In part design, you often face a challenging decision. Creating holes consumes a significant amount of CNC machining time, and selecting the wrong hole type can lead to increased costs and potentially ruin the parts. The distinction between blind holes and through holes is crucial. A blind hole does not extend all the way through the material, while a through hole does. Your choice between these two types impacts machining speed, tool longevity, and overall expenses.

Key Takeaways

- Blind holes are harder and cost more to make. They need careful control of how deep they go. Special tools are needed for blind holes.

- Through holes are easier and quicker to make. They help chips come out better. Tools last longer with through holes.

- Pick blind holes when you need sealed surfaces. Use them for exact spots, like in medical devices and airplanes.

- Blind holes are harder to check. You need special tools to measure how deep and good they are.

- Think about what your design needs. Also, think about how many you will make. This helps you choose blind or through holes for the best results.

Table of Contents

Blind holes vs through holes: Key differences

Blind hole definition and uses

A blind hole does not go all the way through. It stops at a certain depth and leaves material at the bottom. Blind holes are used when you need a sealed surface or a strong material. Flat bottom blind holes help with mounting and alignment. These holes are important in medical devices and precision parts. They help keep surfaces sealed and reduce complexity.

Machining blind holes is tricky. Chips get stuck because they cannot escape easily. You must use slower speeds and peck cycles to protect the tool. The closed space makes the tool heat up faster. This can wear out the tool quickly. You need careful programming to get the right depth and size. Blind holes cost more to make because they are harder and need more checks.

Through hole definition and uses

Through holes go all the way through the part. You can reach both sides of the hole. Through holes are used in plates, brackets, and parts made in large numbers. They make assembly and checking easier because both ends are open. Chips come out easily, so the tool stays cooler and lasts longer. You can cut faster and set up the machine more simply.

Through holes cost less and are quicker to make. You pick through holes when you need easy access and simple records. Through holes are found in plates, car parts, and electronics. They help with fast inspection and easy assembly.

Tip: When you look at blind holes and through holes, think about how each works and what your project needs. Use the tables below to help you choose.

| Feature | Blind Holes | Through Holes |

|---|---|---|

| Chip Evacuation | Harder because chips stay inside | Easier because chips come out |

| Thermal Behavior | More heat builds up inside | Less heat, more stable |

| Tool Wear | Tool wears out faster | The tool lasts longer |

| Dimensional Accuracy | Needs careful programming | Depth is less important |

| Machining Complexity | Harder needs slow speeds and pecking | Easier, faster speeds and simple setup |

| Feature | Blind Holes | Through Holes |

|---|---|---|

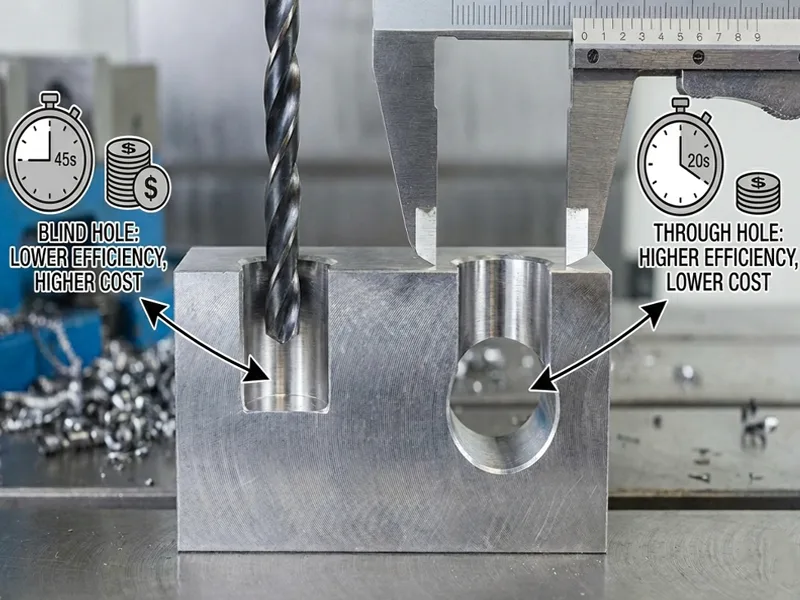

| Cost | Costs 15-30% more to make | Costs less |

| Assembly Complexity | Harder to put together | Easier to assemble |

| Functionality | Stronger material, sealed surface | Open on both sides, easy to check |

| Application Examples | Used in medical and precise parts | Used in plates and mass production |

| Documentation | Good for strict industries | Good for making lots of parts |

You should pick blind holes or through holes based on your design, how fast you want to make it, and your budget. The right choice helps your part work well and is easy to make.

Machining Efficiency: The Technical Perspective

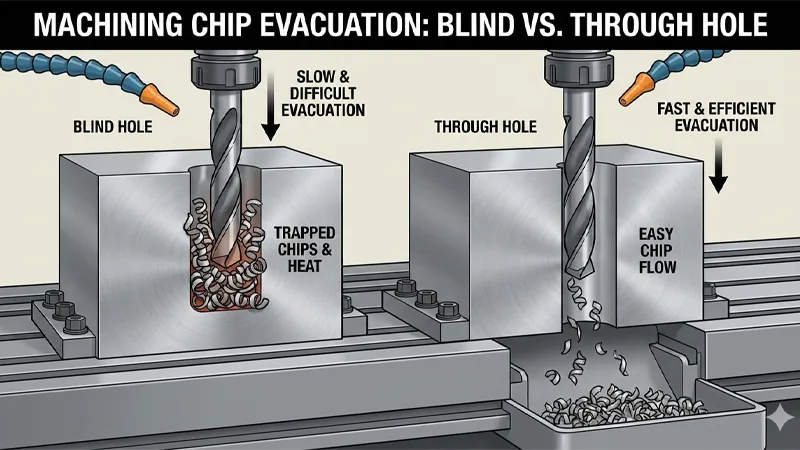

Chip Evacuation

Chip evacuation is very important in machining. In blind holes, chips build up at the bottom. This can break the tool and make the part worse. Metal parts manufacturers need to go slower and stop often to clear chips. This makes the process take longer. Through holes let chips fall out the other side. This keeps the tool cooler and helps it work better. We can see the difference in the table below:

| Comparison Dimension | Blind Hole | Through Hole |

|---|---|---|

| Manufacturing Challenge | Hard to get chips out. Chips stay at the bottom and can break tools or lower quality. | Easy to get chips out. Chips leave fast, so the process is smoother. |

Think about chip removal when you pick a hole type. Good chip removal makes machining faster and more accurate.

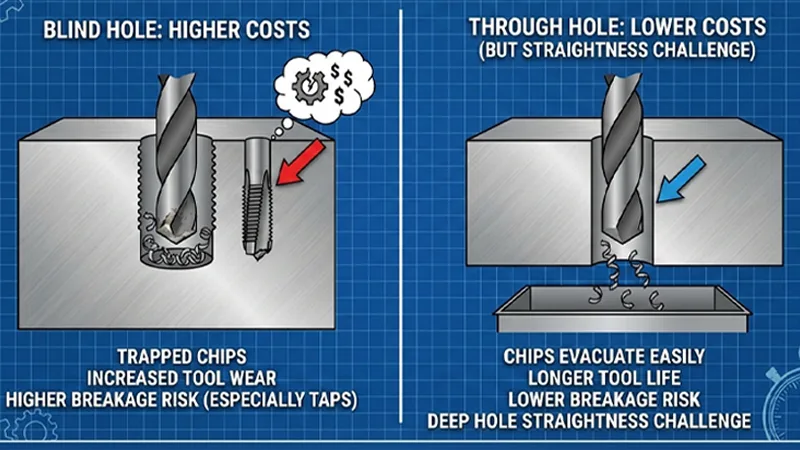

Tapping/Threading

Tapping and threading are not the same for blind holes and through holes. Tapping through holes is usually quicker. Chips come out easily, so they do not get stuck. You can make threads all the way through without extra steps. Blind holes are harder to tap. Taps have a pointy end, so you cannot go as deep. Chips can get stuck and break the tool. Thread milling helps control chips and lets you make threads at any depth. This is good for blind holes.

| Aspect | Through Holes | Blind Holes |

|---|---|---|

| Efficiency | Tapping is usually faster | Thread milling works better |

| Chip Removal | Easier because the end is open | Harder, chips can get stuck |

| Thread Depth | You can reach full depth | Tap length limits depth, may need milling |

- Tapping can make chip removal hard in deep blind holes.

- Thread milling controls chips better and makes threads near the bottom.

- We might need other ways to make threads close to the bottom of blind holes.

Choosing the appropriate thread processing method can change processing efficiency and speed.

Inspection

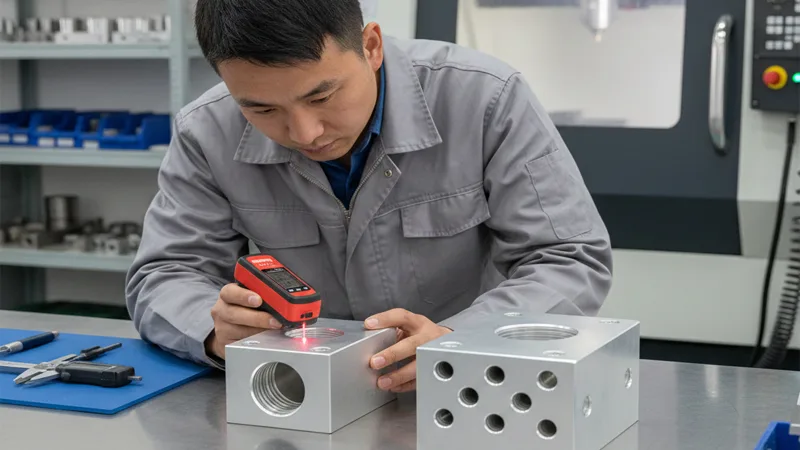

Checking blind holes and through holes is different. Blind holes are harder to check because you cannot see the bottom. You need special tools, like probes or depth gauges, to measure. Small holes make it hard to line up tools. This can cause mistakes. The inside of the hole can be rough or bent, which makes measuring tough. These things make blind holes harder to inspect. Through holes are easier to check. You can look through them and use simple tools to measure size and surface.

Plan how you will check your holes before you start. Good inspection makes sure your parts work well.

Material Compatibility and CNC Automation

The material and CNC automation change how easy it is to machine holes. Metals usually look good after normal machining. Harder metals need special tools. Plastics can melt or smear if you do not use sharp tools or the right speed. Composites are hard to finish the same way every time. You need special tools and careful settings for these.

| Material Type | Effect on Machining | Recommendations |

|---|---|---|

| Metals | Look good with normal machining | Use special tools for hard metals |

| Plastics | Can melt or smear if not careful | Go slower and use sharp tools |

| Composites | Hard to finish the same way every time | Use special tools and careful settings |

CNC automation helps make parts more exact and the same every time. Machines can work faster and save time. You can get good results for both blind holes and through holes with CNC machines.

Tip: When you choose between blind holes and through holes, think about chip removal, threading, checking, material, and CNC machines. These things change how fast, accurate, and well your parts are made.

The Hidden Costs of Hole Selection

When you pick blind holes or through holes, you need to think about more than just how long it takes to make them. There are extra costs that can change your project’s budget, quality, and how well things work.

Tool wear and breakage risks

Blind holes are harder on tools. Chips get stuck inside because they cannot get out. This makes the tool work harder and wear out faster. Tools can break more easily, especially when making threads. Through holes let chips fall out, so tools last longer and break less. But you have to keep the hole straight all the way through, which is hard for deep holes.

- Blind holes need careful control of depth and chips.

- Tools do not last as long in blind holes.

- Through holes help tools last longer by letting chips out.

- Blind holes can break taps more often when threading.

Processing steps

Blind holes need more steps to make than through holes. You can only reach blind holes from one side, so it is less flexible. You need special tools to put things in or take them out. Through holes are open on both sides, so it is easier to install or remove things.

| Feature | Blind Holes | Through Holes |

|---|---|---|

| Access | One side only | Both sides |

| Installation | Special tools needed | Simple process |

| Flexibility | Less flexible because you can’t reach both sides | More flexible and easier to adjust |

We also need to think about design. For blind holes, do not make them deeper than 2-3 times their width. Use spiral flute or bottoming taps for threads. Make the hole entrance smooth with a chamfer. Pick materials that are easy to machine and strong. For both types, leave space for chips to come out and use peck drilling for deep holes.

Scrap Rate

Blind holes can cost 15-30% more to make because they need special tools and slower speeds. For example, making an aluminum bracket with four blind holes can cost $8-15 more for each part than using through holes. The extra cost comes from tools breaking, more checking, and needing the right depth. If chips get stuck or the walls are too thin, you might have to throw parts away. Through holes make it easier for chips to come out and are easier to check, so you waste less.

When designing parts, wall thickness, hole depth, and chip removal must be considered. Wall thickness helps decide how deep you can go and keeps the part strong. Deeper holes need better ways to cool and remove chips. Good chip removal stops problems and keeps you from wasting parts.

Note: Blind holes may cost more, but they can save money on plugs or caps and make checking easier in some industries.

Choosing between blind holes and through holes in machining

Decision framework and evaluation

Picking between blind holes and through holes needs a clear plan. You should look at cost efficiency, how fast you can machine, how well the part works, and how easy it is to check. First, figure out what each hole does in your design. Think about how each type changes assembly, chip removal, and how long tools last.

A good way to decide includes:

- Define the functional requirement: Does your part need to be sealed or open?

- Assess machining efficiency: Will chip removal or tool wear slow you down or cost more?

- Evaluate cost efficiency: Look at all costs, like new tools and checking parts.

- Review scalability: Can you use this hole type for lots of parts or custom jobs?

- Consider advanced technology: Use chip removal systems, special cutting tools, and fluid flow checks to help with both blind holes and through holes.

Tip: This plan helps you balance speed, cost efficiency, and how well your part works. New CNC machines and automation can help you get the same results every time for both hole types.

When to use blind holes

Pick blind holes if you need a sealed surface, exact placement, or want to use less material. Blind holes are used when inside parts must stay safe or when weight matters a lot.

Recommended scenarios for blind holes:

- Electronics: Blind holes help mount things inside phones and laptops.

- Aviation: Airplane parts use blind holes to keep weight low but stay strong.

- Medical devices: Infusion pumps and hip implants use blind holes for exact spots.

- Automotive: Motor blocks and transmissions use blind holes for strong holds and to save material.

- Architecture: Blind holes let you make cool designs in metal and wood with different materials.

| Industry | Application Example | Reason for Use |

|---|---|---|

| Aerospace | Making airplane parts | Keep weight low and strength high |

| Electronics | Circuit boards for spacers or connectors | Add parts without hurting other pieces |

| Architectural | Metal or wood work for cool looks | Make creative designs with different materials |

| Automotive | Motor blocks and transmission parts | Strong holds and less material used |

Pick blind holes if you need to keep inside parts safe, make things lighter, or line things up just right. New machining tools, like better chip removal and special cutters, can make blind holes faster and cheaper to make.

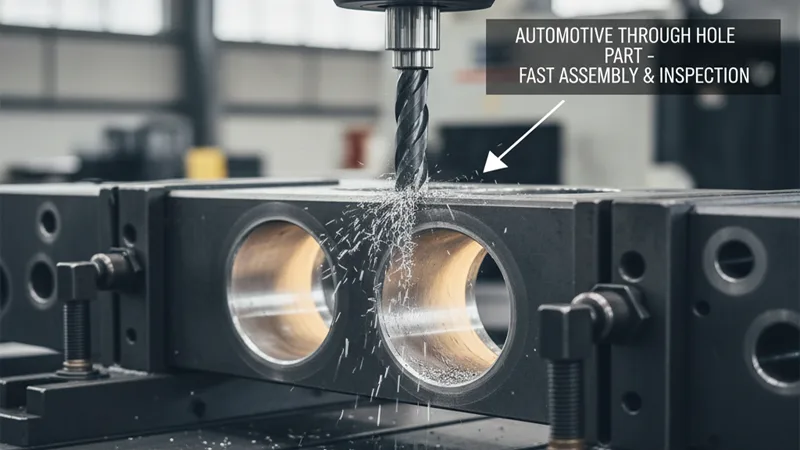

When to use through holes

Through holes are best when you need open access, quick assembly, and easy checks. Pick through holes if you need to reach both sides or want to make the building easier.

Through holes work well with annular cutters. These cutters are faster and use less power than twist drills. They only cut the edge, so they are good for big holes. Through holes are also good for making lots of parts and checking them quickly.

Recommended scenarios for through holes:

- Plates and brackets made in large numbers

- Car parts that need to be put together fast

- Electronics cases for wires and connectors

- Machine parts that need easy checks

To speed up processing, quickly inspect parts, and easily mass-produce parts, through holes can be used. New fluid flow checks and CNC machines help remove chips and speed up the process of making through holes.

Note: Both blind holes and through holes get better with new machining tools. Chip removal systems, special cutters, and fluid flow checks help make both types faster and cheaper. Look at what your design needs and how many parts you want to make to pick the best hole type.

AFI parts’ advantage: Professional hole machining solutions.

Equipment capabilities

Machining blind holes and through holes requires high-performance machines. At AFI Industrial, you get advanced systems for accurate work. Special tools like gun drills and solid carbide drills help make deep and shallow holes. Reamers make holes the right size. BTA drilling systems help make many holes fast. EDM hole drilling and CNC EDM machines can make tiny holes, as small as 300 microns. These machines can keep holes very exact, down to 0.0001 inches. Automation changes electrodes and workpieces by itself. This makes things faster and helps stop mistakes.

| Equipment Type | Description | Precision Level |

|---|---|---|

| Gun Drills | Special tools for deep holes and high accuracy. | High performance |

| Solid Carbide Drills | Strong drills that make holes very well. | High reliability |

| Reamers | Tools that finish holes to the right size. | Enhanced precision |

| BTA Drilling Systems | Advanced machines for deep holes and fast work. | Consistent quality |

- EDM hole drilling makes blind holes and through holes very exact.

- CNC EDM machines can make holes as small as 300 microns.

- Automation lets machines change parts without people.

quality assurance

Both blind holes and through holes require rigorous quality inspection. It helps keep the depth right. Watching cutting conditions and using good measuring tools stops tools from breaking. Through holes are easier to clean and cool. This makes checking them simpler and safer. You get better results with process controls like checking tolerances, surface finish, and picking the right material. These steps help stop problems and keep parts working well.

| Consideration | Impact on Defect Prevention |

|---|---|

| Tolerance | Helps parts fit and work right. |

| Surface Finish | Stops rust and helps signals move better. |

| Material Selection | Hardness and toughness help make smooth holes. |

- Always check tolerances carefully.

- Look at the surface finish to stop rust.

- Pick materials that are easy to machine.

One-stop service

You save time and money with AFI’s one-stop machining for blind holes and through holes. The technical team studies your materials and makes special plans for your parts. You get the right tools, both standard and custom, for deep holes. On-site support helps fix tools fast and makes the process better. After machining, services like tool regrinding and fixing help tools last longer and work better. Regular follow-ups give advice for upgrades as new technology comes out.

| Service Type | Description |

|---|---|

| Pre-planning Customized Process Solutions | Team studies materials and makes special machining plans. |

| Precise Tooling Matching | Many standard and custom tools for deep holes. |

| Full-Process On-Site Technical Support | Fast help for tool fixing and process improvement. |

| Post-Processing Tool Maintenance | Tool regrinding, fixing, and upgrade advice. |

Tip: Make blind holes and through holes better by picking the right reamer flute style, changing feed rates, and using good toolholders. Clean cutting fluid and strong coolant help tools last longer and work better.

When considering blind holes and through holes, the ease of machining and cost must be weighed. Blind holes need careful depth control. They can help signals work better in fast designs. Through holes are simpler to make. They can cost less for many jobs.

| Factor | Description |

|---|---|

| Purpose | Decide why you need the hole, like for joining or assembly. |

| Size and Dimensions | Make sure the depth and width fit your needs. |

| Type of Material | Pick a material that works well with your machining process. |

| Hole Depth | Use a tool that is long enough for the hole. |

| Power Source | Select a machine that has enough power for your job. |

FAQ

The main difference lies in the depth of the hole relative to the workpiece. A through hole passes completely through the material, exiting the opposite side. In contrast, a blind hole stops at a specific depth and does not break through the other side. When designing custom metal parts, choosing between them affects both the machining process and the type of tooling required for precision finishing.

Generally, through holes are more cost-effective to manufacture. They allow for easier chip evacuation and do not require specialized “bottoming” taps for threading. Blind holes often increase manufacturing costs because they require more precise depth control, frequent tool withdrawals to clear metal chips (peck drilling), and more careful inspection to ensure the hole bottom meets engineering specifications.

The hole type significantly dictates the tapping process. For a through hole, a spiral point tap can be used to push chips forward and out the other side. For a blind hole, a spiral flute tap is necessary to pull chips upward and out of the entry point. Additionally, blind holes usually require a “thread relief” or extra depth beyond the required thread length to accommodate the tap’s chamfer and accumulated chips.

You should opt for a blind hole when:

- Aesthetics: You need a clean, unbroken surface on one side of the part.

- Weight Reduction: You need to remove material without compromising the structural integrity of the opposite face.

- Fluid-Tight Applications: You are designing manifolds or housings where a through-exit would cause leaks.

- Space Constraints: The part thickness or assembly requirements prevent the fastener from passing all the way through.

In precision CNC machining, we typically recommend a maximum depth-to-diameter ratio of 3:1 or 4:1 for blind holes. While deeper holes are possible, they significantly increase the risk of tool breakage, wandering (deviation from the center), and poor surface finish due to difficult chip evacuation. Keeping ratios within these limits ensures higher quality for your custom CNC machined parts.