When you pick tube swaging services in 2025, remember these important tips:

- Make sure the service has the right skills, tools, and certificates for your project.

- Find companies that use smart machines and AI to check quality. This helps them work faster and better.

- See if the company has lots of experience with tube swaging.

- Use a list to compare choices and make sure they meet your needs.

The tube swaging market around the world helps many industries grow and change. New ideas, problems, and chances will shape this area in the future.

| Innovation Type | Impact on Efficiency and Reliability |

|---|---|

| Robotic Systems | Work on hard tube swaging shapes fast and accurately. |

| Real-Time Monitoring | Catch mistakes right away by checking tube swaging as it happens. |

| AI-Powered Design Tools | Change tube swaging designs quickly with up-to-date information. |

You will make smarter choices if you use a clear plan and set rules when picking tube swaging.

Key Takeaways

- Pick a tube swaging service with the right skills and tools. Make sure they have certifications for good work.

- Find companies that use new technology like AI. Real-time monitoring helps them work faster and better.

- Experience is important. Choose a provider who has done tube swaging well before. This helps you avoid expensive mistakes.

- Use a checklist to compare different providers. Make sure they can do what your project needs.

- Ask how they check quality. This makes sure your swaged fittings are strong and safe.

- Think about customization choices. You want swage parts that fit your project.

- Look for clear pricing so you know the costs. This helps you avoid surprise charges.

- Pick companies with good customer support and fast replies. This keeps your project moving forward.

Table of Contents

What Is Tube Swaging?

Swaging Process Overview

You might wonder how swaging works and why it is important. Swaging is a method of shaping metal tubes by compressing them. It does not need heat. This method changes the tube’s size and shape in a small area. Tube flaring only changes the ends, but swaging can change the whole tube section. Swaging and tapering use special tools and do not use heat. Swaging differs from rolling or stamping because it allows you to precisely change small sections of the tube. You can make tricky shapes and tight fits. This matters for jobs that need things to be very exact.

- Swaging quickly changes how wide and shaped a tube is.

- The process keeps the tube strong because it does not use heat.

- Swaging helps make tube fitting connections that do not leak.

Swaging is great for making tube fittings that must last and work well. Swaging is very exact, so you can meet tough rules in places like car and airplane making.

Common Applications

Swaging is used in lots of jobs. It helps make tube fittings that stay strong. Here are some ways swaging is used:

| Application Area | Description | Outcome Metrics |

|---|---|---|

| Hydraulic and Pneumatic Systems | Used for strong, leak-proof tube connections in high-pressure places. | 30% less time to put together, 25% fewer problems. |

| Automotive Fuel and Brake Lines | Make sure fluid parts are safe and fit right. | 15% less time to build, better safety rules met. |

| HVAC and Refrigeration Components | Connects cooling tubes tightly so they do not leak. | 20% faster to install. |

| Aerospace Structural Components | Puts together light but tough parts for safety and speed. | 10% faster to build, 5% lighter parts. |

| Custom and Prototype Manufacturing | Let‘s you change and test new designs fast. | 40% less wait time, cheaper tools needed. |

Swaging helps with many tube fitting jobs, from strong hydraulic systems to light airplane parts. It saves time, makes things safer, and cuts costs.

Why Service Choice Matters

Picking the right swaging service is very important for your project. You need someone who knows how to make tube fittings strong and exact. Swaging is more exact and reliable than the old ways. This matters a lot in places like airplanes, cars, and medical tools.

- Swaging makes tube fittings stronger and more exact.

- It lowers joint problems because you do not need welding.

- You use materials better, so you save money and help the planet.

If you choose a skilled swaging company, you know your tube fittings will meet tough rules. This helps you avoid mistakes that cost money and makes sure your products work well.

Service Capabilities & Swaging Technology

When you choose a tube swaging service, you want to know what the company can really do. The best providers in 2025 use advanced equipment, smart automation, and precise machining to make sure every swage meets your needs. Let’s look at what you should check.

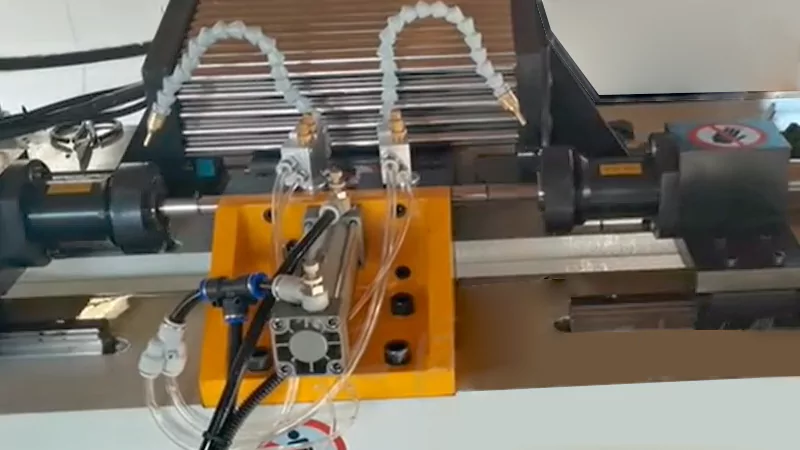

Equipment and Automation

You want a provider that uses the latest machines and technology. In 2025, top swage companies use:

- Automated swage machines that work fast and reduce mistakes.

- Sensors that watch the swage process in real time.

- AI systems that check each swage for problems and fix them right away.

- Robots that handle tricky swage shapes and keep the process moving.

These tools help companies make each swage more accurate and reliable. Automation also means you get your swage parts faster, with fewer delays. If a machine starts to wear out, AI can spot the problem before it causes a breakdown. This keeps your project on track.

Tip: Ask if your provider uses real-time monitoring and AI-driven quality checks. This shows they care about giving you the best swage results.

Material and Size Compatibility

Not every swage job is the same. You need a service that can handle many materials and tube sizes. The best swage providers work with a wide range of metals and sizes. Here is what you can expect:

| Material | Tube Size (O.D.) |

|---|---|

| Stainless Steel | 0.0625 to 6 inches |

| Aluminum | 0.0625 to 6 inches |

| Brass | 0.0625 to 6 inches |

| Copper | 0.0625 to 6 inches |

| Titanium | 0.0625 to 6 inches |

| Specialty Alloys | 0.0625 to 6 inches |

You might need a swage for stainless steel, aluminum, or even a specialty alloy. Some projects use tubes as small as a straw or as big as a pipe. A good swage company can handle all these needs. They use special machines and tools to make sure every swage fits just right, no matter the material or size.

Precision and Tolerances

Precision is what makes a swage strong and safe. You want every swage to meet strict rules for size and shape. In 2025, top companies use advanced machining to reach tight tolerances. Machining lets them make swage parts with very small errors—sometimes as little as 0.01mm. This is important for jobs in cars, planes, and medical devices.

- Precision tubes often have tolerances from 0.02mm to 0.05mm.

- Some swage jobs need even tighter tolerances, down to 0.01mm.

- Standards like DIN 2391-1 and ASTM set the rules for swage tolerances.

Machining is key to making complex swage shapes. With computer-aided tools, companies can create swage parts with special curves or tiny holes. This is important for custom jobs or when you need a swage for a new design. Engineers measure each swage to make sure it matches the plan.

Note: Advanced machining and strict measuring help your swage meet industry standards every time.

Why These Capabilities Matter

When you pick a swage service, you want more than just a basic tube. You want a partner who can handle any material, size, or shape. Automation and AI mean your swage will be checked for quality at every step. Machining lets you get swage parts that fit perfectly, even for tough jobs. With these tools, you get a swage that is strong, safe, and ready for anything.

If you need a custom swage or if your project has strict rules, look for a provider with these advanced capabilities. This way, you know your swage will meet your needs—no matter how big or small the challenge.

Industry Experience & Certifications

Track Record in Tube Swaging

When you pick a tube swaging company, look for one with lots of experience. A good history means the team knows how to make swaged fittings that work for you. Find companies that have done jobs like yours before. This shows they know what problems can happen and how to fix them fast.

A company with experience will have examples of past work. You can ask to see swaged fittings they made for other people. This helps you check if they can do your job right. Companies that know your industry also know the rules you must follow. They help you avoid mistakes that waste time and money.

| Decision Factor | Importance |

|---|---|

| Expertise and experience | Needed for picking providers who know the industry and have done similar jobs before. |

Always ask about the company’s work with swaged fittings. If they made fittings for planes, cars, or medical tools, they know how to meet tough rules. This helps you feel sure your fittings will be strong and safe.

Certifications and Compliance

Certifications show a company follows strict quality rules. In 2025, look for tube swaging companies with the right certificates. These prove the company can make swaged fittings that meet important standards.

- AS9100 is needed by big aerospace and defense companies.

- It means the company follows special aerospace rules.

- AS9100 is known all over the world for aerospace, aviation, and defense.

- It uses ISO 9001 rules and adds more for safety and risk.

- AS9100 is very important for aerospace and defense jobs.

- It shows the company cares about high quality for big companies.

- Companies with ISO 9001 can move up to AS9100.

- You can get AS9100 even if you do not have ISO 9001.

If you see these certificates, you know the company checks quality at every step. This means your swaged fittings will be safe and work well.

Check if the company keeps up with new rules and changes. In 2025, standards might change as technology gets better. A certified company will update how it works to follow new rules. This helps you avoid problems and keeps your fittings up to date.

Tip: Always ask for proof of certificates before you pick a company. This keeps your project safe and helps you feel calm.

Picking a company with lots of experience and the right certificates helps you get swaged fittings that work every time. You can trust your parts to be safe and ready for anything.

Swage Quality & Customization

Quality Control Methods

You want every swage to meet your standards for strength and fit. Good swage quality starts with strong quality control methods. Companies use many ways to check each swage and make sure it is right. Here is a table that shows some of the most effective ways to check swage results:

| Quality Control Method | Description |

|---|---|

| Penetrant Testing (PT) | Finds cracks or surface problems in the swage. |

| Magnetic Particle Testing (MT) | Checks for hidden flaws in steel swages. |

| Radiography Service (X-ray) | Look inside the swage for hidden defects. |

| Solution Annealing | Uses heat to make the swage stronger and more stable. |

You also see companies use visual checks, measuring tools, and even laser scanning to make sure each swage matches the plan. They check wall thickness and shape, and they test for leaks if the swage will carry fluids. You get reports like First Article Inspection (FAI) and Final Inspection Reports (FIR) to show that your swage meets all the rules. For big jobs, like in cars or planes, you might see a Production Part Approval Process (PPAP) to prove the swage is ready for use.

Tip: If you want the best results, ask your provider how they check each swage and what reports you will get.

Customization Options

Every project is different, so you need swage options that fit your needs. Leading companies offer many ways to customize your swage. Here is a table that shows common options and how they help with complex jobs:

| Customization Option | Description | Benefits for Complex Projects |

|---|---|---|

| Tube Cutting | Cuts tubes to exact lengths for your swage. | Reduces waste and speeds up your project. |

| Tube Bending | Shapes tubes for special swage designs. | Makes tricky shapes possible for your system. |

| Tube Welding | Joins tubes for strong, leak-free swage parts. | Needed for high-quality, sealed systems. |

| Tube Swaging and End Forming | Shapes tube ends for perfect connections. | Gives you tight, reliable swage fittings. |

| Extrusion and Drawing | Makes seamless tubes for your swage. | Helps with strict size and strength needs. |

| Perforating and Slotting | Adds holes or slots to your swage. | Let’s you add features for special uses. |

Machining plays a big part in making custom swage parts. With advanced machining, you get swage shapes that are complex or have very tight tolerances. This means your swage will fit exactly where you need it, even if your project is unique.

Prototyping and Design Support

When you start a new project, you want to see how your swage will work before you make a lot of them. Prototyping lets you test your swage design fast. Many top companies help you with design support and prototyping. They use in-house tool design and CNC machining to make your first swage quickly. This saves you time and money.

You can work with their engineers to change your swage design until it is just right. They use special tools to make sure your swage meets all your needs. If you work in medical, aerospace, or automotive fields, this support helps you move from idea to finished swage faster. You get a single team to manage your swage from start to finish, which means fewer delays and better results.

Note: Prototyping and design support help you avoid mistakes and get your swage to market faster.

You want your swage to be strong, safe, and made just for you. By choosing a provider with strong quality checks, lots of customization, and fast prototyping, you make sure your swage fits your project every time.

Turnaround & Scalability

Lead Times

You want your tube swaging job done fast. Lead time means how long it takes from order to delivery. Quick lead times help you finish your project on time. Good tube swaging companies use smart machines and plan to work faster. Automation helps speed up every step. When you ask about lead times, see if the company gives a clear answer. Some companies use AI to plan jobs and find delays early. This helps you get your parts sooner and with fewer problems.

Tip: Always ask for a timeline before you order. A clear schedule helps you plan what to do next.

Scalability for Project Growth

Your project might get bigger over time. You may start with a few parts, then need many more later. The best tube swaging services can handle both small and big orders. They use smart systems to make more parts without losing quality. Companies in different countries use new technology to grow with your needs. Here is a table that shows how some countries use technology to make more tube swaging parts:

| Country | Innovations |

|---|---|

| United States | AI-powered automation systems make work faster and better. |

| Machine learning finds mistakes right away and keeps quality high. | |

| AI research helps create new and stronger materials. | |

| United Kingdom | AI robots help make parts more accurate and quick. |

| Machine learning predicts when machines might break, so they fix them early. | |

| AI design tools help make special tube parts. | |

| Germany | Digital Twin Technologies help make swaging better. |

| Real-time monitoring checks for mistakes and saves materials. | |

| AI helps make new materials with better features. |

These new tools help companies grow with your project. You can start with a small order and ask for more later. The company can keep up because its systems are ready to change.

On-Time Delivery

Getting your parts when you need them is important. You want a company that delivers on time. Good tube swaging services watch every order closely. They use real-time monitoring to check each step. If something goes wrong, they fix it quickly so your order stays on track. Some companies use AI to spot delays and fix them before they cause problems. This means you get your parts when you expect them.

Note: On-time delivery helps you avoid expensive delays. Always check if a company delivers on time before you choose.

When you pick a tube swaging provider, look for fast lead times, the ability to grow with your needs, and a good record of on-time delivery. These things help your project go smoothly from start to finish.

Customer Support & Communication

Good customer support and clear communication are very important. You want a company that listens to you and answers fast. They should help you fix problems when they come up. This kind of help makes your project better, especially when you need swage fittings put in the right way.

Responsiveness

You need a company that gets back to you quickly. Fast answers show they care about your time and your project. If you ask about swage fitting installation, you should get a clear answer soon. Quick replies help you make choices and keep your project moving. Some companies use chat, email, or phone to talk with you. You can test how fast they answer by sending a question before you order. If they reply fast, you know they will help you when you need it.

Note: Fast and nice answers help you stop delays and fix problems early.

Technical Support

Technical support means you get help from experts when you have trouble. Good tube swaging companies have people who know a lot about swaging and tube fitting. They can help if you have problems with size, materials, or swage fitting installation. You might need help picking the right tube size or following safety rules. The best companies give you step-by-step help, clear directions, and even training if you want it. This helps make your job easier and helps you not make mistakes that cost money.

| Support Type | What You Get |

|---|---|

| Phone/Email Support | Answers to your technical questions |

| On-Site Help | Direct support at your location |

| Online Resources | Guides, videos, and FAQs |

Collaboration and Problem-Solving

Working together with your tube swaging company gives better results. When you and the company share ideas and talk often, you fix problems faster. Here are some ways working together helps your project:

- You and the company can fix leaks or other problems as a team.

- Talking on time helps you find answers before things get worse.

- A good supplier stands by your project and helps you do well.

For example, Comfit worked with a petrochemical plant to fix leaks. They used their skills and talked a lot with the client. This teamwork helped them find the right answer fast. When you pick a company that likes to work together, you get a partner who wants you to do well.

Tip: Pick a company that listens to you and works with you to fix problems. This makes your project easier and helps you do better.

Pricing & Value in Swaging Services

Transparent Pricing

When you look for a swage provider, you want clear and honest prices. Transparent pricing means you see exactly what you pay for. Good companies give you itemized quotes. These quotes show the cost for each part of your swage project. You can see the price for materials, labor, and any extra steps. This helps you compare different providers. You know if you are paying more for special tube fittings or for extra machining. If you have questions, a good provider will explain every charge. This makes it easier for you to plan your budget and avoid surprises.

Tip: Always ask for a detailed quote before you agree to a swage job. This helps you understand where your money goes.

Value-Added Services

Some swage companies offer more than just basic tube fittings. These value-added services help your project run smoothly and give you better results. When you choose a provider, look for these extra services:

- Precision tube fabrication

- Custom fabrication

- Welding

- Finishing processes

These services mean you get more than just a simple swage. You can ask for custom shapes, special finishes, or even welded tube fittings. This saves you time because you do not need to find another company for these steps. You get everything you need in one place. If you need a special swage for a new design, these services help you get the right fit.

Total Cost of Ownership

When you think about price, do not just look at the first number. The total cost of ownership means you look at all the costs over time. Swage is a high-speed process. It uses less material and makes less waste. This makes it a smart choice for big projects. Machining, on the other hand, can make more scrap and take longer. This means you pay more for materials and time.

Swage parts often last longer. They are strong and reliable. This means you spend less on repairs and replacements. Over time, you save money because your tube fittings work better and need less fixing. When you choose swage, you get a good balance of price, quality, and service.

Note: Picking a provider with efficient machining and strong swage skills helps you get the best value for your money.

If you want to get the most from your budget, look at the whole picture. Choose a swage provider who offers clear prices, helpful services, and long-lasting tube fittings. This way, you know you are making a smart investment for your project.

Making the Final Choice

When you get to the last step, you want to feel sure. You have looked at many swage companies. Now you need a simple way to pick the best one. This part helps you decide.

Comparison Matrix

A comparison matrix lets you see what each swage company does well or not so well. You can look at things like what they can do, their certificates, and what services they offer. Use a table like this to keep track:

| Provider Name | Capabilities | Certifications |

|---|---|---|

| Tube-Fab Ltd | Complete print to finished assembly service, in-house capabilities | Numerous approvals |

| Woolf Aircraft Products, Inc. | Custom precision tube fabricating, bending, welding, and more | ISO 9001:2015, AS9100:2009 Rev (C) |

| Eagle Stainless Tube & Fabrication, Inc. | High precision tubing, CNC machining, laser welding, and more | N/A |

| Master Swaging, Inc. | Specializes in swaging services, CNC machining, and assembly | N/A |

| Dieform LLC | Swaging, punching, turning, and engineering services | AS9100D, NADCAP certified |

You can write notes about each company. Look for the ones that do the swage work you need. Make sure they have the right certificates and can handle your project size. The matrix helps you see which company is best for you.

Site Visits or Virtual Tours

Going to see a swage company or taking a virtual tour lets you watch how they work. You can look at their machines and see the swage process. You can check if they use new equipment. Here are some things you can do on a visit or tour:

- Watch how they make swage parts.

- Look at the machines they use for swage jobs.

- Check how they make sure each swage is good.

- See if they follow the rules and have certificates.

A visit or tour helps you know if the company meets your needs. You can ask questions and see how they fix problems. This step helps you feel calm before you choose.

References and Case Studies

References and case studies show how well a swage company works. You want to see real examples of their jobs. Look for these kinds of proof:

- Case studies that show how the company fixed problems.

- Customer stories that tell you about their swage work.

- Certificates like ISO 9001 that show they meet quality rules.

Ask the company for names of past customers. Read their case studies to see if they did jobs like yours. Good references and strong case studies show the company can do the swage work you need.

Tip: Always check references and read case studies before you pick a swage company. This helps you avoid problems and makes sure you get good value.

By using a comparison matrix, doing a visit or tour, and checking references and case studies, you make a smart choice. You get a swage company that fits your needs and helps your project do well.

You now have the top tips for choosing swage services in 2025. Start by making a checklist for your swage needs. Use it to compare each swage provider. Look for swage companies with strong skills, the right certificates, and advanced swage technology. Ask about their swage quality checks and how they handle custom swage projects. Use the comparison tools to see which swage company fits your project best. Reach out to your top swage choices or talk to a swage expert. Make your final swage decision with confidence.

FAQ

Swaging is a process that shapes tubes by pressing them. You need swage to make strong, leak-proof connections in many industries. Swage helps you get the right fit for your project.

You should look for a swage provider with experience, advanced machines, and good quality checks. Ask about their swage process and see if they can handle your tube material and size.

Yes, you can use swage for many materials like stainless steel, copper, aluminum, and titanium. Swage works well for both small and large tubes. Always check if your provider can swage your chosen material.

Swage makes tube fittings stronger and more exact. You get better connections without leaks. Swage also helps you save material and lower costs.

You should expect your provider to use tests like X-ray, magnetic particle, and visual checks. Good swage companies give you reports to show your swage meets all rules.

Many companies use smart machines to finish swage jobs quickly. You can ask for a timeline before you order. Fast swage services help you finish your project on time.

Yes, you can ask for custom swage shapes. Providers use special machines and machining to make swage parts that fit your needs. Custom swage helps you with new designs or special projects.

Contact your swage provider right away. Good companies help you fix problems fast. They may offer technical support or even visit your site to solve swage issues.

Note: Always keep your swage reports and talk to your provider if you have questions.