In the competitive landscape of precision machining, the bridge between a conceptual CAD model and a cost-effective physical part is often built on two foundations: material selection and cutting tooling strategy. For mechanical engineers and industrial designers, the pressure to deliver high-performance metal components while minimizing CNC machining costs is a constant challenge.

One of the most overlooked variables in the manufacturing equation is the use of standardized CNC tooling. While custom tools have their place in high-volume specialized production, the vast majority of custom metal parts manufacturing projects can see a 20% to 40% reduction in costs simply by adhering to standardization.

This guide explores ten actionable strategies to leverage standardized tooling, with a specific focus on how these choices interact with alloy steel—the backbone of industrial engineering.

Table of Contents

Understanding the ROI of Tooling Standardization

Standardization in CNC machining isn’t just about using “off-the-shelf” parts; it’s about Design for Manufacturing (DFM). When an engineer designs a feature that requires a custom-ground end mill or a non-standard drill size, they aren’t just paying for the tool. They are paying for:

- Extended Lead Times: Custom tools can take weeks to manufacture.

- Increased Setup Costs: Non-standard tools often require specialized workholding or unique tool offsets.

- Higher Risk of Failure: If a custom tool breaks during a production run of AISI 4140 alloy steel, the entire project halts until a replacement arrives.

By designing around a standard library of carbide inserts and end mills, you ensure that your machining manufacturer can move directly from setup to production, significantly lowering the “per-part” cost.

The Critical Link: Alloy Steel Selection and Tool Life

Before diving into the 10 methods, we must address the “Why” of material selection. Not all steels are created equal. When designing a part, the machinability rating of the alloy steel directly dictates the tooling cost.

For example, choosing AISI 4140 (Annealed) vs. AISI 4340 (Heat Treated) changes the equation. 4140 is a “workhorse” alloy with excellent toughness, but its machinability is significantly better than 4340. By selecting the right grade of alloy steel during the design phase, you allow the machinist to use standard PVD-coated carbide inserts at higher feed rates, reducing cycle time.

Expert Tip: Always check the Brinell Hardness (HB) of your specified alloy. Standardized tools are typically optimized for materials under 35 HRC. Beyond that, you move into the realm of specialized “hard machining” tools, which carry a premium price.

10 Ways to Save Costs Using Standardized CNC Tooling

Design for Standard Internal Radii

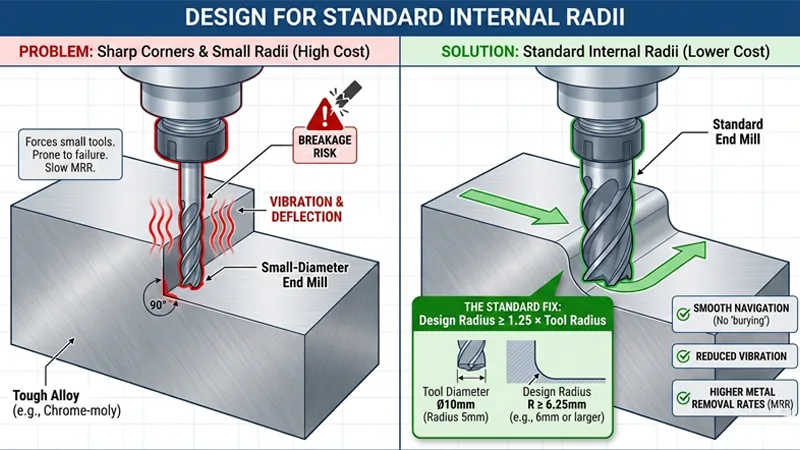

One of the most common “cost-drivers” in CNC milling is the internal corner radius. Engineers often specify sharp 90-degree internal corners or very small radii. This forces the use of small-diameter end mills, which are prone to deflection and breakage in tough alloys like Chrome-moly steel.

- The Standard Fix: Ensure your internal corner radius is at least 1.25 times the radius of a standard end mill. For example, if you want to use a standard 10mm end mill, design your corner radius to be 6mm or larger.

- Why it saves money: This allows the tool to navigate the corner without “burying” itself, reducing vibration and allowing for higher metal removal rates (MRR).

Optimize Hole Depths for Standard Drill Ratios

In precision machining, deep-hole drilling in alloy steel is a high-risk operation. Most standard carbide drills follow specific length-to-diameter (L/D) ratios: 3xD, 5xD, and 8xD.

- The Standard Fix: Avoid designing holes that exceed an 8xD ratio unless absolutely necessary.

- Why it saves money: Drilling a hole that is 10xD requires “Long Series” drills or specialized “Gundrilling” processes. By staying within standard L/D ratios, you can use off-the-shelf high-performance drills that offer better chip evacuation and longer tool life.

Match Alloy Steel Grades to Standard Insert Geometries

Modern tool manufacturers (like Sandvik, Kennametal, or Iscar) design standard inserts specifically for ISO P (Steel) materials. These inserts have “chip breakers” optimized for the stringy chips often produced by alloy steels.

- The Standard Fix: Specify common alloy grades like AISI 1018, 4140, or 8620.

- Why it saves money: Machining manufacturers stock inserts for these materials in bulk. If you specify a rare or exotic alloy, the shop may need to purchase a full box of specialized inserts just for your small run, and that cost will be passed on to you.

Standardizing Thread Sizes (Metric vs. Unified)

While CNC machines can cut almost any thread via thread milling, using standard taps for common sizes is still the fastest and cheapest method for hole threading.

- The Standard Fix: Stick to the “Coarse” thread series (UNC or Metric Coarse) where possible.

- Why it saves money: Coarse threads are more robust and less likely to strip or cross-thread in alloy steels. Furthermore, standard taps for M6, M8, or 1/4-20 are pennies compared to the cost of a custom thread mill for a non-standard pitch.

Utilize Multi-Functional Tooling in Design

Every time a CNC machine changes a tool, it adds “non-cutting time” to the cycle. We must emphasize tool consolidation.

- The Standard Fix: Design features that can be machined by the same tool. For instance, use the same radius for all fillets and internal corners.

- Why it saves money: This allows the manufacturer to use a “Combo-Tool” (like a drill-chamfer tool). Fewer tool changes equal a lower hourly rate for your parts.

Design Around Standard Bar Stock Sizes

Cost savings start before the machine even turns on. If your part is 51mm wide, but standard alloy steel bar stock comes in 50mm or 60mm, you have a problem.

- The Standard Fix: Check the availability of bar stock for your chosen alloy. If the part can be 48mm instead of 51mm, you can use 50mm stock with minimal “clean-up” passes.

- Why it saves money: You avoid paying for the excess material that ends up as chips in the bin, and you reduce the number of machining passes required to reach the final dimension.

Avoid Deep, Narrow Grooves

Narrow grooves often require specialized “grooving blades” or thin carbide saws. In tough alloy steels, these tools are incredibly fragile.

- The Standard Fix: Keep groove widths at standard increments (e.g., 2mm, 3mm, 4mm) and avoid depths that exceed 2.5 times the width.

- Why it saves money: Standard grooving inserts are widely available and much more stable. Stable tools allow for faster feeds and fewer part rejects due to tool breakage.

Implement High-Feed Milling Geometries

When dealing with “difficult-to-machine” alloy steels like AISI 4340, heat management is key. Standard High-Feed Milling (HFM) cutters are designed to direct the cutting forces axially into the spindle.

- The Standard Fix: Allow for 3D surfaces that can be roughed out using HFM tools.

- Why it saves money: HFM tools can move at 5x the speed of traditional end mills. Even though the tool itself is a standard item, its application in the right design context can slash CNC machining time by half.

Standardize Chamfers and Fillets

Many engineers use a mix of chamfers and fillets for deburring and aesthetics. From a machining perspective, this is a nightmare for tool management.

- The Standard Fix: Use a standard 45-degree chamfer for all edges.

- Why it saves money: A single 90-degree spotting drill or chamfer mill can handle all these features. This reduces the “Tool Library” required for your project, making it more attractive for shops to quote competitively.

Leverage Through-Spindle Coolant (TSC) Designs

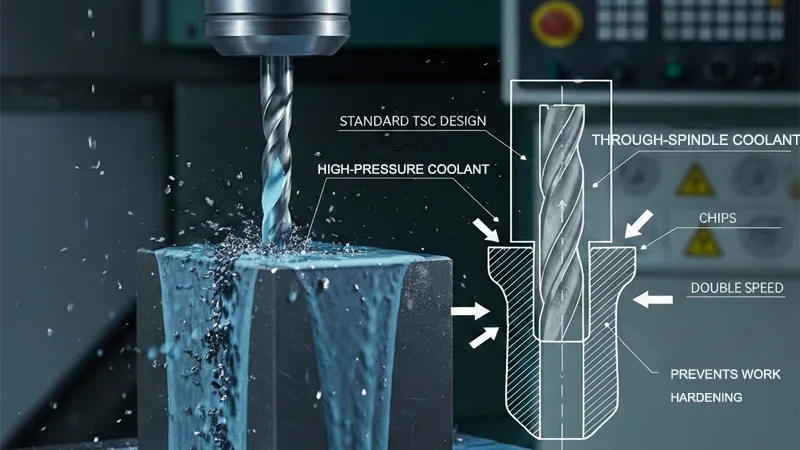

Alloy steels generate significant heat. If your part design features “pockets” or “blind holes,” chip re-cutting becomes a major issue.

- The Standard Fix: Design parts that allow for easy coolant access.

- Why it saves money: Standardized TSC drills can run at double the speed of conventional drills because they evacuate chips using high-pressure coolant from the inside out. This prevents “work hardening” of the alloy steel, a common cause of tool failure.

Technical Comparison: Alloy Steel Machinability

To help you choose the right material for your next project, refer to this table of common alloy steels used in metal parts manufacturing.

| Alloy Steel Grade | Machinability Rating (%) | Best Standard Tooling | Common Applications |

| AISI 1018 | 78% | Uncoated or TiN Carbide | Bushings, Pins, Spacers |

| AISI 4140 | 65% | TiAlN Coated Carbide | Gears, Bolts, Shafts |

| AISI 4340 | 50% | Multi-layer PVD Carbide | Aircraft parts, Heavy-duty crankshafts |

| AISI 8620 | 60% | Case-Hardening Grade | Camshafts, Fasteners |

| AISI 5140 | 65% | Standard ISO P Inserts | Low-stress automotive parts |

Note: Ratings are based on AISI 1212 steel as 100%.

Case Study: Reducing Costs for a 4140 Steel Housing

In a recent project for a hydraulic component, the original design called for:

- Square internal corners.

- Non-standard 7.3mm tapped holes.

- A deep 12:1 L/D ratio oil passage.

Our DFM Intervention: We worked with the design engineers to increase the internal radii to 8mm (allowing for a standard 12mm end mill), changed the holes to a standard M8 thread, and split the oil passage to be drilled from both sides (reducing the L/D to 6:1).

The Result:

- Tooling Cost: Reduced by 35% (eliminated custom taps and extra-long drills).

- Cycle Time: Reduced by 22%.

- Overall Part Cost: Saved $42.00 per unit on a 500-piece run.

Conclusion: The Engineer’s Strategic Advantage

The most successful mechanical engineers don’t just design for function; they design for manufacturability. By understanding the limitations and advantages of standardized CNC tooling, you can create parts that are faster to produce, higher in quality, and significantly cheaper.

When selecting alloy steel for your next project, remember that the “cheapest” material isn’t always the cheapest to machine. Pair a high-machinability alloy with standardized tool geometries, and you will achieve a level of production efficiency that sets your products apart in the market.

FAQ

The most effective way to lower costs is through Design for Manufacturing (DFM) and tooling standardization. In the realm of custom metal parts manufacturing, projects can achieve a 20% to 40% reduction in costs by adhering to standard tooling libraries rather than requiring custom-ground tools. Standardizing avoids extended lead times and reduces the higher setup costs associated with specialized workholding or unique offsets.Accordion content

Engineers often specify sharp 90-degree internal corners, which are impossible to machine without expensive secondary processes or very small-diameter end mills. These small tools are prone to deflection and breakage in tough materials like Chrome-moly steel.+1

- The Standard Fix: Ensure your internal corner radius is at least 1.25 times the radius of a standard end mill.

- The Benefit: This allows the tool to navigate corners without “burying” itself, reducing vibration and allowing for higher metal removal rates (MRR), which lowers the “per-part” cost.

Not all steels are equal; the machinability rating of your chosen alloy directly dictates the tooling expense.

- AISI 1018 (78% machinability): Excellent for bushings and spacers using standard carbide tools.

- AISI 4140 (65% machinability): A “workhorse” alloy with high toughness that still allows for standard PVD-coated carbide inserts at high feed rates.

- AISI 4340 (50% machinability): Requires specialized “hard machining” tools and multi-layer PVD carbide, increasing the price. Choosing a high-machinability alloy paired with standard tool geometries ensures production efficiency.

Deep-hole drilling is a high-risk operation in precision machining. Standard carbide drills typically follow length-to-diameter (L/D) ratios of 3xD, 5xD, and 8xD.

- Design Rule: Avoid designing holes that exceed an 8xD ratio unless absolutely necessary.

- Cost Impact: Holes exceeding this ratio require “Long Series” drills or specialized “Gundrilling” processes, which significantly drive up the price. Staying within standard ratios allows for better chip evacuation and longer tool life.

Every tool change adds “non-cutting time” to the machining cycle. Consolidating your design features can slash these hidden costs:

- Threading: Stick to standard “Coarse” thread series (UNC or Metric Coarse). Standard taps for sizes like M6 or 1/4-20 are far cheaper than custom thread mills.

- Chamfers: Use a standard 45-degree chamfer for all edges. This allows a single 90-degree spotting drill or chamfer mill to handle all features, reducing the “Tool Library” required and making your project more attractive for competitive quotes.

Cost savings begin with material selection before the machine even starts.

- The Problem: If a part is designed at 51mm wide, but standard alloy steel bar stock only comes in 50mm or 60mm, you must pay for the larger size.

- The Fix: Check standard bar stock availability and adjust dimensions slightly—for example, reducing a width to 48mm to fit 50mm stock.

- The Saving: You avoid paying for excess material that ends up as waste chips and reduce the number of machining passes needed to reach final dimensions.