When you look at rapid injection molding and traditional injection molding, you notice big changes in speed, price, and quality. Rapid injection molding helps you get parts fast and for less money. Traditional injection molding takes more time and costs more, but it gives you very exact parts. The table below shows how both methods compare:

| Feature | Rapid Molding | Traditional Molding |

|---|---|---|

| Lead Time | Days to weeks | Weeks to months |

| Cost | Lower | Higher |

| Accuracy/Tolerance | High accuracy but possibly looser tolerances | Very high accuracy and tight tolerances |

You may pick rapid injection molding if you need parts quickly or only need a few. Traditional injection molding is better if you want the most exact parts and can wait longer.

Key Takeaways

- Rapid injection molding is much faster. You get parts in days. You do not wait weeks or months.

- Rapid injection molding costs less. It is good for small batches and prototypes. You save money at the start.

- Traditional injection molding is more accurate. It makes parts with tight tolerances. It works well for making many precise parts.

- Rapid injection molding lets you change designs easily. You can update things quickly. It does not cost a lot to make changes.

- Aluminum molds are used in rapid injection molding. They help make parts faster. They also cost less to start than steel molds.

- Both methods work in many industries. You should pick one based on your need for speed, cost, and quality.

- Rapid injection molding helps test new ideas. It fills supply gaps fast. Traditional molding is better for making lots of parts.

- Always think about the total project cost. This includes tooling and per-part costs. This helps you choose the best option for your project.

Table of Contents

Injection Molding Methods Overview

What Is Rapid Injection Molding

Rapid injection molding is a new way to make plastic parts fast. You begin by sending in a 3D CAD file. The process is quick because it uses computers for quoting and design. The main part of this method is rapid tooling. It uses aluminum molds. Aluminum molds are lighter and cost less than steel molds. These molds are made fast, so you get your first parts in days or weeks.

Rapid injection molding is very easy to change. You can update your design without waiting long or spending much more. This method is great if you want to try out a new idea, make a prototype, or create a small number of parts. Many fields use rapid injection molding. These include aerospace, cars, electronics, and medical devices. For example, it can make light airplane parts, car panels, or gadget cases.

Tip: Rapid tooling is not only for prototypes. You can use it for small production runs or before you start making lots of parts.

What Is Traditional Injection Molding

Traditional injection molding is the old way to make many plastic parts. It uses steel molds. Steel molds take longer to make and cost more money. The process has many steps, like quoting, checking designs, and doing inspections. Steel molds are very strong. You can use them to make hundreds of thousands or even millions of parts.

Traditional molding is best when you need very exact parts and tight tolerances. It is used in cars, home products, and building materials. You might see it for car bumpers, plastic covers, or building parts.

Key Differences

You can see the biggest differences between rapid injection molding and traditional molding in this table:

| Aspect | Traditional Injection Molding | Rapid Injection Molding |

|---|---|---|

| Process Steps | Many steps, like quoting and inspections | Starts with 3D CAD upload and quick quoting |

| Lead Time | Weeks to months for making molds | Days to weeks for molds and parts |

| Tooling Material | Steel molds (cost more, last longer) | Aluminum molds (cost less, made faster) |

| Flexibility | Hard to change, changes cost more | Easy to change, changes are quick and cheap |

| Iteration Process | Needs many manual changes | Can change and update parts quickly |

- Rapid tooling is fast and easy to change.

- Traditional molding is best for making lots of parts that must be perfect.

Rapid injection molding is good for testing, short runs, and changing designs. Traditional injection molding is better for making many parts when you need them to be very exact and can wait longer.

Note: Many companies use both methods. For example, you might use rapid tooling to test a new product, then use traditional molding to make lots of them.

Speed And Lead Time

Tooling And Setup

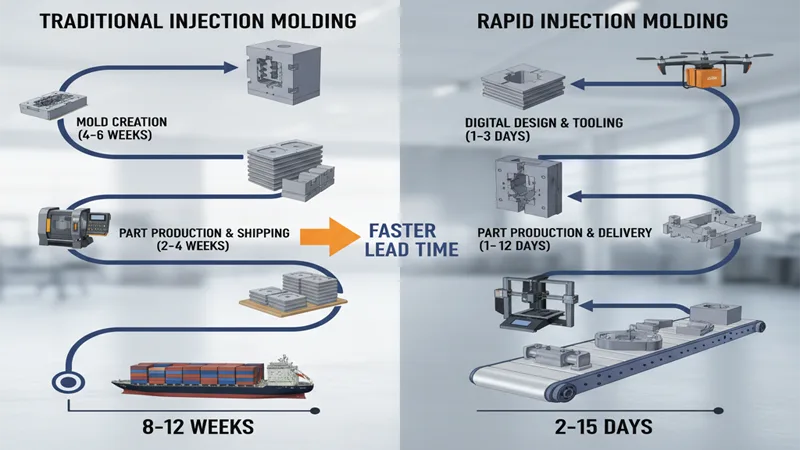

When you choose rapid injection molding, you notice a big difference in how fast you can get started. You send your 3D CAD file, and the process begins almost right away. The tooling uses aluminum, which is much quicker to produce than steel. You can have your molds ready in just a few days. In contrast, traditional injection molding uses steel molds. These take much longer to make, often 8 to 12 weeks. That means you wait a lot longer before you even start making parts.

- Rapid molding is ideal for early production runs. You can get thousands or even tens of thousands of parts quickly.

- Bridge tooling lets you start selling products while your final production molds are still being made. This helps you get to market faster and start earning revenue sooner.

- Bridge molds for low-volume production usually have lead times of 4 to 10 weeks, which is still faster than waiting for full production molds.

You can see that rapid injection molding gives you a clear advantage in setup speed. You can test your product, make changes, and move forward without long delays.

Production Turnaround

The time it takes to get your finished parts is called the production turnaround. This is where rapid injection molding really shines. You can see the average turnaround times in the table below:

| Type of Injection Molding | Average Turnaround Time |

|---|---|

| Traditional Injection Molding | 8-12 weeks |

| Rapid Injection Molding | 2-15 days |

Traditional injection molding often takes 6 to 10 weeks for the whole process. This includes 4 to 6 weeks for making the mold and another 2 to 4 weeks for producing and shipping the parts. Rapid injection molding, on the other hand, can deliver your parts in as little as 2 days. Sometimes it may take up to 15 days, but this is still much faster than the traditional method. If you need a quick turnaround time, rapid injection molding is the best choice.

Impact On Development Cycles

Speed is important when you want to bring a new product to market. The method you choose for making your parts can change your whole development cycle. When you use rapid injection molding, you can test your ideas, make changes, and get new parts quickly. This helps you fix problems early and improve your design before you spend a lot of money on full production.

- Optimizing cycle times in large-scale injection molding can make your process much more efficient. Even small improvements in cycle time can save you a lot of hours and help you get your product out faster.

- Advanced tooling techniques, like CNC machining and 3D printing, let you create prototypes quickly. You can adjust your design and move to production without waiting.

- Cycle time is a key factor for production efficiency. If you reduce cycle time, you save machine hours and lower your costs. This means you can make more parts in less time and get them to your customers sooner.

When you use rapid injection molding, you shorten your lead-time and speed up your whole project. You can respond to market changes, test new ideas, and stay ahead of your competition.

Tip: If you want to launch your product fast or need to test the market, rapid injection molding gives you the speed and flexibility you need.

Cost Comparison

When you plan a new project, understanding the costs is just as important as knowing the design. Both rapid injection molding and traditional injection molding have different cost structures. You need to look at tooling costs, per-part costs, and the total project cost to make the best choice.

Tooling Costs

Tooling costs are the first big expense you face in any molding project. Rapid tooling uses aluminum molds, which are faster and cheaper to make. Traditional molding uses steel molds, which take more time and money to produce. The table below shows how tooling costs compare at different order volumes:

| Order Volume | Traditional Pricing | Bundled Pricing | Break-Even Point |

|---|---|---|---|

| 5,000 units | $1.20/part + $25,000 tooling | $6.20/part | N/A |

| 25,000 units | $0.85/part + $25,000 tooling | $1.85/part | ~25,000 units |

| 100,000 units | $0.45/part + $25,000 tooling | $0.70/part | Traditional wins by $25,000 |

| 500,000 units | $0.22/part + $25,000 tooling | $0.28/part | Traditional wins by $5,000 |

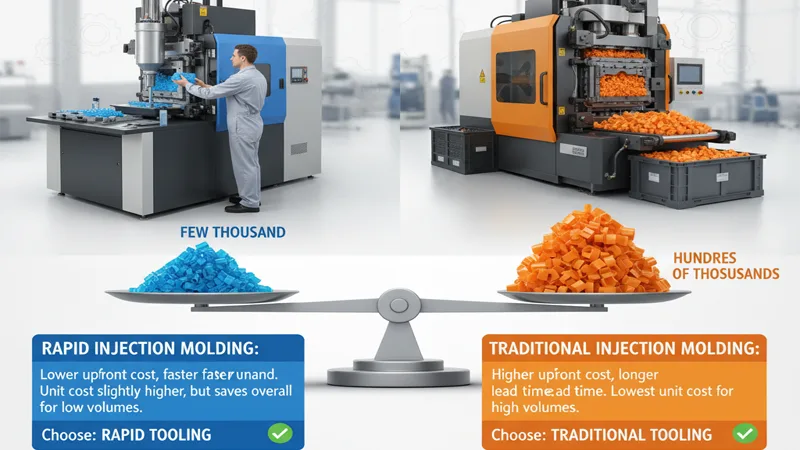

You see that rapid tooling gives you a lower upfront cost. You can get started quickly and avoid a large investment. If you only need a small batch or want to test your design, rapid molding is the smart choice. When you need a very high number of parts, the higher cost of steel molds in conventional injection molding becomes worth it because the cost per part drops.

Note: Rapid tooling is ideal for prototypes, bridge production, and low-volume runs. You can make changes to your design without spending a lot more money.

Per-Part Costs

Per-part costs tell you how much you pay for each finished piece. These costs change based on how many parts you make. Here is what you need to know:

- As you increase your production volume, the total cost goes up, but the cost for each part goes down.

- Different production volumes affect the cost of injection molding. You use more raw material and machine time for bigger orders, but you spread the tooling cost over more parts.

- For high-volume production, per-part costs drop a lot. This gives you a cost advantage if you plan to make many parts.

With rapid injection molding, you pay a bit more per part when you make a large number of parts. However, you save money and time if you only need a few thousand pieces. Traditional molding gives you the lowest per-part cost when you make hundreds of thousands of parts.

Tip: If you want to keep your per-part cost low for a small run, choose rapid tooling. If you plan to make a huge number of parts, traditional molding will save you more in the long run.

Total Project Cost

The total project cost includes more than just tooling and per-part costs. You need to think about several factors that can change your final price. The table below lists the main things that affect your total cost:

| Factor | Description |

|---|---|

| Mold Design Complexity | Complex molds with tight tolerances or special features cost more to make. |

| Material Selection | Steel molds cost more but last longer. Aluminum molds are cheaper but wear out faster. |

| Manufacturing Location | Where you make your parts affects labor and shipping costs. |

| Mold Classifications | Different mold types have different costs based on how many parts you want to make. |

You should also consider the speed of rapid tooling. You can get your parts faster, which means you can test your product, make changes, and get to market sooner. This can save you money and help you earn revenue faster. If you use traditional injection molding, you pay more upfront and wait longer, but you get the lowest cost per part for big orders.

Callout: Always look at the whole picture. Tooling, per-part, and total project costs all matter. Rapid injection molding helps you save money and time for small runs or fast changes. Traditional injection molding is best for large, stable projects where you need the lowest cost per part.

Quality And Precision

When you pick an injection molding process, you want good parts. You care about how smooth, exact, and repeatable your parts are. Let’s look at three things: surface finish, tolerances, and consistency.

Surface Finish

Surface finish is how your part feels and looks. The process you choose changes the final look. Here is a table to help you compare:

| Injection Molding Type | Surface Finish Quality | Texture Support |

|---|---|---|

| Rapid Injection Molding | Generally less refined | VDI 3400 class 18-24 |

| Traditional Injection Molding | More refined, suitable for high precision | VDI 3400 class 12-30 |

Traditional injection molding gives a smoother surface. It can make more textures and finer details. If you want a shiny or very smooth part, this is a good choice. Rapid injection molding still makes nice parts, but the finish is not as smooth. This is fine for prototypes or first runs.

Tip: If you need a special texture or shiny look, ask your supplier which process is best.

Tolerances

Tolerances show how close each part is to the right size. This is important if your parts must fit together. Here is what you should know:

- Traditional injection molding can reach tight machining tolerances, like +/- 0.003 inches (0.076 mm).

- For resin parts, tolerances can be more than but not less than +/- 0.002 inches per inch (0.051 mm/mm).

Traditional injection molding gives tighter tolerances and better precision. This matters for parts that must snap or move together. Rapid injection molding is still good, but tolerances may be a little looser. For most prototypes and many finished parts, this is still okay.

Consistency

Consistency means every part is the same. Both rapid injection molding and traditional injection molding can make many parts fast. Here are some key points:

- Injection molding lets you make thousands or millions of parts with little difference.

- You get good parts because the process uses careful controls and exact molds.

- Automation and checks help keep defects low and quality high.

- Scientific molding makes sure every run uses the same steps.

- Quality control checks for size and surface problems, using tests and machines.

- Suppliers keep tolerances tight by picking good materials, caring for molds, and following rules.

Both methods give you steady results, but traditional injection molding is best for the most exact and repeatable parts. Rapid injection molding still gives good quality, especially for small batches or testing new designs.

Remember: Good quality checks and mold care help keep your parts exact and the same every time.

Material Options And Compatibility

When you pick an injection molding process, you should know what materials you can use. The right material changes how your part looks and works. Both rapid injection molding and traditional injection molding let you use many plastics. But there are some differences with special materials and how you can mix molding with machining.

Supported Plastics

You have lots of choices for plastics. Both rapid injection molding and traditional injection molding work with common plastics. Here are some popular ones:

- ABS (Acrylonitrile Butadiene Styrene)

- PC (Polycarbonate)

- POM (Polyoxymethylene)

- PPA (Polyphthalamide)

- PPS (Polyphenylene Sulfide)

- PEEK (Polyether Ether Ketone)

- PPSU (Polyphenylsulfone)

- PEI (Polyetherimide)

- Acrylic (PMMA)

- Polyethylene (PE)

- Polypropylene (PP)

- Nylon (PA)

These plastics are used for many things. Some are strong, some are clear, and some are bendy. You can choose the best one for your project. Think about if you need strength, flexibility, or heat resistance.

Specialty Materials

Some projects need special materials with extra features. These can be stronger or handle more heat. Not every material works the same in each process. The table below shows how some special materials work with rapid injection molding and traditional injection molding:

| Material Type | Suitability for Rapid Injection Molding | Suitability for Traditional Injection Molding |

|---|---|---|

| Glass-filled Nylon | Can be used but may cause mold wear | Not ideal due to mold wear |

| PVC | Can cause rapid mold wear | Not ideal due to mold wear |

| POM | Can cause rapid mold wear | Not ideal due to mold wear |

You can use glass-filled nylon or PVC in rapid injection molding, but these can wear out molds faster. Traditional injection molding is not always good for these because steel molds can also wear down. Always ask your supplier which material is best for your part.

Machining Integration

Machining can make both rapid injection molding and traditional injection molding even better. When you use machining with molding, you get more benefits:

- You can make parts with tight tolerances and tricky shapes.

- Machining helps you make parts close to the final shape, so there is less waste.

- You can get smoother surfaces and add special features that are hard to mold.

- Machining is good for parts with different wall thicknesses or small batches.

- This lets you make parts that are hard or impossible to mold alone.

After molding, you can use machining to add holes or tiny details. This is great for prototypes or custom parts that need to be very exact. Using both machining and molding gives you more choices and better results.

Tip: If you need a part with special features or very high accuracy, ask your supplier about using both molding and machining. This can help you get the best results.

Mold Materials And Durability

Aluminum Molds

When you choose rapid injection molding, you often work with aluminum molds. Aluminum molds help you get your parts fast. They are easier and quicker to machine than steel molds. This means you can start your project sooner and save money at the beginning. Aluminum molds also cool down faster during production, which helps you make parts quickly.

Here’s a table to show how aluminum molds compare to steel molds:

| Aspect | Aluminum Molds | Steel Molds |

|---|---|---|

| Cost | Up to 5 times less | Higher initial investment |

| Lead Time | 15 to 25 working days | 35 to 60 business days |

| Durability | Up to 50,000 parts | 100,000 to 1,000,000 parts |

Aluminum molds are great for prototypes, testing, and small production runs. You can make changes to your design without spending a lot of money or waiting a long time. If you need your parts fast, aluminum molds are a smart choice.

Tip: Aluminum molds can make up to 50,000 parts before you need to replace or repair them.

Steel Molds

Steel molds are the main choice for traditional injection molding. You use them when you need to make a lot of parts—sometimes millions. Steel molds are very strong and last a long time. They can handle high pressure and many cycles without wearing out.

- Steel molds are highly durable and perfect for high production volumes.

- You can use steel molds to make tens of millions of parts over many years.

- They do cost more at the start and take longer to make.

Steel molds are best when you want the lowest cost per part for big orders. You pay more at first, but you save money in the long run if you make a lot of parts.

Note: Steel molds can produce between 100,000 and 1,000,000 parts before you need maintenance.

Mold Lifespan

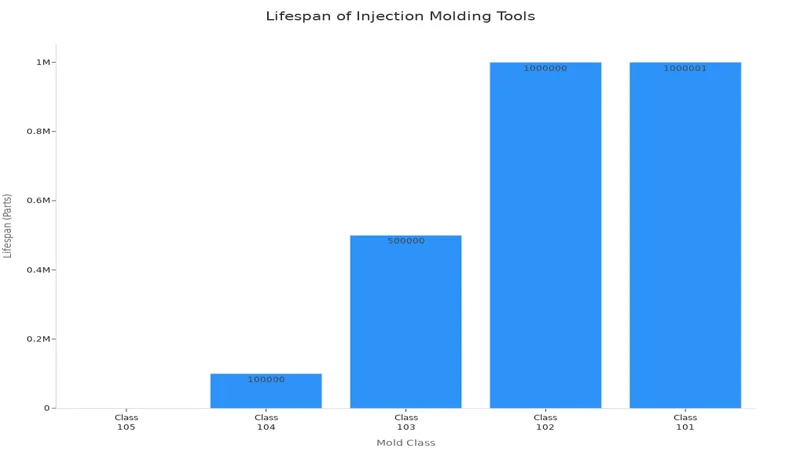

The lifespan of a mold tells you how many parts you can make before you need to repair or replace it. Mold class helps you pick the right tool for your project. Here’s a table to help you understand:

| Mold Class | Typical Lifespan (Parts) | Description |

|---|---|---|

| Class 105 | Up to 500 | Prototype mold for rapid tooling |

| Class 104 | Up to 100,000 | Low-volume production, often aluminum or mild steel |

| Class 103 | Up to 500,000 | Low- to mid-volume, cost-effective for moderate runs |

| Class 102 | Up to 1,000,000 | Medium to high production, durable metals |

| Class 101 | Over 1,000,000 | High-quality tool for very high production |

You should choose your mold based on how many parts you need and how fast you want them. Aluminum molds work well for quick jobs and small batches. Steel molds are better for big projects that last a long time. Picking the right mold helps you control your costs and keep your project on track.

Production Volume And Scalability

Low-Volume Production

Sometimes you only need a few hundred or a thousand parts. Rapid injection molding is great for this. You get your parts fast and spend less money. Here’s why this method is good for small batches:

- Short run injection molding makes small amounts, from hundreds to thousands.

- You save money because the tools are cheaper and ready faster.

- Rapid injection molding works best for fewer than 10,000 parts each year.

- You can change your design quickly and without much cost.

- This is good for testing and fixing your design before making more.

You can use this to test your product or show samples to people. If you want to change something, you can do it without spending a lot or waiting long.

High-Volume Production

If you need hundreds of thousands or millions of parts, use traditional injection molding. This way uses steel molds that last a long time and work fast. The table below shows how both ways compare for big jobs:

| Factor | Rapid Injection Molding | Traditional Injection Molding |

|---|---|---|

| Tooling Durability | Aluminum molds (5,000–20,000 cycles) | Steel molds (500,000+ cycles) |

| Cycle Time Optimization | Longer cycle times | Shorter cycle times, high-speed |

| Material Compatibility | Limited for some high-temp polymers | Works with a wide range of materials |

| Maintenance Frequency | Needs more frequent maintenance | Less frequent maintenance |

Steel molds cost more at first, but they last much longer. This means each part costs less when you make a lot. Traditional injection molding also lets you use more kinds of plastics, even ones that need high heat.

Note: Rapid injection molding uses aluminum molds that cost $5,000 to $20,000. Traditional steel molds cost $20,000 to $100,000 or more, but last for many more uses.

Design Iterations

You might want to try different ideas or materials before picking your final design. Both rapid and traditional injection molding help with this, but rapid injection molding is much faster and easier. Here’s how it helps you:

- You can try out different materials to see what works best.

- Prototyping with injection molding lets you make changes and see results fast.

- You can work with designers and engineers to make your product better.

- Quick changes help you fix your design before making lots of parts.

- You can test many types of plastic for strength or flexibility.

This helps you find problems early and make your product better before spending a lot on big production. You can go from idea to finished product with fewer delays and less risk.

Tip: If you want to try new ideas or need to change things often, rapid injection molding gives you the freedom to do this without slowing down your project.

Application Suitability

Prototyping

If you want to try out a new idea, rapid prototyping is very helpful. This way, you can turn your computer designs into real parts fast. You get to hold and see your product before spending a lot of money. Rapid injection molding works well for this because it gives you real plastic parts in just a few days. You can use these parts to check if they fit, see if they work, or even show them to people early.

Here’s a table that explains why rapid injection molding is great for rapid prototyping:

| Advantage | Description |

|---|---|

| Efficiency | You get parts much faster than with traditional methods. |

| Reduced Waste | Only the needed amount of plastic is used, so you save material. |

| Strength and Durability | Parts are strong and have no weak spots or pores. |

| Surface Finish | You get a smooth finish, which helps with testing and looks. |

| Precision | Parts are made with high accuracy, so you can trust your results. |

| Cost-Effectiveness | Costs drop as you make more parts, making it a smart choice for early runs. |

With rapid prototyping, you can change your design and see what happens fast. This helps you find and fix problems early, so you don’t waste money later. You can also show your parts to others and get their thoughts or approval.

Bridge Production

Bridge production helps you move from testing to making lots of parts. Sometimes you need a small batch while you wait for your final tools. Rapid injection molding is a good choice for this step.

Rapid injection molding is close enough to traditional production tooling to solve many problems and help you work faster. It lets you check if your part can be molded and can make the production mold process easier by changing parts for rapid injection molding. Also, tools made for rapid injection molding can make real parts in the same materials and amounts while you wait for your main tools.

You can use bridge production to fill orders, test your supply chain, or get your product out sooner. This step keeps your project moving while you get ready for big production.

Mass Production

When you need thousands or even millions of parts, you start mass production. You have to pick between rapid injection molding and traditional injection molding. Here’s a table to help you compare:

| Aspect | Rapid Injection Molding | Traditional Injection Molding |

|---|---|---|

| Cost Efficiency | High | Moderate |

| Labor Costs | Lower due to automation | Higher due to manual processes |

| Material Waste | Minimal | Higher |

| Economies of Scale | Achievable | Limited |

- Rapid injection molding lets you make parts faster.

- You can test ideas and react to changes quickly.

Rapid injection molding also helps the environment. You use less material and energy, which is better for the planet. Traditional injection molding is still good for very big jobs, especially when you want the lowest price for each part.

Remember these steps when you think about mass production: 1. Traditional manufacturing has many steps and lots of checking by people. 2. Rapid manufacturing uses computers to speed things up. 3. This means you spend less money and get your parts faster.

If you want to keep up with orders and stay flexible, rapid injection molding is a good choice for mass production. You can make more parts quickly and change your plans if you need to.

Industry Examples

You can find rapid injection molding and traditional injection molding in many industries. Each way works best for different needs. Real examples help you see how these methods help companies make products faster and solve problems.

Here are some ways companies use rapid injection molding:

- Rapid Prototyping: You can make molded parts fast to test new ideas. This helps you develop products quickly.

- Short-run Production: You can make small batches, usually under 2,000 parts. This is good when you do not need a big order.

- Line-down Solutions: If your supply chain has trouble, rapid molding keeps your products in stores.

- Bridge Production: You can use this to move from making prototypes to making lots of parts.

Many industries use injection molding for different products. The table below shows some main uses:

| Industry | Notable Applications |

|---|---|

| Automotive | Bumpers, headlights, hose fittings, door handles, dashboard buttons, and switches |

| Consumer Products | Kitchen appliances, furniture, toothbrushes, toys, and wall decorations |

| Pharmaceutical | Drug-delivery devices, laboratory tubes and beakers, and packaging for solid oral doses |

| Food and Beverage | Utensils, container caps and lids, food storage containers |

| Building and Construction | Window and door hardware, construction tools, pipe, and electrical fittings |

| Packaging | Food packaging containers, consumer product packaging, and bottle blanks |

| Transportation | Train seats, train fairings, overhead baggage containers |

There are also special uses in the medical and automotive fields:

- Medical: You can make complex, high-quality parts fast. This is important for liquid silicone rubber (LSR) parts used in medical devices.

- Automotive: You can make light, strong, and exact parts. These help cars be safer and work better.

Tip: If you work in these industries, rapid injection molding helps you fix urgent problems, test new products, or fill supply gaps.

Both rapid and traditional injection molding are important in many fields. You can pick the best way for your needs. You might want to test an idea, make a small batch, or start mass production. This flexibility helps you keep up in a fast-changing market.

Choosing The Right Method

Decision Criteria

When you pick between rapid injection molding and traditional injection molding, you need to think about a few key things. Picking the right way helps you save time and money. It also makes your work easier. Here are some things to check before you start:

- Technical Capabilities: Make sure your partner can use the materials you want. They should have the right mold-making tools and be able to make parts as exact as you need.

- Speed: Ask how quickly they can make your parts. Make sure they do not lose quality when working fast.

- Flexibility: See if they can handle changes in your design or order size.

- Scalability: Check if they can go from making a few parts to making many parts.

- Quality Assurance: Look for strong checks on quality. They should follow the rules for your industry.

- Compliance Standards: Make sure they can give you the right papers and track your parts.

If you want to test your idea fast, rapid prototyping and rapid tooling are good choices. These let you make changes quickly and see results soon. If you need a lot of parts with very tight tolerances, traditional molding might be better.

Common Mistakes

Many people make mistakes when picking between rapid injection molding and traditional molding. You can avoid problems if you know what to look for:

- If you forget to pick the right material, your parts may break.

- If you do not think about how easy it is to make your part, you may have delays.

- If you do not check tolerances and fits, your parts may not work right.

Here are some common design mistakes:

- If your part walls are too thin or too thick, they can bend or warp.

- If your part shape is too tricky, the mold will cost more and take longer.

- If you do not design for easy filling, you may pay more and have problems making parts.

Always design your parts so they are easy to make. If you skip this, you may have trouble moving from testing to making lots of parts. Sometimes, engineers forget simple rules for making parts, which can cause defects and higher costs.

Practical Tips

You can make better choices and avoid problems by following these tips:

Tip: Talk to your supplier early. Show your design and ask for advice on rapid tooling and rapid prototyping.

- Use rapid prototyping to test your design before spending a lot on molds.

- Pick rapid tooling if you want to try different materials or make changes fast.

- If you want to make more parts later, ask if your partner can switch from rapid molding to traditional molding without waiting.

- Keep your design simple. Simple shapes are cheaper and easier to mold.

- Plan for changes. Rapid tooling lets you fix your design fast if you find a problem.

- Check the mold class and how long it lasts. Pick the right tool for how many parts you need and how fast you need them.

You can save time and money if you plan. Rapid injection molding and rapid tooling help you go from idea to finished part quickly. If you need millions of parts, traditional injection molding is best for saving money in the long run.

Rapid injection molding is fast and lets you change things easily. Traditional injection molding is better for making lots of parts that must be exact. Think about what your project needs most. If you need parts quickly or want to try out ideas, use rapid injection molding. If you need many parts and want the lowest price for each, use traditional injection molding. Always look at speed, cost, quality, material, and how many parts you need before you choose.

FAQ

You get parts much faster. Rapid injection molding lets you test ideas and make changes quickly. This helps you bring products to market sooner.

Yes, you can. Rapid injection molding works for prototypes and small production runs. You can use it to make real parts for testing or early sales.

Aluminum molds usually make up to 50,000 parts. This number depends on the part design and the material you use.

You can use many plastics, like ABS, polycarbonate, and nylon. Some specialty materials may wear out molds faster. Always ask your supplier for the best choice.

Machining lets you add holes or special features after molding. You get tighter tolerances and more complex shapes. This is great for custom or high-precision parts.

Pick traditional injection molding when you need millions of parts or the tightest tolerances. This method gives you the lowest cost per part for large orders.

Yes, you can change your design with rapid injection molding. Aluminum molds are easy to update. You save time and money if you need to fix or improve your part.