You face numerous choices when working with plumbing. Each type of valve has its own strengths and weaknesses. You might wonder which is best for your project. The answer depends on what you need. Some types of valves work well for quick shutoff. Others control water flow more precisely. You can make a smart choice when you know the main differences.

Key Takeaways

- Discover the primary types of plumbing valves. These are gate, globe, ball, check, butterfly, and needle valves. Each one has a special job.

- Ball valves shut off water fast and do not leak much. They work well in emergencies. But they are not good for controlling flow.

- Gate valves let water flow easily when open all the way. They are good for turning water on or off. But they open and close slowly. They can also get stuck.

- Globe valves are great for controlling how much water flows. You can make small changes with them. But they cause more pressure loss.

- Butterfly valves are small and light. They save money on big pipes. But they do not work well under high pressure.

- Check valves stop water from flowing backward by themselves. They keep your water safe. But they can get stuck. They do not control flow.

- Pick valves made with careful, exact work. This helps stop leaks and makes them last longer.

- Always think about what your plumbing needs. Check the pressure, temperature, and type of liquid before you pick a valve.

Table of Contents

Types of Valves in Plumbing Systems

Overview of Valve Types

You will find many types of valves in plumbing systems. Each one has a special job. Some control water flow. Others stop water from going the wrong way. You need to know the main types of valves to pick the right one for your project.

Here are the most common types of valves you will see in homes and businesses:

- Gate valve

- Globe valve

- Check valve

- Plug valve

- Ball valve

- Butterfly valve

- Needle valve

You use these types of valves for different reasons. Some work best for turning water on or off. Others help you control how much water flows through a pipe. Some keep water from flowing backward, which protects your plumbing.

Let’s look at a table that shows how each type works and what it does:

| Valve Type | How It Works | Use Description |

|---|---|---|

| Gate Valve | A metal gate slides in and out of the flow path. | Best for fully open or fully closed applications. |

| Globe Valve | A movable disk presses against a seat for flow control. | Ideal for regulating the amount of water flow. |

| Ball Valve | A ball with a hole rotates 90 degrees to open or close the flow. | Great for quick shutoff and minimal pressure drop. |

| Check Valve | Allows flow in one direction; a flap closes if flow reverses. | Prevents backflow, protecting the clean water supply. |

| Angle Stop (Supply Valve) | Controls flow to individual fixtures, usually under sinks. | Lets you shut off water to a sink or toilet individually. |

| T&P Relief Valve | Let’s you shut off water to a sink or toilet individually. | A critical safety device on water heaters. |

| Hose Bib (Outdoor Faucet) | A simple valve that allows water out through a hose thread. | For garden hoses, irrigation, or draining water heaters. |

| Meter Stop (Water Meter Valve) | Shuts off the entire water supply to your property. | Similar to a ball or gate valve, placed at the water meter. |

You will notice that each type of valve has a unique design. This design helps it do its job well. For example, a ball valve is great when you need to turn water off fast. A globe valve is better when you want to control how much water flows.

Role of Machining in Valve Quality

You might wonder why some valves last longer or work better than others. The answer often comes down to how well the parts are made. Machining is the process that shapes and finishes the metal parts inside a valve. Precision in machining is very important for the quality of all types of valves.

- Machining precision is critical for the sealing performance of plumbing valves.

- Accurate machining prevents leaks by making sure the ball and sealing ring fit together perfectly.

- High-precision CNC machining improves the accuracy and consistency of valve parts. This leads to better quality and longer-lasting valves.

Tip: When you choose a valve, look for one made with high-precision machining. This helps you avoid leaks and keeps your plumbing system working well for years.

You can see that the types of valves you pick and the way they are made both matter. When you understand the main valve types and the role of machining, you can make better choices for your plumbing projects.

Ball Valve Pros and Cons

When you pick a valve for plumbing, you want to know the good and bad points. Ball valves are very popular. You see them in houses, stores, and factories. Many people choose ball valves for good reasons. But you should think about some things before you decide.

Ball Valve Advantage

Quick Shutoff

You can turn a ball valve on or off fast. It only takes a quarter turn of the handle. This lets you stop water quickly. In an emergency, you can react right away. People like this because it saves time and is easy.

Minimal Leakage

Ball valves have a strong seal inside. The ball fits tightly against the seats. This stops leaks, even after many years. Ball valves help keep your plumbing dry and safe. If you want to avoid water damage, this is important.

Durability

Ball valves last a long time. Most brass ball valves work for 20 to 30 years. You may not need to replace them for decades. The material you pick also matters. It affects how long the valve lasts and if it resists rust.

Here is a table that shows common ball valve materials and how they work:

| Material | Properties | Applications |

|---|---|---|

| Brass | Resists rust, not too expensive | Used in homes and businesses |

| Stainless Steel | Very strong, resists chemicals | Used in factories with high pressure |

| PVC | Light resists chemicals | Used for water and chemical pipes |

- Picking the right material is important for how long the valve lasts.

- Each material (like stainless steel, plastic, brass, or cast iron) is different.

- The right choice helps your valve work well and saves money.

You can get two-way ball valves for simple on/off jobs. Three-way ball valves are for more complex water paths. Some systems use three-piece ball valves for easy cleaning.

Note: Ball valves usually cost less than gate valves in small sizes. Globe valves often cost more than ball valves of the same size.

Ball Valve Disadvantages

Not Ideal for Throttling

Ball valves are not good for controlling water flow. They are not made for fine adjustments. If you leave the valve partly open, it can wear out. This can cause leaks or make the valve break. For better flow control, use globe valves.

Higher Cost

Ball valves can cost more than some other types. This is true if you need special materials or big sizes. They are cheaper than gate valves in many cases. But they still cost more than basic stop valves or hose bibs. The price is higher because of the good materials and careful making.

You should know about common problems with ball valves in high-pressure systems:

- Leaks around the stem (from worn parts)

- Valve stuck (from rust or dirt)

- Less flow or blockage (from dirt buildup)

- Handle problems (loose or hard to turn)

- Leaks at the seat (when the ball does not seal)

When you look at the good and bad points, ball valves have many benefits for plumbing. They shut off water fast, do not leak much, and last a long time. But you should think about the higher price and that they are not good for flow control before you choose.

Gate Valve Advantages and Disadvantages

When you compare the pros and cons of different plumbing valves, gate valves stand out for some unique reasons. You see gate valves in many water supply systems. They work well for certain jobs, but you should know both their strengths and weaknesses before you choose them over ball valves.

Gate Valve Advantages

Low Flow Resistance

Gate valves offer very low flow resistance when you open them all the way. The inside of a gate valve creates a straight path for water. This means water moves through with almost no pressure drop. You get better flow than with ball valves, especially if you need to move a lot of water at once.

Here is a table that shows how gate valves and ball valves compare for flow resistance:

| Valve Type | Flow Resistance |

|---|---|

| Gate Valve | Lower when fully open |

| Ball Valve | Higher, especially when partially open |

- Gate valves provide less resistance to flow when fully open.

- Ball valves can create a higher pressure drop, particularly in partially open positions.

If you want to keep water pressure high and reduce energy loss, gate valves are a smart choice. This is one of their main advantages.

Suitable for On/Off Control

You use gate valves for turning water on or off. They work best when you need a valve that is either fully open or fully closed. You do not use them for adjusting flow. When you open a gate valve, the gate lifts out of the way, letting water move freely. When you close it, the gate drops down and blocks the water. This simple design makes them reliable for main shutoff points in plumbing systems.

Tip: If you need a valve for quick shutoff, ball valves are faster. But if you want a valve that keeps flow resistance low, gate valves are better.

Gate Valve Disadvantages

Slow Operation

Gate valves take more time to open or close than ball valves. You need to turn the handle many times to move the gate up or down. This slow action can be a problem in emergencies when you need to stop water fast. Ball valves only need a quarter turn, but gate valves need several turns.

Prone to Jamming

Gate valves can jam or get stuck. Rust, dirt, or lack of lubrication can make the gate hard to move. Sometimes, the valve gets stuck in the open or closed position. When this happens, you cannot control the water flow. Operators should check the valve often to make sure it works smoothly.

- Gate valves can become stuck in the open or closed position due to rust, debris, or a lack of lubrication.

- Stuck valves cannot perform their intended function, leading to operational failures.

- Regular maintenance and inspections are necessary to prevent these issues.

- Operators should monitor the operational smoothness of the valve.

- A sudden torque rise is an early sign of potential failure and should be addressed immediately.

You may need to repair or replace a gate valve if it jams. This can add to your maintenance work. In places where water has a lot of minerals or dirt, gate valves may jam more often.

When you look at the pros and cons, gate valves give you low flow resistance and work well for on/off control. But you should think about their slow operation and the risk of jamming. If you need fast shutoff or want to avoid maintenance, ball valves might be a better choice. Knowing these differences helps you pick the right valve for your plumbing system.

Globe Valve Pros and Cons

When you compare the pros and cons of different plumbing valves, you will notice that globe valves have a special place. You often see globe valves in systems where you need to control water flow with care. These valves look different from ball valves and gate valves. The shape of the body and the way the disc moves up and down give globe valves their unique features.

Globe Valve Advantages

Good Throttling Ability

You can use globe valves when you want to adjust how much water flows through a pipe. The design lets you open the valve a little or a lot, depending on what you need. This is called throttling. Ball valves and gate valves do not work as well for this job. If you try to use ball valves for throttling, you might wear them out quickly. Globe valves handle this task better because the disc moves straight down onto the seat, letting you control the flow with more accuracy.

Precise Flow Control

You get precise flow control with globe valves. The way the valve works lets you make small changes to the water flow. This is important if you need to keep the flow at a certain level. For example, you might use globe valves in heating systems or places where you want to keep water pressure steady. Ball valves and gate valves cannot match this level of control. You can turn the handle of a globe valve and see the flow change right away. This makes globe valves a top choice for jobs that need careful adjustments.

Note: Globe valves are also designed for easy maintenance. You can reach the inside parts without taking the whole valve out of the pipe. This saves you time and money when you need to fix or clean the valve.

Globe Valve Disadvantages

Higher Pressure Drop

You should know that globe valves have some disadvantages. One main issue is the higher pressure drop. When water flows through a globe valve, it has to change direction. This creates more resistance than in ball valves or gate valves. You might notice that the water pressure drops more after passing through globe valves. If you want to keep pressure high, you may want to use ball valves or gate valves instead.

More Complex Design

Globe valves have a more complex design than other types. This means there are more parts inside the valve. You need to check these parts often because they can wear out from the high fluid friction. The good news is that you can replace or resurface the disc and seat, which helps the valve last longer. Still, you should plan for regular inspections and maintenance. The intricate design allows for precise flow control, but it also means you need to pay attention to the valve’s condition.

- Globe valves are designed for easy maintenance, making their components readily accessible, which helps in reducing downtime and costs.

- The ability to replace or resurface the disc and seat prolongs the valve’s life and ensures efficient operation.

- The intricate design allows for precise flow control, which is essential for effective maintenance.

- Regular inspections are necessary due to high fluid friction and potential wear in the valve’s trim components.

When you look at the pros and cons, you see that globe valves give you great control over water flow and are easy to maintain. However, you need to think about the higher pressure drop and the need for more frequent checks. If you want precise flow control, globe valves are a strong choice. If you want fast shutoff or low pressure loss, you might pick ball valves or gate valves instead.

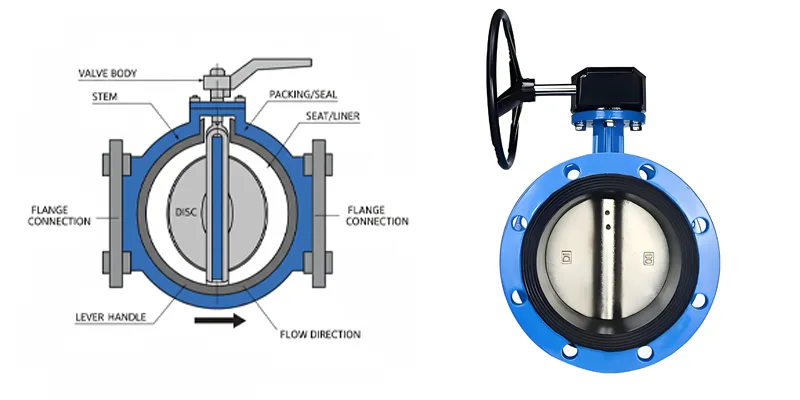

Butterfly Valve Types and Performance

When you look at plumbing, you often see butterfly valves. These valves look different because of their special design. They work in a way that is not like other valves. If you want to know the good and bad things about butterfly valves, you should learn what makes them special.

Butterfly Valve Advantages

Compact Size

Butterfly valves are small and slim. You can put them in tight spots. Other valves might not fit in these places. This makes them good for crowded rooms. You can save space with them. You do not need much room to use or install them. Their shape lets you put them near walls or pipes.

Lightweight

Butterfly valves are lighter than many other valves. This makes them easy to carry and put in place. You do not need big supports or special tools. Because they are light, you can use them where weight matters. For example, on pipes that hang from the ceiling.

Cost-Effective for Large Pipes

Butterfly valves work well in big pipes. Here are some things to know:

- Flanged butterfly valves come in sizes from 4 inches to 72 inches.

- You can use them for big water pipes, factories, or large cooling systems.

- The price stays low even when the pipe is very big.

If you look at other valves, butterfly valves are often cheaper for big pipes. This is why people use them in big buildings and city water systems.

Note: You can use butterfly valves for water and air. Their simple shape keeps costs low and makes them easy to fix.

Butterfly Valve Disadvantages

Not for High-Pressure Systems

Butterfly valves do not work well with high pressure. The disc inside can bend or leak if the pressure is too strong. If you need a valve for high pressure, pick a different type. Ball valves or gate valves are better for those jobs.

Potential for Leakage

Butterfly valves can leak more than some other valves. Look at this table to see the difference:

| Valve Type | Leakage Rate | Sealing Capability |

|---|---|---|

| Butterfly Valve | More likely to leak | Not best for tight shut-off |

| Ball Valve | Hardly leaks | Great sealing |

Some butterfly valves meet certain leak rules. They are usually fine for water pipes. Some can be as tight as ANSI B16.104 Class V or better. But if you need a valve that stops every drop, ball valves are better. Butterfly valves are not the best when you need no leaks at all.

Tip: Always think about the good and bad before you pick a valve. Butterfly valves are small, light, and cheap for big pipes. But you should remember their limits with pressure and leaks.

When you know how butterfly valves work, you can see if they are right for your plumbing. Knowing what they do well and what they do not helps you choose the best valve for your job.

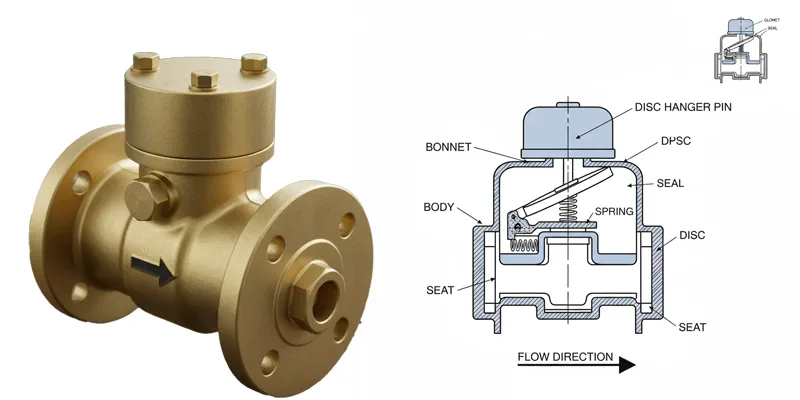

Check Valve Pros and Cons

When you look at the pros and cons of check valves, you see why they are so common in plumbing. Check valves play a big role in keeping water safe and moving in the right direction. You find them in almost every plumbing system, from homes to large buildings.

Check Valve Advantages

Prevents Backflow

You use a check valve to stop water from flowing backward. This is important because backflow can let dirty water mix with clean water. In the United States, over 80 percent of plumbing systems use backflow preventers, which include check valves. You protect your water supply by installing these valves. They help keep your drinking water safe and clean.

- Check valves stop water from moving the wrong way.

- You often see them in sump pumps, water heaters, and irrigation systems.

- A swing check valve is a popular type for home plumbing.

Automatic Operation

Check valves work automatically. You do not need to turn a handle or push a button. When water flows in the right direction, the valve opens. If water tries to go backward, the valve closes by itself. This makes check valves easy to use and reliable. You can install a silent check valve if you want less noise when the valve closes. A ball check valve is another type that works well in systems with solids or debris.

Tip: If you want a quiet plumbing system, choose a silent check valve. It closes softly and helps reduce water hammer noise.

Check Valve Disadvantages

Can Get Stuck

Check valves can get stuck and stop working. This happens for several reasons. You might see problems if you do not install the valve correctly or if you skip regular maintenance. Debris in the pipeline can cause the valve to stick open or closed. Water hammer, which is a sudden change in water flow, can damage the valve. High temperatures can also make the parts expand and wear out faster.

Here is a table that shows common causes of check valve failure:

| Cause of Failure | Description |

|---|---|

| Debris in Pipeline | Debris can build up and make the valve stick in one position. |

| Water Hammer | Pressure surges can damage the valve and cause leaks. |

| Failing Seat Seal | Seals can wear out, letting water leak through the valve. |

| Incorrect Installation | If you install the valve wrong, it can wear out quickly. |

| High Temperatures | Heat can damage the valve and make it leak. |

| Low Fluid Pressure | Not enough pressure can make the valve open and close too often, causing wear. |

You should check your check valves often to make sure they work well. If you notice the valve is stuck or leaking, you may need to clean or replace it.

Limited Flow Control

Check valves do not let you control how much water flows through the pipe. They only allow water to move in one direction. You cannot use a check valve to adjust flow or pressure. If you need to control water flow, you should use a different type of valve. A silent check valve or a ball check valve still only stops backflow, not regulates flow.

- Check valves are not made for flow control.

- You cannot use them to throttle or adjust water pressure.

- They work best when you only need to stop backflow.

Note: If you want to control water flow, look at globe valves or ball valves instead. Check valves are best for automatic backflow prevention.

When you weigh the pros and cons, you see that check valves are great for stopping backflow and working automatically. However, you need to watch for problems like sticking and remember that they do not control flow. By understanding these advantages and disadvantages, you can choose the right valve for your plumbing system.

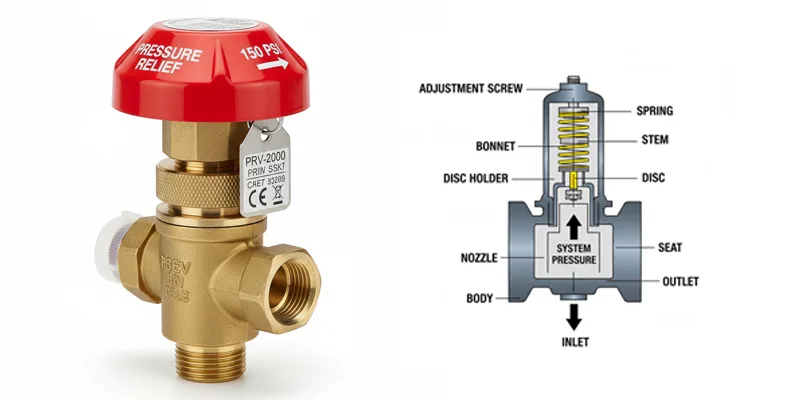

Specialty Valve Types in Plumbing

Sometimes, plumbing needs special valves for certain jobs. These valves help control pressure or change water direction. Some let you make small changes to the water flow. Three important types are pressure relief valves, angle valves, and needle valves.

Pressure Relief Valves

Pressure relief valves keep your pipes safe from too much pressure. If water pressure gets too high, the valve opens and lets water out. This stops pipes and fixtures from breaking. You often see these valves on water heaters and boilers.

Here is a table with the best pressure settings for homes:

| Recommended Pressure Setting | Description |

|---|---|

| 40 to 80 psi | Good range for pressure relief valves |

| Maximum 80 psi | Most plumbing codes do not allow more |

| Ideal 50-55 psi | Best to stop leaks and damage |

Tip: Check your pressure relief valve every year. If it leaks or will not open, replace it fast. This can stop big problems before they start.

You might use a check valve with a pressure relief valve. The check valve stops water from going backward. The relief valve keeps pressure from getting too high. Both together help keep your plumbing safe.

Angle Valves

Angle valves help control water in small spaces. You often find them under sinks or behind toilets. These valves turn water by 90 degrees. This saves space and makes them easy to put in.

Use angle valves when:

- You need a valve in a tight spot, like under a sink.

- You want to turn water without extra pipe parts.

- You want to save money and space when installing.

Angle valves make repairs easier. You can turn off the water to one faucet without shutting off the whole house. Plumbers often use angle valves with check valves. This helps stop backflow and lets you control water at each fixture.

Needle Valves

Needle valves let you control water flow very carefully. Use them when you need slow, small changes to water flow. The long, thin tip inside helps you make tiny adjustments.

Here is a table that shows where needle valves are used:

| Application | Description |

|---|---|

| Flow control | Lets you change the water flow very exactly |

| Pressure regulation | Helps keep water pressure just right |

| Starting a pump | Controls water when starting a pump |

| Turbine bypass | Used in systems with turbines |

| Discharge | Controls water leaving a system |

| Reservoir inlets | Manages water going into a reservoir |

You might see needle valves in chemical plants or power stations. They are also used in places that need careful flow control. Sometimes, a check valve is used with a needle valve. This stops water from going backward but still lets you adjust the flow.

Note: Needle valves are not for quick shutoff. Use them when you need slow, careful changes to water flow.

Specialty valves like these help fix tricky plumbing problems. When you know how to use them, you keep your plumbing safe and easy to take care of.

Comparison of Valve Types: Advantages and Disadvantages

Quick Reference Table

You want to pick the best valve for your plumbing system. To help you, here is a quick table that compares the main types of valves. You can see what each valve does, how it works, and where you might use it.

| Valve Type | Function | Design Description | Applications |

|---|---|---|---|

| Gate Valve | On/off control | A gate slides up and down to open or close the flow. | Used for isolation in pipelines. |

| Globe Valve | Flow regulation | Features a stem and disc that move up and down. | Best for systems needing flow adjustment. |

| Ball Valve | Quick on/off operation | Uses a ball that rotates to control flow. | Ideal for quick shutoff in many pipelines. |

| Butterfly Valve | Flow control/throttling | Uses a rotating disc to control flow. | Suitable for large-diameter pipes. |

| Check Valve | Prevents backflow | Simple design with a spring or ball to stop reverse flow. | Common in pumps and pipelines. |

| Swing Check Valve | Prevents backflow | The disc swings like a door when the flow direction changes. | Used in larger pipelines to prevent backflow. |

You can also compare the installation costs for each valve type. This helps you plan your budget before you start your project.

| Valve Type | Installation Cost Range |

|---|---|

| Ball Valve | $200 – $500 |

| Gate Valve | $375 – $600 |

| Globe Valve | $150 – $300 |

| Check Valve | $100 – $400 |

| Butterfly Valve | $500 – $1200 |

Note: Installation costs can change based on the size of the valve, the material, and how hard it is to install. Always check with your plumber for the most accurate price.

Summary of Key Differences

You have many choices when it comes to valves. Each type has its own advantages and disadvantages. Ball valves give you fast shutoff and a tight seal. Gate valves are great for low flow resistance when fully open. Globe valves let you control water flow with precision. Butterfly valves save space and work well in big pipes. Check valves stop water from going backward and protect your system.

You should also think about how the valve is made. Machining precision makes a big difference in how well a valve works. When a valve is made with high-precision machining, the parts fit together better. This means you get less leakage, smoother operation, and a longer-lasting valve. For example, a ball valve with a perfectly machined ball and seat will seal tightly and last for years. If the machining is not precise, you might see leaks or the valve might wear out faster.

Here are some points to help you compare:

- Ball valves: Fast shutoff, strong seal, higher cost, not for flow control.

- Gate valves: Low flow resistance, good for on/off, slow to operate, can jam.

- Globe valves: Best for flow control, easy to maintain, and higher pressure drop.

- Butterfly valves: Compact, lightweight, cost-effective for big pipes, not for high pressure.

- Check valves: Automatic, prevent backflow, can get stuck, no flow control.

Tip: Always match the valve type to your plumbing needs. Think about how often you will use the valve, how much control you need, and how important a tight seal is for your system.

When you look at all the advantages and disadvantages, you can see that no single valve is perfect for every job. Your best choice depends on what you need most—speed, control, cost, or safety. Remember, valves made with high-precision machining will give you better performance and reliability in the long run.

How to Choose the Right Valve Type

Picking the right valve for your plumbing can seem hard. You want a valve that works well, lasts long, and does not cost too much. Here are some steps and tips to help you choose wisely.

Assessing Plumbing Needs

First, look at what your plumbing needs. Every system is different, so check a few things before you pick a valve.

- Pressure: Make sure the valve can handle your system’s highest pressure.

- Temperature: Choose materials that can withstand hot and cold temperatures.

- Fluid Compatibility: Make sure the valve will not rust or break when touching water or chemicals.

- End Connections: Match the valve ends to your pipes to stop leaks.

- Delivery Requirement: Think about when you need the valve and if your supplier can deliver on time.

Also, check your pipe size, fluid type, and how fast the water flows. For example, some valves work better with dirty water or chemicals. If you pick the wrong valve, you might get leaks or damage.

Tip: Write down your system’s pressure, temperature, and fluid type before you shop. This helps you avoid mistakes and saves time.

Application and Valve Type Match

Next, match the valve to your job. Each valve works best for certain tasks. Ball valves are good for quick shutoff. Globe valves help you control flow. Check valves stop water from going backward. Think about what you want the valve to do.

Here is a table to help you match valve types to jobs:

| Application | Best Valve Type | Why It Works Well |

|---|---|---|

| Quick shutoff | Ball Valve | Fast, easy to use, tight seal |

| Precise flow control | Globe Valve | Good for adjusting flow |

| Preventing backflow | Check Valve | Stops water from moving backward |

| Large pipe systems | Butterfly Valve | Lightweight, cost-effective for big pipes |

| On/off control in pipelines | Gate Valve | Low flow resistance when fully open |

| Water and wastewater applications | Check Valve, Ball Valve | Handles solids, resists corrosion |

| Wastewater pumping systems | Check Valve | Prevents reverse flow, protects pumps |

Think about the fluid type, too. Clean water, dirty water, and chemicals need different valve materials. Rules in your area may also change your choice. Some jobs need valves that can handle dirt without clogging.

Note: Always check local rules before you buy a valve. Some jobs need special approvals or materials.

Budget, Maintenance, and Machining Quality

Your budget matters when picking a valve. Cheaper valves may not last as long or work as well. In water and wastewater jobs, low-quality valves can leak and cost more to fix.

Think about these things:

- Maintenance: Valves need regular checks. Hard-to-maintain valves can cost more to fix.

- Machining Quality: Well-made valves fit together better. This means fewer leaks and smoother use. Bad machining can cause leaks or cause the valveto break. You might need to fix or replace them more often.

- Long-Term Costs: Spending more on a good valve can save money later. You will have fewer problems and lower repair bills.

Here is a checklist to help you balance cost and quality:

- Does the valve fit your budget?

- Is the valve easy to maintain?

- Is the machining quality high?

- Will the valve last in your system?

- Does the valve meet all rules?

Tip: Ask your supplier how they make and check their valves. Good machining means better performance and fewer problems.

If you follow these steps, you can pick the right valve for your needs. You will save money and keep your plumbing working well. The best valve matches your job, fits your budget, and lasts a long time.

You need to pick the right valve for your plumbing job. Every valve type has good and bad points. Look at this table for a quick guide:

| Valve Type | Advantages | Disadvantages |

|---|---|---|

| Ball Valves | Last a long time, do not leak much | Not good for controlling flow |

| Gate Valves | Easy to use, works well if not used often | Not good for flow control, may break |

When picking a valve, think about:

- What you need it to do

- How easy it is to use

- How long will it last

- If it is good for turning water on or off

- If it might wear out or get blocked

Remember to think about what you need, how much you can spend, and how well the valve is made. If you are not sure, ask a plumber or check your system before buying.

FAQ

You should use a ball valve. It turns off the water with just a quarter turn. This makes it fast and easy to use in emergencies.

No. Ball valves work best for on/off control. If you want to adjust water flow, you should use a globe valve for better precision.

Poor machining or low-quality materials cause leaks. Always choose valves made with high-precision machining. This helps prevent leaks and extends the valve’s life.

Check your water type and system needs. Use brass or stainless steel for most homes. For chemicals or special fluids, pick materials that resist corrosion.

A check valve stops water from flowing backward. This protects your clean water supply and keeps your plumbing safe.

Inspect valves once a year. Look for leaks, rust, or hard-to-turn handles. Replace any valve that does not work smoothly or shows signs of damage.

Butterfly valves work best in large pipes. For small pipes, use ball or gate valves. These give you better control and sealing.