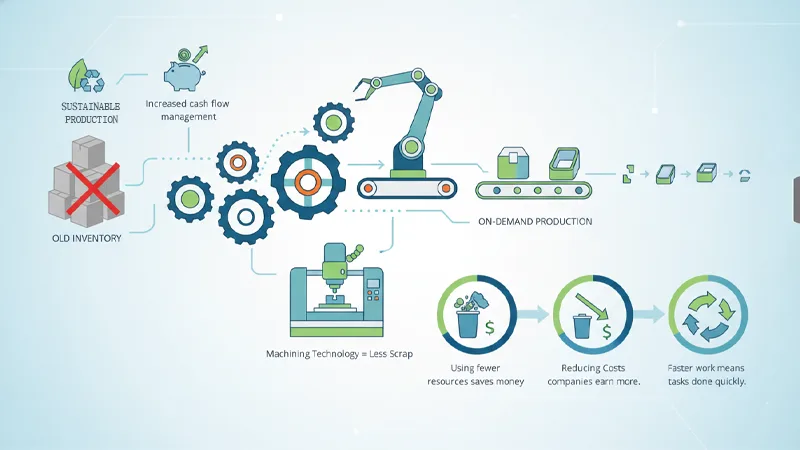

On-demand manufacturing helps lower inventory pressure by strictly matching production cycles to real-time consumption signals. Unlike traditional “Push” systems that rely on speculative forecasting, this “Pull” approach ensures companies make only what is needed. This fundamentally shifts the financial landscape, transforming dormant stock into active cash flow.

By synchronizing restocking triggers with actual market demand, businesses can eliminate the “Bullwhip Effect”—where small fluctuations in retail demand cause massive overproduction upstream—thereby saving significantly on overhead and storage. Machining serves as the cornerstone of this flexibility, offering a high-mix, low-volume (HMLV) capability that allows businesses to pivot instantly when orders change.

Market Growth and Sector Adoption

The adoption of on-demand manufacturing is accelerating across precision-reliant industries. The following data reflects the projected market expansion as companies move away from mass-production models:

| Sector | Market Size (2024) | Projected Growth (2032) | Estimated CAGR (%) |

|---|---|---|---|

| Automotive | USD 4.60 billion | USD 13.80 billion | 14.7% |

| Aerospace | USD 3.20 billion | USD 8.45 billion | 12.9% |

| Medical Equipment | USD 2.85 billion | USD 9.12 billion | 15.6% |

Key Takeaways

On-demand manufacturing eliminates the “Safety Stock” trap by producing goods only upon order confirmation. This transition is supported by AI-driven inventory systems and real-time tracking, ensuring businesses maintain optimal lean levels without risking stockouts.

Table of Contents

What Is Inventory Pressure?

Inventory Challenges for Businesses

Inventory pressure is the operational and financial strain caused by the inability to balance supply with demand. For manufacturers, this manifests as a “Goldilocks” problem: maintaining enough stock to fulfill orders without over-committing capital to slow-moving items.

Critical Challenges in Modern Inventory Management

| Challenge | Technical Impact | Solution Strategy |

| Poor Management | Increased “Dead Stock” and warehouse congestion. | Implement automated tracking. |

| Inaccurate Forecasting | Misalignment between production and sales. | Use predictive AI analytics. |

| Supply Chain Disruptions | Lead time variability leading to stockouts. | Diversify with local on-demand sourcing. |

| Lack of Visibility | Siloed data preventing agile decision-making. | Siloed data prevents agile decision-making. |

The Financial Burden of Excess Stock

Excess inventory is not just a space issue; it is a financial liability. The Inventory Carrying Cost can be calculated as:

C = I x W x H

(Where C is total cost, I is average inventory value, W is the carrying cost percentage—typically 20-30%—and H is the storage factor).

Beyond the formula, businesses face risks of obsolescence, where products lose value before they are sold, and liquidity traps, where cash is “frozen” in warehouse racks rather than invested in R&D. AI-integrated inventory management in manufacturing mitigates these risks by providing the granularity needed to run “Lean.”

.

How On-Demand Manufacturing Works

The core principle of on-demand manufacturing is the Just-in-Time (JIT) philosophy. Rather than producing based on monthly estimates, production is triggered by a “Buy” signal.

Comparison: On-Demand vs. Traditional Manufacturing

- Time to Market: On-demand utilizes rapid prototyping and digital workflows to bypass lengthy setup phases.

- Cost Structure: While the unit price may be higher, the Total Cost of Ownership (TCO) is lower due to zero storage fees and no unsold waste.

- Flexibility: It thrives on “Batch Size One,” allowing for infinite customization compared to the rigid “Mass Production” of traditional models.

AI now plays a predictive role, identifying potential supply bottlenecks before they occur, allowing companies to adjust pricing or procurement strategies dynamically

Principles of On-Demand Manufacturing

On-demand manufacturing matches what is made with what people want. Companies watch orders and supplies as they happen. They make products only when someone needs them. Technology helps businesses keep demand and supply balanced. This cuts down on waste and makes things run better.

| Principle | On-Demand Manufacturing | Traditional Manufacturing |

|---|---|---|

| Time to Market | Gets products out faster with quick testing and fast making. | Takes longer because planning and setup take more time. |

| Cost | Costs more for each item but saves money on extra stock. | Costs less for each item when making lots at once. |

| Waste | Makes only what is needed, so there is less waste. | Can make too much if guesses about demand are wrong. |

| Flexibility | Changes quickly to what customers want. | Works best for making lots of the same thing. |

| Technology | Uses smart digital tools to handle orders. | Uses regular machines for making many items. |

Just-in-time production means making things only when needed. Companies keep less extra stock and work closely with suppliers. This saves money on storage and keeps products from getting old. Watching everything in real time helps teams see how things are going. Everyone gets updates fast and knows what is happening.

Manufacturing is changing. AI can see problems before they happen. This helps some companies do better than others.

Role of Machining in On-Demand Production

CNC machining is the physical engine of on-demand manufacturing. Unlike injection molding, which requires expensive, time-consuming tools, Small-batch CNC machining is a “tool-less” process.

- Rapid Iteration: Engineers can modify designs in CAD and begin production of the updated part within hours

- High Precision: CNC technology maintains tolerances in the micrometer range, ensuring that small batches meet the same quality standards as mass-produced parts.

- HMLV Efficiency: It bridges the gap between prototyping and full-scale production, allowing startups to scale without heavy upfront capital.

How On-Demand Manufacturing Reduces Inventory

Achieving Leaner Inventory

On-demand manufacturing leverages the Reorder Point (ROP) formula more effectively than traditional methods:

ROP = (d x L) + SS

(Where d is daily usage, L is lead time, and SS is safety stock).

By using automated systems

to reduce the lead time (L), the required safety stock (SS) can be drastically lowered.

| Mechanism | Operational Impact |

| Value Stream Mapping (VSM) | Identifying and removing non-value-added steps can reduce inventory by 30-50%. |

| Predictive Analytics | Companies are 2.3x more likely to have clear supply chain visibility. |

| Automated Storage (ASRS) | Reduces human error in retrieval and facilitates JIT material flow. |

Lowering Holding Costs and Risks

By producing only what is ordered and paid for, businesses eliminate the need for massive warehousing. This strategy significantly impacts the environment; less energy is consumed in the maintenance of climate-controlled storage and the long-distance transport of unsold goods. This “Agile” approach ensures that resources—both financial and natural—are utilized with maximum efficiency.

Agile Response to Market Changes

In a volatile market, the ability to launch “micro-updates” to a product is a competitive advantage. On-demand manufacturing allows for frequent, small releases based on customer feedback, ensuring the product evolves at the speed of the market rather than the speed of the factory’s tooling schedule

Business Benefits of Leaner Inventory

Efficiency and Cost Savings

Leaner inventory directly correlates with improved Return on Assets (ROA). By reducing the capital tied up in stock, companies can reallocate funds to marketing or product development.

| Benefit | Financial Impact |

|---|---|

| Reduced Material Scrap | Precision machining cuts materials exactly, minimizing raw material waste. |

| Improved Cash Flow | Capital is freed from the warehouse and moved to the balance sheet. |

| Lower Insurance Premiums | Less stock on hand reduces the risk and cost of insuring the facility. |

Improved Resource Allocation

Local and flexible manufacturing models reduce the “Carbon Miles” of a product. By utilizing digital tools to monitor production in real-time, teams can make data-backed decisions that shorten lead times and enhance customer trust.

Statistical data indicates that companies investing in modernized manufacturing ERPs

often see a 66% Return on Investment (ROI) within three years, with a typical payback period of just 16 months.

As we move toward 2026, data analytics and high-precision machining will continue to define the leaders in inventory flexibility.

FAQ

Our on-demand manufacturing services cover a wide spectrum of industrial needs, ranging from simple brackets to complex aerospace components. We specialize in custom metal parts produced via CNC machining, sheet metal fabrication, and metal 3D printing. Whether you need rapid prototyping or full-scale production runs, our facility is equipped to handle diverse geometries and strict specifications.

We work with an extensive catalog of metals to ensure your parts meet specific mechanical requirements. Common materials include:

- Aluminum (6061-T6, 7075) for lightweight strength.

- Stainless Steel (304, 316) for corrosion resistance.

- Carbon Steel and Alloy Steel for structural durability.

- Copper and Brass for electrical conductivity.

- Titanium for high-performance, medical, or aerospace applications.

Speed is the core of on-demand manufacturing. For rapid prototyping, we can often ship CNC machined parts or sheet metal components in as little as 3 to 5 business days. For larger low-volume production orders, lead times typically range from 2 to 4 weeks, depending on the complexity of the design and the required surface finishes.

Precision is non-negotiable. Our CNC machining services typically achieve standard tolerances of +/- 0.005” (0.127mm). For critical applications requiring tighter fits, we can achieve high-precision tolerances as low as +/- 0.001” (0.025mm) upon request. We recommend specifying your critical dimensions in your technical drawings to ensure 100% compliance.

One of the biggest advantages of partnering with AFI Parts is our flexibility. We offer no minimum order quantity (MOQ) for custom metal parts. Whether you need a single “bridge-to-production” prototype or low-volume manufacturing (10 to 1,000+ units), our process is optimized to remain cost-effective at any scale.

To ensure your custom metal components are “assembly-ready,” we provide a comprehensive suite of post-processing and finishing services, including:

- Anodizing (Type II and Type III)

- Powder Coating and Painting

- Bead Blasting and Polishing

- Plating (Zinc, Nickel, Chrome)

- Passivation and Heat Treatment