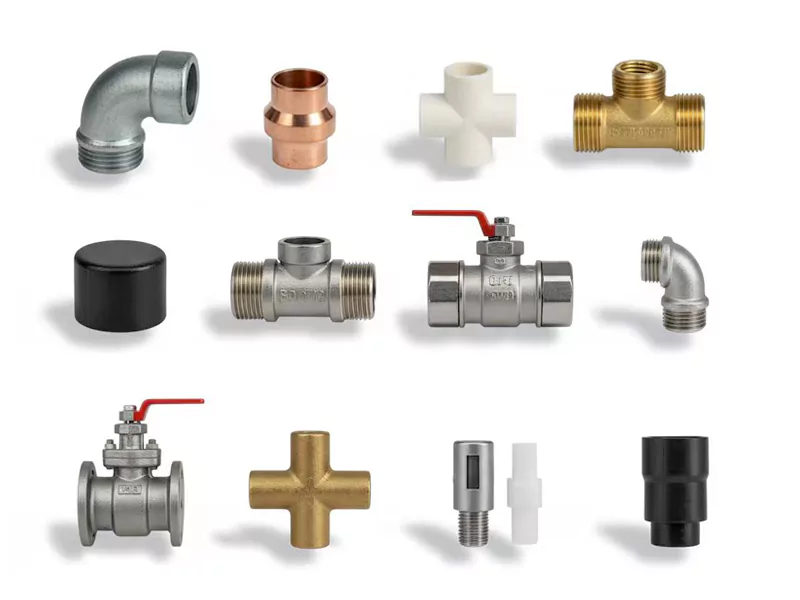

You use different types of pipe fittings to connect, guide, or control liquids and gases. These are used in plumbing and in factories. Pipe fittings include elbows, flanges, nipples, traps, tees, unions, and wyes. Each fitting has its own job. Some change the flow direction. Others join more than one pipe. The right pipes and fittings keep systems safe and working well. They stop leaks and handle changes in pressure or heat. Knowing about pipe fitting types helps you pick the best one. This is true for home repairs or big projects.

Key Takeaways

- Pipe fittings join, guide, and control how liquids and gases move. They are used in plumbing and factories. Elbows help change the way things flow. Tees split or join flows. These are important for good pipe layouts. Picking the right material, like steel or PVC, makes fittings last longer. It also helps stop leaks. Checking and caring for pipe fittings often can stop leaks. This keeps the system working well. Adapters and couplings make it easy to connect different pipes. They help with repairs and upgrades. Traps stop sewer gases from getting inside. This keeps homes and buildings safe and comfortable. Knowing what each fitting does helps you pick the right one. This makes your project safer and work better. Following rules and codes keeps piping systems safe and reliable. It also makes sure they follow the law.

Table of Contents

Types of Pipes and Fittings Overview

Elbows

Function

Elbows change the direction of flow in a piping system. You use them when you need to turn a pipe around a corner or obstacle. Most elbows come in 90-degree or 45-degree angles. Some elbows, called reducing elbows, also connect pipes of different sizes. These fittings help you guide water, gas, or other fluids exactly where you want them to go.

Tip: Choosing the right elbow material, like steel, copper, or PVC, helps your system last longer and work better.

Applications

You find elbows in many places. In your home, elbows connect pipes under sinks, behind walls, and above ceilings. Plumbers use them to fit pipes around corners or through tight spaces. In factories, elbows help move liquids or gases safely and efficiently. For example, a 90-degree elbow lets you run a pipe along a wall and then turn it up or down. Reducing elbows help you join pipes of different sizes without leaks.

| Material Type | Properties | Durability Impact |

|---|---|---|

| Steel | Handles high pressure and temperature | Stainless steel lasts long; carbon steel may rust |

| Copper | Resists corrosion and bacteria | Great for drinking water systems |

| Brass | Stands up to heat and corrosion | Good for plumbing and heating |

| PVC | Resists chemicals | Durable in many plumbing systems |

| CPVC | Handles higher temperatures than PVC | Best for hot water pipes |

| PEX | Flexible and tough | Long life in homes |

| HDPE | Resists cracking and damage | Used in tough industrial jobs |

| Composite | Mixes metal and plastic strengths | Works well in harsh environments |

Tees

Function

Tees let you split the flow of a pipe into two directions or combine two flows into one. The shape looks like the letter “T.” You use a tee when you want to branch off from a main pipe. This fitting helps you add new lines or connect different parts of a system.

Applications

You see tees in many types of piping systems:

- Residential plumbing

- Water supply lines

- Wastewater treatment plants

- Chemical factories

- Oil and gas pipelines

For example, in your house, a tee fitting might connect the main water line to both the kitchen and bathroom. In a factory, tees help mix or separate fluids in large systems. Tees make it easy to expand or change your piping layout.

Couplings

Function

Couplings connect two straight pieces of pipe. You use them when you need to extend the length of a pipe or repair a broken section. Couplings have a simple, round shape and often use glue, threads, or welding to hold pipes in place. They are one of the most basic pipe fittings.

| Type of Fitting | Primary Function |

|---|---|

| Coupling | Connects two lengths of pipe, often for long distances. |

Applications

You use couplings in both home and industrial settings. For example, if you need to fix a leaking pipe under your sink, you might cut out the bad section and join the new piece with a coupling. In factories, couplings help build long pipelines that carry water, oil, or chemicals over great distances. Couplings are also used when you need to replace a damaged pipe without taking apart the whole system.

Note: The right choice of pipe fitting types, such as elbows, tees, or couplings, helps your plumbing system last longer and work better. Picking the correct material, like CPVC for hot water or PEX for flexibility, can prevent leaks and failures.

Reducers

Function

Reducers join pipes that are not the same size. You use a reducer when a big pipe needs to connect to a smaller one. This fitting makes the change in size smooth. It helps the fluid keep moving without sudden drops in speed or pressure. Reducers also help control the flow. They stop air from building up at the pump inlets. Using reducers can make your system work better and more efficiently.

Tip: The right reducer stops leaks and keeps things working well.

Here are some main jobs of reducers:

- Join pipes with different sizes for a smooth change.

- Change direction or speed of the flow.

- Lower pressure loss helps things move better.

| Function | Description |

|---|---|

| Pipe Diameter Reduction | Joins pipes of different sizes so fluid moves smoothly. |

| Flow Control | Keeps the flow steady and stops big changes. |

| Cavitation Prevention | Stops air from building up at the pumps, so things run well. |

Applications

Reducers are used in many places and jobs. You see them in power plants, chemical factories, and metal plants. They are also found in oil and water wells. These places are connecting pipes of different sizes because the ground can change. In medical and cosmetic machines, reducers join small and large pipes. When you use different pipe fittings, reducers help you join pipes of all sizes without leaks or flow trouble.

- Used in power, chemical, and metal plants to join pipes of different sizes.

- Needed in oil and water wells to fit pipes to the changing ground.

- Used in medical and cosmetic machines to join small and large pipes.

Reducers are very important for moving fluids in many jobs. They help keep pressure and flow steady. This is needed for water treatment, oil and gas, and chemical work.

Unions

Function

Unions let you take apart and put together two pipes easily. You do not have to cut or hurt the pipes. A union has three parts: two ends and a nut in the middle. You use unions when you want to remove a pipe for fixing, cleaning, or swapping. Unlike couplings, unions let you take pipes apart without turning the whole line. This makes unions great for fixing and upgrading your system.

Note: Unions save time and make pipe work easier.

Applications

You use unions where you might need to take out a pipe. Unions are found in water heaters, pumps, and other things that need service. In factories, unions help you take pipes apart fast for cleaning or checking. You also see unions in home plumbing, like under sinks or near machines. Using unions makes it easier to keep your system working and fix things quickly.

- Used in plumbing for easy fixing and care.

- Common in factory machines that need cleaning or checking.

- Helpful in homes for things that may need to be changed.

Adapters

Function

Adapters help you join pipes or fittings that are not the same. You use an adapter to connect a metal pipe to a plastic one. You also use it to join pipes with different threads. This fitting lets you use many kinds of pipes together. Adapters come in many shapes and sizes for different jobs.

| Advantage | Description |

|---|---|

| Versatility | One adapter can do many jobs, so you need fewer fittings. |

| Compatibility | Makes it easy to join different thread types, so no big changes are needed. |

| Time-saving installation | Makes it quick to add new parts to your system. |

| Enhanced reliability | Gives a strong connection, so leaks are less likely. |

| Overcoming material compatibility | Lets you join pipes made of different stuff, stopping leaks and other problems. |

Applications

You use adapters when pipes or fittings do not match. For example, to join a copper pipe to a PVC pipe, you use an adapter. In factories, adapters help connect machines with different threads or materials. In homes, adapters let you add new things to your pipes. Adapters are important in systems with many kinds of pipes. They make it easy to change or add to your setup without starting over.

- Used to join pipes made of different materials, like metal and plastic.

- Good for joining pipes with different threads or sizes.

- Common in homes and factories for upgrades and repairs.

Adapters help you build and fix piping systems. They stop leaks and keep connections strong, even with different pipe fittings.

Caps and Plugs

Function

Caps and plugs close the ends of pipes or fittings. A cap goes on the end of a pipe. A plug fits inside a fitting to block the flow. Both help keep your plumbing safe and clean. When you use a cap or plug, you stop leaks. This keeps pressure steady and stops spills. You also use them for repairs or testing. Caps and plugs keep out dirt and water. This protects pipes from damage.

Note: Caps and plugs are very important for safety. They stop leaks, block dirt, and make fixing pipes easier.

Applications

You see caps and plugs anywhere you need to close or protect a pipe. Here are some ways you might use them: – Close off pipe ends not being used during work. – Keep open pipes safe from dirt and water during building. – Block parts of a system for pressure tests. – Close pipes for a short time during repairs.

Caps and plugs help keep your plumbing working well. They make it easy to fix or upgrade pipes without leaks or dirt getting in. You find these fittings in homes, factories, and big plants. Using caps and plugs keeps your system clean, safe, and ready to use.

How caps and plugs help with safety and care:

- They seal pipes so fluids do not leak out. This keeps pressure up and stops leaks.

- You use them during building and fixing to stop dirt and keep things working well.

- They act as shields, making plumbing safer and more reliable.

Nipples

Function

Nipples are short pipes with threads on both ends. You use them to join two pipes or fittings. Nipples help you make pipes longer or connect different fittings. They are good for tight spaces. Nipples come in many sizes and lengths. You can pick the right one for your job. Nipples are important for strong, leak-free connections, especially with high pressure.

Applications

You see nipples in many pipe fitting types. They are used to connect pipes in a straight line. Nipples are common in plumbing, heating, and factories. They are also used in high-pressure jobs, like steam pipes and boilers. The nipple you pick depends on the job and the pressure needed.

| Type of Pipe Nipple | Description | Typical Uses |

|---|---|---|

| Welded Nipples | Welded in place for a strong, safe link. | Used in steam pipes, boilers, and places needing no leaks. |

| Seamless Nipples | Made without seams, so they are stronger. | Used in chemical plants, refineries, and power plants. |

| Swage Nipples | Join pipes of different sizes and keep the flow smooth. | Used in oil, gas, and chemical plants for good flow. |

You use nipples to join pipes, make lines longer, or connect fittings in small spaces. They are also good for quick pipe fixes. Nipples help you build and fix systems that handle high pressure and heat.

Crosses and Wyes

Function

Crosses and wyes are special pipe fittings. They help you split or join flows in tricky pipe layouts. A cross has four openings like a plus sign. You use it to join four pipes at right angles. A wye looks like a “Y” and lets you branch off at an angle. Both help you control flow and send fluids where you want.

Applications

You use crosses and wyes to split or join flows. They are common in drains, waste, and vent pipes. You also see them in factories with many pipes. Crosses and wyes help you make pipe layouts that save space. They let you add new branches or join parts of a system.

| Benefit | Description |

|---|---|

| Efficient Flow Distribution | Splits fluid into two branches for a balanced system. |

| Space-Saving | The Y shape fits well in small spaces. |

| Versatility | Many sizes and materials work for lots of jobs. |

| Cost-Effective | Cheaper than other complex pipe setups. |

When you use crosses and wyes, you can build pipes that are easy to change. These fittings help you control flow, join pipes at angles, and keep your system working well.

Bushings

Function

You use bushings to connect pipes of different sizes. This fitting acts as a reducer or adapter, making it easy to join a large pipe to a smaller one. When you need a smooth transition between two pipes with different diameters, a bushing gives you a tight, leak-free connection. Bushings help you avoid sudden changes in flow, which keeps your system running smoothly.

- Bushings connect pipes of different sizes.

- They act as reducers or adapters.

- You get a seamless transition between different pipe diameters.

You find bushings made from many materials. Common choices include PVC, copper, brass, stainless steel, plastic, and cast iron. Each material works best for certain jobs. For example, you might use brass or stainless steel bushings in places with high pressure or heat. PVC bushings work well in home plumbing where you need a lightweight and corrosion-resistant option.

Applications

You use bushings in many types of pipe fittings. They are common in both home and industrial systems. For example, you might need a bushing when you add a new appliance to your kitchen, and the pipe sizes do not match. In factories, bushings help connect pipes of different sizes in chemical plants, water treatment systems, or oil refineries. You also see bushings in heating and cooling systems, where they help join pipes for boilers or air conditioners.

Tip: Always pick a bushing made from a material that matches your system’s needs. This helps prevent leaks and keeps your system safe.

Flanges

Function

You use flanges to connect and disconnect pipe sections quickly and securely. Flanges create a strong joint by using bolts and gaskets. This design lets you assemble or take apart pipes without cutting or damaging them. When you need to inspect, clean, or replace a part of your system, you can unbolt the flange and access the inside. Flanges make it easy to maintain or upgrade your piping without a lot of extra work.

Flanges are important in many pipe fitting types because they provide a rigid, leak-proof connection. You often see them in places where you need to take pipes apart for repairs or checks.

Applications

You find flanges in many industrial settings. They are common in power plants, chemical factories, oil refineries, and water treatment plants. Flanges help you connect large pipes that carry steam, water, oil, or chemicals. You also see flanges in fire sprinkler systems and shipbuilding. When you need to replace a valve or inspect a section of pipe, flanges let you do the job quickly and safely.

| Flange Type | Typical Use Case |

|---|---|

| Weld Neck | High-pressure, high-temperature systems |

| Slip-On | Low-pressure, easy installation |

| Blind | Sealing the end of a pipe |

| Threaded | Quick assembly, no welding needed |

| Lap Joint | Systems needing frequent disassembly |

Note: Flanges save you time and effort during maintenance. You can unbolt them to check or fix your system without taking apart the whole pipeline.

Traps

Function

Traps are special pipe fittings that protect your home or building from sewer gases. You install a trap under sinks, showers, or floor drains. The trap holds a small amount of water, which creates a seal. This water barrier blocks bad smells and dangerous gases from coming up through the pipes. Every time you run water, the trap refills and keeps the seal strong.

- Traps keep sewer gases out of your living space.

- They use a water seal to block odors and gases.

- The seal stays in place as long as water flows through the fixture.

If the water in the trap dries out, the seal breaks. This can let bad smells into your home. That is why you should run water in unused sinks or drains from time to time.

Applications

You use traps in almost every plumbing system. They are found under kitchen sinks, bathroom sinks, bathtubs, showers, and floor drains. Traps are also used in commercial kitchens, hospitals, and schools. In each case, the trap keeps the air clean and safe by blocking sewer gases.

Tip: If you notice a bad smell near a drain, check the trap. Pouring water into the drain can restore the seal and stop the odor.

Traps are a key part of modern plumbing. They help you keep your home or building safe, healthy, and comfortable.

Materials and Manufacturing of Pipe Fittings

Metal Fittings

Metal fittings are strong and last a long time. They work well when pressure or heat is high. You often see them in factories and water plants. Oil pipelines also use metal fittings. Here are some metals used for pipe fittings and how they help:

- Alloy steel is strong and bends without breaking. It does not rust easily and can be welded. You find it in food factories and petrochemical plants.

- Stainless steel does not rust and lasts a long time. It is used in food, chemical, and marine jobs.

- Carbon steel is strong and costs less. It is common in building and oil pipelines.

- Brass is easy to shape and does not rust. You see it in plumbing and heating systems.

Tip: Choose the best metal for your job. Stainless steel is good for stopping rust. Carbon steel is strong and saves money.

Plastic Fittings

Plastic pipe fittings are light and simple to use. You can cut and shape them easily. They do not rust and are safe with many chemicals. Here are their good points and limits:

| Advantages of Plastic Pipe Fittings | Limitations of Plastic Pipe Fittings |

|---|---|

| Easy to shape and cut | Can bend with heat |

| Do not react with other materials | Some types have a few sizes |

| Do not rust | Not always safe for hot water |

| Do not carry heat well | Sunlight can damage them |

You might use plastic fittings for home pipes or gardens. They last because they do not rust. You can put them in fast, which saves time and money. But heat and sunlight can hurt them.

Note: Plastic pipe fittings do not resist fire as well as metal. They also get bigger when hot, so plan for that.

Composite Fittings

Composite fittings mix metal and plastic strengths. Makers use strong plastics and things like fiberglass or aluminum. These fittings are tough, light, and bend easily. They do not rust and handle pressure well.

- Composite pipe fittings use strong plastics and other materials.

- They are tough but light and simple to install.

- These fittings work well where you need strength and chemical resistance.

You see composite fittings in water plants and heating systems. Some factories use them too. They handle heat and pressure better than just plastic. You can use them where metal might rust or plastic is not strong enough.

If you want a fitting that lasts, does not rust, and is easy to use, composite pipe fittings are a smart pick.

The Role of Machining in Pipe Fitting Quality

When you look at pipe fittings, you might wonder how they get their exact shape and size. Machining plays a big part in making sure each fitting works well and lasts a long time. You want your fittings to fit tightly, stop leaks, and handle pressure. Machining helps make this possible.

Several machining processes shape and finish pipe fittings. Each process has a special job. Here are some of the most important ones:

- Forging and Pressing: These methods make fittings strong. You use them for heavy-wall or high-pressure pipe fittings. The metal gets pressed or hammered into shape, which makes it tough and able to handle stress.

- Roller Method: This process helps fittings stay round and keeps the wall thickness even. You get a smooth, even pipe fitting that fits well with other parts.

- Stamping Method: Stamping is fast and good for making many fittings at once. It shapes the metal with a press, so every fitting comes out the same.

- Bending and Forming: You need these methods to make elbows or other angled fittings. They let you bend the metal without breaking it, so the fitting stays strong.

- Rolling Method: Rolling is important for heavy-duty fittings. It keeps the wall thickness the same all the way around, which helps the fitting last longer.

- Bulging Method: This method lets you expand part of a fitting with great control. You can make special shapes or sizes without hurting the metal.

Tip: High-quality machining means your pipe fittings will fit better, last longer, and work safely under pressure.

Machining does more than just shape the fittings. It also makes sure the inside and outside surfaces are smooth. Smooth surfaces help stop leaks and make it easier to join fittings together. When you use well-machined pipe fittings, you get a system that is safer and easier to maintain.

| Machining Process | What It Does | Why It Matters |

|---|---|---|

| Forging & Pressing | Makes fittings strong and tough | Handles high pressure and stress |

| Roller Method | Keeps fittings round and even | Ensures a tight, leak-free fit |

| Stamping | Shapes many fittings quickly | Good for large projects |

| Bending & Forming | Creates angles and curves | Needed for elbows and special shapes |

| Rolling | Maintains even wall thickness | Increases fitting life |

| Bulging | Expands parts with precision | Makes custom shapes possible |

When you choose pipe fittings, always think about how they were made. Good machining means fewer problems later. You get fittings that are easy to install, safe to use, and ready for tough jobs.

How to Choose Pipe Fitting Types

Assessing Project Requirements

When you start a new piping project, you need to look at several important factors before picking your pipe fittings. First, think about what the system will carry. Will it move water, gas, oil, or chemicals? The type of fluid affects which fittings you should use. Next, check the pressure and temperature the system will face. Fittings must handle the highest pressure and temperature in your system. If you choose a fitting with a low pressure rating, it might leak or even break. Always pick fittings that meet or exceed your system’s needs.

You also need to consider the size of the pipes. Fittings must match the inside diameter of the pipes. Common sizes range from 1/4 inch to 48 inches. If you use the wrong size, you could cause flow problems or pressure drops. Think about how the pipes will connect. Some systems need elbows, tees, or couplings for secure seals. Make sure the fitting type matches the job.

Plan for the future. Sometimes, you may need to change flow rates, pressures, or even the type of fluid. Choose fittings that can adapt to changes. This helps your system last longer and makes upgrades easier. Finally, make sure the fittings are easy to install and maintain. If you can reach and replace them easily, you will save time and trouble later.

Tip: Always check if your fittings can handle future changes in your system. This keeps your setup flexible and ready for upgrades.

Matching Material to Application

You must match the fitting material to the environment where you will use it. Different materials work better in different places. For example:

- Carbon steel fittings can rust if exposed to moisture or chemicals. In coastal areas with salt spray, these fittings may not last long.

- Polyethylene (PE) fittings resist chemicals and stay flexible, even when temperatures change. They often last more than fifty years.

- Polypropylene Random Copolymer (PPR) fittings work well for hot and cold drinking water. They resist scaling and stay strong under heat.

- Press fittings made from copper or stainless steel install quickly and seal tightly. They last a long time in tough jobs.

Environmental conditions like humidity, temperature swings, and pollutants can shorten the life of some fittings. Even inside buildings, high humidity or chemical exposure can cause corrosion at connection points. Always choose a material that matches your system’s needs and the environment.

Note: Picking the right material helps your system last longer and keeps it safe.

Sizing and Compatibility

Getting the right size and making sure everything fits together is key. Pipe fittings must match the pipes in both size and type. If you use the wrong size, you can cause leaks, pressure drops, or even damage the system. Fittings come in many sizes, and you need to check both the inside diameter and the wall thickness.

| Pipe Schedule | Description |

|---|---|

| Schedule 40 | Standard wall thickness, used in many systems. |

| Schedule 80 | Thicker walls, good for higher pressure jobs. |

You also need to watch out for different thread types. Some fittings use NPT threads, while others use BSPP or BSPT. Even if two fittings have the same nominal size, the threads might not match. Not all thread types seal well together, so you may need special sealing methods.

- Different thread types can look the same but may not fit together.

- Some old systems use thread types that are not common today.

- Always check the thread type and use the right sealant if needed.

Make sure the fitting works with your pipe joining method. Some systems use welding, others use threading or gluing. Pick fittings that are easy to install and maintain. This helps your system run smoothly and makes repairs easier.

Tip: Double-check the size, thread type, and joining method before you buy or install any fitting.

Standards and Codes

When you pick pipe fittings, you must follow certain rules. These rules are called standards and codes. They help keep your system safe and strong. Standards tell you how to make and test fittings. Codes are rules made by groups or governments to protect people and buildings.

There are many standards and codes for plumbing and factories. Some important ones are:

- ASME B31.3 – Process Piping

- API 570 – Piping Inspection Code

- ASME B31.1 – Power Piping

- ASTM A106 – Standard Specification for Seamless Carbon Steel Pipe

- ANSI/ASME B16.5 – Pipe Flanges and Flanged Fittings

- ASTM A234 – Standard Specification for Piping Fittings

These standards explain how to make and use different fittings. They say what materials to use and how strong fittings should be. They also tell you how to test them. If you follow these standards, your system will be safer and last longer.

The International Plumbing Code (IPC) is another set of rules. It gives the lowest requirements for plumbing in buildings. The IPC covers things like stopping dirty water from going backward, water supply, drains, and where to put fixtures. When you follow the IPC, you help keep water clean and protect everyone’s health.

Here is a table that shows what some standards focus on:

| Standard/Code | What It Covers |

|---|---|

| ASME B31.3 | Process piping in factories and plants |

| API 570 | Inspection and repair of piping systems |

| ASME B31.1 | Power piping, like in power plants |

| ASTM A106 | Seamless carbon steel pipe |

| ANSI/ASME B16.5 | Flanges and flanged fittings |

| ASTM A234 | Piping fittings (wrought carbon and alloy) |

| International Plumbing Code (IPC) | Plumbing safety and health in buildings |

Tip: Always check which standards and codes you need before you buy or put in pipe fittings. Using the right standards helps you avoid problems and keeps your system safe.

If you work in another country or state, there may be other rules. Always ask or look up the rules for your area. When you follow the right standards and codes, your fittings will work well and meet the law.

Specialized and Advanced Pipe Fittings

Flexible Fittings

Flexible fittings help you solve tough piping challenges. You use them when pipes do not line up perfectly or when you need to handle vibration, movement, or expansion. These fittings bend and stretch, so you can connect pipes even if they shift a little. You often see flexible fittings in places where the ground moves, like near pumps or in earthquake zones. They also work well for repairs, letting you fix a pipe without cutting out a big section.

Here is a table showing common types of flexible fittings and when you might use them:

| Type of Fitting | Description | Preferred Scenario |

|---|---|---|

| Couplings | Connects two pipes of similar diameter. | When the pipe ends are close together. |

| Saddles | Attaches to the side of a pipe without cutting through it. | Adding new pipes to existing lines without major changes. |

| Straight Couplings | Same diameter across its length for similar OD pipes. | Connecting pipes of similar sizes, like concrete to PVC. |

| Reducing Couplings | Connects pipes of different diameters. | Joining pipes of varying sizes, such as 10″ to 8″. |

| Flexible Caps | Seals the end of a pipe to prevent leaks. | Temporary or permanent sealing, above or below ground. |

| Flexible Sewer Saddles | Fits onto one side of the pipe, adaptable for various sizes. | Tee or wye connections in sewer systems. |

| PVC Inserta Tee | Allows insertion into solid wall pipe materials without glue. | Tapping into existing sewer lines easily. |

| QwikSeal Connectors | Taps into solid wall pipe for new drain lines. | Connecting new drain lines to existing ones. |

| Pipe Plugs | Used to seal the ends or inside of pipes. | Useful for non-testing applications in various sizes. |

Tip: Flexible fittings make repairs and upgrades easier. You can use them to add new lines or fix leaks without a lot of extra work.

Compression Fittings

Compression fittings give you a leak-proof connection without soldering or welding. You use them by sliding the fitting over the pipe and tightening a nut. As you tighten, the ferrule inside the fitting presses against the pipe and the fitting body. This pressure makes the ferrule deform slightly, creating a tight seal that stops leaks. You do not need special tools or heat, so you can install these fittings quickly and safely.

- When you tighten the compression nut, it pushes the ferrule into the pipe and fitting.

- The ferrule changes shape to fit tightly, making a strong seal.

- This method works well for copper pipes and is popular with both pros and DIYers.

You often use compression fittings in water supply lines, under sinks, or in places where you might need to take the pipes apart later. They are practical and efficient, making them a smart choice for many plumbing jobs.

Note: Always check that the pipe is cut straight and clean before installing a compression fitting. This helps the seal stay strong and leak-free.

Push-Fit Fittings

Push-fit fittings, also called push-to-connect fittings, make plumbing fast and simple. You just push the pipe into the fitting until it clicks. The fitting grabs the pipe and seals it tight. You do not need glue, solder, or special tools. This saves you time and lowers the chance of mistakes.

Push-fit fittings work well in many places. You can use them for water, air, or even heating systems. They are great for repairs because you can install them quickly, even in tight spots. These fittings are also easy to remove if you need to change something later.

Here is a table showing the main benefits of push-fit fittings:

| Benefit | Description |

|---|---|

| Time-Saving Installation | Quick to install, no complex tools needed. |

| Reduced Risk of Human Error | Easy to use, so fewer mistakes happen during installation. |

| Versatility and Adaptability | Works in many systems, from plumbing to air lines. |

| Routine Inspection | You should check them regularly to keep your system reliable. |

| Replacements and Upkeep | Over time, you may need to replace them to keep connections strong. |

| Signs of Potential Issues | Watch for leaks or loose fittings to catch problems early. |

Tip: Make sure you push the pipe all the way into the fitting. If you do not, you might get leaks. Always use high-quality fittings for the best results.

Push-fit fittings help you finish jobs faster and with less stress. They are a good choice when you want a reliable, easy-to-use solution for connecting pipes.

Specialty Valves and Connectors

Specialty valves and connectors help you control how liquids and gases move. You use them when you need more than a basic connection. Specialty valves can start, stop, or change the flow direction. Connectors join different pipes or equipment together. These parts are important in places like factories and labs. High-tech industries also use them.

There are many kinds of specialty valves and connectors. Each one does a special job. Some work in very clean places, like making computer chips. Others help different system parts work together. Here is a table with some common specialty valves and what they do:

| Specialty Valve Type | Unique Function |

|---|---|

| Dymatrix® Valves | Supports the semiconductor industry with fast delivery and high purity needs. |

| EM-Technik™ Valves | Connects point-of-use components to piping systems for better compatibility. |

You use specialty valves and connectors for many reasons. They help you control how fluids move through pipes. They protect the inside parts of a system. They let different pipes or equipment work together. They help you fix or upgrade your system without taking it all apart.

Valves are very important in advanced piping systems. You use them to control how much fluid goes through pipes. The main part of a valve is called the body. The bonnet covers and protects the inside parts. When you know how valves work, you see why they keep your system safe and working well.

Specialty connectors help you solve tough problems. For example, you might need to join pipes made from different materials or sizes. Specialty connectors let you do this without leaks or weak spots. You can also use them to add new equipment or change your system as needed.

When you pick specialty valves and connectors, think about what your system needs. Choose the right type for your job. This helps your pipe fittings last longer and keeps your system working well. Good fittings make it easier to fix or upgrade your system.

Tip: Specialty valves and connectors give you more control and options. They help you build systems that are safe, strong, and ready for changes later.

Installation, Maintenance, and Replacement

Installation Tips

When you install pipe fittings, you want every connection to be strong and leak-free. Good installation starts before you even cut the pipe. Think about the whole job and plan each step. Use sharp tools to make clean cuts. Always cut the pipe straight across at a 90-degree angle. This helps the fitting seal tightly.

- Remove any burrs or rough edges from the cut pipe. This keeps seals from getting damaged.

- Do not flatten or crimp the pipe ends when cutting.

- Clean away any grit or debris before you connect the pipes.

- If your fitting needs it, use a safe, approved lubricant to help slide the pipe in.

- Mark the correct depth on the pipe for insertion-style connections.

- Smooth the outer edge of the pipe to help it fit better.

- Double-check that every pipe and fitting is clean before you put them together.

Tip: Careful preparation and clean cuts help your system last longer and prevent leaks.

Maintenance Guidelines

Keeping your fittings in good shape helps your system work well for years. Check your pipes and connections regularly. Look for signs of leaks, rust, or buildup. If you see water stains or hear strange noises, check the area right away.

- Wipe down pipes and fittings to spot leaks early.

- Tighten any loose connections, but do not over-tighten.

- Watch for changes in water pressure or color.

- Flush your system if you notice slow drainage or blockages.

- Replace worn-out washers or seals to stop drips.

Note: Regular checks and quick fixes keep your plumbing safe and efficient.

When to Replace Pipe Fittings

Sometimes, you need to replace pipe fittings to keep your system safe. Watch for these signs:

- Leaks or pipe bursts happen often.

- Pipes get blocked or drain slowly.

- Water bills go up for no clear reason.

- Water pressure drops.

- Water looks rusty or discolored.

- Pipes make strange noises.

- You see rust or corrosion on the outside.

- The pipe size does not match your needs.

- Water quality changes, like a bad taste or smell.

If you notice any of these problems, it may be time to replace the fitting. Quick action can prevent bigger issues and keep your system running smoothly.

Tip: Replacing old or damaged fittings helps avoid leaks, saves money, and protects your home or business.

You have learned about the main pipe fitting types and how each one works in different systems. When you pick the right types of pipe fittings, you help your system stay safe, efficient, and strong. Always check your fittings before you install them. If you need help, talk to a professional. Want to learn more? Look for guides or videos about pipe fittings and how to use them.

FAQ

You often use elbows and tees in home plumbing. Elbows help you turn corners. Tees let you branch off to different rooms.

Always match the fitting material to your pipe and job. For hot water, use copper or CPVC. For outdoor use, pick stainless steel or HDPE.

You can reuse some metal fittings if they are not damaged or corroded. Plastic fittings usually work best as new parts.

Tighten the fitting. Use thread sealant or plumber’s tape on threaded joints. Replace worn washers or seals. If leaks continue, replace the fitting.

| Coupling | Union |

|---|---|

| Permanent connection | Easy to take apart |

| Needs cutting to remove | No cutting needed |

Replace a fitting if you see rust, cracks, leaks, or if water pressure drops. Old or damaged fittings can cause bigger problems.

Not all fittings need glue or sealant. Push-fit and compression fittings seal without glue. Threaded fittings need tape or sealant for a leak-free joint.